Help with Rustler / Slash gearbox (stripping gears)

#1

Hi all,

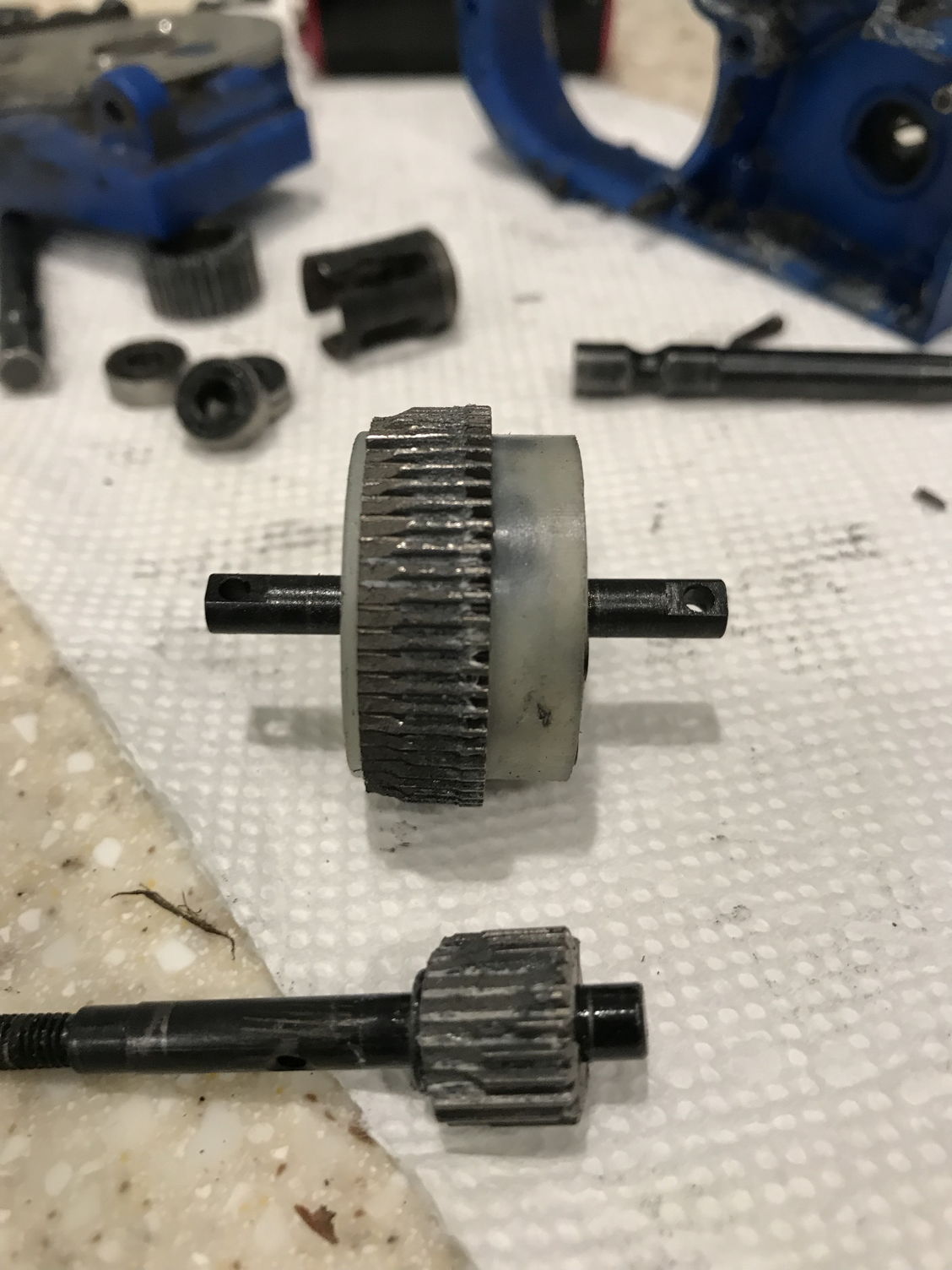

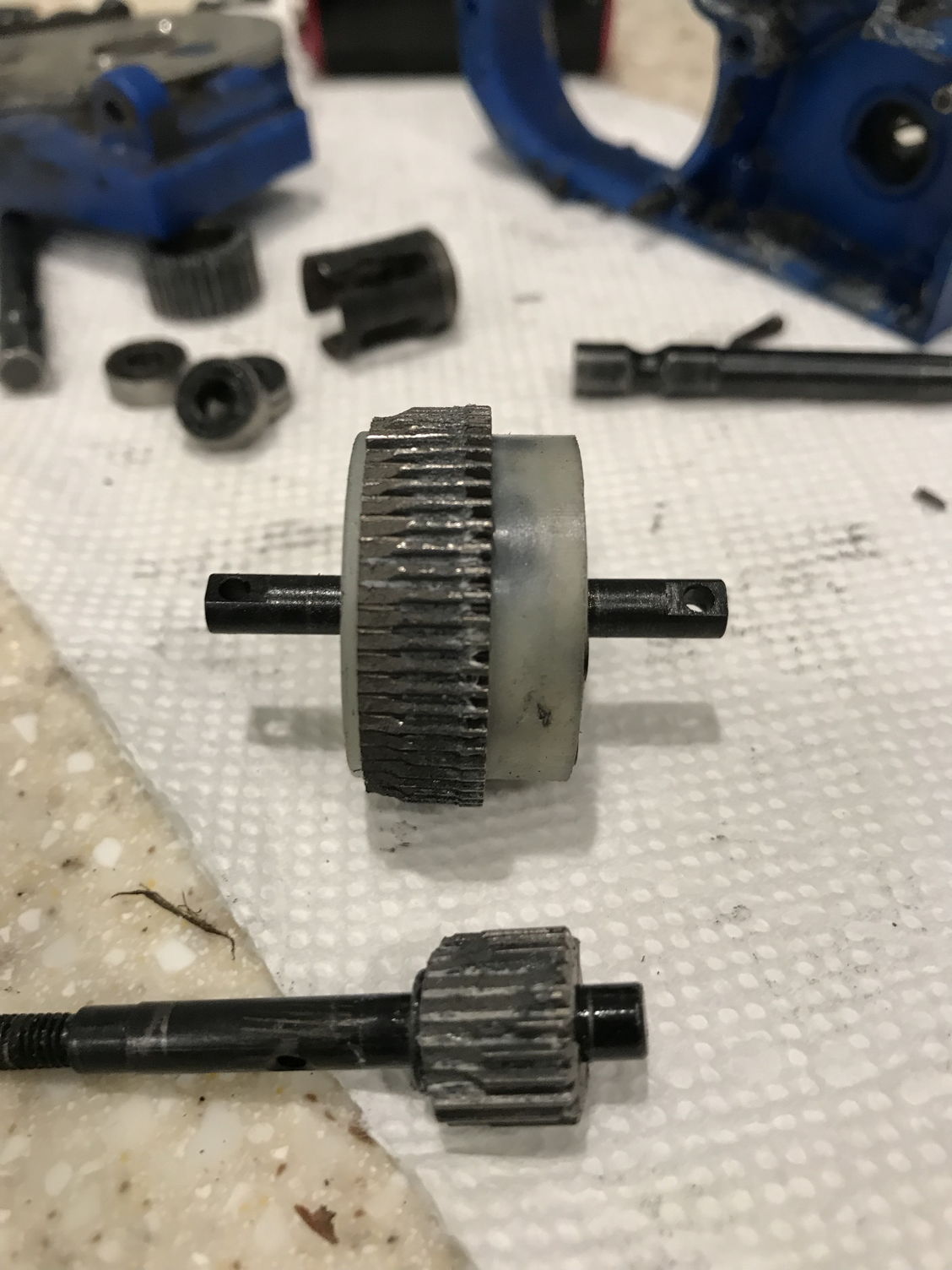

I am having trouble with my Rustler (same as Slash 2wd) gearbox. As of recently, I have started stripping the transmission gears constantly (as in, every run). I replaced the idler with a hardened version from Robinson Racing, so that one no longer breaks, but the top gear and diff gear now break. You can see the carnage in the pic below.

Rustler top gear and diff gear

I have torn down the rebuilt the gearbox many times, cleaning it thoroughly in between each rebuild, and I can't figure out what is wrong. I also went into the ESC settings and reduced the torque on the motor, in case I was overpowering it too much (Tenshock SC401 motor - quite a bit more powerful than even the VXL Rustler) but I still can't find the real problem.

I have checked the bearings, shimmed everything, lubricated everything, etc. Nothing seems to be obviously out of alignment or damaged.

The one major change vs stock is that I run a mid-motor chassis from Chuckworks (amazing chassis by the way) and maybe there is something about how the gearbox is mounted that is creating misalignment. BUT - I spin the gears and wheels a lot after installation and everything is very smooth. I made this change a while back, so it is not obviously associated with this issue.

In addition, in this most recent case, the car ran fine for a few min, with no strange noise, and then the gears stripped for no obvious reason (no crash, no sudden jolt) while driving on the street.

I believe *something* is causing the gears to run at an angle, because you can almost see a slant in the broken teeth in the picture. I am struggling to figure out where the misalignment is coming from... When the transmission is sitting on the bench, everything seems perfectly aligned, so I am wondering if something about the installation is tweaking the case, or perhaps being put under stress while accelerating causes the teeth to be at an angle to one another.

Anyone have any thoughts on how to debug this? I probably went > 2 yrs with no such problems before this month... so clearly *something* changed recently. I am just having trouble figuring out what.

Thanks!

