The Mirage...

#1

...or that's the best name I could come up with so far. "thumbsup"

Specs:

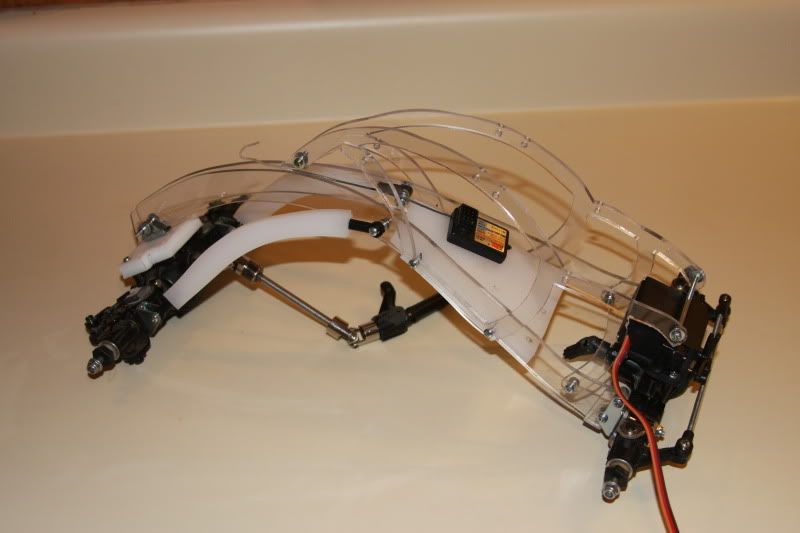

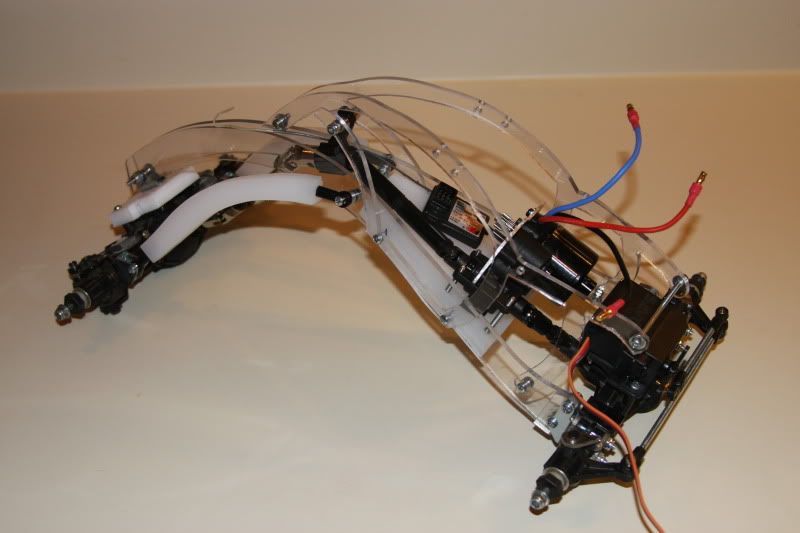

I've been rocking a DIY version of a BMVII for about 6 years now and decided that it was time to change things up a bit. I been seeing some very impressive chassis being developed for MOAs, but the shaft-driven world has been overlooked, for the most part. There were two chassis that kept drawing me in for a closer look...the Mantis and the Dahu. Both use MOAs (Bergs) but the overall design really intrigued me with the arches and the high clearance rear links. The more I looked at them, the more I wanted to design a chassis for my TLT axles with similar features. Thus begins the build.

