Tekin RX8: Has yours been reliable?

#106

RX8s have been reliable for me.

I got 1.5 years out of my first one in an E-8 (an original 4-hole case model that I never upgraded) before I ended up selling it after building another E-8 with a new RX-8.

That's now almost at the end of its second year with no problems.

Aside from the fact that it is a great product, I also attribute the reliability to the care I used in mounting it.

I have my RX-8s screwed down to a flexible mount with foam and O-rings for cushioning.

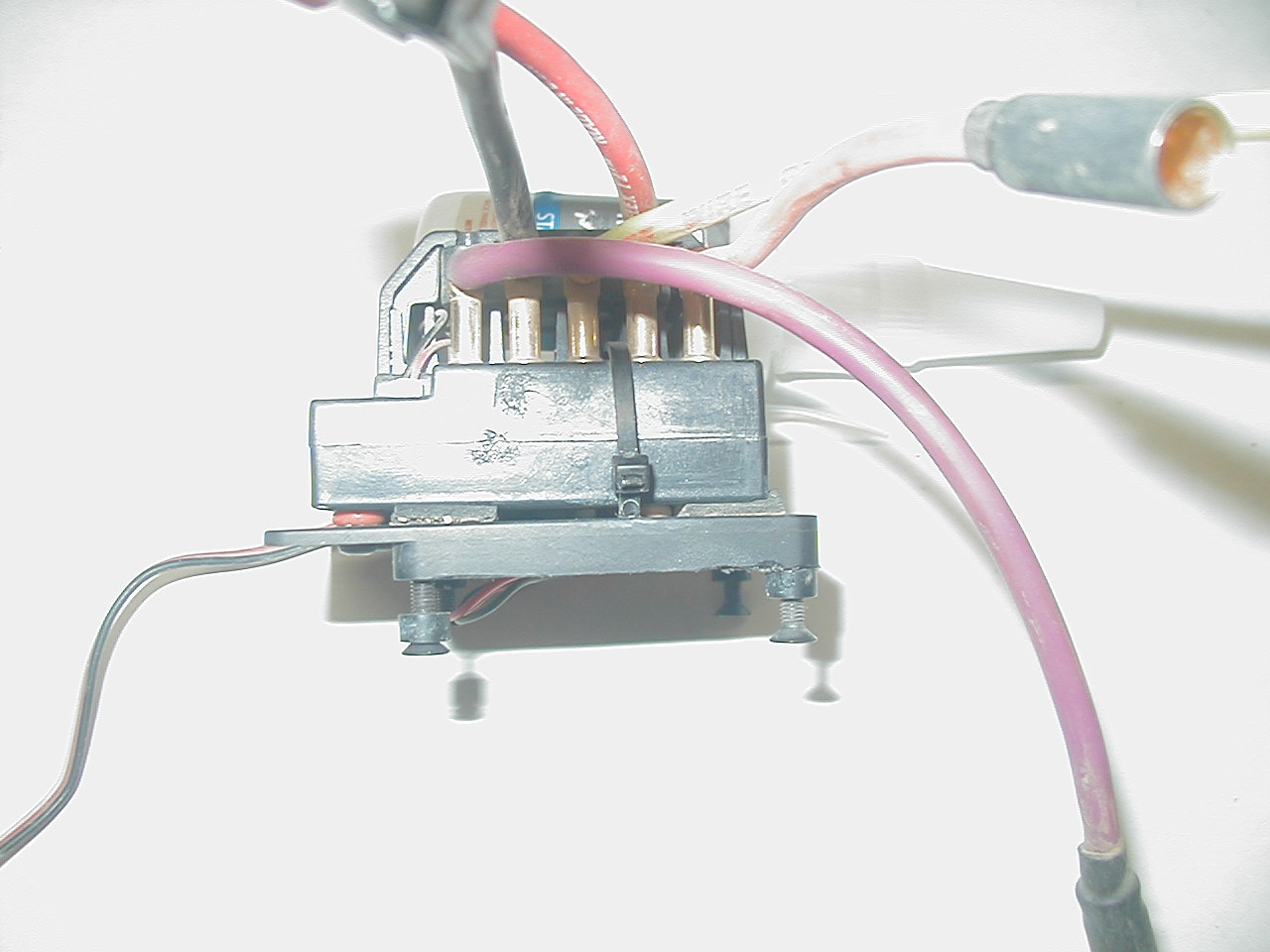

