Plastic Spur Gear - Wear Part?

#1

Greetings all,

Do you consider a plastic spur gear a wear part? Something that has a short life span? I consider tires a wear part, knowing that they will wear out with standard use at a faster rate that other parts on the buggy. Does the spur gear fall into this group, or do you favor a steel spur gear and look to have a long service life from the part?

s.

Do you consider a plastic spur gear a wear part? Something that has a short life span? I consider tires a wear part, knowing that they will wear out with standard use at a faster rate that other parts on the buggy. Does the spur gear fall into this group, or do you favor a steel spur gear and look to have a long service life from the part?

s.

#2

Tech Prophet

iTrader: (9)

Join Date: Nov 2014

Location: Far south suburbs of Chicago area

Posts: 17,630

Trader Rating: 9 (100%+)

I’ve been running the same spur gear since July. There no signs of wear on it. Between the 3 classes I primarily run, I’ve replaced 3 spur gears in 7 months. All due to error by not getting motor properly tightened down.

#3

Thanks Bill.

I had a Losi RTR OEM pinion gear go down hill on me pretty fast, and I think it ate up the spur gear prematurely, but I wasn't really sure. I have swapped out to a Tekno pinion gear and will install a new plastic spur gear and see how it holds up.

s

I had a Losi RTR OEM pinion gear go down hill on me pretty fast, and I think it ate up the spur gear prematurely, but I wasn't really sure. I have swapped out to a Tekno pinion gear and will install a new plastic spur gear and see how it holds up.

s

#4

Tech Prophet

iTrader: (9)

Join Date: Nov 2014

Location: Far south suburbs of Chicago area

Posts: 17,630

Trader Rating: 9 (100%+)

