XPRESS Execute XQ2S

#226

Tech Regular

Thank you gigaplex

I am thinking Hobbywing Justock and 21.5T Combo. Suggestions for a spur gear to go with the motor ?

Cheers

I am thinking Hobbywing Justock and 21.5T Combo. Suggestions for a spur gear to go with the motor ?

Cheers

#228

Hi All,

Yesterday received my XQ2S, I am excited to start building the car!

I live in Mexico City and have not been able to find any local clubs. Plan to practice on a local basketball court until I return to the USA.

I am starting to order electronics and thinking to go with Savox Low Profile High-Speed Metal Gear Digital Servo Model: SC-1251MG ($64 with shipping) any feedback?

What motor pinion should I use?

What weight shock oil should I use 450CT? What weight differential oil should I use? Thank you!

Cheers

Yesterday received my XQ2S, I am excited to start building the car!

I live in Mexico City and have not been able to find any local clubs. Plan to practice on a local basketball court until I return to the USA.

I am starting to order electronics and thinking to go with Savox Low Profile High-Speed Metal Gear Digital Servo Model: SC-1251MG ($64 with shipping) any feedback?

What motor pinion should I use?

What weight shock oil should I use 450CT? What weight differential oil should I use? Thank you!

Cheers

#229

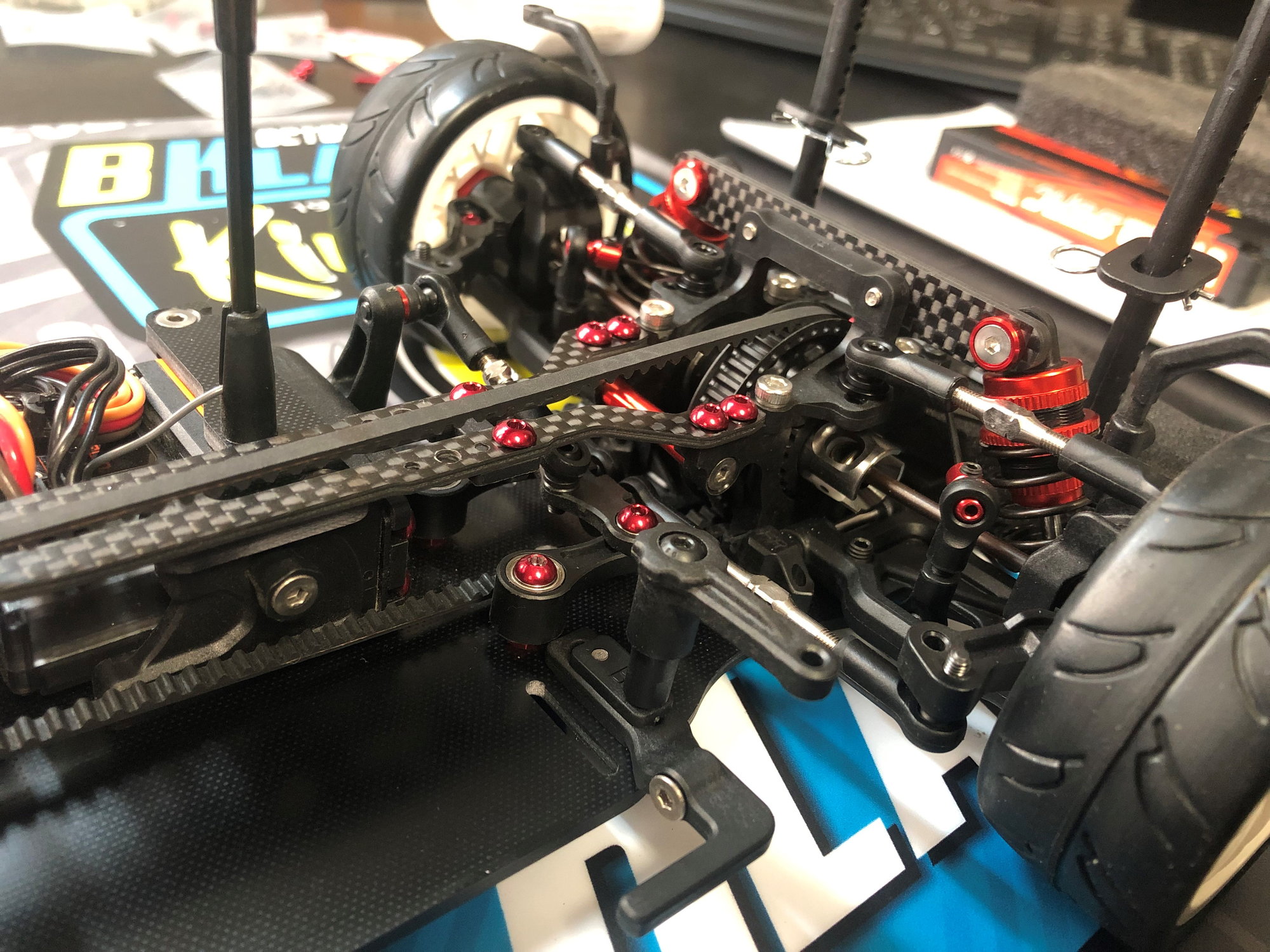

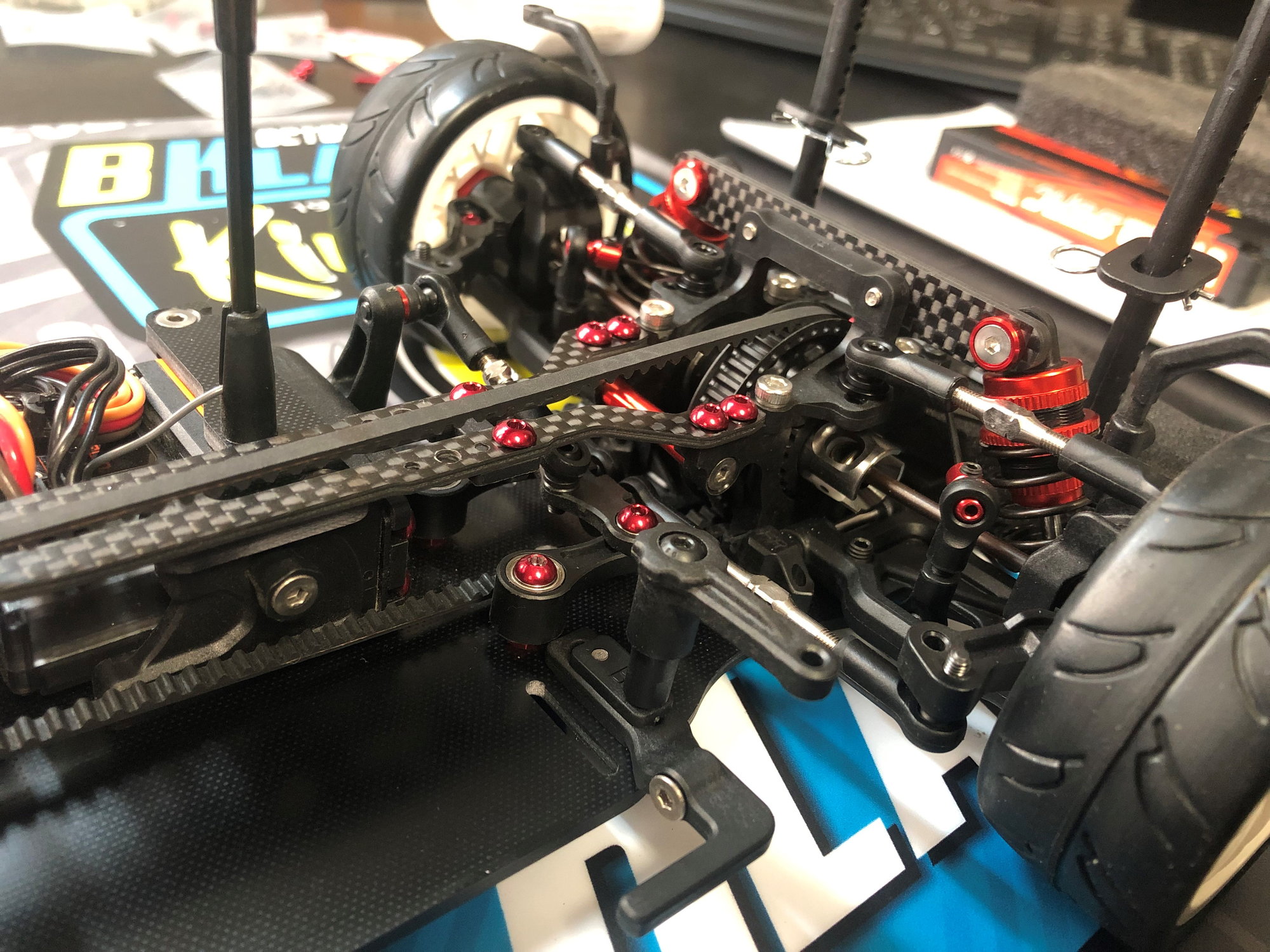

Farther along... Need motor fan, transponder and proper length sensor wire. The double cardan front driveshafts are a HUGE improvement. They should come in the kit, even if the kit is a little more $$, it's still an incredible value.

Has anyone played with either shorty lipos or slim lipos? I have some cheap practice packs to run laps and shake down and sort the chassis, but I would like to run the slim packs for race batteries. Looking at the mounting system, we need a different battery holder. Am I fabricating, or does someone make this already?

Has anyone played with either shorty lipos or slim lipos? I have some cheap practice packs to run laps and shake down and sort the chassis, but I would like to run the slim packs for race batteries. Looking at the mounting system, we need a different battery holder. Am I fabricating, or does someone make this already?