I am having trouble with my Rustler (same as Slash 2wd) gearbox. As of recently, I have started stripping the transmission gears constantly (as in, every run). I replaced the idler with a hardened version from Robinson Racing, so that one no longer breaks, but the top gear and diff gear now break. You can see the carnage in the pic below.

Rustler top gear and diff gear

I have torn down the rebuilt the gearbox many times, cleaning it thoroughly in between each rebuild, and I can't figure out what is wrong. I also went into the ESC settings and reduced the torque on the motor, in case I was overpowering it too much (Tenshock SC401 motor - quite a bit more powerful than even the VXL Rustler) but I still can't find the real problem.

I have checked the bearings, shimmed everything, lubricated everything, etc. Nothing seems to be obviously out of alignment or damaged.

The one major change vs stock is that I run a mid-motor chassis from Chuckworks (amazing chassis by the way) and maybe there is something about how the gearbox is mounted that is creating misalignment. BUT - I spin the gears and wheels a lot after installation and everything is very smooth. I made this change a while back, so it is not obviously associated with this issue.

In addition, in this most recent case, the car ran fine for a few min, with no strange noise, and then the gears stripped for no obvious reason (no crash, no sudden jolt) while driving on the street.

I believe *something* is causing the gears to run at an angle, because you can almost see a slant in the broken teeth in the picture. I am struggling to figure out where the misalignment is coming from... When the transmission is sitting on the bench, everything seems perfectly aligned, so I am wondering if something about the installation is tweaking the case, or perhaps being put under stress while accelerating causes the teeth to be at an angle to one another.

Anyone have any thoughts on how to debug this? I probably went > 2 yrs with no such problems before this month... so clearly *something* changed recently. I am just having trouble figuring out what.

Thanks!

#2

Tech Addict

iTrader: (1)

Hi all,

I am having trouble with my Rustler (same as Slash 2wd) gearbox. As of recently, I have started stripping the transmission gears constantly (as in, every run). I replaced the idler with a hardened version from Robinson Racing, so that one no longer breaks, but the top gear and diff gear now break. You can see the carnage in the pic below.

Rustler top gear and diff gear

I have torn down the rebuilt the gearbox many times, cleaning it thoroughly in between each rebuild, and I can't figure out what is wrong. I also went into the ESC settings and reduced the torque on the motor, in case I was overpowering it too much (Tenshock SC401 motor - quite a bit more powerful than even the VXL Rustler) but I still can't find the real problem.

I have checked the bearings, shimmed everything, lubricated everything, etc. Nothing seems to be obviously out of alignment or damaged.

The one major change vs stock is that I run a mid-motor chassis from Chuckworks (amazing chassis by the way) and maybe there is something about how the gearbox is mounted that is creating misalignment. BUT - I spin the gears and wheels a lot after installation and everything is very smooth. I made this change a while back, so it is not obviously associated with this issue.

In addition, in this most recent case, the car ran fine for a few min, with no strange noise, and then the gears stripped for no obvious reason (no crash, no sudden jolt) while driving on the street.

I believe *something* is causing the gears to run at an angle, because you can almost see a slant in the broken teeth in the picture. I am struggling to figure out where the misalignment is coming from... When the transmission is sitting on the bench, everything seems perfectly aligned, so I am wondering if something about the installation is tweaking the case, or perhaps being put under stress while accelerating causes the teeth to be at an angle to one another.

Anyone have any thoughts on how to debug this? I probably went > 2 yrs with no such problems before this month... so clearly *something* changed recently. I am just having trouble figuring out what.

Thanks!

I am having trouble with my Rustler (same as Slash 2wd) gearbox. As of recently, I have started stripping the transmission gears constantly (as in, every run). I replaced the idler with a hardened version from Robinson Racing, so that one no longer breaks, but the top gear and diff gear now break. You can see the carnage in the pic below.

Rustler top gear and diff gear

I have torn down the rebuilt the gearbox many times, cleaning it thoroughly in between each rebuild, and I can't figure out what is wrong. I also went into the ESC settings and reduced the torque on the motor, in case I was overpowering it too much (Tenshock SC401 motor - quite a bit more powerful than even the VXL Rustler) but I still can't find the real problem.

I have checked the bearings, shimmed everything, lubricated everything, etc. Nothing seems to be obviously out of alignment or damaged.

The one major change vs stock is that I run a mid-motor chassis from Chuckworks (amazing chassis by the way) and maybe there is something about how the gearbox is mounted that is creating misalignment. BUT - I spin the gears and wheels a lot after installation and everything is very smooth. I made this change a while back, so it is not obviously associated with this issue.

In addition, in this most recent case, the car ran fine for a few min, with no strange noise, and then the gears stripped for no obvious reason (no crash, no sudden jolt) while driving on the street.

