Pro 10: 235mm Le Mans Prototype Pan Car Discussion

#1651

Tech Fanatic

iTrader: (35)

That video clearly puts to rest peoples negative nancy nonsense about running Pro10 on indoor carpet.

I should have the first set of build pics up soon for my modded RC10L2. Just waiting on 1 more parts shipment and the custom upper and lower plates then I'm golden. I plan to test the car with the prototype upper plate and stock lower plate in the meantime.

I should have the first set of build pics up soon for my modded RC10L2. Just waiting on 1 more parts shipment and the custom upper and lower plates then I'm golden. I plan to test the car with the prototype upper plate and stock lower plate in the meantime.

#1652

Hey John, I take it that you are running 10.5t on 1s?

Is this blinky or boosted?

We run on pavement here in Camarillo and I love the class! I have always believed that this could be a real fun class on carpet as we can plainly see... even if it were a spec class. I was just about as fast with 10.5t blinky as I am with 10.5t boosted due to better consistency. 1s of course...

I was just about as fast with 10.5t blinky as I am with 10.5t boosted due to better consistency. 1s of course...

Is this blinky or boosted?

We run on pavement here in Camarillo and I love the class! I have always believed that this could be a real fun class on carpet as we can plainly see... even if it were a spec class.

I was just about as fast with 10.5t blinky as I am with 10.5t boosted due to better consistency. 1s of course...

I was just about as fast with 10.5t blinky as I am with 10.5t boosted due to better consistency. 1s of course...

#1653

Hey John, I take it that you are running 10.5t on 1s?

Is this blinky or boosted?

We run on pavement here in Camarillo and I love the class! I have always believed that this could be a real fun class on carpet as we can plainly see... even if it were a spec class. I was just about as fast with 10.5t blinky as I am with 10.5t boosted due to better consistency. 1s of course...

I was just about as fast with 10.5t blinky as I am with 10.5t boosted due to better consistency. 1s of course...

Is this blinky or boosted?

We run on pavement here in Camarillo and I love the class! I have always believed that this could be a real fun class on carpet as we can plainly see... even if it were a spec class.

I was just about as fast with 10.5t blinky as I am with 10.5t boosted due to better consistency. 1s of course...

I was just about as fast with 10.5t blinky as I am with 10.5t boosted due to better consistency. 1s of course...

#1656

Tech Fanatic

iTrader: (35)

Conversation moved from the Speedmerchant Roadkill 10 235mm Pro10 Pancar thread.

Yup, I will have limited quantities available for sale. I will have to wait to finish each run to put together prices however. I'll list the prototype parts I'm having made below in the order they'll be produced.

1st: lower pod plate in 3.18mm 7075-T6 aluminum, same layout as factory L2 piece just thicker and considerably higher quality aluminum, will provide better heat dissipation for the motor along with adding strength and rigidity to the rear pod.

-10 of these will be made to start. I'm keeping @ least 3 and I'm setting 1 more aside for THEBIGBULL if he wants it.

2nd: upper pod plate in 2mm carbon fiber, designed for use with side shocks or dampers, also designed for easier motor solder tab access.

-12 of these will be made to start. I'm keeping @ least 4 and I'm setting 1 more aside for THEBIGBULL if he wants it.

3rd: lower pod plate in 2.5mm carbon fiber, will basically be a replica of the PRC carbon fiber lower pod plate, including the notch to allow larger spur gears.

-4 of these will be made, probably no more. I'm keeping 1 and setting aside however many THEBIGBULL wants, he asked me to have them made.

The 1st run of prototype aluminum lower pod plates should be done in 1-2 weeks maybe less. Then I'll try to have the prototype upper plates done asap after that. I'm modifying the stock upper plate in the meantime to test placement of the side shocks mounting holes before production. When each run is done I'll post in this thread with pics, prices, quantity available. Let me know if your interested in any of it, I'll reserve plates for you. No obligation if you don't like the finished work of course. I'm not doing this for money just to help out myself and other racers in the process.

Sounds good, I'll set 1 each aside for you. Again no obligation.