#230

Tech Initiate

I managed to break a front swing shaft at the joint end yesterday

would the double joint shafts be stronger or is there a better option for replacement?

would the double joint shafts be stronger or is there a better option for replacement?

#231

The double joint prevents chatter during steering lock. I wouldn't say they are stronger but more durable when using a spool.

#232

No doubt the stock shafts up front get hammered in the corners. The double joints are a big improvement. I think the X-Square are the most economical. I got the Yeah Racing because they were in stock when I needed them.

#233

Tech Initiate

Any idea how best to fit a narrow lipo to the chassis? The side bars won't adjust in far enough. Anyone come up with a good system other than resorting to tape?

#234

#235

Should perfectly fit your needs. Does fit on the XQ2S too although not mentioned.

#236

Tech Rookie

Hi All,

Long time stalker - first time poster in this thread. I'm hoping for a little advice. I've just build my first electric touring car, an XQ2S with the mid mount conversion kit. I also fitted the sway bar kit, the aluminium wheel hexes and the double cardan shafts on the advice given out in this sub (which is awesome, thanks!).

However, the last time I played with electric on-road racing was way back in the brushed motor / NiCd era and I am still learning about the sensored brushless motors and gearing them properly / safely. In the old days when I last ran electric, gearing was dictated by the batteries and avoiding the dreaded battery dump before the race was over.

I was wondering if someone could give me any suggestion on gear ratio's and how much static timing to run for a track with a 50M (80 foot) main straight with a 13.5T motor, with this particular car. I would consider changing to 48P if that's a better way to proceed - but i'm also fine with setting gear mesh on 64P gears.

I guess I would like to get in the ballpark without having to buy a dozen different pinions and spurs and risk burning up things whilst learning.

Thanks in advance!

Long time stalker - first time poster in this thread. I'm hoping for a little advice. I've just build my first electric touring car, an XQ2S with the mid mount conversion kit. I also fitted the sway bar kit, the aluminium wheel hexes and the double cardan shafts on the advice given out in this sub (which is awesome, thanks!).

However, the last time I played with electric on-road racing was way back in the brushed motor / NiCd era and I am still learning about the sensored brushless motors and gearing them properly / safely. In the old days when I last ran electric, gearing was dictated by the batteries and avoiding the dreaded battery dump before the race was over.

I was wondering if someone could give me any suggestion on gear ratio's and how much static timing to run for a track with a 50M (80 foot) main straight with a 13.5T motor, with this particular car. I would consider changing to 48P if that's a better way to proceed - but i'm also fine with setting gear mesh on 64P gears.

I guess I would like to get in the ballpark without having to buy a dozen different pinions and spurs and risk burning up things whilst learning.

Thanks in advance!

#237

Tech Apprentice

Blinky ie no boost/turbo? 50M is a long straight! With a modern 13.5 you will need to gear that about 4.5 I would say. If the can timing goes from 0-60 then high 40s say 48 but all are slightly different. I would start off with it a bit lower, run for a few minutes and check the temperature, if it isn't getting too hot then increase it a bit more. 100% must run a fan though

#238

Tech Initiate

very pertinent conversation this, im about to buy one of these, and exclusively user 48DP in all my off road cars. Was going to switch to a 48dp spur but the gearing side of Onroad I just cant get my head around

#239

Tech Apprentice

48dp is a bit stronger but the gaps between ratios are bigger compared to 64dp. If you already have a load of 48dp pinions then it would make sense to use 48dp in your onroad car.

FDR, presuming you are running blinky so zero esc timing advance (boost/turbo) you get it as well as you can so you hit top speed halfway on the main straight or bit nearer the end. You don't want it accelerating still at the end of the straight as then it means it will bog down on the infield

With FDR a lower number means higher geared (just to make things confusing). A typical 13.5 you would gear at say 4.5 to 5.5 depending on the track size. 17.5s don't rev as high so you would gear them higher ie lower FDR so 3.7-4.5 perhaps.

You need to monitor the motor temperatures as wrong gearing either way can result in a lot of extra heat so best to adjust a small bit at a time and have the thermal cut out configured on your esc and always use a decent 40mm fan on the motor

FDR, presuming you are running blinky so zero esc timing advance (boost/turbo) you get it as well as you can so you hit top speed halfway on the main straight or bit nearer the end. You don't want it accelerating still at the end of the straight as then it means it will bog down on the infield

With FDR a lower number means higher geared (just to make things confusing). A typical 13.5 you would gear at say 4.5 to 5.5 depending on the track size. 17.5s don't rev as high so you would gear them higher ie lower FDR so 3.7-4.5 perhaps.

You need to monitor the motor temperatures as wrong gearing either way can result in a lot of extra heat so best to adjust a small bit at a time and have the thermal cut out configured on your esc and always use a decent 40mm fan on the motor

#240

Tech Rookie

Thanks for your advice, dlruk! Yes, Blinky and have a 40mm fan fitted. Will try 4.5 FDR and creep up on the timing.

198Likes

198Likes