I believe *something* is causing the gears to run at an angle, because you can almost see a slant in the broken teeth in the picture. I am struggling to figure out where the misalignment is coming from... When the transmission is sitting on the bench, everything seems perfectly aligned, so I am wondering if something about the installation is tweaking the case, or perhaps being put under stress while accelerating causes the teeth to be at an angle to one another.

Anyone have any thoughts on how to debug this? I probably went > 2 yrs with no such problems before this month... so clearly *something* changed recently. I am just having trouble figuring out what.

Thanks!

#4

It looks to me like the wear is off center. Is there a way to install that diff backwards? Or perhaps there is excess play in the bearings or the bearing seats allowing something to wobble around inside the tranny.

#5

Tech Master

iTrader: (6)

Are you running a slipper? You may want to if not. Also, replace all the gears and the case this time. If the case is warped or the motor plate bent I can see that make trouble.

Shims, one on ea side of the top shaft and diff. One shim on the spur gear side of the idler.

Give that a try.

Oh, how good do the diff half's fit at the bottom? If dirt gets in it will make a mess out things. Common problem on Black Traxxas cases. I've not tried a traxxas gray case or RPM yet. Fixs: electrical tape, long nut and bolt at bottom front, RTV Sealent and, my fix:

Shims, one on ea side of the top shaft and diff. One shim on the spur gear side of the idler.

Give that a try.

Oh, how good do the diff half's fit at the bottom? If dirt gets in it will make a mess out things. Common problem on Black Traxxas cases. I've not tried a traxxas gray case or RPM yet. Fixs: electrical tape, long nut and bolt at bottom front, RTV Sealent and, my fix:

#6

I checked the bearings, and while there is a tiny amount of slop when you test them by hand, when the various gearshafts are installed there is no detectable amount of play. I'll replace the bearings anyway though.

Are you running a slipper? You may want to if not. Also, replace all the gears and the case this time. If the case is warped or the motor plate bent I can see that make trouble.

Shims, one on ea side of the top shaft and diff. One shim on the spur gear side of the idler.

Give that a try.

Oh, how good do the diff half's fit at the bottom? If dirt gets in it will make a mess out things. Common problem on Black Traxxas cases. I've not tried a traxxas gray case or RPM yet. Fixs: electrical tape, long nut and bolt at bottom front, RTV Sealent and, my fix:

Shims, one on ea side of the top shaft and diff. One shim on the spur gear side of the idler.

Give that a try.

Oh, how good do the diff half's fit at the bottom? If dirt gets in it will make a mess out things. Common problem on Black Traxxas cases. I've not tried a traxxas gray case or RPM yet. Fixs: electrical tape, long nut and bolt at bottom front, RTV Sealent and, my fix:

The transmission case I'm running was the replacement to the old one (only about 4 months old, maybe 10-20 runs). But, I will check it for any warping and consider a new one.

I do run a slipper but I like to keep them tightened down a lot. I find the traxxas slippers very hard to tune "just right", and so I err on the side of "very tight". With this mid-motor chassis I think there is actually more stress on the gears because there is a lot more weight forward, so there are fewer wheelies. I guess the wheelies were a form of pressure release, and now there's a lot more weight forward keeping the nose down.

#7

Tech Master

iTrader: (35)

I have Rustler with transmission and motor forward mounted and still never had the problem you have. Also have a RTR one. Both had been running for about two years before I decided to shelf them.

Can I see a pic of your mid motor chassis? Wonder if it is from the same guy I got mine?

Can I see a pic of your mid motor chassis? Wonder if it is from the same guy I got mine?

#8

Tech Master

iTrader: (204)

Do you have a pic of the idler gear, also did you have any grease on gears, also would like to see a pic of the inside of the RPM case as wondering when the problem started VS the diff case change, as RPM makes a quality product I believe they are more prone to flexing, and what are you running for a motor?

#9

I have Rustler with transmission and motor forward mounted and still never had the problem you have. Also have a RTR one. Both had been running for about two years before I decided to shelf them.

Can I see a pic of your mid motor chassis? Wonder if it is from the same guy I got mine?

Can I see a pic of your mid motor chassis? Wonder if it is from the same guy I got mine?

Rustler Mid Motor Chassis ? ChuckworksRC

Is that the one you have? What motor do you run?

Do you have a pic of the idler gear, also did you have any grease on gears, also would like to see a pic of the inside of the RPM case as wondering when the problem started VS the diff case change, as RPM makes a quality product I believe they are more prone to flexing, and what are you running for a motor?