Originally Posted by RoyU

OrganicMechanic, what prototype parts are you having made for the 10l2? Will it be available for sale? I've got a L2 also.

OrganicMechanic, what prototype parts are you having made for the 10l2? Will it be available for sale? I've got a L2 also.

1st: lower pod plate in 3.18mm 7075-T6 aluminum, same layout as factory L2 piece just thicker and considerably higher quality aluminum, will provide better heat dissipation for the motor along with adding strength and rigidity to the rear pod.

-10 of these will be made to start. I'm keeping @ least 3 and I'm setting 1 more aside for THEBIGBULL if he wants it.

2nd: upper pod plate in 2mm carbon fiber, designed for use with side shocks or dampers, also designed for easier motor solder tab access.

-12 of these will be made to start. I'm keeping @ least 4 and I'm setting 1 more aside for THEBIGBULL if he wants it.

3rd: lower pod plate in 2.5mm carbon fiber, will basically be a replica of the PRC carbon fiber lower pod plate, including the notch to allow larger spur gears.

-4 of these will be made, probably no more. I'm keeping 1 and setting aside however many THEBIGBULL wants, he asked me to have them made.

The 1st run of prototype aluminum lower pod plates should be done in 1-2 weeks maybe less. Then I'll try to have the prototype upper plates done asap after that. I'm modifying the stock upper plate in the meantime to test placement of the side shocks mounting holes before production. When each run is done I'll post in this thread with pics, prices, quantity available. Let me know if your interested in any of it, I'll reserve plates for you. No obligation if you don't like the finished work of course. I'm not doing this for money just to help out myself and other racers in the process.

Originally Posted by RoyU

I'm interested in all 3 pieces. If the carbon fiber lower pod plate is a very limited run then, the other 2 pieces will be just fine.

Thanks Roy

I'm interested in all 3 pieces. If the carbon fiber lower pod plate is a very limited run then, the other 2 pieces will be just fine.

Thanks Roy

Last edited by OrganicMechanic; 08-23-2014 at 12:52 PM.

#1657

Tech Fanatic

iTrader: (35)

I suggest using these side pod plates for anyone looking to modify their L2 with the upper/lower pod plates listed above.

link to pod plates: http://www.muddslidemotorsports.com/podplates1.html

link to pod plates: http://www.muddslidemotorsports.com/podplates1.html

Last edited by OrganicMechanic; 08-23-2014 at 09:59 AM. Reason: added link

#1658

Tech Fanatic

iTrader: (35)

Moved this one too lol... Should have my mess cleaned up now lol...

Should have my mess cleaned up now lol...

Yes they do. I have a set of black and a set of silver IRS side pod plates sitting on my work table. They say they are for the L3/L4 but the L2 is the same design.

Where do you think I got the inspiration from? Pro10noob, Joost K., 2wdrive, MarkA

Pro10noob, Joost K., 2wdrive, MarkA

Thanks guys!

I'm starting with micro VCS shocks but the 12R5 center shocks will also work, so will dampers.

Should have my mess cleaned up now lol...

Should have my mess cleaned up now lol...

Originally Posted by Pro10noob

Question for OrganicMechanic...

Do the IRS motorpod plates have the same bolt pattern as the Asso RC10L2??

Regards Roy

Question for OrganicMechanic...

Do the IRS motorpod plates have the same bolt pattern as the Asso RC10L2??

Regards Roy

Originally posted by Pro10noob

Perfect

Then i am a bit ahead of you as i am running a modded top plate on my car for the past year.

Also my lowerpodplate is a design for the IRS motorpodplates.

We use the R5 centre dampers on the side.

