Tamiya XV-01

#961

Tech Addict

There's an inconspicuous donut-shaped piece on the NN parts tree -- NN12 according to the online manual -- that I stumbled across while trying to find a way to fit that spur onto the slipper shaft. I don't know for sure what NN12 was originally meant for, but given that it's the perfect fit for this application (the hole in the spur is English whereas the slipper shaft is Metric), I find it hard to believe it wasn't intended for this purpose.

If the spurs are flat, I will just sandwich them locked. Good to know if I ever want to go 69 or under.

As for torque control, maybe I will practice my hand at more drift to learn that feather touch throttle control technique. Or just cheat with the slipper 😂

I've always thought shaft driven cars were more rugged. But learned that belts are more energy efficient than gears.

For a while I was hoping for a TB05, but they kept making Tb04s evo such-and-such. I finally conceded that the xv-01 was the way to go. So successful is the single belt, they designed the ta07, which is also and interesting bit of engineering.

Now that the car is geared pretty high, I'll have to find something else to tweak. In the world of rc, there is never an end to mucking. 🚗

#962

#963

Yeah, belts are way more efficient. The 4WD entire drivetrain can be transverse, with no right-angle gears needed anywhere. My TA-05 v2 has two gears, two center pulleys, and two diff pulleys -- no greased parts anywhere in the drivetrain. (grease makes things heavier, you know.  ) Belt-drive bicycles are also more efficient, though the lack of shiftable gears is a problem for most riding conditions, so chains are used as a compromise.

) Belt-drive bicycles are also more efficient, though the lack of shiftable gears is a problem for most riding conditions, so chains are used as a compromise.

Associated makes a 69-tooth slipper-compatible spur that fits just fine. You only need to look at custom solutions if you want to go below 69t.

If you want more things to tweak, you can always get another XV-01 kit and build it differently. That's what I did...four times.

That's what I did...four times.

) Belt-drive bicycles are also more efficient, though the lack of shiftable gears is a problem for most riding conditions, so chains are used as a compromise.

) Belt-drive bicycles are also more efficient, though the lack of shiftable gears is a problem for most riding conditions, so chains are used as a compromise.Associated makes a 69-tooth slipper-compatible spur that fits just fine. You only need to look at custom solutions if you want to go below 69t.

If you want more things to tweak, you can always get another XV-01 kit and build it differently.

That's what I did...four times.

That's what I did...four times.

Last edited by fyrstormer; 09-08-2016 at 08:54 PM.

#964

Tech Addict

There's an inconspicuous donut-shaped piece on the NN parts tree -- NN12 according to the online manual -- that I stumbled across while trying to find a way to fit that spur onto the slipper shaft. I don't know for sure what NN12 was originally meant for, but given that it's the perfect fit for this application (the hole in the spur is English whereas the slipper shaft is Metric), I find it hard to believe it wasn't intended for this purpose.

#965

Tech Addict

Associated makes a 69-tooth slipper-compatible spur that fits just fine. You only need to look at custom solutions if you want to go below 69t.

If you want more things to tweak, you can always get another XV-01 kit and build it differently. That's what I did...four times.

That's what I did...four times.

If you want more things to tweak, you can always get another XV-01 kit and build it differently.

That's what I did...four times.

That's what I did...four times.Yes I saw that Associated makes them. Didn't find one until now, I should have just got the kimbrough 69T !!! I don't know why I was bent on a Jconcepts one. Ugh. Oh well they are only 6 bones... I can swing that.

#967

Tech Regular

iTrader: (5)

Yes, if i lose another shaft I'll be doing CVDs on at least one gearbox. Speaking of which, does one usually do CVDs on the front only?

#968

Yes, it's gone. I spent like 20 minutes looking for the driveshaft to no avail. I somehow knew the hingepin was more special/rare. Glad I found it.

Yes, if i lose another shaft I'll be doing CVDs on at least one gearbox. Speaking of which, does one usually do CVDs on the front only?

Yes, if i lose another shaft I'll be doing CVDs on at least one gearbox. Speaking of which, does one usually do CVDs on the front only?

#969

Tech Addict

Yes, it's gone. I spent like 20 minutes looking for the driveshaft to no avail. I somehow knew the hingepin was more special/rare. Glad I found it.