The idler gear is a Robinson Racing hardened steel unit so it has no damage, whereas the top gear and the diff gear both lost many teeth:

Broken top gear and diff, intact idler

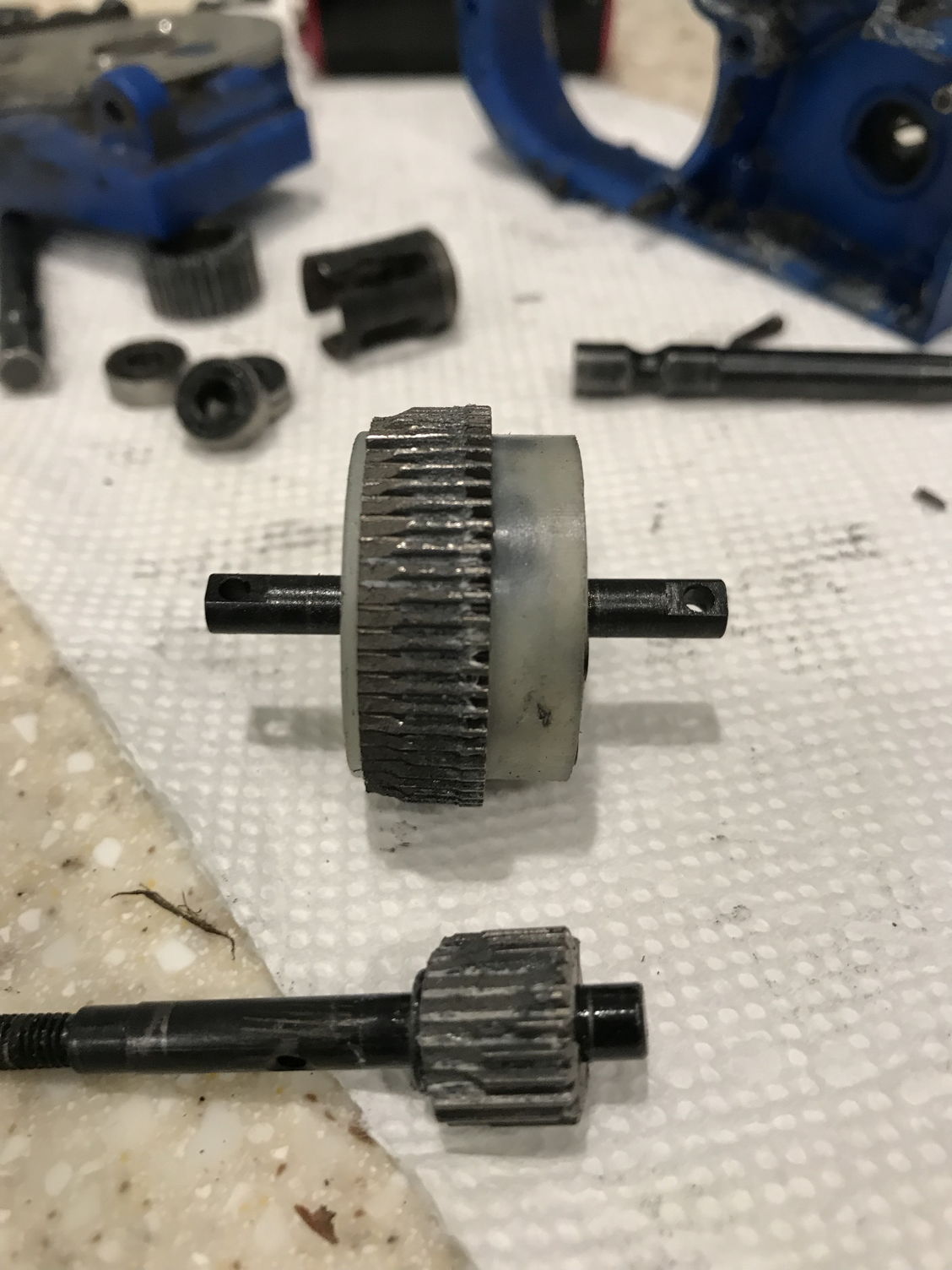

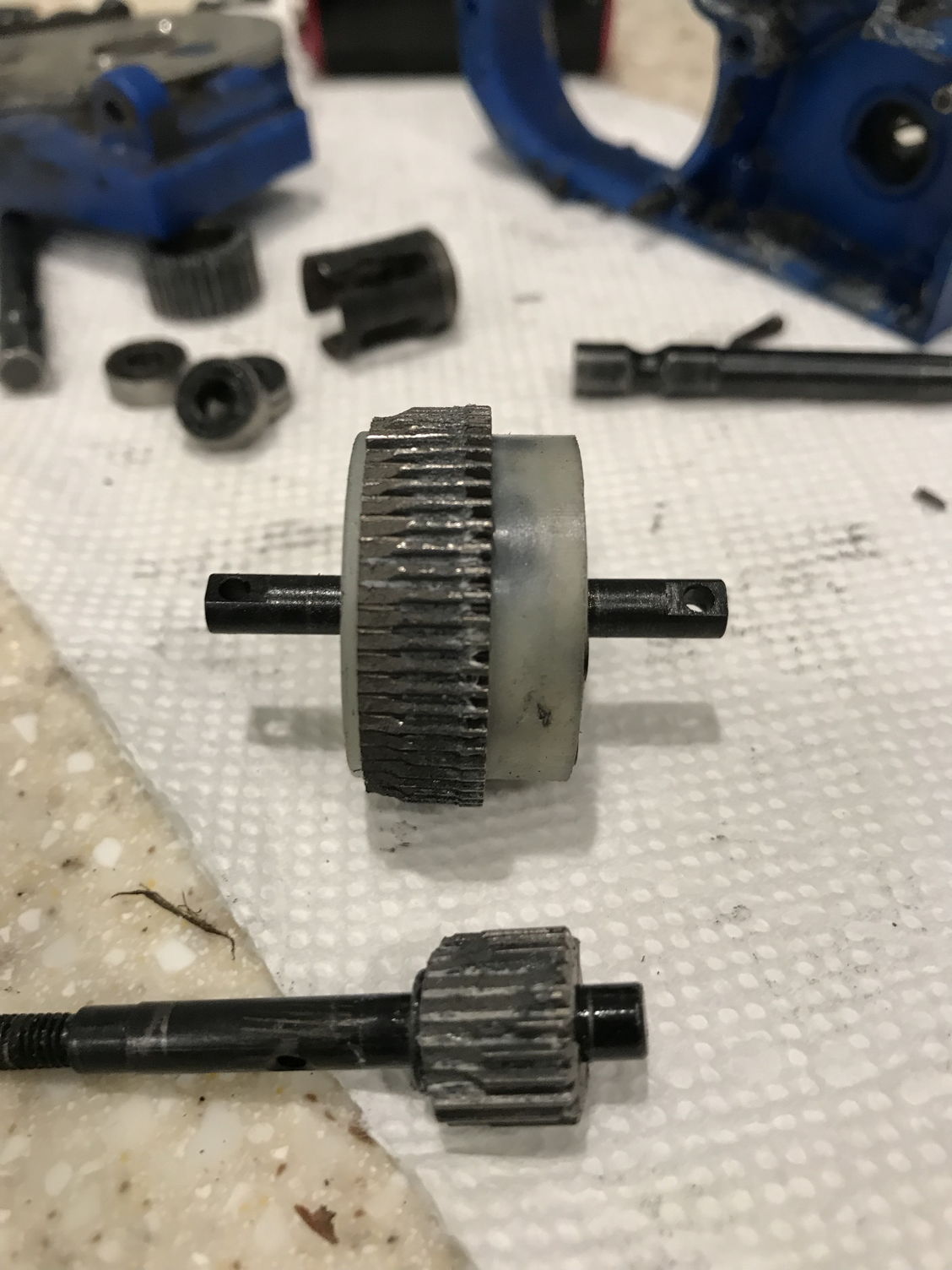

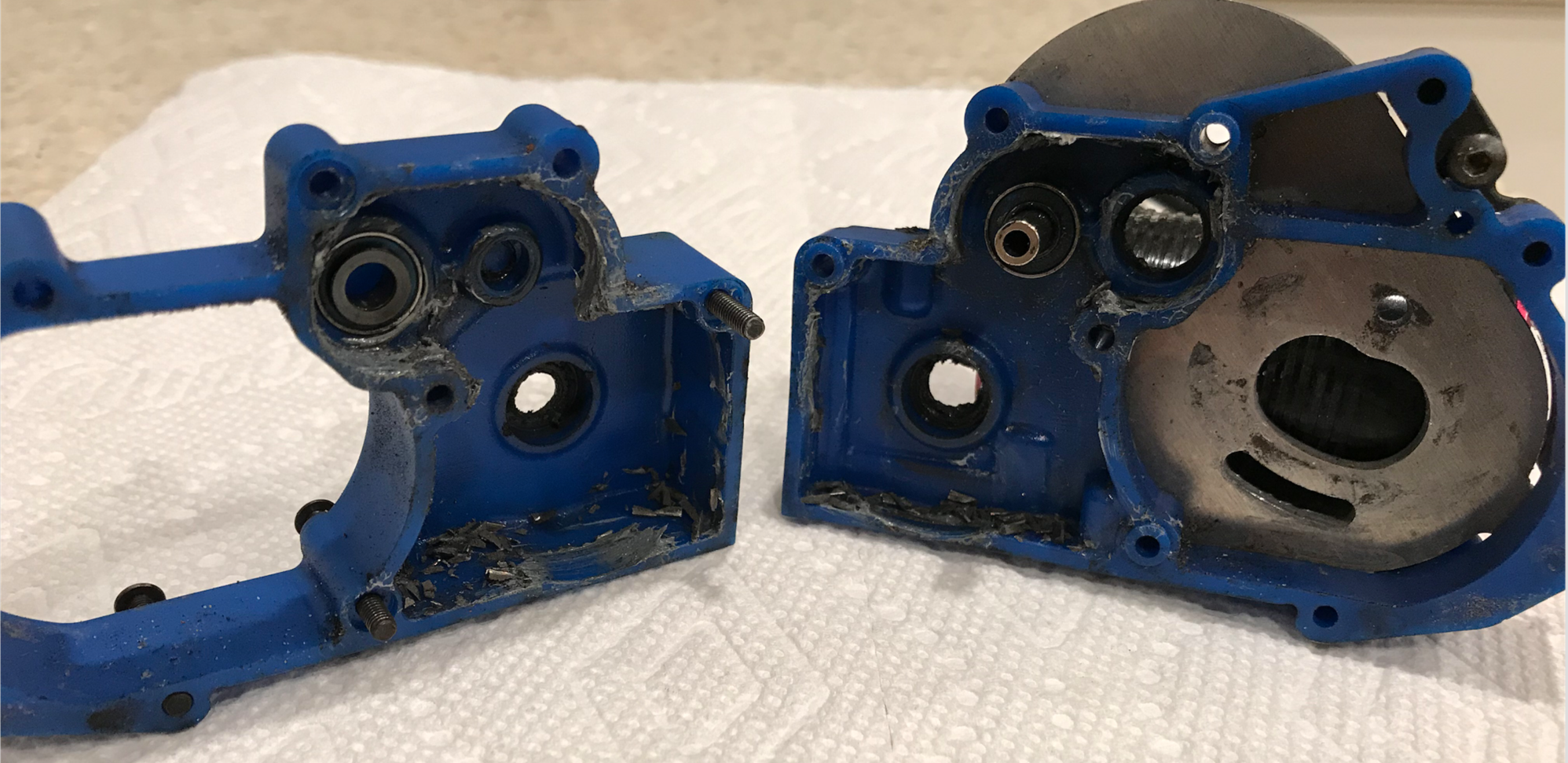

Here is the gearbox (not yet clean, broken metal teeth everywhere):