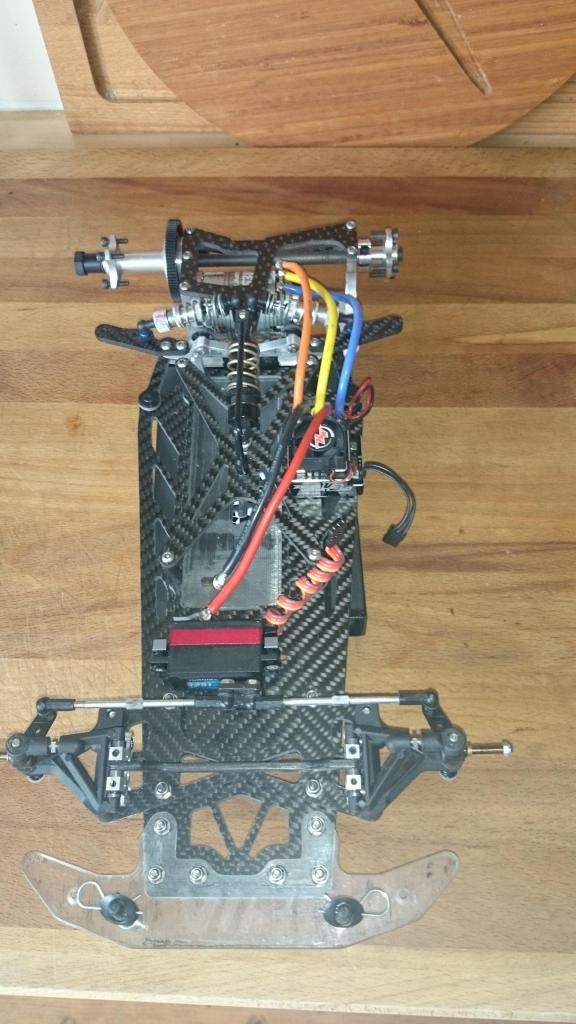

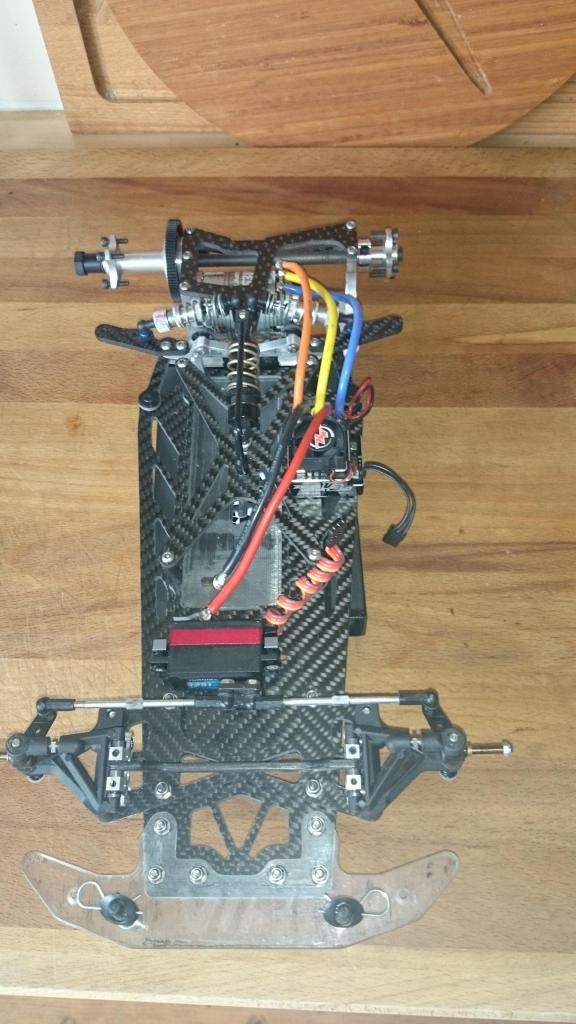

Also a pic of my Mod Pro10.

Regards Roy

Perfect

Then i am a bit ahead of you as i am running a modded top plate on my car for the past year.

Also my lowerpodplate is a design for the IRS motorpodplates.

We use the R5 centre dampers on the side.

Also a pic of my Mod Pro10.

Regards Roy

Pro10noob, Joost K., 2wdrive, MarkA

Pro10noob, Joost K., 2wdrive, MarkAThanks guys!

I'm starting with micro VCS shocks but the 12R5 center shocks will also work, so will dampers.

