Associated SC10.2 Factory Team

#3811

Tech Master

iTrader: (1)

Has anyone ever tapped their FT aluminum bellcrank to accept 3mm threaded ballstuds?

Would a 4-40 threaded piece still have enough material to tap a 3mm thread?

I have a couple of one piece (#91455) SC5M steering links that I thought about using, but they use the 5.5mm heavy duty ballstuds. The reason for me thinking about using the one piece steering link is that I've tore the standard ballcups from the threaded rod after only running two battery packs through stock linkage. The ballcup separating from the steering link threads maybe saved some damage happening elsewhere? The bad landing didn't seem all that bad though .

.

Would a 4-40 threaded piece still have enough material to tap a 3mm thread?

I have a couple of one piece (#91455) SC5M steering links that I thought about using, but they use the 5.5mm heavy duty ballstuds. The reason for me thinking about using the one piece steering link is that I've tore the standard ballcups from the threaded rod after only running two battery packs through stock linkage. The ballcup separating from the steering link threads maybe saved some damage happening elsewhere? The bad landing didn't seem all that bad though

.

.

#3812

Tech Fanatic

Hmm steering link,yes... it's one one of only two "mechanical failures" I've had with the SC10. I had the ballcup come off the rod in my first club race 3,5 years ago having not driven the car much at all at that point. Someone lent me shortened RPM ballcups that we installed instead, has held ever since.

As for the threads, 4-40 won't hold in a 3mm thread. 3mm rod could go into a 4-40 hole, though, it'd carve its own threads in there in plastic - for aluminum I'm not sure how that would go, depends on the aluminum. But other options include gluing the the ballcup onto the rod as a form of "threadlock" - I'm not actually sure if my RPM ones are glued or not. And with that said you could indeed get some stronger RPM ballcups instead of the standard ones to use on the link rod. There's basically no rod showing on mine so they're dug in deep and won't be coming off accidentally.

As for the threads, 4-40 won't hold in a 3mm thread. 3mm rod could go into a 4-40 hole, though, it'd carve its own threads in there in plastic - for aluminum I'm not sure how that would go, depends on the aluminum. But other options include gluing the the ballcup onto the rod as a form of "threadlock" - I'm not actually sure if my RPM ones are glued or not. And with that said you could indeed get some stronger RPM ballcups instead of the standard ones to use on the link rod. There's basically no rod showing on mine so they're dug in deep and won't be coming off accidentally.

#3813

Tech Addict

iTrader: (1)

Did anyone try these yet? (x-rings in V1 shocks) We still have 12 mm V1's on one truck. I ordered some o-rings from Revolution Design Products that I'm going to try on the next rebuild. Our V2's will be getting x-rings next time around.

Last edited by bubbaslash; 06-30-2018 at 04:43 PM.

#3814

Tech Master

iTrader: (1)

Has anyone ever tapped their FT aluminum bellcrank to accept 3mm threaded ballstuds?

Would a 4-40 threaded piece still have enough material to tap a 3mm thread?

I have a couple of one piece (#91455) SC5M steering links that I thought about using, but they use the 5.5mm heavy duty ballstuds. The reason for me thinking about using the one piece steering link is that I've tore the standard ballcups from the threaded rod after only running two battery packs through stock linkage. The ballcup separating from the steering link threads maybe saved some damage happening elsewhere? The bad landing didn't seem all that bad though .

.

Would a 4-40 threaded piece still have enough material to tap a 3mm thread?

I have a couple of one piece (#91455) SC5M steering links that I thought about using, but they use the 5.5mm heavy duty ballstuds. The reason for me thinking about using the one piece steering link is that I've tore the standard ballcups from the threaded rod after only running two battery packs through stock linkage. The ballcup separating from the steering link threads maybe saved some damage happening elsewhere? The bad landing didn't seem all that bad though

.

.