Transmission halves

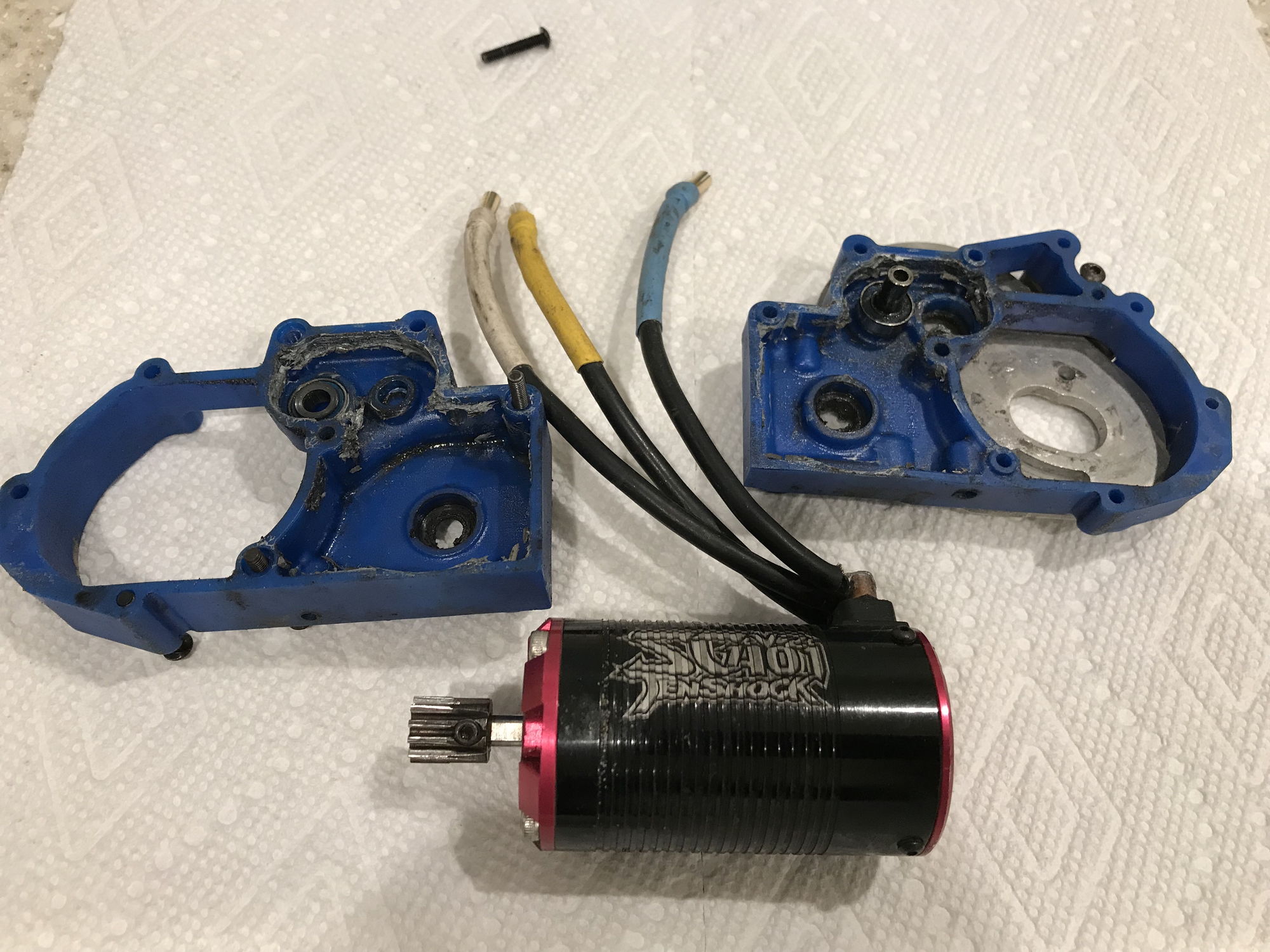

And here's the motor:

Tenshock SC401 Motor

In terms of when the problem started, it got very bad after I switched to the mid-motor chassis. I used to run a normal chassis (also with a prior RPM gearbox) and that handled a powerful motor no problem. With the mid-motor chassis I have been chewing up gears all the time...

Thanks for your help!!

#10

Tech Master

iTrader: (6)

I'm going to say that the motor plate is bending and sending pinion into the spur. Then the top shaft is pushing on the idler and lastly into the diff. RPM probably never tested running the whole mess backwards for that long. It doesn't look like there is a lot holding that gearbox in in a stock rear mount set up. Front mount with the motor running backwards maybe to much for the plastic to put up with.

Or, that chassis has a hole drilled off center and that is putting stress on the gear box. It happens.

Here is a old therad on Traxxas that talks about the RPM case.

https://forums.traxxas.com/showthrea...ot-Junior-quot

Or, that chassis has a hole drilled off center and that is putting stress on the gear box. It happens.

Here is a old therad on Traxxas that talks about the RPM case.

https://forums.traxxas.com/showthrea...ot-Junior-quot

#11

Ill guarantee your slipper is too tight. The Tenshock motors are a ton of power to be sending straight through with a fully tightened slipper. Even on the stock VXL system you will shred gears with the slipper at full tight. Landing at full power on a tight slipper and all that oomph has to go somewhere and something is going to bend/break.

Also, shim per the Traxxas directions. No need for any extra shims in the Traxxas style cases.

Also, shim per the Traxxas directions. No need for any extra shims in the Traxxas style cases.

#12

Tech Master

iTrader: (35)

That is the same chassis although looks like he updated it a little since I bought mine. I don't have that big top deck above the battery. Other than that looks the same and it really did change the driving characteristics dramatically!

Where you using the shim under the transmission case?

I never had that problem I was running the veleneon system on 3s always.