Yes, if i lose another shaft I'll be doing CVDs on at least one gearbox. Speaking of which, does one usually do CVDs on the front only?

Yes, if i lose another shaft I'll be doing CVDs on at least one gearbox. Speaking of which, does one usually do CVDs on the front only?

I didn't know the hinge pins were a special size.

How did the hinge pin pop out? Was it from a broken suspension mount?

#970

Tech Regular

iTrader: (5)

Well in the meantime, you have your choice of running FWD or RWD, which i have been meaning to try, but having the CVDs makes it a little harder to do.

I didn't know the hinge pins were a special size.

How did the hinge pin pop out? Was it from a broken suspension mount?

I didn't know the hinge pins were a special size.

How did the hinge pin pop out? Was it from a broken suspension mount?

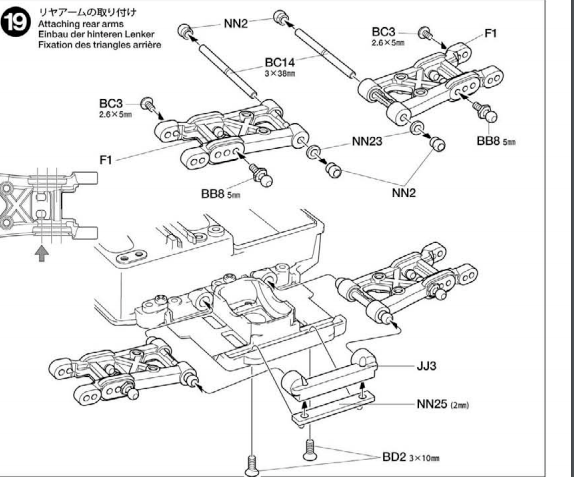

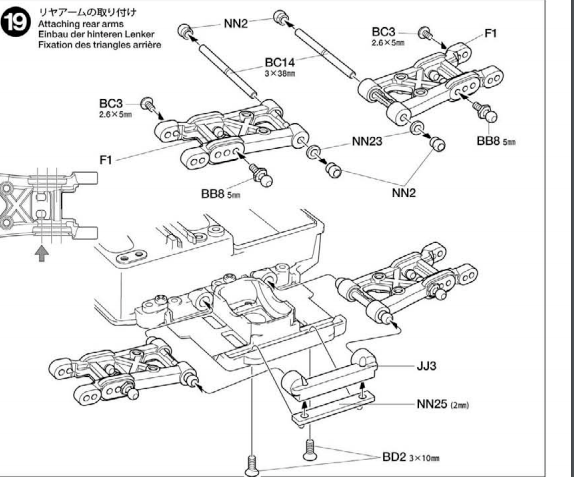

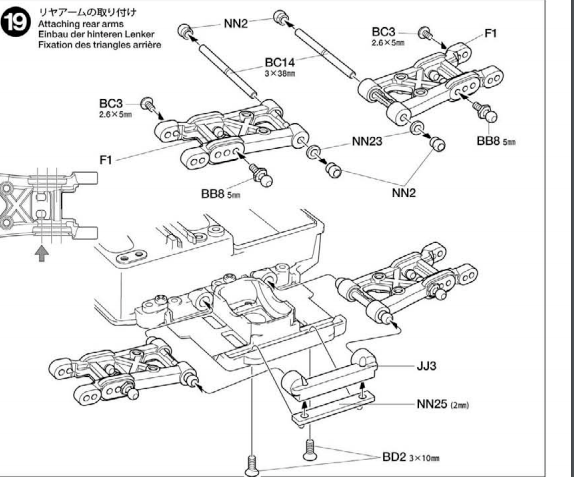

I surmise since the lower control arm mounts (chassis/JJ3) were still in place that the impact on the right rear wheel knocked out the hingepin bushings/spacers (NN2/NN23) which lets the hingepin loose which in turn let the lower control arm loose which in turn allowed the driveshaft to exit the car.

I'm electing not to drive it FWD/RWD because without any hingepin bushings on that corner, the hingepin will just roam around and cause horrible handling.. and could elongate/distort its mounting holes.

#971

Tech Addict

Well since you asked. The car did a few very violent cartwheels after rolling.