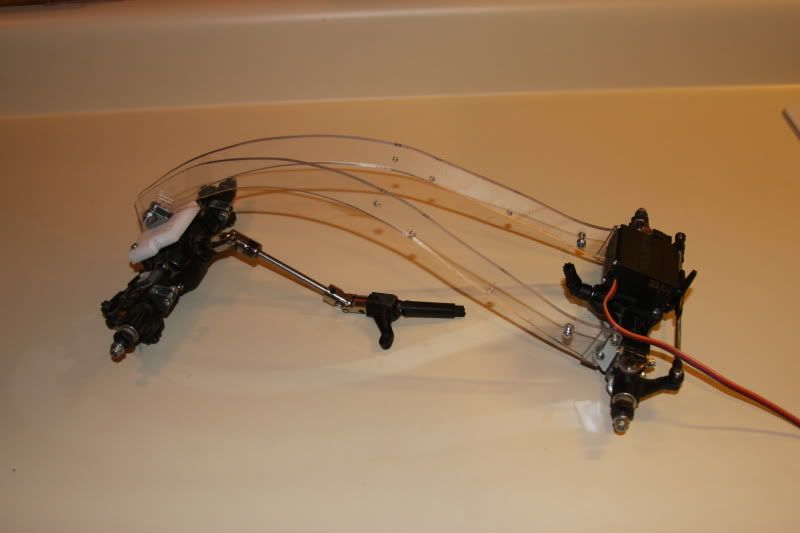

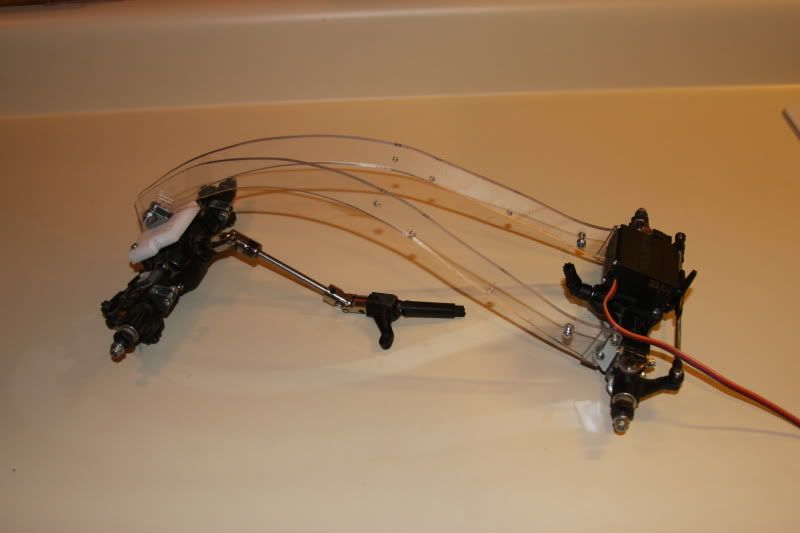

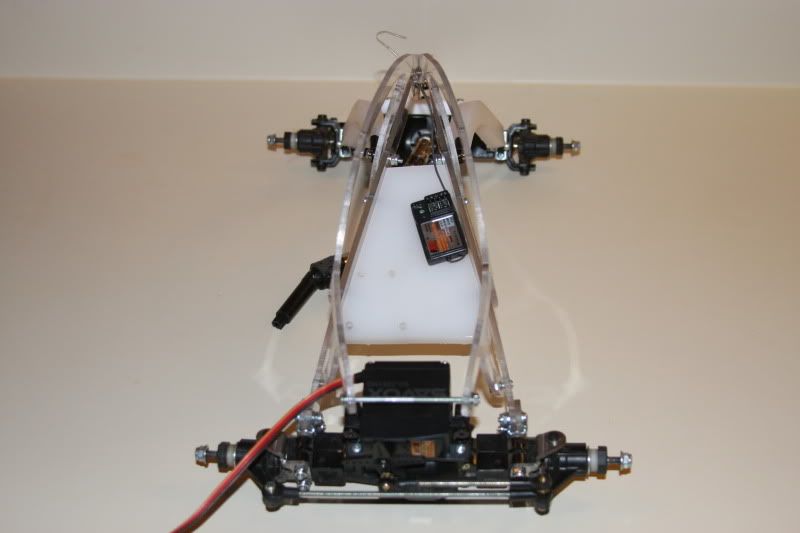

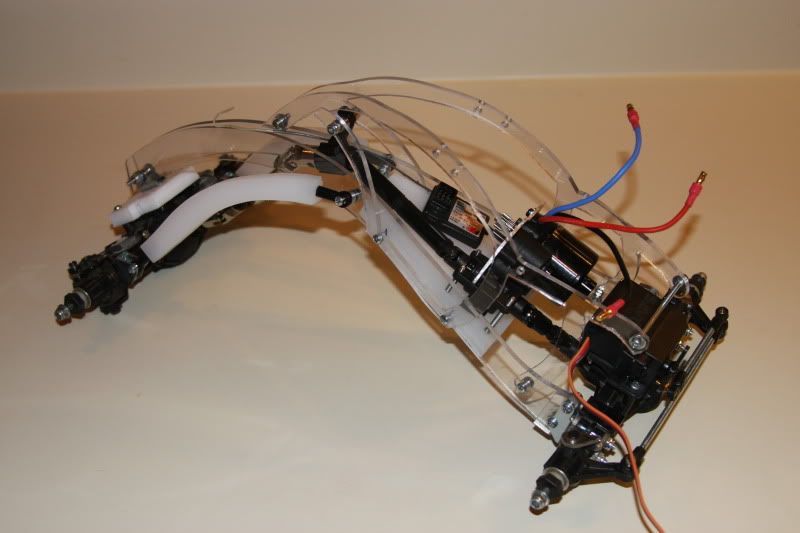

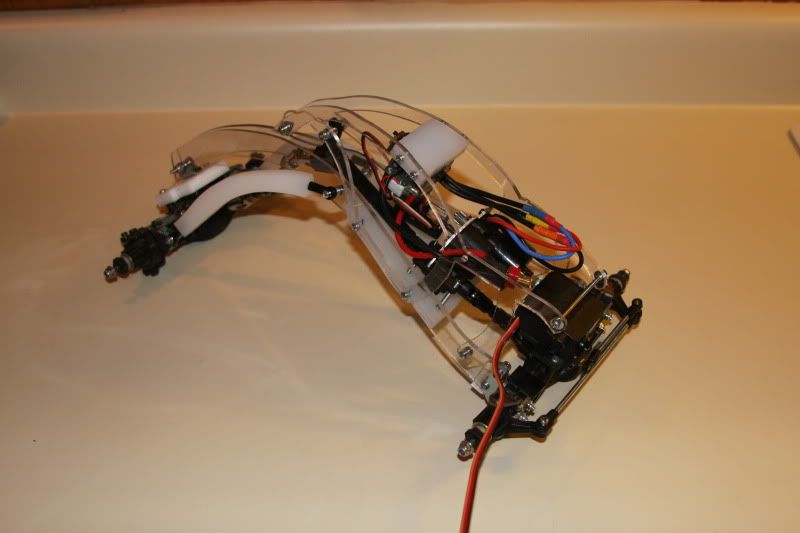

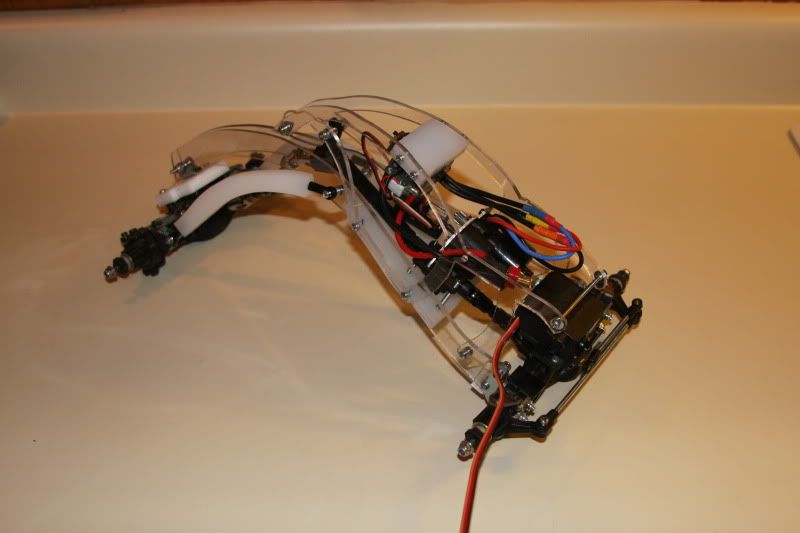

I drew the chassis out in AutoCAD, playing with the curves and driveline angles to see if it was even possible. Once the design was finalized, I cut templates out of cardboard. The chassis plates are made from 1/8" Lexan and the rear links, rear mount, skid plate and ESC top plate are made from cutting board. I used a plexiglass blade in my jigsaw to cut all the pieces out, so be NICE. :flipoff: Here's everything that makes up the crawler, less the wheels and tires.

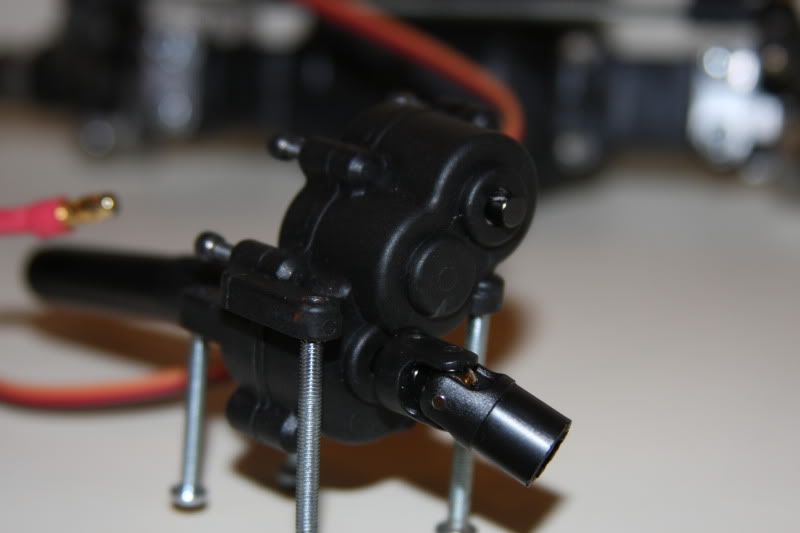

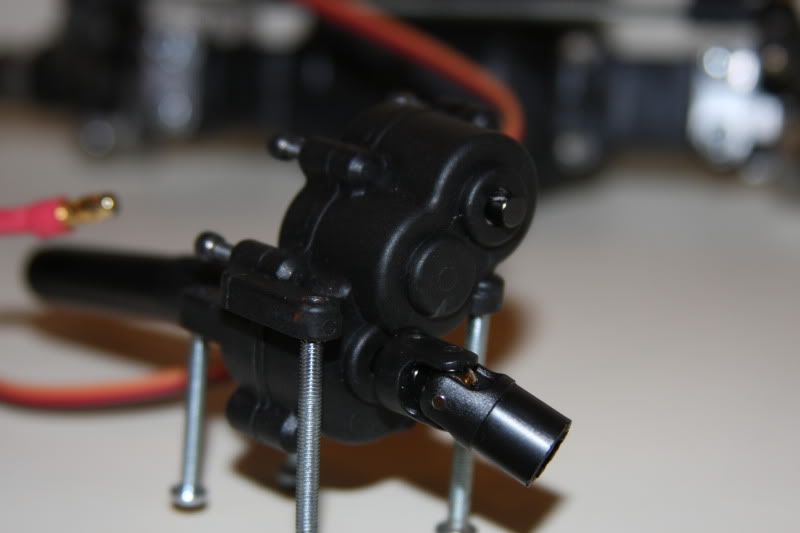

Transmission is a Traxxas Mini Summit with the idler and top gear swapped to give me an internal ratio of 3.74:1. I plan to use a 55-tooth spur and 14-tooth pinion.