Where you using the shim under the transmission case?

I never had that problem I was running the veleneon system on 3s always.

#13

Ill guarantee your slipper is too tight. The Tenshock motors are a ton of power to be sending straight through with a fully tightened slipper. Even on the stock VXL system you will shred gears with the slipper at full tight. Landing at full power on a tight slipper and all that oomph has to go somewhere and something is going to bend/break.

Also, shim per the Traxxas directions. No need for any extra shims in the Traxxas style cases.

Also, shim per the Traxxas directions. No need for any extra shims in the Traxxas style cases.

The damage in this thread was from a simple pavement test, no jumps, no major shocks to the system.

I think I might have found the problem:

Drive pin cut from a drill bit - a bit too long, and perhaps causing idler gear teeth to skip.

I did switch from the "roll pin" that is stock with the top gear shaft to this drill bit solution only recently, and that is when the problem really got bad. Before that, it was probably having the slipper too tight and landing on-power.

On a side note, is the traxxas slipper fundamentally a poor design compared to slippers that have pads on both sides? I have a very hard time getting it just right.

#14

Tech Addict

iTrader: (1)

On our Chuckworks A6, we ran the STRC topshaft with hardened pin. It allows use of an Associated B4/T4/SC10 dual disc slipper which gives better adjustability than the Traxxas unit. The slipper can be sourced cheaply from Ebay RC chop shops. Might as well kill 2 birds with one stone. Oh, make that 3 birds. There are many more spur gear sizes available for the AE slipper.

Last edited by bubbaslash; 12-12-2017 at 05:27 PM.

#15

Tech Master

iTrader: (6)

On our Chuckworks A6, we ran the STRC topshaft with hardened pin. It allows use of an Associated B4/T4/SC10 dual disc slipper which gives better adjustability than the Traxxas unit. The slipper can be sourced cheaply from Ebay RC chop shops. Might as well kill 2 birds with one stone. Oh, make that 3 birds. There are many more spur gear sizes available for the AE slipper.

https://www.amainhobbies.com/team-as...c91175/p226949

1Likes

1Likes