Team Associated TC6 Thread

#3737

Tech Apprentice

Does anyone know (team drivers specifically) how many grams are shaved off switching from the steel screws to the new FT aluminum screws? I need to slim my car down just a bit. Looks like the screw kit is $40-$50 depending on place, and just wanted some numbers before I dropped the money on it.

Also, does anyone know if the upcoming gear diffs can handle mod motors?

Also, does anyone know if the upcoming gear diffs can handle mod motors?

#3740

Tech Master

iTrader: (20)

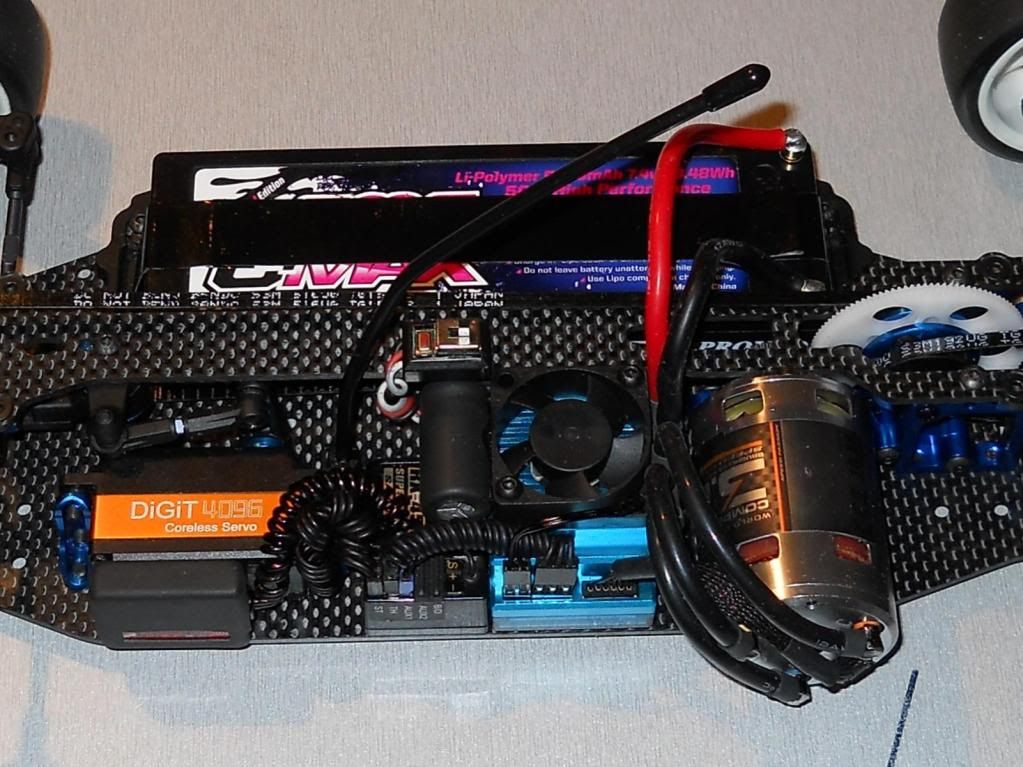

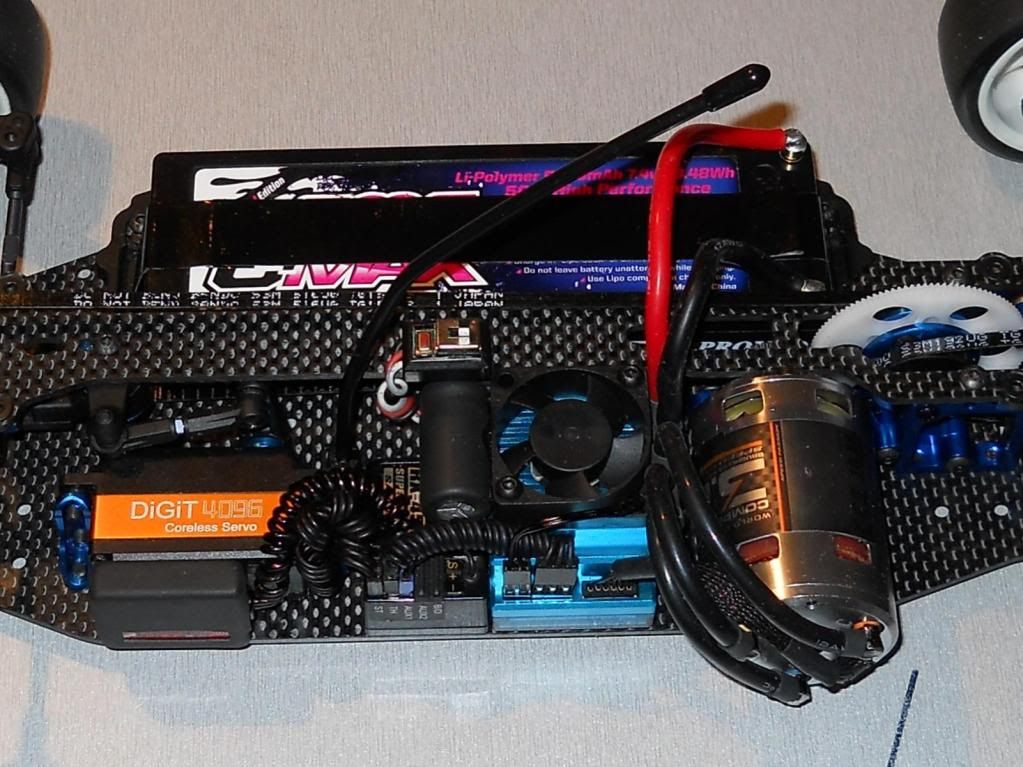

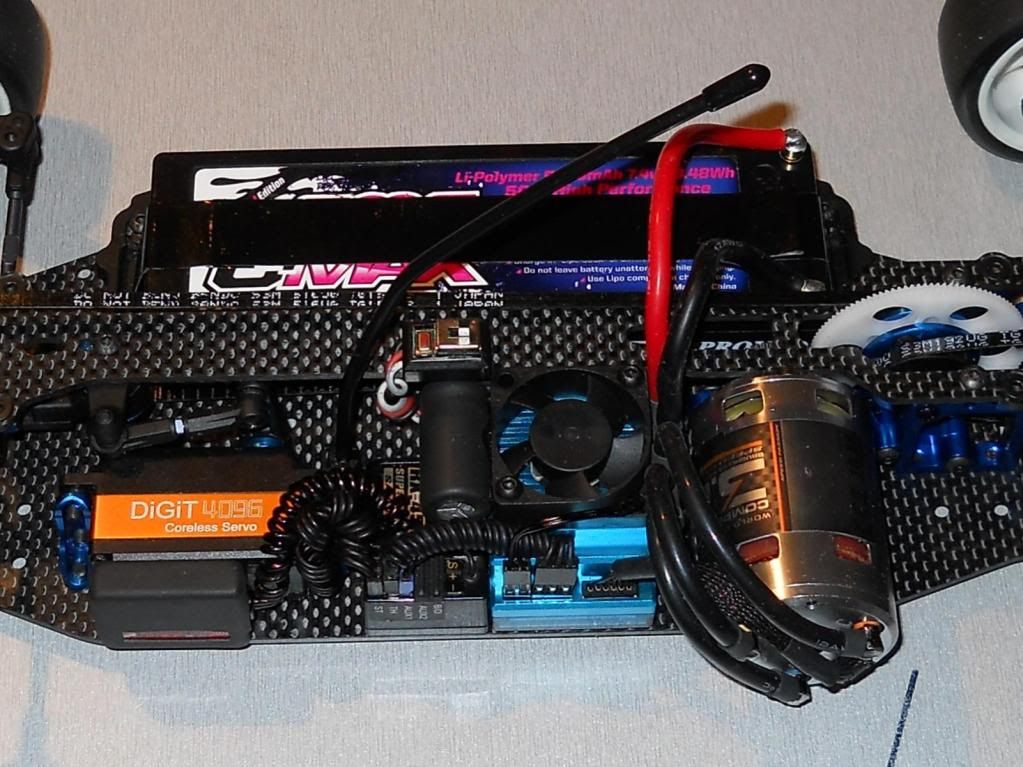

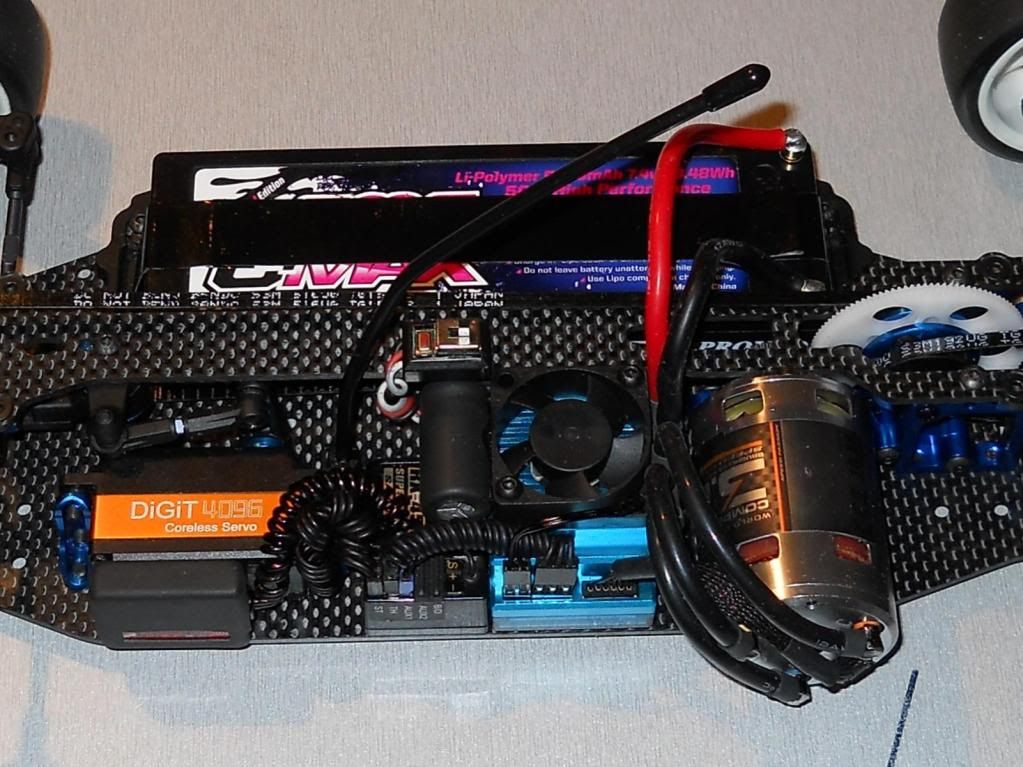

I am relatively new to the onroad scene fellas. I knew coming into onroad from offroad that weight, tolerances etc are more important than running 1/8 stuff. Not that it isn't important, but I know I must pay a little more attention to detail running 1/10 scale onroad. That being said, I am working on installation of my electronics. I have chosen the Tekin RS Pro ESC, 10.5T Tekin motor, and a Savox SC-1251MG Low Profile Digital "High Speed" Metal Gear Servo. I have a Mylaps