Last edited by OrganicMechanic; 08-23-2014 at 10:00 AM.

#1660

Tech Fanatic

iTrader: (35)

he's talented! It's nice of you to display his work though. Does he farm out the machine work or do it himself?

he's talented! It's nice of you to display his work though. Does he farm out the machine work or do it himself?I'm hoping my buddy will hook me up with a copy of his CAD program so I can play around with it and make production of parts a breeze.

#1661

Just thought I'd post some thoughts here and my setup.

Chassis: SpeedMerchant Roadkill 10

Tires: Double Purple Front, Double Pink Rear 61mm or 2.4 inch OD UNCUT

Ride Height: 8mm (please don't laugh)

Body: Protoform P905b, no side air dams

Bumper: Parma Ultimate cut to fit the P905b body

Center shock: gold spring (5 lb) with 40 wt Losi Silicon, 2 hole piston

Rear droop: 2mm

Pod sag: less than 1mm

Front droop: .5mm

Spur: 75 tooth 48P

Pinion: 19 tooth 48P

Rollout: 48.5

Caster: 4*

Camber: -.5*

Front spring: .20

Battery: Turnigy 6400mAh Ultimate

ESC: Tekin RS Gen 2

Radio: KO Eurus w/210S receiver

Servo: JR3650 mounted with no spacers with screws in top holes of the servo mount.

2 1/4" Turnbuckles are mounted to the front of the Kimbrough medium servo saver. The ballstuds are on the inner holes of the servo saver arm. Turnbuckles are swept back from inside to outside, about 1cm difference. The turnbuckles are flat went viewing from the front. No noticeable bump steer.

All weight is under the center line of the rear axle visually.

The only thing above the tire tops are the rear body posts.

Car does not over or under steer at this time.

Corner rotation is perfect.

Diff will bark a little in tight corners when trying to rapidly accelerate.

Complaints: none

Issues: More advanced driver states steering balance between into and out of corners could be better. Right it's better in than out. Might need a stiffer front spring or ackerman change. This would lead to perfection.

Solution: Just drive it and drive it a lot.

Chassis: SpeedMerchant Roadkill 10

Tires: Double Purple Front, Double Pink Rear 61mm or 2.4 inch OD UNCUT

Ride Height: 8mm (please don't laugh)

Body: Protoform P905b, no side air dams

Bumper: Parma Ultimate cut to fit the P905b body

Center shock: gold spring (5 lb) with 40 wt Losi Silicon, 2 hole piston

Rear droop: 2mm

Pod sag: less than 1mm

Front droop: .5mm

Spur: 75 tooth 48P

Pinion: 19 tooth 48P

Rollout: 48.5

Caster: 4*

Camber: -.5*

Front spring: .20

Battery: Turnigy 6400mAh Ultimate

ESC: Tekin RS Gen 2

Radio: KO Eurus w/210S receiver

Servo: JR3650 mounted with no spacers with screws in top holes of the servo mount.

2 1/4" Turnbuckles are mounted to the front of the Kimbrough medium servo saver. The ballstuds are on the inner holes of the servo saver arm. Turnbuckles are swept back from inside to outside, about 1cm difference. The turnbuckles are flat went viewing from the front. No noticeable bump steer.

All weight is under the center line of the rear axle visually.

The only thing above the tire tops are the rear body posts.

Car does not over or under steer at this time.

Corner rotation is perfect.

Diff will bark a little in tight corners when trying to rapidly accelerate.

Complaints: none

Issues: More advanced driver states steering balance between into and out of corners could be better. Right it's better in than out. Might need a stiffer front spring or ackerman change. This would lead to perfection.

Solution: Just drive it and drive it a lot.

#1663

Tech Fanatic

iTrader: (35)

Just thought I'd post some thoughts here and my setup.

