Tekno RC EB410 Thread

|

|||

#4052

Has anyone with the Exotek spurgear experienced a failure? Also are you setting your mesh as tight as recommended with the stock spur when using the exotek spur

#4054

#4055

Joey A.

So since there has been some people wondering about running the shocks in the front of the arm I though I would try explaining everything that I did to get them to work and why. My goal was to run as much stock stuff as possible with the least amount of modifications.

Arms- need to be flipped and 1mm shaved off the back (spacing the arm farther back) running it this way the car is still a mm shorter then stock but more material could be removed for more adjustability but I have found no need to make the car longer.

Inner ball stud- there are 2 ways of mounting, the first can be used with the stock plastic tower. All you need to do is use a 10mm ball stud instead of the lower shock mount screw and a little clearance from the shock tower and diff case. Using this method will work but the ball stud is moved lower and farther in then the stock locations which requires different pivot locations to try and correct roll centers. The other way (preferred) using the option carbon tower drill a hole higher and farther out if done properly you will be able to get the ball stud location in the correct hight(0mm) and between the two stock locations.

Shocks- only 2 changes from stock you will need to space the top shock mount 2mm out. You will also need to run around 1.5-2mm less droop depending on your setup.

Sway bar- this is the hardest part of the swap. This can be done a million ways I chose to print a mount in the stock ball stud location which allowed me to use the stock swaybars and arm mounting position. You can also bend your own bar and use the stock mounts on the back. You will have to drill your arms on the other side and closer to the pivot for this to work (remember you will need a thinner bar the closer you mount the lower pickup on the arm to get the same feeling as stock).

Other- you will need to remove the drop screws on the rear arm. Depending on rear rims,hubs,ballcups and setup you might need to clearance the outer ball cup so it doesn’t rub on the wheel.

Why- the benefits of running the shocks in the front are the ability to run a softer rear shock package without giving up corner speed and pack. The car will land without chassis slapping or packing out as easy allowing you to drive the car harder and it corners flatter and rotates faster without losing rear grip.

Sorry for the shity grammar,

TJR

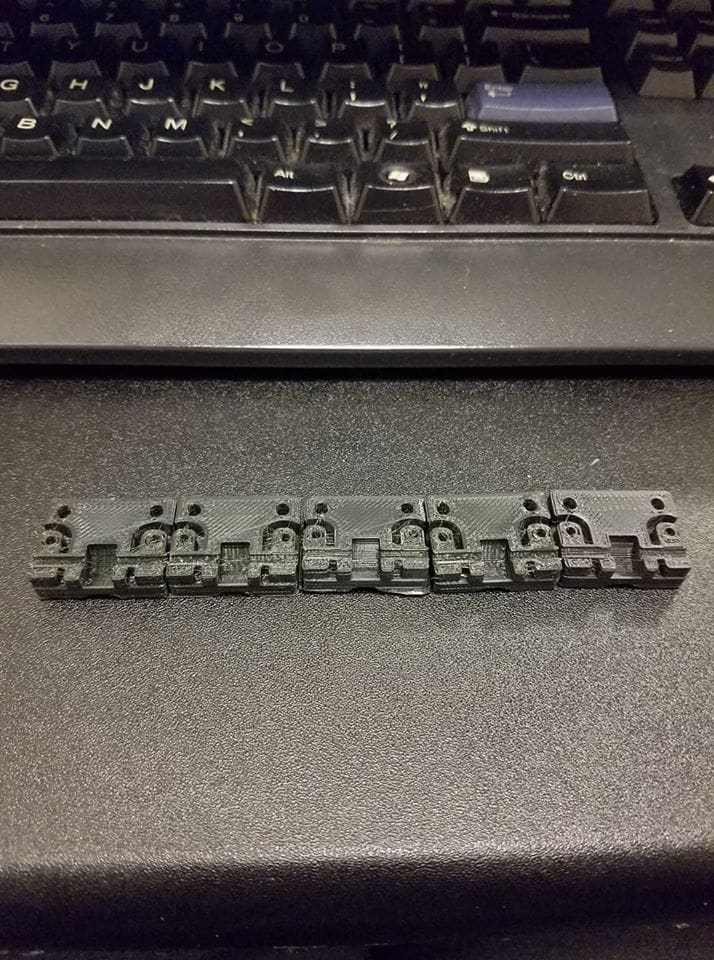

And this is the ebay printed sway bar mount

https://www.ebay.com/itm/Tekno-EB410...4AAOSwYNxahFkq

#4056

Yeah I can't imagine it's the plastic either. My Tekno spurs haven't stripped either the stock 81t and now the 70t. Though I'm also using plastic pinions and my track doesn't really have loose stuff that can rattle around inside. All it takes is a little pebble between the 81t spur and the chassis.

I've witnessed other EB410's have failures that could not be explained along with my own and many others who have posted similar stories here and on FB. Typically meshing your gears as tight as we do with the EB410 would lead to a spur gear failure from being too tight on most other vehicles.

I also suspect that the revised bulk heads used a different type of plastic or process as they are almost identical to the previous bulks aside from a minor change by the output hole, maybe the same type of issue with the spurs?