xponder mounted on the front bumper, but I dont like how the wire comes close to the drive train. But, here is a photo of a pretty clean installation I found on Google of a TC6 and its electronics.

My question is, it looks like the wires for his electronics are all custom. Does anyone know how he did this? I mean, how would you open the transponder and rewire it? I like how all the wires are curled and tucked away, and I know that having the shortest wires decreases extra weight. Any advice is appreciated. Thank you.

My question is, it looks like the wires for his electronics are all custom. Does anyone know how he did this? I mean, how would you open the transponder and rewire it? I like how all the wires are curled and tucked away, and I know that having the shortest wires decreases extra weight. Any advice is appreciated. Thank you.

#3741

Does anyone know (team drivers specifically) how many grams are shaved off switching from the steel screws to the new FT aluminum screws? I need to slim my car down just a bit. Looks like the screw kit is $40-$50 depending on place, and just wanted some numbers before I dropped the money on it.

Also, does anyone know if the upcoming gear diffs can handle mod motors?

Also, does anyone know if the upcoming gear diffs can handle mod motors?

We are pushing for the IIC/early October.

I am relatively new to the onroad scene fellas. I knew coming into onroad from offroad that weight, tolerances etc are more important than running 1/8 stuff. Not that it isn't important, but I know I must pay a little more attention to detail running 1/10 scale onroad. That being said, I am working on installation of my electronics. I have chosen the Tekin RS Pro ESC, 10.5T Tekin motor, and a Savox SC-1251MG Low Profile Digital "High Speed" Metal Gear Servo. I have a Mylaps xponder mounted on the front bumper, but I dont like how the wire comes close to the drive train. But, here is a photo of a pretty clean installation I found on Google of a TC6 and its electronics.

My question is, it looks like the wires for his electronics are all custom. Does anyone know how he did this? I mean, how would you open the transponder and rewire it? I like how all the wires are curled and tucked away, and I know that having the shortest wires decreases extra weight. Any advice is appreciated. Thank you.