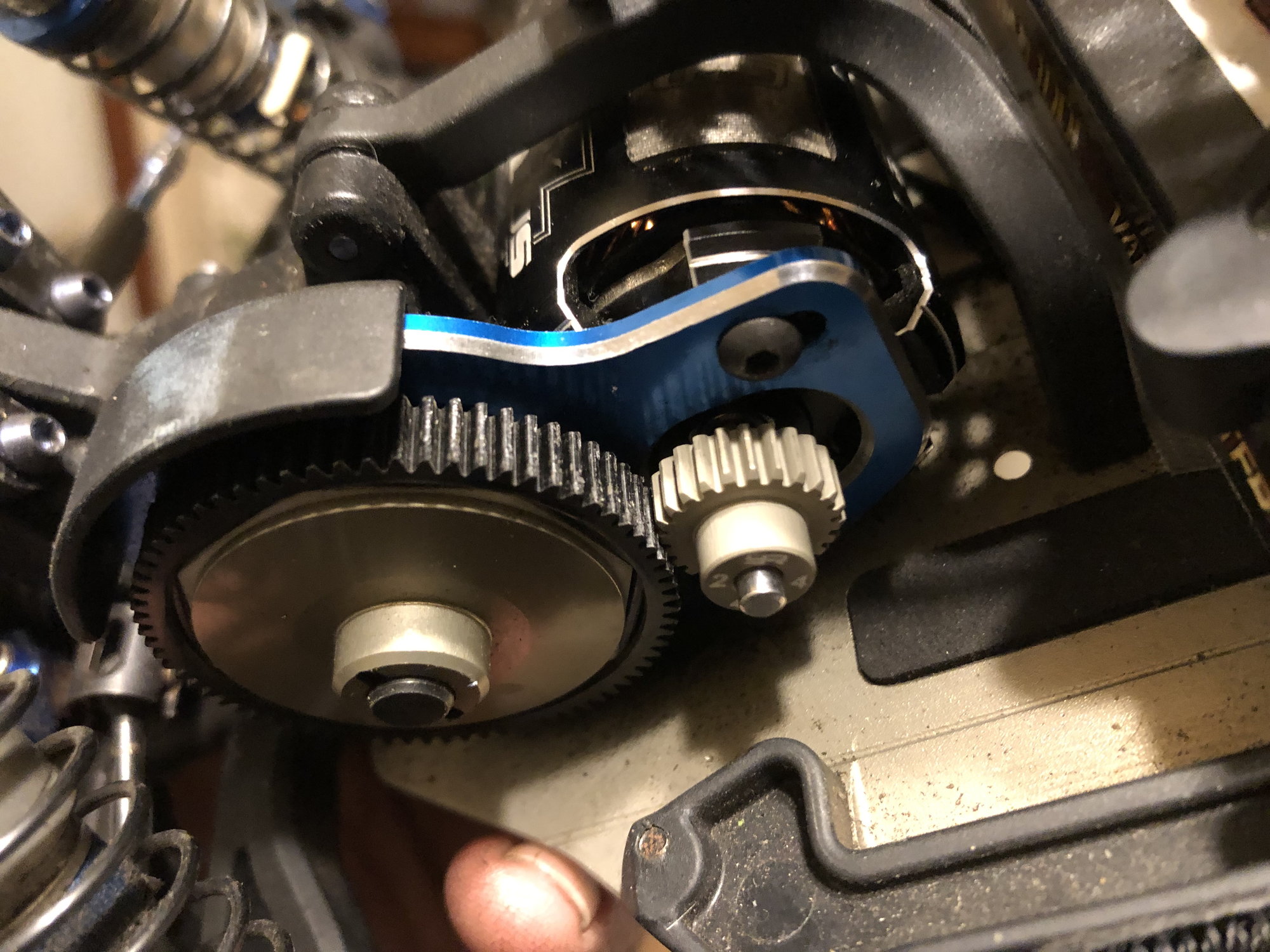

This one since July

This one had been fine since November. Less then a half a lap with a motor screw not completely tight.

#5

Greetings all,

Do you consider a plastic spur gear a wear part? Something that has a short life span? I consider tires a wear part, knowing that they will wear out with standard use at a faster rate that other parts on the buggy. Does the spur gear fall into this group, or do you favor a steel spur gear and look to have a long service life from the part?

s.

Do you consider a plastic spur gear a wear part? Something that has a short life span? I consider tires a wear part, knowing that they will wear out with standard use at a faster rate that other parts on the buggy. Does the spur gear fall into this group, or do you favor a steel spur gear and look to have a long service life from the part?

s.

Spur life span for me is dependent on application and installation. Back in the day when heavily loading a spur, it would get flipped and re-installed weekly to wear the teeth as evenly as possible. That was before the day of integral slippers and the like. Also, they'd get a periodic check with a magnifying glass to see if there was any pinion grooving occurring on the spur gear tooth face. What I have done for years is use the tiniest dab of Tamiya Ceramic Grease for the pinion/spur interface. Too much and they begin attracting dirt, but a bit on the end of a toothpick seems to work well.

Also, when checking gear lash/separation, check the gap in two places half a rotation of the spur apart. Sometimes I had to "split the difference" between a bit too tight and a bit too loose to get good gear mesh. Not often, but on occasion. Today's manufacturing tolerances seemed to have alleviated that issue. I still do it anyway-old habits die hard. Oh, and gear mesh gets set by feel and sound, not by the paper shim method. After a while, you'll develop and 'feel' and 'ear' for what's right. And check it during an event as well as before and after.

[Edit] One more thing. For years my cars and trucks have used steel pinion gears. I polish them before use by attaching them to a 1/8" piece of rod stock, chucking them up in a drill press, coating them with valve grinding compound, and polishing them with a counter-rotating stainless steel brush in a dremel. They come out s-m-o-o-t-h. Adds life to the spur.

Hope this helps you with spur life and answers the mail. Good luck. Cheers. 'AC'

#6

Great info! I'm installing a Tekno pinion and new polymer spur gear tonight and I will give the setup a good check over. The pinion and spur had about 110 packs through them on the desert track since September when I got the buggy new. Since then i've beat on it pretty intense, but with regular maintenance and no bashing. The fine dust from our desert course gets in every possible spot, so I can imagine it acted as a fine lapping agent over this time.

Appreciate the help and sharing your experience; help the new guys like me out quite a bit.

s.

Appreciate the help and sharing your experience; help the new guys like me out quite a bit.

s.

#8

Tech Master

iTrader: (16)

All depends on track surface.

We used to run 64 pitch on dirt oval cars back in the day. They usually lasted until you had a motor back off. Sometimes they picked up a rock that did some damage. I only replaced them pre-emptively when going to a big race.