Chassis: SpeedMerchant Roadkill 10

Tires: Double Purple Front, Double Pink Rear 61mm or 2.4 inch OD UNCUT

Ride Height: 8mm (please don't laugh)

Body: Protoform P905b, no side air dams

Bumper: Parma Ultimate cut to fit the P905b body

Center shock: gold spring (5 lb) with 40 wt Losi Silicon, 2 hole piston

Rear droop: 2mm

Pod sag: less than 1mm

Front droop: .5mm

Spur: 75 tooth 48P

Pinion: 19 tooth 48P

Rollout: 48.5

Caster: 4*

Camber: -.5*

Front spring: .20

Battery: Turnigy 6400mAh Ultimate

ESC: Tekin RS Gen 2

Radio: KO Eurus w/210S receiver

Servo: JR3650 mounted with no spacers with screws in top holes of the servo mount.

2 1/4" Turnbuckles are mounted to the front of the Kimbrough medium servo saver. The ballstuds are on the inner holes of the servo saver arm. Turnbuckles are swept back from inside to outside, about 1cm difference. The turnbuckles are flat went viewing from the front. No noticeable bump steer.

All weight is under the center line of the rear axle visually.

The only thing above the tire tops are the rear body posts.

Car does not over or under steer at this time.

Corner rotation is perfect.

Diff will bark a little in tight corners when trying to rapidly accelerate.

Complaints: none

Issues: More advanced driver states steering balance between into and out of corners could be better. Right it's better in than out. Might need a stiffer front spring or ackerman change. This would lead to perfection.

Solution: Just drive it and drive it a lot.

Chassis: SpeedMerchant Roadkill 10

Tires: Double Purple Front, Double Pink Rear 61mm or 2.4 inch OD UNCUT

Ride Height: 8mm (please don't laugh)

Body: Protoform P905b, no side air dams

Bumper: Parma Ultimate cut to fit the P905b body

Center shock: gold spring (5 lb) with 40 wt Losi Silicon, 2 hole piston

Rear droop: 2mm

Pod sag: less than 1mm

Front droop: .5mm

Spur: 75 tooth 48P

Pinion: 19 tooth 48P

Rollout: 48.5

Caster: 4*

Camber: -.5*

Front spring: .20

Battery: Turnigy 6400mAh Ultimate

ESC: Tekin RS Gen 2

Radio: KO Eurus w/210S receiver

Servo: JR3650 mounted with no spacers with screws in top holes of the servo mount.

2 1/4" Turnbuckles are mounted to the front of the Kimbrough medium servo saver. The ballstuds are on the inner holes of the servo saver arm. Turnbuckles are swept back from inside to outside, about 1cm difference. The turnbuckles are flat went viewing from the front. No noticeable bump steer.

All weight is under the center line of the rear axle visually.

The only thing above the tire tops are the rear body posts.

Car does not over or under steer at this time.

Corner rotation is perfect.

Diff will bark a little in tight corners when trying to rapidly accelerate.

Complaints: none

Issues: More advanced driver states steering balance between into and out of corners could be better. Right it's better in than out. Might need a stiffer front spring or ackerman change. This would lead to perfection.

Solution: Just drive it and drive it a lot.

#1664

I noticed Stan's diff "barks" as well. I know I'm a noob to racing so maybe I'm wrong but I think you need to lower your rollout. When I finally get my Pro10 on the rug I'll be running a 35-37mm rollout. When playing with my Bolink @ HTO I changed my gearing until I could just barely touch full throttle for a sec in the straight. This point was ~39mm rollout. It didn't make the car any less drivable in the technical areas even with the added torque. My Bolink has a 8.5T@4200kv, my L2 will have a 10.5T@4900kv, which is why I'm lowering the rollout more. Example: I've read on this thread that the Europeans run ~45mm rollout with 10.5T and ~35mm rollout with mod motors(3-5.5T) on large 1/8 scale outdoor tracks obviously. So my theory is 35-37mm rollout will allow full throttle for a split second and allow full use of the the boost/turbo functions. Just my .02cents.

Turbo function comes on after boost, after .1 sec WOT and takes about 1.5 seconds to max out based on ramp rate. I may hit WOT, but I need to stay @ WOT to run it all the way up. By that time, my car would be 100' past the sweeper and still accelerating (and pulling like a freight train.)

1568Likes

1568Likes