#3815

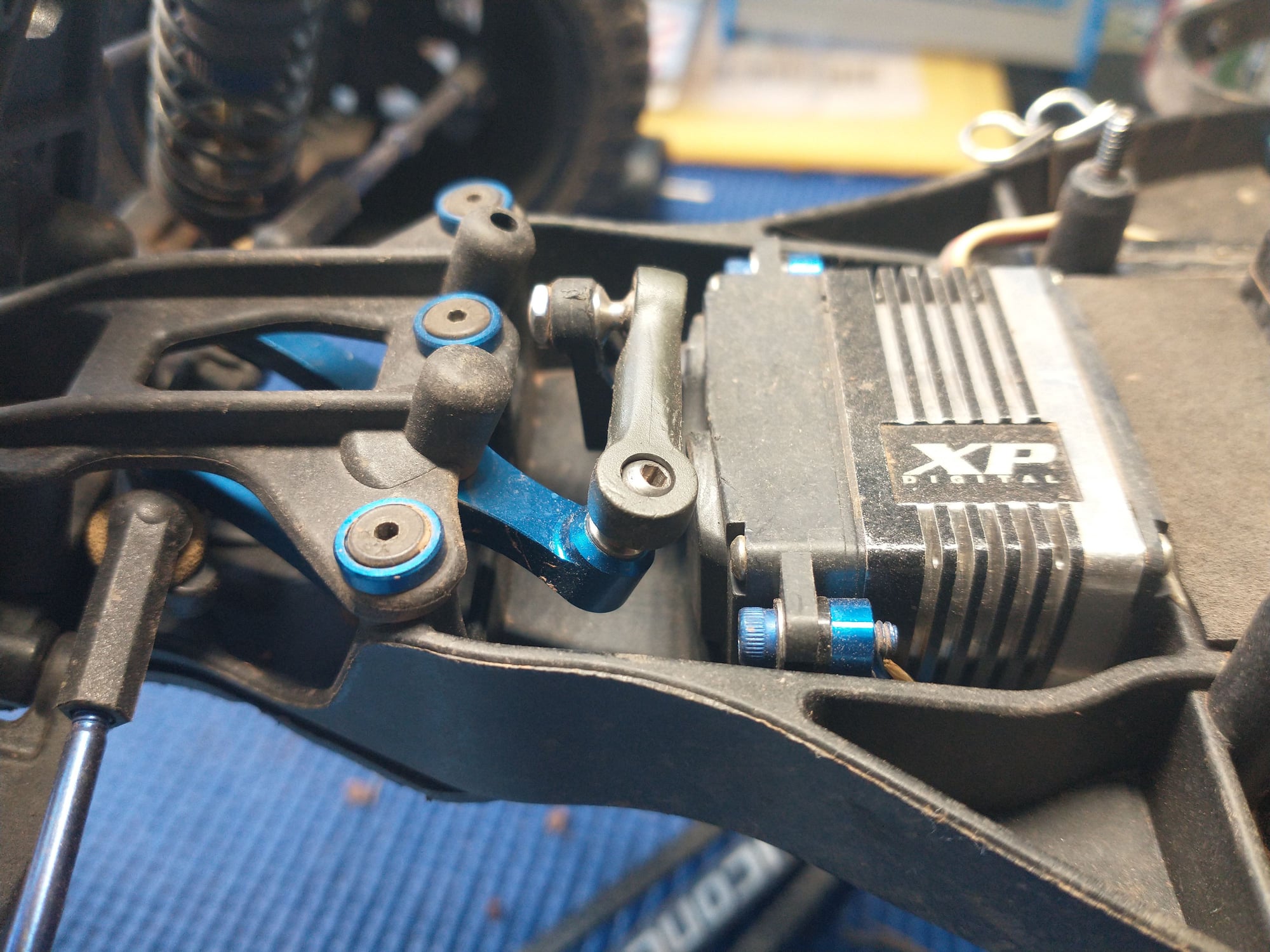

Those threads do not look very good. I bet you will have a problem with that ball stud coming loose, and if you try to tighten it that the aluminum threads will strip. Probably better to drill the hole smooth, and use a longer ball stud with a nut.

