Team Associated TC6 Thread

#8222

My son and I are running our TC6 in USGT. We are very happy with the way it drives. The only continous problem we have are the front arm mounts. Most of the time, if we hit anything, even lightly, the front axle pulls out of the arm mounts. Usually ruining the mounting hole so that the mount has to be replaced.

It doesn't seem to happen on my TC5 as much.

Do you guys experience the same thing with your TC6's? Is there something I can do to help prevent that from happening? Its a cheap fix, so I'd rather have that happen then the arm break or worse, but it just pulls out too easy it seems.

It doesn't seem to happen on my TC5 as much.

Do you guys experience the same thing with your TC6's? Is there something I can do to help prevent that from happening? Its a cheap fix, so I'd rather have that happen then the arm break or worse, but it just pulls out too easy it seems.

#8224

I just run a longer srew. For whatever shims I use to get the spacing I want, I use a scre thats close to flush in the bulkhead.

#8226

My son and I are running our TC6 in USGT. We are very happy with the way it drives. The only continous problem we have are the front arm mounts. Most of the time, if we hit anything, even lightly, the front axle pulls out of the arm mounts. Usually ruining the mounting hole so that the mount has to be replaced.

It doesn't seem to happen on my TC5 as much.

Do you guys experience the same thing with your TC6's? Is there something I can do to help prevent that from happening? Its a cheap fix, so I'd rather have that happen then the arm break or worse, but it just pulls out too easy it seems.

It doesn't seem to happen on my TC5 as much.

Do you guys experience the same thing with your TC6's? Is there something I can do to help prevent that from happening? Its a cheap fix, so I'd rather have that happen then the arm break or worse, but it just pulls out too easy it seems.

http://www.reflexracing.net/RSD-TC6-...ocks_p_18.html

#8228

The RSD solution looks ideal. Their page has them out of stock, but I'll print the page you sent and come back and check later.

Thanks!

#8229

My son and I are running our TC6 in USGT. We are very happy with the way it drives. The only continous problem we have are the front arm mounts. Most of the time, if we hit anything, even lightly, the front axle pulls out of the arm mounts. Usually ruining the mounting hole so that the mount has to be replaced.

It doesn't seem to happen on my TC5 as much.

Do you guys experience the same thing with your TC6's? Is there something I can do to help prevent that from happening? Its a cheap fix, so I'd rather have that happen then the arm break or worse, but it just pulls out too easy it seems.

It doesn't seem to happen on my TC5 as much.

Do you guys experience the same thing with your TC6's? Is there something I can do to help prevent that from happening? Its a cheap fix, so I'd rather have that happen then the arm break or worse, but it just pulls out too easy it seems.

#8231

The only way thos blocks will roll is if the screw comes loose. The plastic cant rotate on he bushing, they are keyed together.

I normally just leave them both a little loose and then pinch them tight, while still allowing the arm to rotate freely, and tighten them up under pressure where they need to be.

I normally just leave them both a little loose and then pinch them tight, while still allowing the arm to rotate freely, and tighten them up under pressure where they need to be.

#8232

Yupp, you should pick up a set of the offset hinge blocks. They are much better as they have a larger contact area against the bulkhead since no shims are needed. This equates to less rotation. You would be surprised how much more secure the blocks are by flipping the insert and adding a washer behind the screw head in the mean time until you get the offset blocks.

#8233

The only way thos blocks will roll is if the screw comes loose. The plastic cant rotate on he bushing, they are keyed together.

I normally just leave them both a little loose and then pinch them tight, while still allowing the arm to rotate freely, and tighten them up under pressure where they need to be.

I normally just leave them both a little loose and then pinch them tight, while still allowing the arm to rotate freely, and tighten them up under pressure where they need to be.

#8234

It would have to be one hard impact, or the screws come loose.