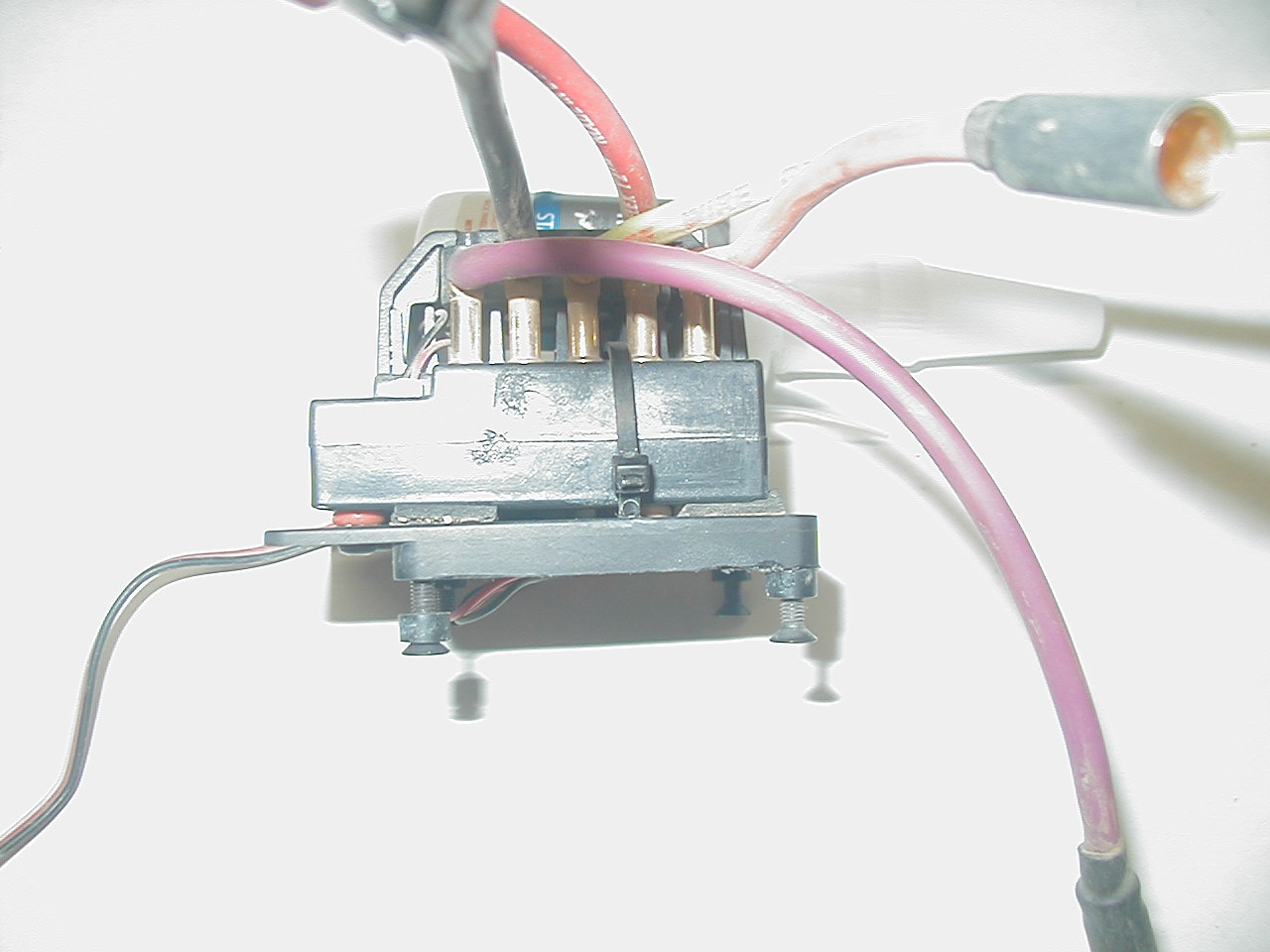

This is how the original 4-hole unit was mounted:

I got 1.5 years out of my first one in an E-8 (an original 4-hole case model that I never upgraded) before I ended up selling it after building another E-8 with a new RX-8.

That's now almost at the end of its second year with no problems.

Aside from the fact that it is a great product, I also attribute the reliability to the care I used in mounting it.

I have my RX-8s screwed down to a flexible mount with foam and O-rings for cushioning.