I'll purchase the Exotex spur for now, but my hope is that Tekno makes a revised or improved spur made of something more durable that will eliminate these fluke failures and work with traditional mesh adj.

#4057

Tech Master

The reason I believe it is the plastic is I have yet to hear of a failure of any type with the Exotek spur setup made from the stronger Delrin material. I've also never experienced failures like this with any other 10th scale buggy eating spur gears unless there was an identifiable cause (loose mount, motor or pinion).

I've witnessed other EB410's have failures that could not be explained along with my own and many others who have posted similar stories here and on FB. Typically meshing your gears as tight as we do with the EB410 would lead to a spur gear failure from being too tight on most other vehicles.

I also suspect that the revised bulk heads used a different type of plastic or process as they are almost identical to the previous bulks aside from a minor change by the output hole, maybe the same type of issue with the spurs?

I'll purchase the Exotex spur for now, but my hope is that Tekno makes a revised or improved spur made of something more durable that will eliminate these fluke failures and work with traditional mesh adj.

I've witnessed other EB410's have failures that could not be explained along with my own and many others who have posted similar stories here and on FB. Typically meshing your gears as tight as we do with the EB410 would lead to a spur gear failure from being too tight on most other vehicles.

I also suspect that the revised bulk heads used a different type of plastic or process as they are almost identical to the previous bulks aside from a minor change by the output hole, maybe the same type of issue with the spurs?

I'll purchase the Exotex spur for now, but my hope is that Tekno makes a revised or improved spur made of something more durable that will eliminate these fluke failures and work with traditional mesh adj.

#4058

The reason I believe it is the plastic is I have yet to hear of a failure of any type with the Exotek spur setup made from the stronger Delrin material. I've also never experienced failures like this with any other 10th scale buggy eating spur gears unless there was an identifiable cause (loose mount, motor or pinion).

I've witnessed other EB410's have failures that could not be explained along with my own and many others who have posted similar stories here and on FB. Typically meshing your gears as tight as we do with the EB410 would lead to a spur gear failure from being too tight on most other vehicles.

I also suspect that the revised bulk heads used a different type of plastic or process as they are almost identical to the previous bulks aside from a minor change by the output hole, maybe the same type of issue with the spurs?

I'll purchase the Exotex spur for now, but my hope is that Tekno makes a revised or improved spur made of something more durable that will eliminate these fluke failures and work with traditional mesh adj.

I've witnessed other EB410's have failures that could not be explained along with my own and many others who have posted similar stories here and on FB. Typically meshing your gears as tight as we do with the EB410 would lead to a spur gear failure from being too tight on most other vehicles.

I also suspect that the revised bulk heads used a different type of plastic or process as they are almost identical to the previous bulks aside from a minor change by the output hole, maybe the same type of issue with the spurs?

I'll purchase the Exotex spur for now, but my hope is that Tekno makes a revised or improved spur made of something more durable that will eliminate these fluke failures and work with traditional mesh adj.

It's a sweet buggy and it'd be a bummer to keep getting bogged down by the spur.

It's a sweet buggy and it'd be a bummer to keep getting bogged down by the spur.

#4059

Tech Regular

iTrader: (18)

As far as moving the rear shocks to the front. I know a couple of guys that did this and the 3D printed sway bar mount seems to me very brittle. He broke one just taking it off. Another guy did as well. Bought off Ebay.

Anyone else experiencing this?

The carbon fiber one mentioned earlier might be the way to go.

Anyone else experiencing this?

The carbon fiber one mentioned earlier might be the way to go.

#4060

As far as moving the rear shocks to the front. I know a couple of guys that did this and the 3D printed sway bar mount seems to me very brittle. He broke one just taking it off. Another guy did as well. Bought off Ebay.

Anyone else experiencing this?

The carbon fiber one mentioned earlier might be the way to go.

Anyone else experiencing this?

The carbon fiber one mentioned earlier might be the way to go.

#4061

The only reason I really considered the plastic to not be the issue is that I actually managed to break a tooth off of my composite pinion gear from Kimbrough before actually stripping a Tekno spur. But I admit it seems the Tekno spurs seem to be more prone to failure, whether its the softness of the plastic or the molding process used i can't be sure. But hopefully the Exotek spur changes things for you  It's a sweet buggy and it'd be a bummer to keep getting bogged down by the spur.

It's a sweet buggy and it'd be a bummer to keep getting bogged down by the spur.

It's a sweet buggy and it'd be a bummer to keep getting bogged down by the spur.

It's a sweet buggy and it'd be a bummer to keep getting bogged down by the spur.

Also I'm running Mod with a 5.5T motor on hard packed Dirt that changes from low to high grip depending on watering conditions.

#4062

One thing I recommend when installing the diff cover whether its the Tekno spur or the Exotek spur plate, you want to get some pliers and clamp down around the differential to make sure the spur or the spur plate is completely seated. This'll help avoid warping the spur when tightening it down. This is what I do with my Tekno spurs since at times the thing doesn't want to seat fully unless you give it some muscle.

2421Likes

2421Likes