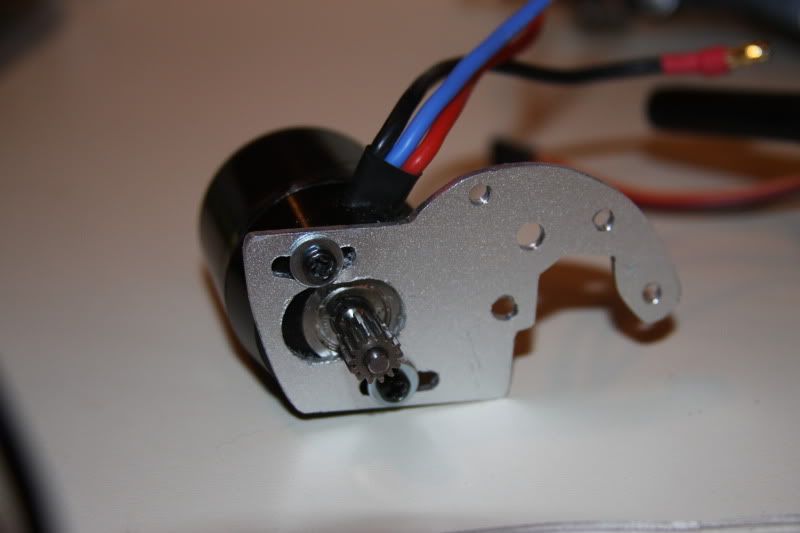

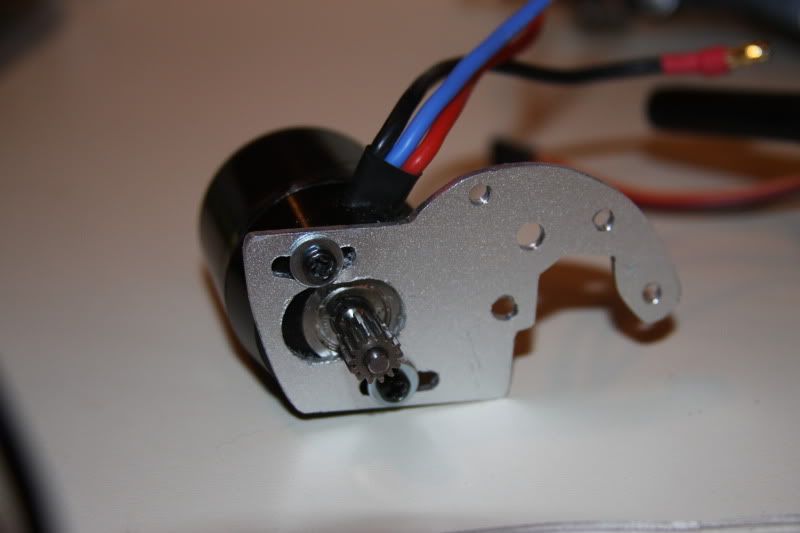

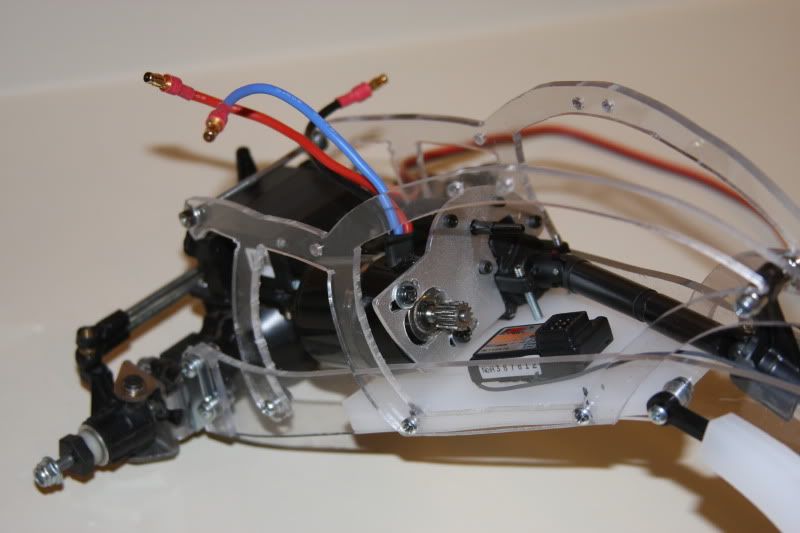

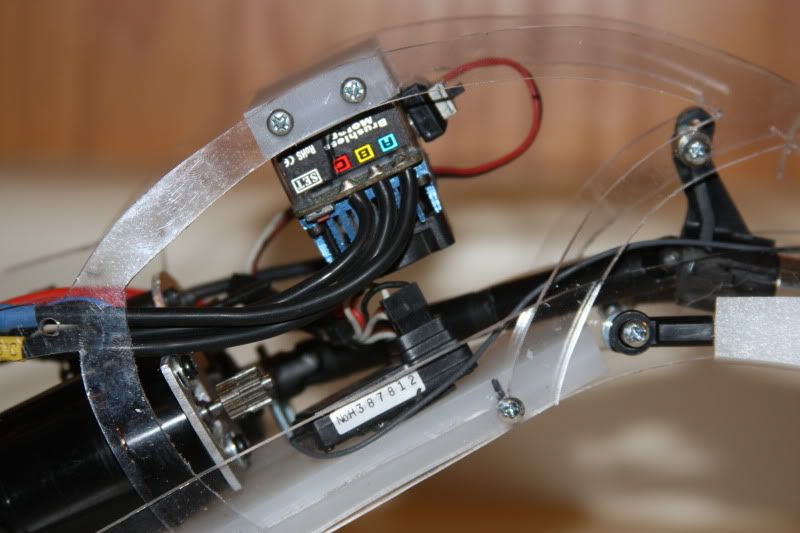

Motor is a Holmes Hobbies Revolver Black Outrunner. I created my own mounting plate. You can buy a motor plate for the transmission that will work with a 540 motor, but the motor sits too high. Plus, it costs $30 :flipoff:. With a little bit of time, a Dremel and a file I was able to make a plate from a defective external hard drive enclosure.

The front axles utilize clocked Cs that KC_Jones was kind enough to develop for me. In addition, I added bearings left over from my old TLT kit in the Cs for the knuckle screws.

Specs:

- Custom chassis made from Lexan and cutting board

- TLT axles

- KC_Jones clocked axle Cs

- Savox 0251 Servo

- Traxxas Mini Summit Transmission w/gear swap

- Traxxas Mini Summit driveshafts (front)

- Tamiya CC-01 telescoping metal driveshaft (rear)

- Carrier bearing assembly using TA04 steering knuckle w/bearings

- Holmes Hobbies Revolver Black Outrunner

- HobbyWing EZRun 35A ESC

- Sky Lipo 2S 40C 1300mah Lipo

- FlySky GT-3B Tx/Rx (firmware modded)

- 2.2 Rovers (white dot)

I've been rocking a DIY version of a BMVII for about 6 years now and decided that it was time to change things up a bit. I been seeing some very impressive chassis being developed for MOAs, but the shaft-driven world has been overlooked, for the most part. There were two chassis that kept drawing me in for a closer look...the Mantis and the Dahu. Both use MOAs (Bergs) but the overall design really intrigued me with the arches and the high clearance rear links. The more I looked at them, the more I wanted to design a chassis for my TLT axles with similar features. Thus begins the build.

I drew the chassis out in AutoCAD, playing with the curves and driveline angles to see if it was even possible. Once the design was finalized, I cut templates out of cardboard. The chassis plates are made from 1/8" Lexan and the rear links, rear mount, skid plate and ESC top plate are made from cutting board. I used a plexiglass blade in my jigsaw to cut all the pieces out, so be NICE. :flipoff: Here's everything that makes up the crawler, less the wheels and tires.

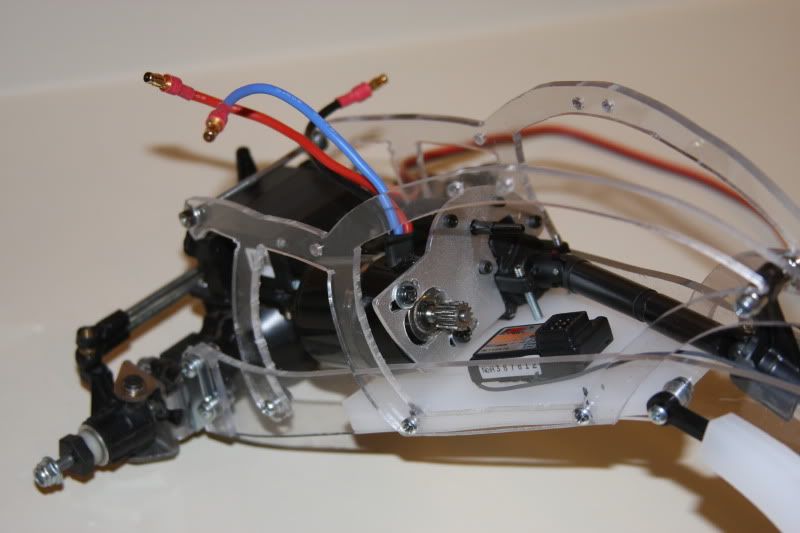

Transmission is a Traxxas Mini Summit with the idler and top gear swapped to give me an internal ratio of 3.74:1. I plan to use a 55-tooth spur and 14-tooth pinion.