This is how the original 4-hole unit was mounted:

#107

I've never had a flame out on one, but could never seem to get a control board to last very long. They have all eventually just died or started acting glitchy.

I like the way they drive but the consistent control board issues drove me away. The 3 hole case was an improvement and made them last longer. Now they make it through the warranty period before they start acting up. I'm running other stuff now. I'll be back after the next design revision.

I will say this though. Tekin has great service and always fixed it when it died within the warranty period. I just wish the warranty period was a little longer and it would be alot cheaper to run the RX8.

I like the way they drive but the consistent control board issues drove me away. The 3 hole case was an improvement and made them last longer. Now they make it through the warranty period before they start acting up. I'm running other stuff now. I'll be back after the next design revision.

I will say this though. Tekin has great service and always fixed it when it died within the warranty period. I just wish the warranty period was a little longer and it would be alot cheaper to run the RX8.

#108

If a specific area is having this many catastrophic issues I not only would expect to hear about it whether internally or externally through our team drivers and or the customers themselves.

We put ourselves out in the public eye daily for Tekin. We do this simply because we want to help out customers which is why we make ourselves so easy to reach.

Our internal groups are in constant discussion when it comes to customer service, technical support,etc. Part of our job is to watch for patterns of failure in products. So if we get a half dozen items from one area or region or worse yet a single person we will often go out of our way to talk to him/her and help find out what's going on.

We've admitted to having issues in the past. We've fixed them and will continue to look for them as the product life continues.

@Goodhews hopefully this clears up any confusion between us. RP

We put ourselves out in the public eye daily for Tekin. We do this simply because we want to help out customers which is why we make ourselves so easy to reach.

Our internal groups are in constant discussion when it comes to customer service, technical support,etc. Part of our job is to watch for patterns of failure in products. So if we get a half dozen items from one area or region or worse yet a single person we will often go out of our way to talk to him/her and help find out what's going on.

We've admitted to having issues in the past. We've fixed them and will continue to look for them as the product life continues.

@Goodhews hopefully this clears up any confusion between us. RP

#109

I run adhesive backed heatsink on my rx8 posts after I solder the wires so there is not too much mechanical stress on the solder joint. Mine has been rock solid thus far. I do not though like the solder post implementation. Would much rather have it like the hobbywing or even tekins 1/10 scale escs.

#110

Tekin motors are the best I tried by far but these posts make the RX8 too fragile, of course it works for some with many caushions but the connection of the motor cables could be more simple/ safer. When I look at these wires on the MMP I just tell to myself "why didn't they do the same on the rx8??". I'm also saying this forTekin I can't imagine how many failures are due to bad solderings or stressed posts. This is even more frustrating considering the RX8 is so good otherwise

#111

+1

Tekin motors are the best I tried by far but these posts make the RX8 too fragile, of course it works for some with many caushions but the connection of the motor cables could be more simple/ safer. When I look at these wires on the MMP I just tell to myself "why didn't they do the same on the rx8??". I'm also saying this forTekin I can't imagine how many failures are due to bad solderings or stressed posts. This is even more frustrating considering the RX8 is so good otherwise

Tekin motors are the best I tried by far but these posts make the RX8 too fragile, of course it works for some with many caushions but the connection of the motor cables could be more simple/ safer. When I look at these wires on the MMP I just tell to myself "why didn't they do the same on the rx8??". I'm also saying this forTekin I can't imagine how many failures are due to bad solderings or stressed posts. This is even more frustrating considering the RX8 is so good otherwise

All too often I see people post pictures of their cars on here. And the wiring jobs can be hideous. Not to mention their cars look like they have never been cleaned or cared for. I see horrible wiring jobs at my local track all the time as well. And I always offer help when it comes to wiring stuff up or doing soldering.

Ultimately it's the end users responsibility to care for their equipment. If you fail to do so, ANYTHING will fail. Some people really need to take a look at what THEY are doing instead of blame the issue on the part that failed. Stop and ask, "What could I have done to prevent this?"

I will admit I have received one ESC that was DOA from Amain. Had a new one within the week. Other than that I've never had a single ESC failure from Tekin. But I take my time when I'm wiring a car up. I've taken the time to learn how to properly solder. I also do regular maintenance on my cars. So very rarely does anything fail on my cars.