One solution might be to put a set screw in the blocks to touch the hinge pin. This might keep them from rolling on impact and/or the screw coming loose. The hinge pin is long enought that it shouldn't be able to fall out unless those blocks roll a long way. Maybe they are worn out to much and you just need new blocks. I have never experienced this or heard of theis problem until now so I am just trying to think of options.

One solution might be to put a set screw in the blocks to touch the hinge pin. This might keep them from rolling on impact and/or the screw coming loose. The hinge pin is long enought that it shouldn't be able to fall out unless those blocks roll a long way. Maybe they are worn out to much and you just need new blocks. I have never experienced this or heard of theis problem until now so I am just trying to think of options.

#8235

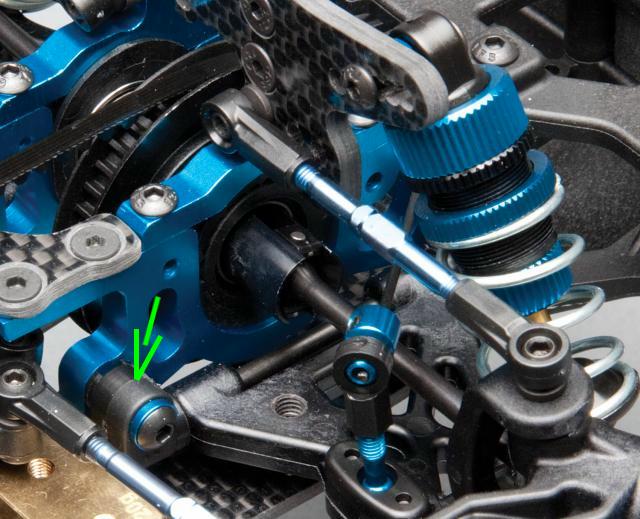

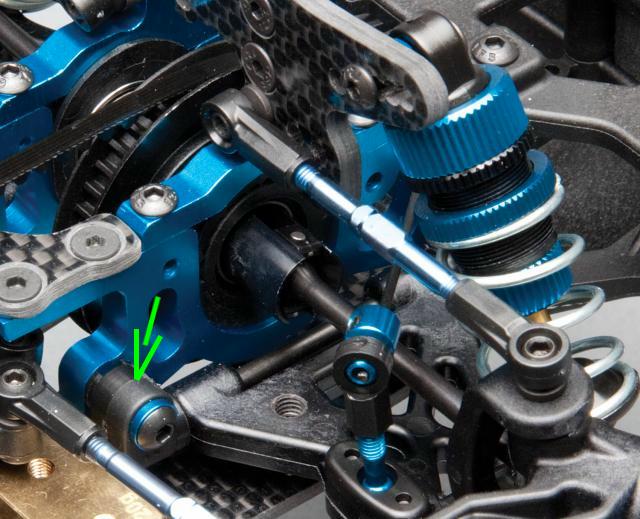

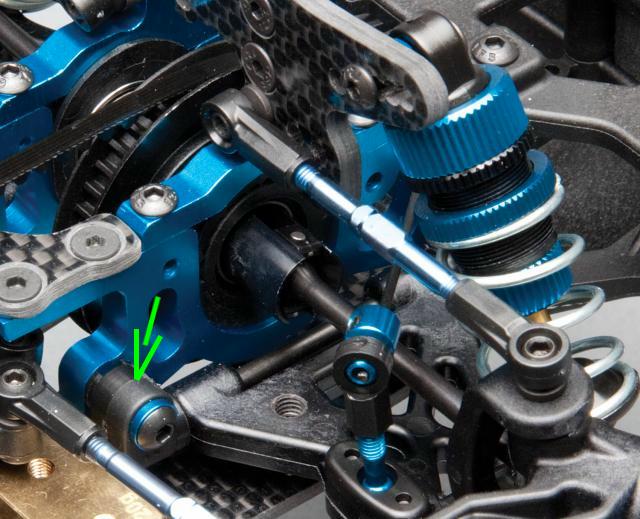

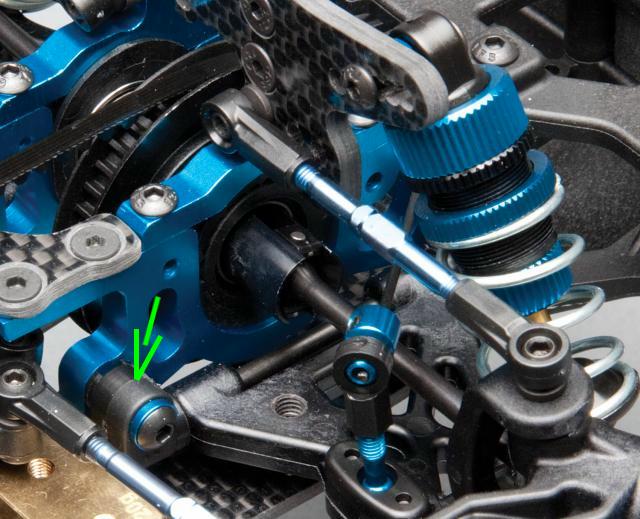

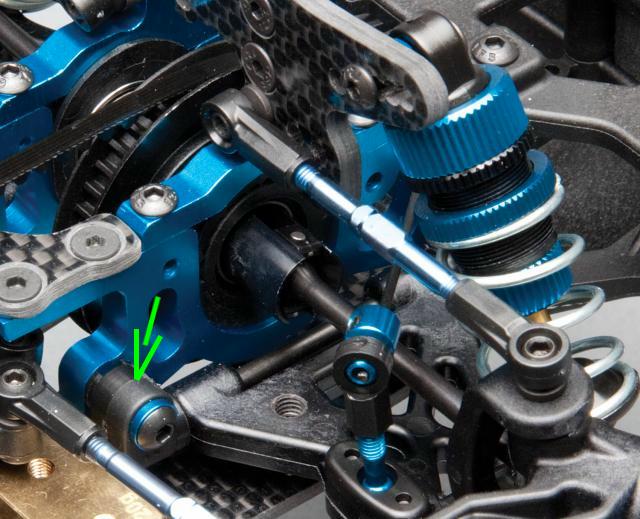

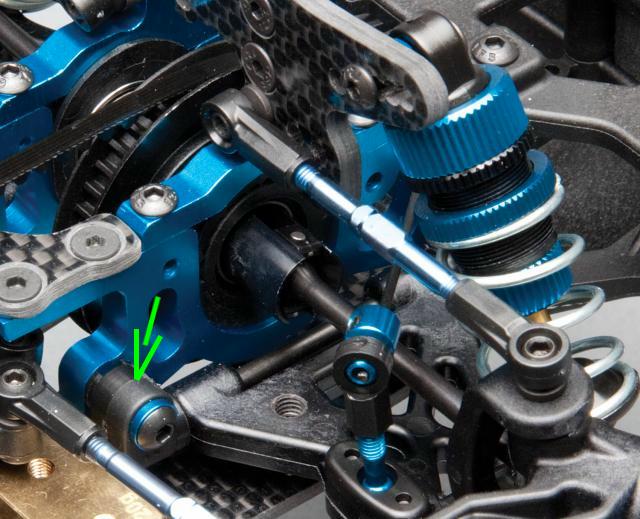

It looks like you are using a shim under the standard hinge pin block. You should use the offset blocks without any shims or flip the aluminum insert around backwards which will act as the shim. I found this was more solid and you don't loose any thread contact. Also as mentioned before, longer screws can help too. I have only had one screw pull out very early on then I switched to slightly longer screws and no problem since. I also notice you are running really high roll center. How's that working for you?

My car is not set up the same as the photo. I'm using the "0" mounts with shims.

20Likes

20Likes

[/IMG]

[/IMG]