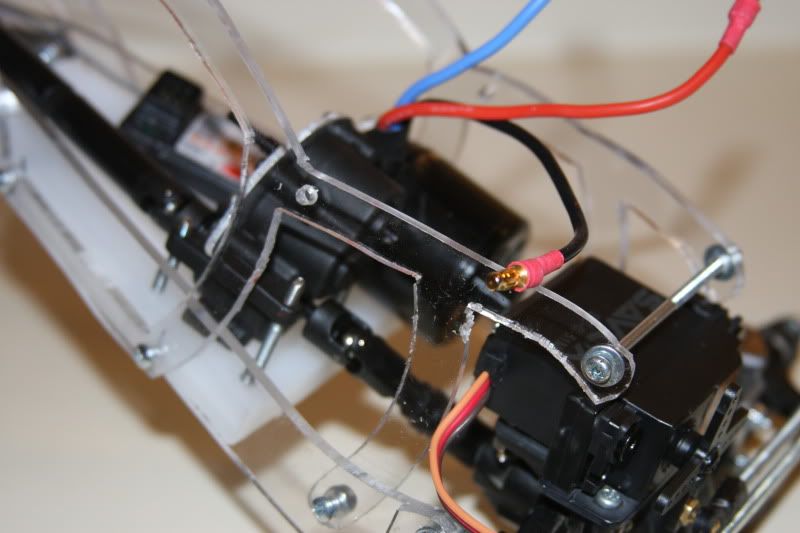

Motor is a Holmes Hobbies Revolver Black Outrunner. I created my own mounting plate. You can buy a motor plate for the transmission that will work with a 540 motor, but the motor sits too high. Plus, it costs $30 :flipoff:. With a little bit of time, a Dremel and a file I was able to make a plate from a defective external hard drive enclosure.

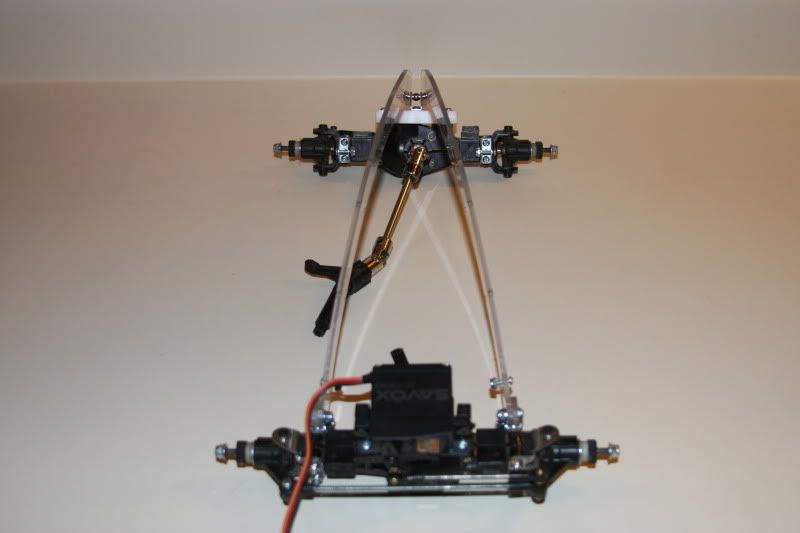

The front axles utilize clocked Cs that KC_Jones was kind enough to develop for me. In addition, I added bearings left over from my old TLT kit in the Cs for the knuckle screws.

#2

Now, to put this all together...

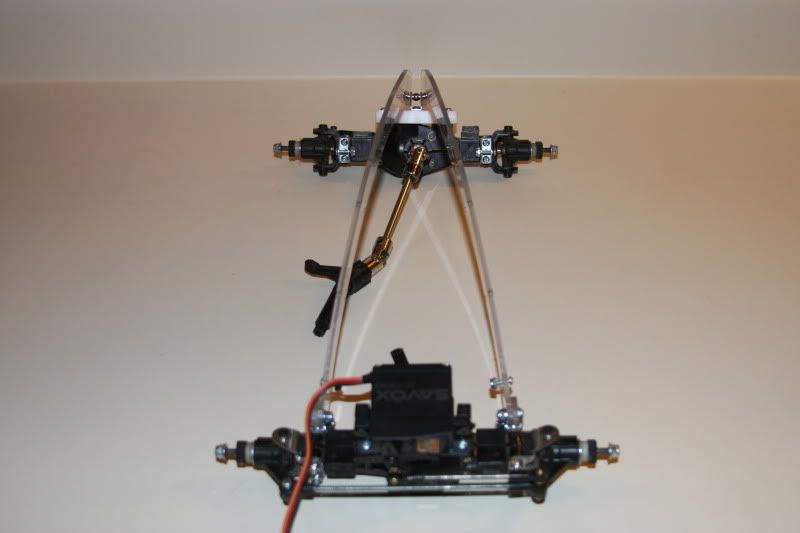

First thing to go together are the two side plates. These are the "backbone" of the chassis and where the torsional flex will come from. I used TLT hardware to mount the plates to the axles. Seen in the pictures is the rear driveline assembly, including the carrier bearing.