#3816

#3817

Tech Master

iTrader: (1)

Yeah, time will tell. What's weird is, all my other B4, T4s, SC10s never had an issue with stock servo linkage. This SC10.2 has only a handful of runs on it after bringing it out of retirement. Every other run results in servo link's threaded rod pulling out of RPM, JConcepts, and stock AE ballcups. Since this truck is the only Associated platform to give me a steering headache, something had to be done. So far, so good. After a few good runs on the track, the newly cut threads on the SC10.2's bellcrank are solid, and holding. I can once again enjoy the SCT, and not do the hang my head in shame walk.

#3818

Tech Master

iTrader: (1)

I couldn't find any posts on the use of Schelle Racing Spinfree front axles.

Schelle Racing makes their axles similar to JConcepts in the fact that they eliminate the Associated C-clip design. The Schelle Racing axles didn't have good reviews on Amain Hobbies, so I was a bit hesitant in ordering a couple of sets. If they end up being total garbage, then I'll mod them, or grind the rib off.

Anyone ever use Schelle's axles on their SC10?

Schelle Racing makes their axles similar to JConcepts in the fact that they eliminate the Associated C-clip design. The Schelle Racing axles didn't have good reviews on Amain Hobbies, so I was a bit hesitant in ordering a couple of sets. If they end up being total garbage, then I'll mod them, or grind the rib off.

Anyone ever use Schelle's axles on their SC10?

#3819

Tech Master

iTrader: (1)

Well, after I asked (earlier post), I got the Schelle Racing axles at my front doorstep.

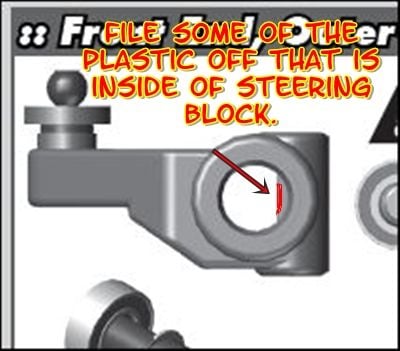

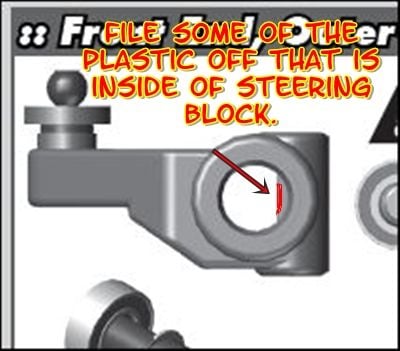

I now know why people were giving the Schelle axles a bad rap. The axle itself, the part of it which passes through and around the steering block hinge pin, is a bit too thick when compared to the stock #9881 axle. After installing the Schelle axles, there is indeed resistance...wheels will not spin freely. Taking a small file and sanding some material off the inside of the steering block, the Schelle Racing Spinfree axles do operate smoothly as their name implies.

Since I don't know when, or if Associated will have more of the stock axles produced, I wasn't taking any chances. I had to make sure I had spare axles on hand. The options out there are slim pickings at the moment, and I'm not about to stop bashing my 4 series of trucks from Associated.

I now know why people were giving the Schelle axles a bad rap. The axle itself, the part of it which passes through and around the steering block hinge pin, is a bit too thick when compared to the stock #9881 axle. After installing the Schelle axles, there is indeed resistance...wheels will not spin freely. Taking a small file and sanding some material off the inside of the steering block, the Schelle Racing Spinfree axles do operate smoothly as their name implies.

Since I don't know when, or if Associated will have more of the stock axles produced, I wasn't taking any chances. I had to make sure I had spare axles on hand. The options out there are slim pickings at the moment, and I'm not about to stop bashing my 4 series of trucks from Associated.

#3823

Tech Master

iTrader: (1)

5Likes

5Likes