My question is, it looks like the wires for his electronics are all custom. Does anyone know how he did this? I mean, how would you open the transponder and rewire it? I like how all the wires are curled and tucked away, and I know that having the shortest wires decreases extra weight. Any advice is appreciated. Thank you.

You can open the electronics and shorten the wires. Sometimes this is simple and sometimes it is difficult. But doing this means that use in other vehicles is no longer possible.

You can also shorten the wires by installing a new plug. You can buy new female pins and crimp them on.

#3742

Tech Master

iTrader: (3)

A lot of people use a black sharpie to color their wires, or if they go through the pain of opening components and changing the wires to black (TQ Wires), then they usually make them custom length, too.

Those coils are done by wrapping the wires tightly around a screwdriver shank tightly, then keeping them coiled when plugged in.

Not worth the effort trying to save a little weight by shortening wires, since most current chassis require ballast weight to make minimum weight in racing classes anyway.

Those coils are done by wrapping the wires tightly around a screwdriver shank tightly, then keeping them coiled when plugged in.

Not worth the effort trying to save a little weight by shortening wires, since most current chassis require ballast weight to make minimum weight in racing classes anyway.

#3743

Tech Regular

iTrader: (3)

im not sure how he changed out the wires for all black ones with the ESC and Servo, but in an attempt to clean mine up, i went to my LHS and bought a pack of new servo wire plugs and the special crimper tool. Then I but the servo and ESC leads to length, and installed a new plug on the end. This leads for a pretty clean look. Although if its not too difficult, I would like to do this as well as switch out the wires for all black ones. Then I would be content with my wiring lol

#3744

Tech Master

iTrader: (10)

Sweet, can't wait for them

I've used both Sharpies and black paint pens to color wiring. To coil it, I found it easiest to wrap it around a driver like others have said and heat them up. I'll hold my soldering iron near them for 30-60 seconds (like you are heating shrink-wrap) and it turns out nice.

I've used both Sharpies and black paint pens to color wiring. To coil it, I found it easiest to wrap it around a driver like others have said and heat them up. I'll hold my soldering iron near them for 30-60 seconds (like you are heating shrink-wrap) and it turns out nice.

#3746

Hi all, just saw on SpecR website gear differential set:

Spec-R Gear Differential Set 40T(For Associated - TC6)

Spec-R Gear Differential Set 40T(For Associated - TC6)

#3747

I am relatively new to the onroad scene fellas. I knew coming into onroad from offroad that weight, tolerances etc are more important than running 1/8 stuff. Not that it isn't important, but I know I must pay a little more attention to detail running 1/10 scale onroad. That being said, I am working on installation of my electronics. I have chosen the Tekin RS Pro ESC, 10.5T Tekin motor, and a Savox SC-1251MG Low Profile Digital "High Speed" Metal Gear Servo. I have a Mylaps xponder mounted on the front bumper, but I dont like how the wire comes close to the drive train. But, here is a photo of a pretty clean installation I found on Google of a TC6 and its electronics.

My question is, it looks like the wires for his electronics are all custom. Does anyone know how he did this? I mean, how would you open the transponder and rewire it? I like how all the wires are curled and tucked away, and I know that having the shortest wires decreases extra weight. Any advice is appreciated. Thank you.

My question is, it looks like the wires for his electronics are all custom. Does anyone know how he did this? I mean, how would you open the transponder and rewire it? I like how all the wires are curled and tucked away, and I know that having the shortest wires decreases extra weight. Any advice is appreciated. Thank you.

black/stleath look is what you like.

There are also`crimping tools for servo wires for

re-crimping when they have been shortened.

There is a excellent thread

http://www.rctech.net/forum/electric...tion-pics.html

ive got so much from this i've just re wired my first esc

i will post in that thred when its installed

hope this helps

#3750

Tech Master

iTrader: (20)

Hi you can curl the wires neatly and effectively around a hex driver/screwdriver, you can blackout all the wires with a paint pen if the

black/stleath look is what you like.

There are also`crimping tools for servo wires for

re-crimping when they have been shortened.

There is a excellent thread

http://www.rctech.net/forum/electric...tion-pics.html

ive got so much from this i've just re wired my first esc

i will post in that thred when its installed

hope this helps

black/stleath look is what you like.

There are also`crimping tools for servo wires for

re-crimping when they have been shortened.

There is a excellent thread

http://www.rctech.net/forum/electric...tion-pics.html

ive got so much from this i've just re wired my first esc

i will post in that thred when its installed

hope this helps

20Likes

20Likes