I surmise since the lower control arm mounts (chassis/JJ3) were still in place that the impact on the right rear wheel knocked out the hingepin bushings/spacers (NN2/NN23) which lets the hingepin loose which in turn let the lower control arm loose which in turn allowed the driveshaft to exit the car.

I'm electing not to drive it FWD/RWD because without any hingepin bushings on that corner, the hingepin will just roam around and cause horrible handling.. and could elongate/distort its mounting holes.

I surmise since the lower control arm mounts (chassis/JJ3) were still in place that the impact on the right rear wheel knocked out the hingepin bushings/spacers (NN2/NN23) which lets the hingepin loose which in turn let the lower control arm loose which in turn allowed the driveshaft to exit the car.

I'm electing not to drive it FWD/RWD because without any hingepin bushings on that corner, the hingepin will just roam around and cause horrible handling.. and could elongate/distort its mounting holes.

#973

Tech Addict

Though, if I had to do it all over again, I think just getting the carbon reinforced parts would have saved me over 50 dollars. It's nice to have bling, but the car just works.

I didn't know that rally cars were acrobats. Doing cartwheels, show off

#974

Tech Addict

The new low FDR 4.9:1 (low compared to anything remotely stock ~8:1) has completely changed how this car drives.

It's not as zippy as before, which is to be expected. The acceleration is a little more drawn out. It is definitely not as pow-pow I-do-what-I-want wheel-spinny on-demand power. But still plenty enough to lose control if you are treating the throttle like a light switch.

Top end is blistering with turbos. I think this car can hit 50+ MPH. Only I cannot do it on my street anymore, because it is still accelerating by the time I need to slow down. I will have to find a drag strip somewhere to do a real speed run.

The car feels foreign to me. I am much more hesitant to drive the car like a newbie teenager at the wheel of an over powered vehicle. The car isn't as balanced, acceleration and deceleration has changed. Like stretching an elastic band.

The new lower gear ratio makes the car accelerate a little slower, and coast much longer. It covers more distance than it did before on and off power. I would say this ratio setup would probably be good for a big sweeping turn track.

Which is why it makes me feel like my street is now more restrictive.

Anyway, just another way to to train ones reflexes.

It's not as zippy as before, which is to be expected. The acceleration is a little more drawn out. It is definitely not as pow-pow I-do-what-I-want wheel-spinny on-demand power. But still plenty enough to lose control if you are treating the throttle like a light switch.

Top end is blistering with turbos. I think this car can hit 50+ MPH. Only I cannot do it on my street anymore, because it is still accelerating by the time I need to slow down. I will have to find a drag strip somewhere to do a real speed run.

The car feels foreign to me. I am much more hesitant to drive the car like a newbie teenager at the wheel of an over powered vehicle. The car isn't as balanced, acceleration and deceleration has changed. Like stretching an elastic band.

The new lower gear ratio makes the car accelerate a little slower, and coast much longer. It covers more distance than it did before on and off power. I would say this ratio setup would probably be good for a big sweeping turn track.

Which is why it makes me feel like my street is now more restrictive.

Anyway, just another way to to train ones reflexes.

Last edited by 4roller; 09-09-2016 at 09:27 PM.

#975

Yes, it's gone. I spent like 20 minutes looking for the driveshaft to no avail. I somehow knew the hingepin was more special/rare. Glad I found it.

Yes, if i lose another shaft I'll be doing CVDs on at least one gearbox. Speaking of which, does one usually do CVDs on the front only?

Yes, if i lose another shaft I'll be doing CVDs on at least one gearbox. Speaking of which, does one usually do CVDs on the front only?

The only place I still use dogbones by choice is on the rear axle of my DF-03Ra. The rear axle is swept forward to achieve a proper touring-car wheelbase, because the underlying chassis comes from a buggy, and having mismatched axle joints (dogbones on the inboard ends and CVDs on the outboard ends) caused severe vibrations, so I switched back to dogbones on the rear axle. The DF-03Ra is the only vehicle I've ever run that actually needed dogbones to work right, though; the rest I upgrade to CVDs (or sometimes universal-joints on the rear axle only) as soon as I can.

167Likes

167Likes