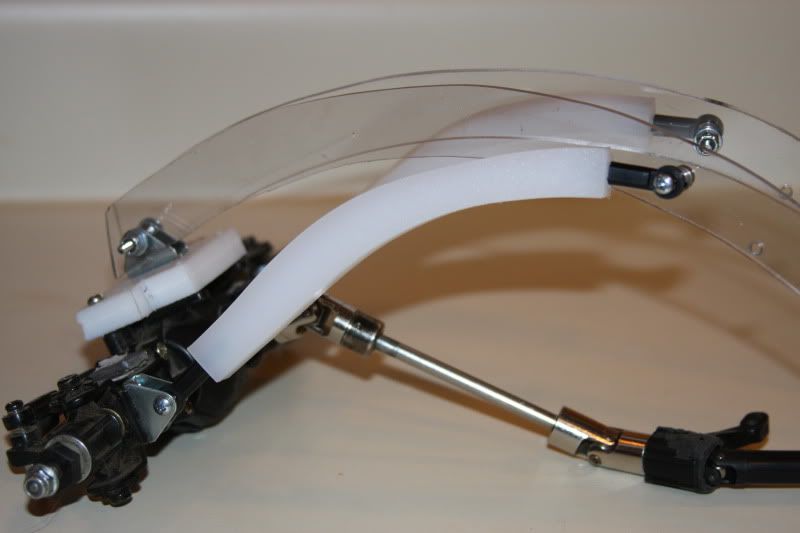

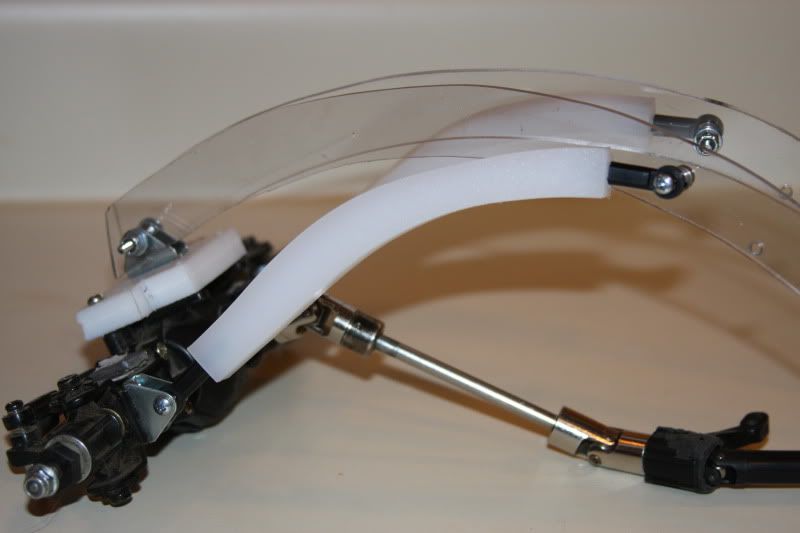

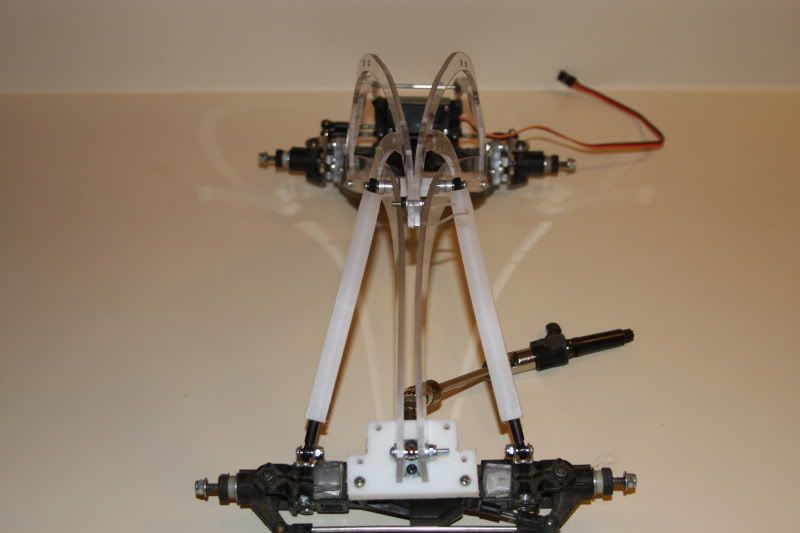

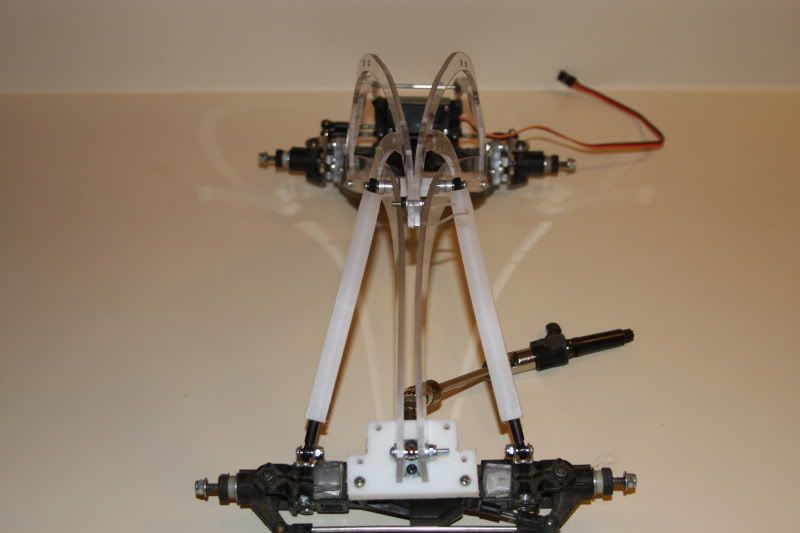

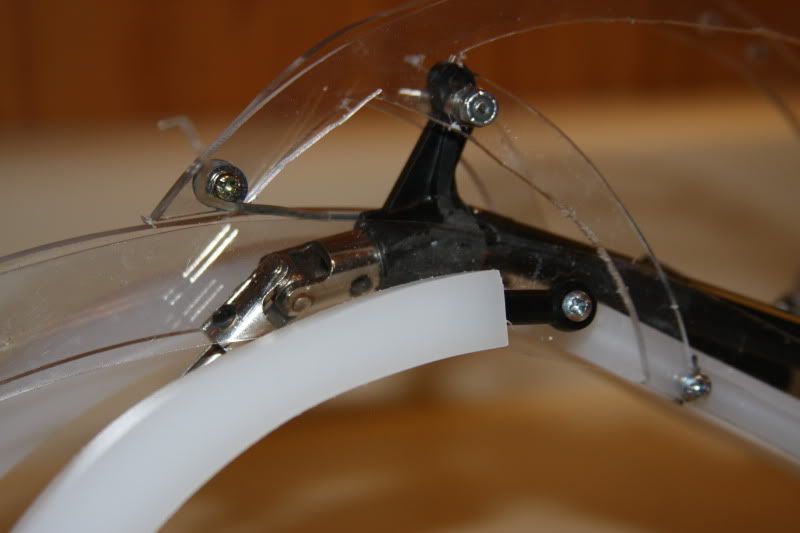

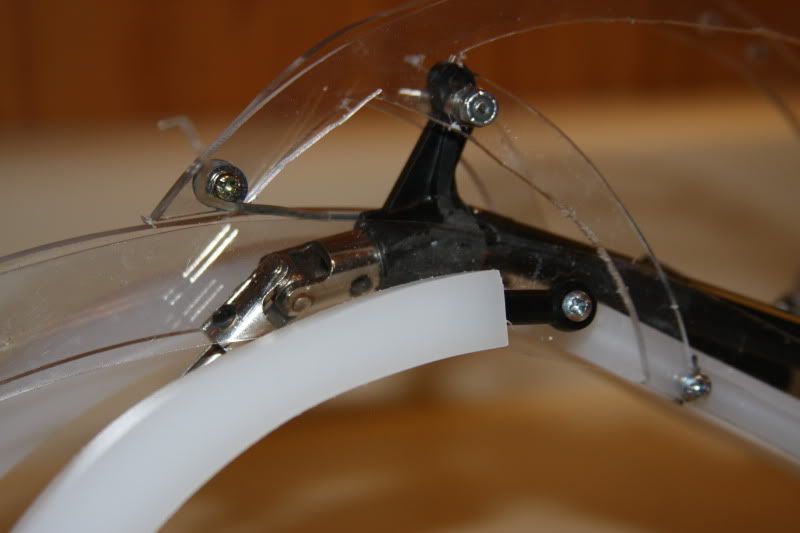

Next on the agenda are the rear links. I wanted them to follow a high arch for ground clearance, but at the same time protect the rear driveline as much as possible. I cut the link bodies from cutting board and then screwed 6-32 all-thread in each end. Link ends are currently Tamiya pieces from the TLT kit, but I will more than likely replace them with some Traxxas or Losi ones. Once again, the links were mounted to the rear axle using TLT brackets.

First thing to go together are the two side plates. These are the "backbone" of the chassis and where the torsional flex will come from. I used TLT hardware to mount the plates to the axles. Seen in the pictures is the rear driveline assembly, including the carrier bearing.

Next on the agenda are the rear links. I wanted them to follow a high arch for ground clearance, but at the same time protect the rear driveline as much as possible. I cut the link bodies from cutting board and then screwed 6-32 all-thread in each end. Link ends are currently Tamiya pieces from the TLT kit, but I will more than likely replace them with some Traxxas or Losi ones. Once again, the links were mounted to the rear axle using TLT brackets.

#3

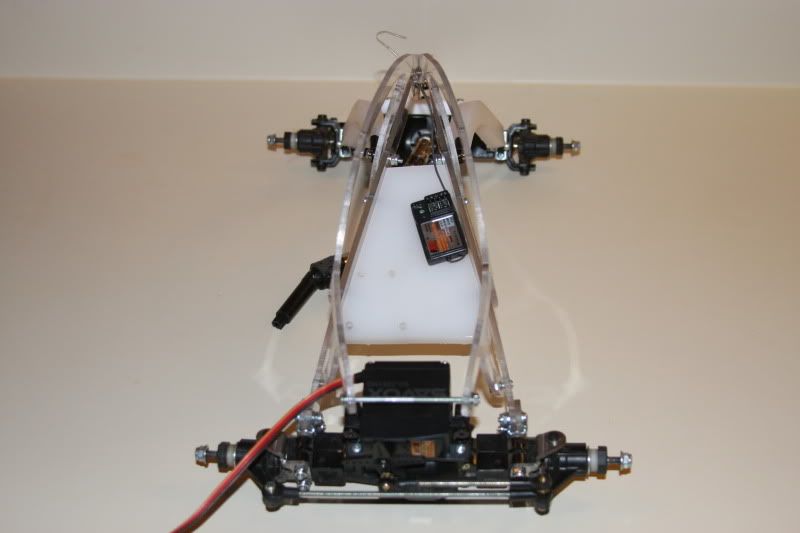

Here is the "body" that I designed. As you might be able to tell by my username, I'm a fan of VWs. I wanted the body to resemble a Bug while still having a unique look. I designed the body panels to aide in rollovers. When the truck turns on it's top, there is ALWAYS at least two wheels on the ground.