#112

Amen brother Tekin ROCKS

#113

So, if you have used a Tekin RX8, please post the following information:

-Which version it is, including which motor - not sure I bought it last november running it with a pro4 4600kv motor in a losi SCTE

-When you got it/how long you've been using it - ran it almost every weekend since november, indoor in the winter 40-50* ambient temps to 100* temps this summer

-The setup in which you used it

car - Losi SCTE

voltage - 2s lipo

gearing - 13p -54s

intensity - I race it pretty hard

-Any problems you have had with it - broke the fan blades on the first fan, 2nd fan ive had no trouble

-Your experience with Tekin's repair service if you had to send it in - havent had to send it in, hopefully it keeps chugging along

I went through 3 novak speed controls and 2 motors (all defective from factory)

after that i bit the bullet and bought tekin stuff, no problems since

-Which version it is, including which motor - not sure I bought it last november running it with a pro4 4600kv motor in a losi SCTE

-When you got it/how long you've been using it - ran it almost every weekend since november, indoor in the winter 40-50* ambient temps to 100* temps this summer

-The setup in which you used it

car - Losi SCTE

voltage - 2s lipo

gearing - 13p -54s

intensity - I race it pretty hard

-Any problems you have had with it - broke the fan blades on the first fan, 2nd fan ive had no trouble

-Your experience with Tekin's repair service if you had to send it in - havent had to send it in, hopefully it keeps chugging along

I went through 3 novak speed controls and 2 motors (all defective from factory)

after that i bit the bullet and bought tekin stuff, no problems since

#114

As long as we're on the subject of the solder posts.....

Why not make solder tabs similar to soldering a wire onto the motor? There isn't a single RC driver in the entire world that's had any trouble at all getting wires to stick to Tekin motors (as long as they remember to scuff the tab a little).

Why not make solder tabs similar to soldering a wire onto the motor? There isn't a single RC driver in the entire world that's had any trouble at all getting wires to stick to Tekin motors (as long as they remember to scuff the tab a little).

#115

Tech Apprentice

iTrader: (5)

Have a Rx8 2050kv combo on my rc8.2e for 6 months now with no issues. Just added a Rx8 to my Scte to power my Tenshock sc411. Mamba max pro had too many issues powering that motor. The internal Bec in the Tekin is awesome too. No problems powering high powered servos.

#116

As long as we're on the subject of the solder posts.....

Why not make solder tabs similar to soldering a wire onto the motor? There isn't a single RC driver in the entire world that's had any trouble at all getting wires to stick to Tekin motors (as long as they remember to scuff the tab a little).

Why not make solder tabs similar to soldering a wire onto the motor? There isn't a single RC driver in the entire world that's had any trouble at all getting wires to stick to Tekin motors (as long as they remember to scuff the tab a little).

#117

Tech Fanatic

iTrader: (30)

+1 Lucid

+1 Odin

Soldering posts and motor tabs - You can purchase small soldering tabs from AMain (I bought them and they were very very cool and made soldering wires to tabs or posts very simple.

My buddy had a warrantied RX8 this spring. Came back to him DOA, they had another one to him in less than a week.

Randy, Ty...I'm sorry for resurrecting this thread that's been dead for about 2 years. I just wanted to get Dan's input after having his RX8 for some time. I also just wanted it to stay on topic with everyone giving the info asked for and telling is THEIR overall experience. It's off topic.

In regards to an ESC fire, I've seen it twice. Once at an indoor track, once at an outdoor track. The equipment/electronics used, I don't remember...I think the outdoor might have a MMM (8th scale buggy) if memory serves. In BOTH cases, however, one was due to the motor shaft having a slight bend in it 'causing increased electrical resistance backward through the circuit of motor/ESC/battery. The lipo was saved, the motor was DONE, and the ESC was crispy (outdoor track). The indoor was bridging due to poor soldering or connections. The person had bullets but they were loose and revealing themselves. Bridge! Zap! Phoom! (indoor track) Body was unsalvagable, chassis was okay, ESC was DONE, battery saved, motor...can't remember how it came out but I'm sure it could have easily been toast.

When it comes to an ESC up in smoke/flames, look at resistance in the circuit/wiring and what you are using for components. The more connections you have, the more resistance you build in the circuit regardless of "zero loss" or "low/ultra low resistance" connectors.

Soldering directly is the FIRST and BEST option to take if you can!

B.

+1 Odin

Soldering posts and motor tabs - You can purchase small soldering tabs from AMain (I bought them and they were very very cool and made soldering wires to tabs or posts very simple.

My buddy had a warrantied RX8 this spring. Came back to him DOA, they had another one to him in less than a week.