As for today's 48 pitch gears. I'd expect them to last a really long time until the motor backs off or a rock gets picked up. I still wouldn't pre-emptively replace them.

We used to run 64 pitch on dirt oval cars back in the day. They usually lasted until you had a motor back off. Sometimes they picked up a rock that did some damage. I only replaced them pre-emptively when going to a big race.

As for today's 48 pitch gears. I'd expect them to last a really long time until the motor backs off or a rock gets picked up. I still wouldn't pre-emptively replace them.

#9

My Tekno EB48 2.0 is still on the original plastic spur gear with 6 months of hard use, averaging 2-3 days a week at the track for hours at a time. Bought an extra spur right off the bat expecting to occasionally have it wear out, but the original one that's stilll in the buggy still looks great now. I locked my motor screws down super snug, with threadlock of course.

#10

Also, when checking gear lash/separation, check the gap in two places half a rotation of the spur apart. Sometimes I had to "split the difference" between a bit too tight and a bit too loose to get good gear mesh. Not often, but on occasion. Today's manufacturing tolerances seemed to have alleviated that issue. I still do it anyway-old habits die hard. Oh, and gear mesh gets set by feel and sound, not by the paper shim method. After a while, you'll develop and 'feel' and 'ear' for what's right. And check it during an event as well as before and after.

#11

Always a good idea to have a spare spur gear, as well as many other common wear items, arms, spindles, hubs, pins.... basically any moving part will wear.

To help increase the longevity of a spur, I would be sure to use a gel based thread lock when fastening the motor mount screws. Anytime you get into a wreck/tumble, it would be a good idea to re-set the mesh and apply fresh thread lock.

I like to use scotch tape to set mesh on 48P gears and notebook paper to set mesh on Mod 1 gears..... I tend to replace the pins on my drive shafts far more often than replacing my spur gears.

Good Luck!

To help increase the longevity of a spur, I would be sure to use a gel based thread lock when fastening the motor mount screws. Anytime you get into a wreck/tumble, it would be a good idea to re-set the mesh and apply fresh thread lock.

I like to use scotch tape to set mesh on 48P gears and notebook paper to set mesh on Mod 1 gears..... I tend to replace the pins on my drive shafts far more often than replacing my spur gears.

Good Luck!

#13

Thanks guys.

I had one spare that I was able to use, and swapped out the OEM Losi pinion gear with a new Tekno gear. Looking close, it seems that the pinion gear wore down, and this in turn damaged the spur gear.

I have a handful of new spur gears on the way as backups, and I'll get this properly set up later today.

Thank you all again for the help and insight.!

I had one spare that I was able to use, and swapped out the OEM Losi pinion gear with a new Tekno gear. Looking close, it seems that the pinion gear wore down, and this in turn damaged the spur gear.

I have a handful of new spur gears on the way as backups, and I'll get this properly set up later today.

Thank you all again for the help and insight.!

#14

All depends on track surface.

We used to run 64 pitch on dirt oval cars back in the day. They usually lasted until you had a motor back off. Sometimes they picked up a rock that did some damage. I only replaced them pre-emptively when going to a big race.

As for today's 48 pitch gears. I'd expect them to last a really long time until the motor backs off or a rock gets picked up. I still wouldn't pre-emptively replace them.

We used to run 64 pitch on dirt oval cars back in the day. They usually lasted until you had a motor back off. Sometimes they picked up a rock that did some damage. I only replaced them pre-emptively when going to a big race.

As for today's 48 pitch gears. I'd expect them to last a really long time until the motor backs off or a rock gets picked up. I still wouldn't pre-emptively replace them.

Had the same experience running 48-pitch on my RC drag racing rail with open exposed gearset. Did a change up to 32-pitch-I called them my 'rock crushers'-and ended the issue of rock and small stone damage to the gearset. Of course, the trade-off is not having a tight a shot group on choosing a gear ratio. But worth the extra spur life to me at the time.

Having a tight fitting or perhaps even a sealed gear cover is extra added insurance adding to spur and gearset longevity. Cheers, guys. 'AC'

#15

Our track environment is a bit dusty, and while the Lasernut has a gear cover ( love it ), the dust is everywhere.

Lasernut

s

Lasernut

s

5Likes

5Likes