Attaching these to the previous assembly requires me to add the skid plate as well. As mentioned before, the skid is made from a section of cutting board. 4-40 screws pass through the body panels, then the main side plates and into the skid plate.

Attaching these to the previous assembly requires me to add the skid plate as well. As mentioned before, the skid is made from a section of cutting board. 4-40 screws pass through the body panels, then the main side plates and into the skid plate.

#4

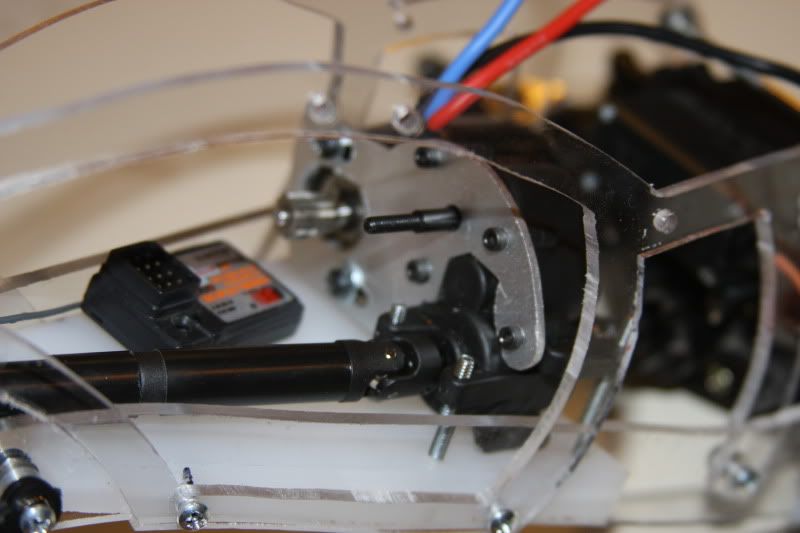

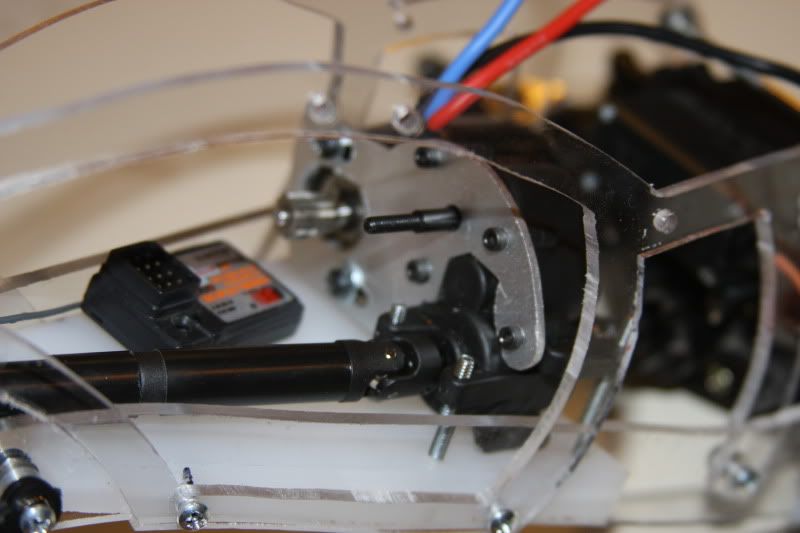

Transmission is next. I chose to run Mini Summit driveshafts in the front section to save precious space. I hope I'm not disappointed in their performance. The yolk that mates up to the carrier bearing as well as the one on the output shaft of the front axle have been bored out to 5mm (stock is 4mm). As mentioned before the idler and top gear have been swapped in the transmission. Stock setup gives an internal ratio of 1.94:1. By swapping the gears, I am able to get a 3.74:1 internal ratio. A 55-tooth spur will be used along with a 14-tooth pinion. The 55-tooth spur is the largest spur that can be installed on this transmission.

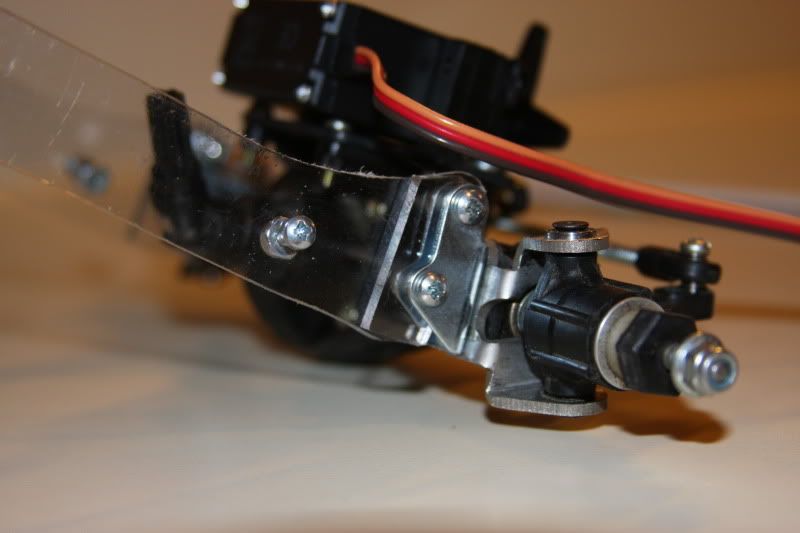

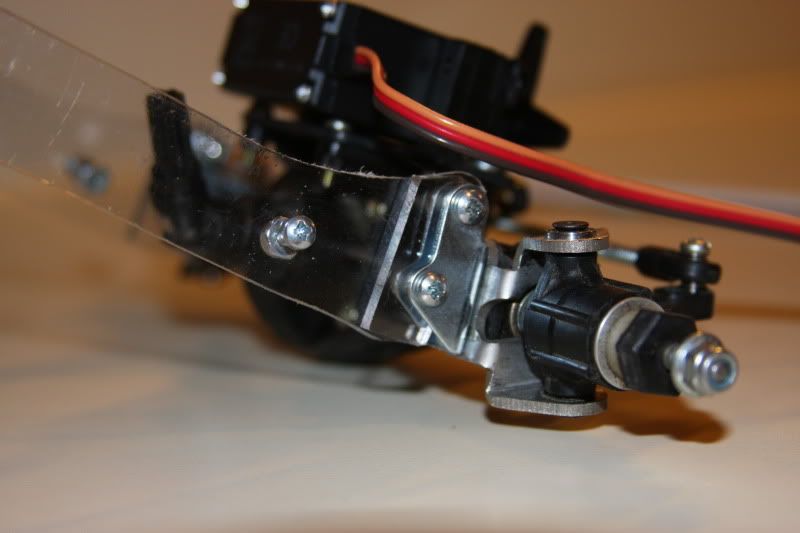

Here is a closeup of the carrier bearing assembly. I used a TA04 steering knuckle and cut a small piece from the CC-01 metal driveshaft as the carrier shaft.

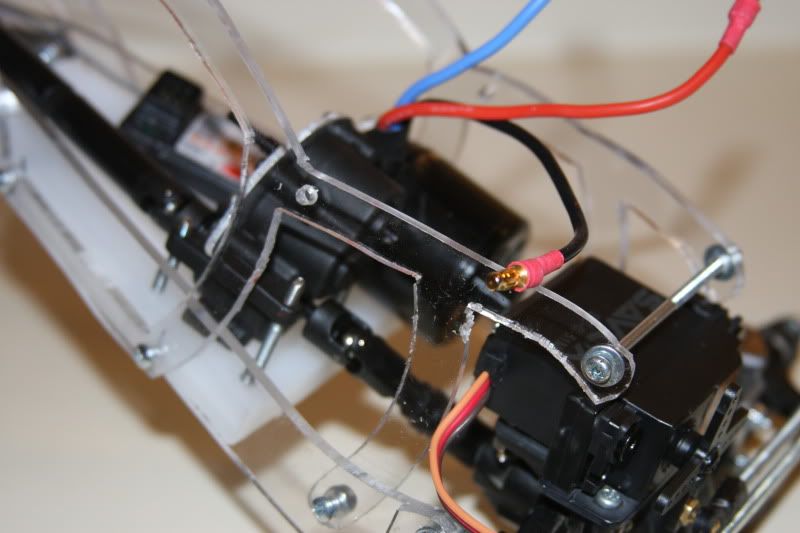

Underside of chassis showing skid plate and driveshafts.

