Tamiya TA05 Touring Sedan

#9556

Thanks for your inputs. I got a 05R, so the stock spur is the 105T already. So I gotta go smaller to get the lower ratios.

#9560

So from the inputs here, 51T is the pinion limit for 90T and 56T is the limit for 87T? I'll probably go for the 90/96T spur, with my existing 47T, I can get down to 4.3, which is probably good enough for 13.5T, and with 51T, I can get down to 3.97, which is marginal for a 17.5? But if I can fit a 56T with the 90T, I can get down to 3.6!

#9562

hope that helps

#9563

Pls advice me on which 48p pinions/spur to get to the 3.5-4.5 region? Reason is to drive on unprep asphalt, I think using 64p would hasten wear and damage?

thanks!

thanks!

#9564

hey guys,

i have the light weight/reversible suspension upgrade, and well, i bought some aluminum rear hubs and front knuckles from 3racing, and discovered that not only the knuckle wont fit into the lightweight front chub, but also that the driveshaft axle doesnt come out all the way so i can put in the axle pin...anyone run the 3racing rear hubs and front knuckles? i think the upgrade universal axle part for the stock ta05 is part number TAM53499. can anyone confirm this? thanks guys.

i have the light weight/reversible suspension upgrade, and well, i bought some aluminum rear hubs and front knuckles from 3racing, and discovered that not only the knuckle wont fit into the lightweight front chub, but also that the driveshaft axle doesnt come out all the way so i can put in the axle pin...anyone run the 3racing rear hubs and front knuckles? i think the upgrade universal axle part for the stock ta05 is part number TAM53499. can anyone confirm this? thanks guys.

#9566

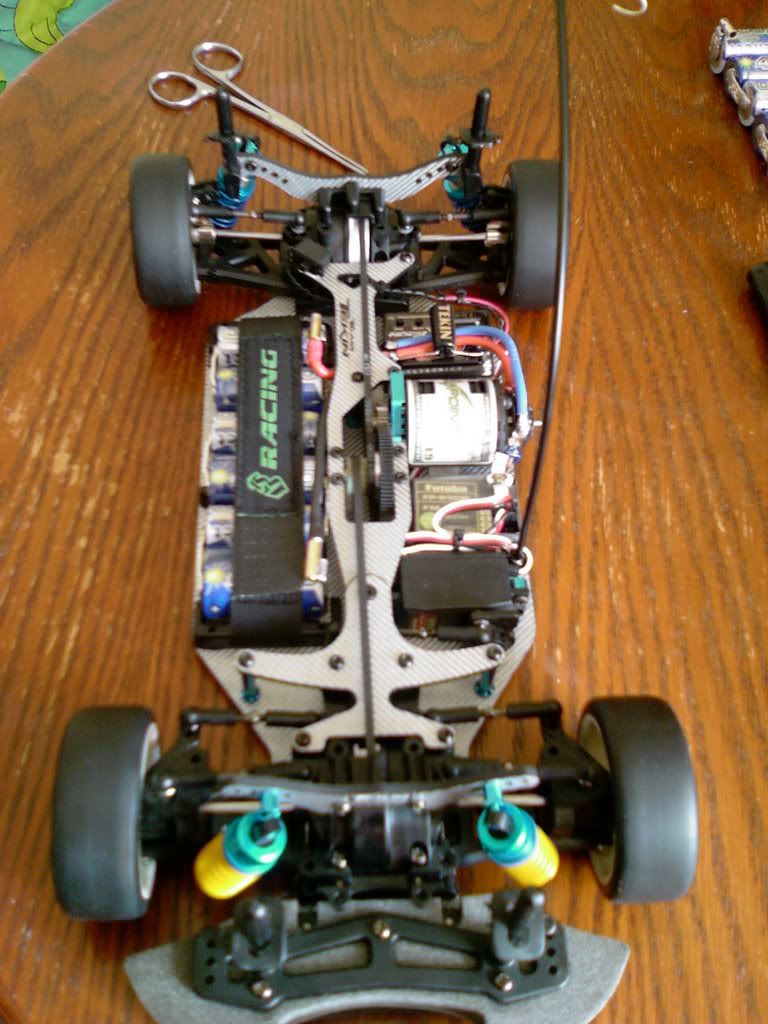

Hey all am looking at a racing return, have a TA05 IFSR is it worth going the IFS suspension or should I convert back (ie shock tower and mount) to the TA05 set up which I am more used to.

Also can I fit a Mamba Max ESC in here? I have a Futaba 9551 servo (low profile) and enough room to fit my receiver behind the motor (Spektrum SRM3100)

Also can I fit a Mamba Max ESC in here? I have a Futaba 9551 servo (low profile) and enough room to fit my receiver behind the motor (Spektrum SRM3100)

#9567

instead of worrying about your final drive so much try and use roll out instead here is the formula for it

pinion/spur *internal drive ratio /tire diameter

i run a 10.5 turn brushless at 33 mm roll out and have power when i need it

my gearing is 48pt

pinion 27t

spur 72t

internal drive is2.25 up front and 2.18 down back(used a pulley from tao4 35 tooth not 36

72/27=2.66*2.25=6.0

tire diameter is 64mm*3.14=200.96

200.96/6=33.49 mm roll out

if you need to add weight place it in the centre line under the belts ,

pinion/spur *internal drive ratio /tire diameter

i run a 10.5 turn brushless at 33 mm roll out and have power when i need it

my gearing is 48pt

pinion 27t

spur 72t

internal drive is2.25 up front and 2.18 down back(used a pulley from tao4 35 tooth not 36

72/27=2.66*2.25=6.0

tire diameter is 64mm*3.14=200.96

200.96/6=33.49 mm roll out

if you need to add weight place it in the centre line under the belts ,

#9568

Tech Regular

iTrader: (1)

instead of worrying about your final drive so much try and use roll out instead here is the formula for it

pinion/spur *internal drive ratio /tire diameter

i run a 10.5 turn brushless at 33 mm roll out and have power when i need it

my gearing is 48pt

pinion 27t

spur 72t

internal drive is2.25 up front and 2.18 down back(used a pulley from tao4 35 tooth not 36

72/27=2.66*2.25=6.0

tire diameter is 64mm*3.14=200.96

200.96/6=33.49 mm roll out

if you need to add weight place it in the centre line under the belts ,

pinion/spur *internal drive ratio /tire diameter

i run a 10.5 turn brushless at 33 mm roll out and have power when i need it

my gearing is 48pt

pinion 27t

spur 72t

internal drive is2.25 up front and 2.18 down back(used a pulley from tao4 35 tooth not 36

72/27=2.66*2.25=6.0

tire diameter is 64mm*3.14=200.96

200.96/6=33.49 mm roll out

if you need to add weight place it in the centre line under the belts ,

Kevin

#9569

Rollout is used when you race on foam tires that will have varying diameters as you true them and as they wear out. Rubber tires remain constant in diameter so all you need to do is calculate the FDR and you're in the ballpark.

#9570

Tech Regular

iTrader: (1)

Absolutely no advantages if you use rubber tires.

Rollout is used when you race on foam tires that will have varying diameters as you true them and as they wear out. Rubber tires remain constant in diameter so all you need to do is calculate the FDR and you're in the ballpark.

Rollout is used when you race on foam tires that will have varying diameters as you true them and as they wear out. Rubber tires remain constant in diameter so all you need to do is calculate the FDR and you're in the ballpark.

68Likes

68Likes