Tekno RC EB410 Thread

|

|||

#3497

Gearing feedback request:

EB410 community I have my 410 just about ready to hit the track, clay surface small to medium in size w/ good flow. Running a 13.5 Monster HP Trinity and Orion 10.1 ESC.

I see guys running both 81t and 70t spur gears, seems the AE pinions mesh well but wanted to try some of the polypro hybrid pinions as well.

Question: What’s a good range of pinions to stock if you’re playing with those spur gear options? Don’t like running near the ragged edge of Equipment ability, so I prefer a milder setup.

Thanks guys for feedback!

EB410 community I have my 410 just about ready to hit the track, clay surface small to medium in size w/ good flow. Running a 13.5 Monster HP Trinity and Orion 10.1 ESC.

I see guys running both 81t and 70t spur gears, seems the AE pinions mesh well but wanted to try some of the polypro hybrid pinions as well.

Question: What’s a good range of pinions to stock if you’re playing with those spur gear options? Don’t like running near the ragged edge of Equipment ability, so I prefer a milder setup.

Thanks guys for feedback!

Maybe start there and go up or down a tooth on the pinion if necessary?

#3498

Tech Master

Gearing feedback request:

EB410 community I have my 410 just about ready to hit the track, clay surface small to medium in size w/ good flow. Running a 13.5 Monster HP Trinity and Orion 10.1 ESC.

I see guys running both 81t and 70t spur gears, seems the AE pinions mesh well but wanted to try some of the polypro hybrid pinions as well.

Question: Whatís a good range of pinions to stock if youíre playing with those spur gear options? Donít like running near the ragged edge of Equipment ability, so I prefer a milder setup.

Thanks guys for feedback!

EB410 community I have my 410 just about ready to hit the track, clay surface small to medium in size w/ good flow. Running a 13.5 Monster HP Trinity and Orion 10.1 ESC.

I see guys running both 81t and 70t spur gears, seems the AE pinions mesh well but wanted to try some of the polypro hybrid pinions as well.

Question: Whatís a good range of pinions to stock if youíre playing with those spur gear options? Donít like running near the ragged edge of Equipment ability, so I prefer a milder setup.

Thanks guys for feedback!

Just a note on spur. Since these guys are in the 28-29t pinion range, and you want to try the polypro (also 175rc, exotec, and other super-lightweight options) You'll probably want to stick with the 81t spur. Those lightweight pinions stop at 26t pinion, and the ones I've contacted have no interest in making any smaller than 26t.

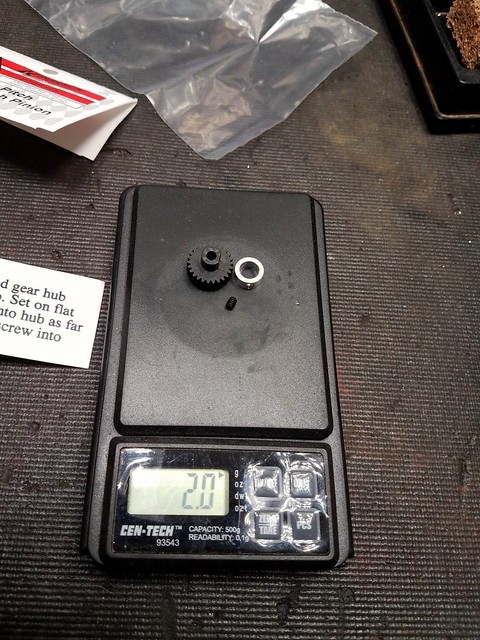

BUT, if you want to drop to the 70t spur to get the motor closer to the centerline and better weight distribution, you then have the option to with the AE TE pinions. They weight in at 1g, which isn't too shabby, considering my RR pinions weighed in a 3-4g's.

I would love to know what the polypro and other options actually come in weight wise.

#3500

I've got about 4 race days on my Kimbrough Carbon Pinion gear, works great, very efficient and they sell pinions all the way down to 15T:

Pinion Gears: 48P - Kimbrough Racing Products - RC Spur Gears, Pinion Gears, Servo Savers

I've added this link to the Wiki as well

#3501

I've got about 4 race days on my Kimbrough Carbon Pinion gear, works great, very efficient and they sell pinions all the way down to 15T:

Pinion Gears: 48P - Kimbrough Racing Products - RC Spur Gears, Pinion Gears, Servo Savers

I've added this link to the Wiki as well

Pinion Gears: 48P - Kimbrough Racing Products - RC Spur Gears, Pinion Gears, Servo Savers

I've added this link to the Wiki as well

#3502

Tech Master

I've got about 4 race days on my Kimbrough Carbon Pinion gear, works great, very efficient and they sell pinions all the way down to 15T:

Pinion Gears: 48P - Kimbrough Racing Products - RC Spur Gears, Pinion Gears, Servo Savers

I've added this link to the Wiki as well

Pinion Gears: 48P - Kimbrough Racing Products - RC Spur Gears, Pinion Gears, Servo Savers