Here is a closeup of the carrier bearing assembly. I used a TA04 steering knuckle and cut a small piece from the CC-01 metal driveshaft as the carrier shaft.

Underside of chassis showing skid plate and driveshafts.

#5

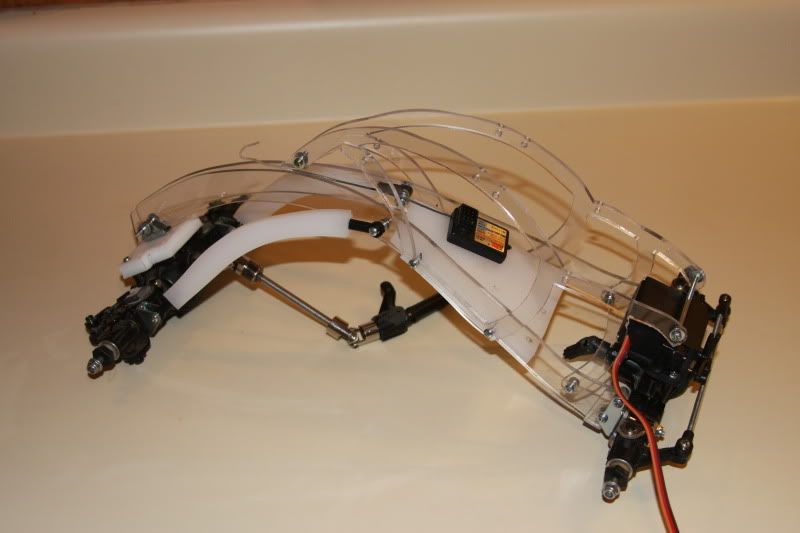

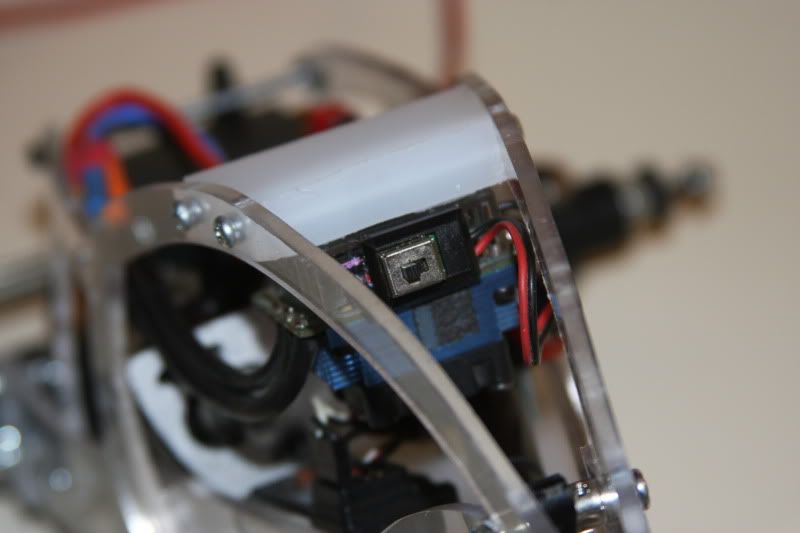

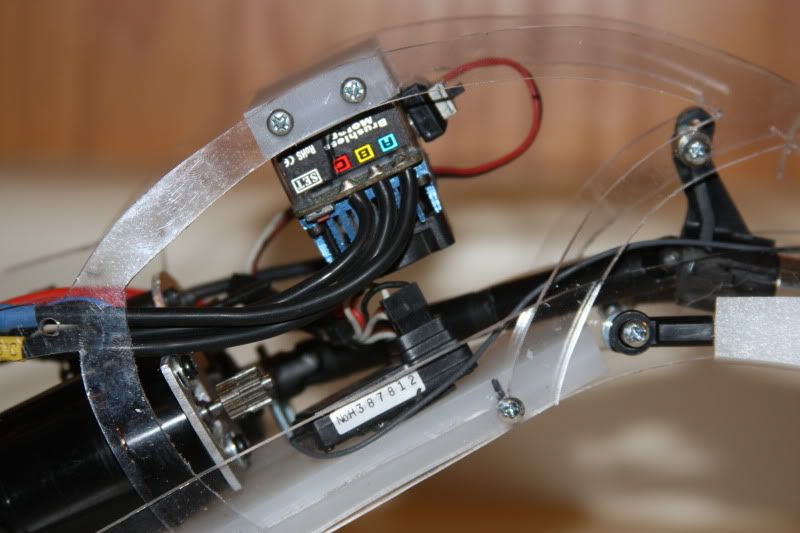

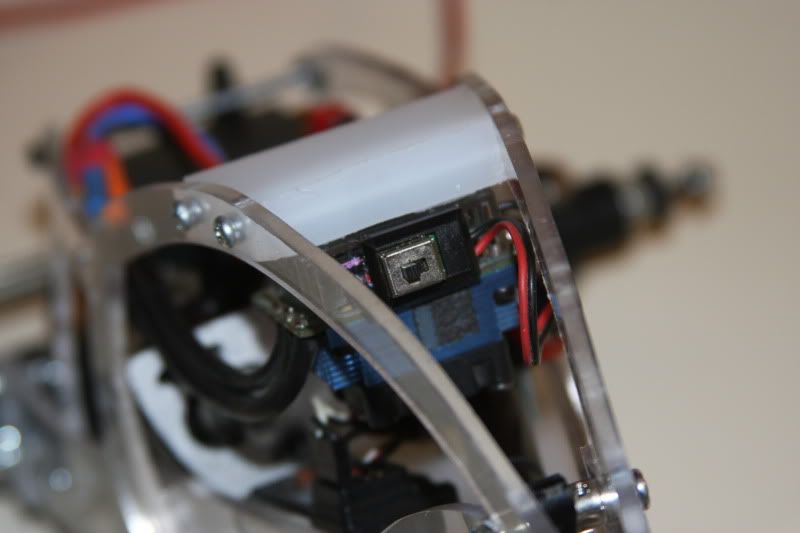

With the build wrapping up and me still having most of the electronics NOT installed, I started to wonder if I was going to be able to get everything in the chassis area. My goal from the beginning has always been to try and keep all of the weight as low as possible and as far forward as possible. Thank goodness my ESC isn't very large. :roll: I had to ditch my Turnigy 15A BEC due to size constraints. I plan to add a CC BEC soon, which will take up NO space. "thumbsup"

I tried for a couple of days to figure out where to put the ESC and still have room for the battery. I finally came up with mounting the ESC on the "roof". A plate made from cutting board was positioned so that the weight was still forward as much as possible and still allow for a "windshield area" once I create a hood. I really think that this ended up turning out perfect. On/off switch is currently mounted to the ESC and is easy to access, but still protected in the event of a rollover.

I tried for a couple of days to figure out where to put the ESC and still have room for the battery. I finally came up with mounting the ESC on the "roof". A plate made from cutting board was positioned so that the weight was still forward as much as possible and still allow for a "windshield area" once I create a hood. I really think that this ended up turning out perfect. On/off switch is currently mounted to the ESC and is easy to access, but still protected in the event of a rollover.

#6

Alrighty, here's the semi-final product. I'm running 2.2 White Dot Rovers all around with factory foams. I am still working on a hood to cover and protect the Lipo. Plan is to do a cowl induction style hood, where the scoop is where the battery sets. It will be hinged at the bottom via zipties and will close with studs and mini body clips just below the windshield area.

Now, about ground clearance. I think I have JUST a bit. :flipoff:

Flex? It's a torsion, so it's not going to have TONS, but I believe it has plenty. A change to different link ends on the rear will help to increase flex as well.

Now, with all of that ground clearance, won't it be top-heavy? I thought it might. The pictures tell me different. "thumbsup""thumbsup"

This is a 10" high hearth. Rear tires are touching the wall and the ground. Front tires are firmly planted as well.

How's this for a pic? :ror:

It was hard to tell exactly how close the rear tires were from the wall, so I grabbed my cutting mat and placed it beneath the tires. The beginning of the measure is right at the trim.