Randy, Ty...I'm sorry for resurrecting this thread that's been dead for about 2 years. I just wanted to get Dan's input after having his RX8 for some time. I also just wanted it to stay on topic with everyone giving the info asked for and telling is THEIR overall experience. It's off topic.

In regards to an ESC fire, I've seen it twice. Once at an indoor track, once at an outdoor track. The equipment/electronics used, I don't remember...I think the outdoor might have a MMM (8th scale buggy) if memory serves. In BOTH cases, however, one was due to the motor shaft having a slight bend in it 'causing increased electrical resistance backward through the circuit of motor/ESC/battery. The lipo was saved, the motor was DONE, and the ESC was crispy (outdoor track). The indoor was bridging due to poor soldering or connections. The person had bullets but they were loose and revealing themselves. Bridge! Zap! Phoom! (indoor track) Body was unsalvagable, chassis was okay, ESC was DONE, battery saved, motor...can't remember how it came out but I'm sure it could have easily been toast.

When it comes to an ESC up in smoke/flames, look at resistance in the circuit/wiring and what you are using for components. The more connections you have, the more resistance you build in the circuit regardless of "zero loss" or "low/ultra low resistance" connectors.

Soldering directly is the FIRST and BEST option to take if you can!

B.

#118

Get rid of the top grid on the case and leave only the mounting holes, the fan will not brake easily anymore. After installing the first time it's also useful to let the fan run in for 10/20 minutes before start to run the car in the dust. I do this on mine and fans last for months, beside I use them only in the summer when the temperature is above 85°F, otherwise the esc will run just fine without.

Now I will typically mount a 10mm fan on top of the case wherever space allows, temp. has been quite high for the med. size indoor track here

Now I will typically mount a 10mm fan on top of the case wherever space allows, temp. has been quite high for the med. size indoor track here

#119

And yet neither of these is caused by the ESC's design or anything else. 99% of the time failures are caused by the end user. Period. People don't want to take responsibility for what they do so they blame the ESC. Learn to wire your car up properly. Learn to solder properly. If you are going through a bunch of ESC's then YOU are doing something wrong.

All too often I see people post pictures of their cars on here. And the wiring jobs can be hideous. Not to mention their cars look like they have never been cleaned or cared for. I see horrible wiring jobs at my local track all the time as well. And I always offer help when it comes to wiring stuff up or doing soldering.

Ultimately it's the end users responsibility to care for their equipment. If you fail to do so, ANYTHING will fail. Some people really need to take a look at what THEY are doing instead of blame the issue on the part that failed. Stop and ask, "What could I have done to prevent this?"

All too often I see people post pictures of their cars on here. And the wiring jobs can be hideous. Not to mention their cars look like they have never been cleaned or cared for. I see horrible wiring jobs at my local track all the time as well. And I always offer help when it comes to wiring stuff up or doing soldering.

Ultimately it's the end users responsibility to care for their equipment. If you fail to do so, ANYTHING will fail. Some people really need to take a look at what THEY are doing instead of blame the issue on the part that failed. Stop and ask, "What could I have done to prevent this?"

If there were no other design choices on the market then yes it would be a good solution but there are plenty of easier way to connect an esc..

Anyway, did you see my buggies? I did 5 conversions at least, and I'm quite crazy about doing things as well as I can. When I do an error I ask questions, read, mail tekin etc.. Randy knows about it so don't always blame the user, sometimes even if everything seems to be fine it causes troubles. And if it happens more to the RX8 (I've tested many ESC), then can say it and it has nothing to do with Tekin quality of products overall.

Look at it this way: how would you improve a product with users that give no feedback when something fails? I do the necessary to understand when I fail so I'm waiting the same from a brand like Tekin

#120

I absolutely love the solder post on the RX8

even a monkey can solder them up if they can melt solder with an iron.

personally I like to tin my wire and then smash it into a square slot with a vice so that it fits pefect in the solder tab slots

melt it and top off with a little more solder

heck I even did mine with a cheap radio shack 40w iron

much better design than trying to solder it to the board of some other speed controls

+1 tekin

even a monkey can solder them up if they can melt solder with an iron.

personally I like to tin my wire and then smash it into a square slot with a vice so that it fits pefect in the solder tab slots

melt it and top off with a little more solder

heck I even did mine with a cheap radio shack 40w iron

much better design than trying to solder it to the board of some other speed controls

+1 tekin