I've added this link to the Wiki as well

#3503

Tech Initiate

Ok hereís my few questions for today, first with the Tekin pro spec 13.5 it seems as though everyone is running between 21-23 pinion gears. Would there be any other reason to go up or down there? Refresher, in pinions and spurs if you go up in one do you go down on another? Higher spur over lower spur, whatís the advantage here and same question for pinion gears. I remember there is a science to this, I just donít remember the science. And last, the MIP drivetrain set up. Is it worth it, have any of you noticed better performance or any other types of details that would validate the cost? Just thinking about this since I will be rebuilding my diffs once my PT oils arrive if itís worth getting and installing at that time. Thanks everyone in advance

#3504

Ok hereís my few questions for today, first with the Tekin pro spec 13.5 it seems as though everyone is running between 21-23 pinion gears. Would there be any other reason to go up or down there? Refresher, in pinions and spurs if you go up in one do you go down on another? Higher spur over lower spur, whatís the advantage here and same question for pinion gears. I remember there is a science to this, I just donít remember the science. And last, the MIP drivetrain set up. Is it worth it, have any of you noticed better performance or any other types of details that would validate the cost? Just thinking about this since I will be rebuilding my diffs once my PT oils arrive if itís worth getting and installing at that time. Thanks everyone in advance

The Tekin Spec-r motor is tuned to have more overall RPM so most guys running the Spec-r motor are geared a lot lower than others would be on a motor like the Maclan team edition or the standard Tekin redline 13.5. That is why you see such a difference in gearing.

Going up in pinion teeth or down in spur teeth will give you more top speed. Less teeth on the pinion or more teeth on the spur gives you less speed

#3505

Tech Master

And last, the MIP drivetrain set up. Is it worth it, have any of you noticed better performance or any other types of details that would validate the cost? Just thinking about this since I will be rebuilding my diffs once my PT oils arrive if itís worth getting and installing at that time. Thanks everyone in advance

The real question is, is it worth the cost? That boils down to one thing for me. Can you consistently put in runs with no mistakes or crashes? Then yes, it will get you the few 10ths to stay at the top and always battle for the win.

If your like me, and a mistake free run is an occasional dream, then no, it is not worth it to me.

Same logic with ceramic bearings in my mind.

#3506

Tech Initiate

Ahh makes sense now on the gearing, didn’t know this motor was that bad ass but at least now I know. And yeah,far from worrying about 10ths of a second right now so I will save that money for something else. Just so much interesting add on’s and replacement parts out there, aluminum and composite . But I don’t want to be that guy who has all this cool stuff and can’t drive for crap to utilize it or know exactly what it’s purpose really is to appreciate it.

#3507

Did more testing of the car yesterday and now It Begins to feel pretty dialed.

Changed diff fluids to 7k in rear and front, run AE slipper in the middle. Now it behaves much better on high grip carpet than with thicker fluids in the front. A nice feel of Power and much easier to Control.

The rear shocks was drilled to 2mm and 800 oil. A huge difference now when landing. The shocks goes in nice and Easy and then rebound in a nice way on the track.

I have been working a lot with the body roll in the back and need some suggestions what to look at. When exit a long corner at high speed I want the car to "sweep". No the cars rear have a tendency to come out when hitting the throttle. Maybe it could be the slipper that needs to be loosen, did not have time to check that yesterday. But is there a general rule for avoiding the rear to come out when accelerating out of corners?

Had a team driver testing the car yesterday and his verdict was that the car is now totally on the right way just work with this and the car will be among the fastest at the track.

I can also say that I have not had any more bulk failures After mounting the Exotek bulk strenghtener in the front and going back for stock front deck. This car slowly comes back to me now as the perfect 1/10 4wd buggy.

Changed diff fluids to 7k in rear and front, run AE slipper in the middle. Now it behaves much better on high grip carpet than with thicker fluids in the front. A nice feel of Power and much easier to Control.

The rear shocks was drilled to 2mm and 800 oil. A huge difference now when landing. The shocks goes in nice and Easy and then rebound in a nice way on the track.

I have been working a lot with the body roll in the back and need some suggestions what to look at. When exit a long corner at high speed I want the car to "sweep". No the cars rear have a tendency to come out when hitting the throttle. Maybe it could be the slipper that needs to be loosen, did not have time to check that yesterday. But is there a general rule for avoiding the rear to come out when accelerating out of corners?

Had a team driver testing the car yesterday and his verdict was that the car is now totally on the right way just work with this and the car will be among the fastest at the track.

I can also say that I have not had any more bulk failures After mounting the Exotek bulk strenghtener in the front and going back for stock front deck. This car slowly comes back to me now as the perfect 1/10 4wd buggy.

#3508

#3510

Ok hereís my few questions for today, first with the Tekin pro spec 13.5 it seems as though everyone is running between 21-23 pinion gears. Would there be any other reason to go up or down there? Refresher, in pinions and spurs if you go up in one do you go down on another? Higher spur over lower spur, whatís the advantage here and same question for pinion gears. I remember there is a science to this, I just donít remember the science. And last, the MIP drivetrain set up. Is it worth it, have any of you noticed better performance or any other types of details that would validate the cost? Just thinking about this since I will be rebuilding my diffs once my PT oils arrive if itís worth getting and installing at that time. Thanks everyone in advance

2421Likes

2421Likes