Yeah, that's less than 1"!!

Now, about ground clearance. I think I have JUST a bit. :flipoff:

Flex? It's a torsion, so it's not going to have TONS, but I believe it has plenty. A change to different link ends on the rear will help to increase flex as well.

Now, with all of that ground clearance, won't it be top-heavy? I thought it might. The pictures tell me different. "thumbsup""thumbsup"

This is a 10" high hearth. Rear tires are touching the wall and the ground. Front tires are firmly planted as well.

How's this for a pic? :ror:

It was hard to tell exactly how close the rear tires were from the wall, so I grabbed my cutting mat and placed it beneath the tires. The beginning of the measure is right at the trim.

Yeah, that's less than 1"!!

#7

Now, how it actually does on the rocks has yet to be seen. I should be getting the slipper clutch assembly and spur gear on Friday. I hope to have some time over the weekend to try the truck out to see if I encounter any major issues. I'm pretty sure that I'll need to add some weight to the rear. Currently I'm running about 8 oz in each front tire and none in the rear. That's how my BMVII seemed to work best. I will probably add at least a couple of oz in each rear tire, but I want to see how it runs as-is first. Hopefully my gearing works out. I know the final rollout ratio is almost identical to the BMVII running a Evader Pro tranny and an 87/14 combo. Only time will tell.

Hopefully you have been able to follow my ramblings during this build. I am very pleased with the results so far. Hopefully, if all goes well I can have some videos to post up around the first of next week.

Any comments, questions, suggestions? Let me know.

Hopefully you have been able to follow my ramblings during this build. I am very pleased with the results so far. Hopefully, if all goes well I can have some videos to post up around the first of next week.

Any comments, questions, suggestions? Let me know.

#8

Now, for a bit of a downer  . I had ordered the slipper clutch assembly and 55-tooth spur and both were due to be in my LHS Friday. Well, the slipper clutch assembly came in, but the spur is on backorder. The shop called around to all of its suppliers to see if one could be obtained any sooner. No such luck. Traxxas is out of stock on them. So, I ended up ordering a 45-, 50- and 55-tooth pinion from an online supplier. Hopefully they will be here soon. So, my hopes of getting it on the rocks this weekend have been dashed. It will probably be closer to the middle or end of this coming week.

. I had ordered the slipper clutch assembly and 55-tooth spur and both were due to be in my LHS Friday. Well, the slipper clutch assembly came in, but the spur is on backorder. The shop called around to all of its suppliers to see if one could be obtained any sooner. No such luck. Traxxas is out of stock on them. So, I ended up ordering a 45-, 50- and 55-tooth pinion from an online supplier. Hopefully they will be here soon. So, my hopes of getting it on the rocks this weekend have been dashed. It will probably be closer to the middle or end of this coming week.

On a good note, I was able to make a bit of progress on my hood. I had brainstormed with a good friend on how best to make the hood so it is both light and at the same time will provide some protection for the Lipo. Then, night before last I had a brainfart. My other obsession/hobby is building paper models (see papermodelers.com if you are not familiar). So, with my knowledge of doing those, I decided to create my own hood from 80# cardstock. The cardstock will be coated with 2 or 3 coats of fiberglass resin to harden it up. Once that is done, then I can use it as a positive to create a hood from lexan using a vacuuform machine (that a friend and me still need to build a small one of). I could probably use the fiberglassed hood, but there is the potential of it being too brittle still. I could layer up some cloth or fibers on the backside, but then weight and overall fit becomes a concern. This is going to be a "wait and see" sort of endeavor.

My other obsession/hobby is building paper models (see papermodelers.com if you are not familiar). So, with my knowledge of doing those, I decided to create my own hood from 80# cardstock. The cardstock will be coated with 2 or 3 coats of fiberglass resin to harden it up. Once that is done, then I can use it as a positive to create a hood from lexan using a vacuuform machine (that a friend and me still need to build a small one of). I could probably use the fiberglassed hood, but there is the potential of it being too brittle still. I could layer up some cloth or fibers on the backside, but then weight and overall fit becomes a concern. This is going to be a "wait and see" sort of endeavor.

Anyway, here are pics of the hood. It is made up of 7 pieces (3 for the scoop and 4 for the hood base and sides.) I intend on having it hinged on the lower end and will be secured at the upper end by pins and mini body clips. Sorry for the quality of the pics. It was almost 1am and I took them with my phone. I didn't want to get the good camera out.

Here's a picture of the hood from the underside. You can see all of the little glue tabs that holds it all together.

. I had ordered the slipper clutch assembly and 55-tooth spur and both were due to be in my LHS Friday. Well, the slipper clutch assembly came in, but the spur is on backorder. The shop called around to all of its suppliers to see if one could be obtained any sooner. No such luck. Traxxas is out of stock on them. So, I ended up ordering a 45-, 50- and 55-tooth pinion from an online supplier. Hopefully they will be here soon. So, my hopes of getting it on the rocks this weekend have been dashed. It will probably be closer to the middle or end of this coming week.

. I had ordered the slipper clutch assembly and 55-tooth spur and both were due to be in my LHS Friday. Well, the slipper clutch assembly came in, but the spur is on backorder. The shop called around to all of its suppliers to see if one could be obtained any sooner. No such luck. Traxxas is out of stock on them. So, I ended up ordering a 45-, 50- and 55-tooth pinion from an online supplier. Hopefully they will be here soon. So, my hopes of getting it on the rocks this weekend have been dashed. It will probably be closer to the middle or end of this coming week.On a good note, I was able to make a bit of progress on my hood. I had brainstormed with a good friend on how best to make the hood so it is both light and at the same time will provide some protection for the Lipo. Then, night before last I had a brainfart.

My other obsession/hobby is building paper models (see papermodelers.com if you are not familiar). So, with my knowledge of doing those, I decided to create my own hood from 80# cardstock. The cardstock will be coated with 2 or 3 coats of fiberglass resin to harden it up. Once that is done, then I can use it as a positive to create a hood from lexan using a vacuuform machine (that a friend and me still need to build a small one of). I could probably use the fiberglassed hood, but there is the potential of it being too brittle still. I could layer up some cloth or fibers on the backside, but then weight and overall fit becomes a concern. This is going to be a "wait and see" sort of endeavor.

My other obsession/hobby is building paper models (see papermodelers.com if you are not familiar). So, with my knowledge of doing those, I decided to create my own hood from 80# cardstock. The cardstock will be coated with 2 or 3 coats of fiberglass resin to harden it up. Once that is done, then I can use it as a positive to create a hood from lexan using a vacuuform machine (that a friend and me still need to build a small one of). I could probably use the fiberglassed hood, but there is the potential of it being too brittle still. I could layer up some cloth or fibers on the backside, but then weight and overall fit becomes a concern. This is going to be a "wait and see" sort of endeavor.Anyway, here are pics of the hood. It is made up of 7 pieces (3 for the scoop and 4 for the hood base and sides.) I intend on having it hinged on the lower end and will be secured at the upper end by pins and mini body clips. Sorry for the quality of the pics. It was almost 1am and I took them with my phone. I didn't want to get the good camera out.

Here's a picture of the hood from the underside. You can see all of the little glue tabs that holds it all together.

#9

i'll stay tuned...

its a pretty interesting build so far, cant wait to see more body parts done to it.

its a pretty interesting build so far, cant wait to see more body parts done to it.

#10

Body parts are going to be pretty minimal. USRCCA rules have specs that I intend to follow, but with the exception of the hood the rest of the body panels will be clear lexan. I really like the see-through aspects of the chassis and want to try and keep it as such as much as possible.

Thanks for watching!

As a small update, I got notification that my spurs have shipped. Hopefully I will have them in before the weekend. I was also able to get a coat of polyester resin on both sides of the hood. I MAY put one layer of cloth on the inside, but I'm beginning to think that maybe another couple of coats with the polyester resin would take care of it. Durable yet still flexible, much like lexan.

Thanks for watching!

As a small update, I got notification that my spurs have shipped. Hopefully I will have them in before the weekend. I was also able to get a coat of polyester resin on both sides of the hood. I MAY put one layer of cloth on the inside, but I'm beginning to think that maybe another couple of coats with the polyester resin would take care of it. Durable yet still flexible, much like lexan.