Tamiya mini cooper

Is that a JDM Tamiya pie plate?

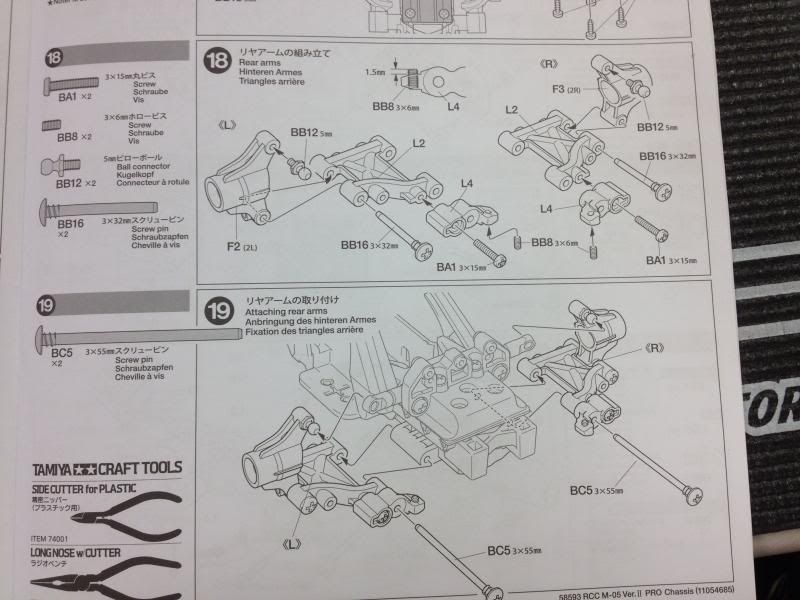

Thanks for the pics. The motor plate looks almost identical, save for the slight indentation on the motor side. I guess most of the 4.5mm came from re-organizing the chassis.

I don't suppose you'd want to show us the page in the manual with the parts numbers on it, would you?

And on the subject of Tamiya screws again - does anyone know if they're Phillips or JIS? I've noticed my Arrowmax "Phillips" drivers fit them very well, when compared to any N. American hardware store drivers I usually use.

I don't suppose you'd want to show us the page in the manual with the parts numbers on it, would you?

And on the subject of Tamiya screws again - does anyone know if they're Phillips or JIS? I've noticed my Arrowmax "Phillips" drivers fit them very well, when compared to any N. American hardware store drivers I usually use.

There are currently no part numbers for the 3 new items in the v.2 kit.

Cool. Just thought I'd check. Can't wait to disassemble my old 05 and build something more to my liking.

And on the subject of Tamiya screws again - does anyone know if they're Phillips or JIS? I've noticed my Arrowmax "Phillips" drivers fit them very well, when compared to any N. American hardware store drivers I usually use.

I believe the bits w/ the "P2" designation have the blunt ends, whereas "P1" is pointy ...but I may be wrong on that. Here is what I am using for my M05's screws w/ success:

http://www.searsoutlet.com/P2-1-in-P...59&mode=seeAll

P1 and P2 are both Phillips. They're just different sizes. I've got drivers from P4 down to P0, and a few that are way smaller than 0, but they may carry a different designation. That's probably why the article I linked earlier has 30 pages.

[QUOTE=Clawhammers;13269493]the new M06 body kit

[/QUOTE

[/QUOTE

LOL. Only Tamiya! Needs a gun rack to be complete

[/QUOTE

[/QUOTELOL. Only Tamiya! Needs a gun rack to be complete

So...more than 3 new parts...chassis, arms, droop adjusters, motor plate...

Personally speaking I don't think there are any benefits to changing to hex hardware on a Mini.

The biggest improvement you can make is to start using a JIS pattern cross head screwdriver rather than an American/European Phillips head (the two are not the same). A Tamiya tool would be the ideal choice, I have TOP tools which are JIS, I suspect a few of the other expensive RC brand tools are JIS too. Phillips screwdrivers strip the heads of JIS screws.

The tapping thread of the kit screws is ideal for the ABS plastic most of the car is made out of, the screw hole tolerances are engineered for tapping screws as well. You'll find that machine screws strip out the ABS a lot more often because they don't cut very deep into the relatively soft material.

The biggest improvement you can make is to start using a JIS pattern cross head screwdriver rather than an American/European Phillips head (the two are not the same). A Tamiya tool would be the ideal choice, I have TOP tools which are JIS, I suspect a few of the other expensive RC brand tools are JIS too. Phillips screwdrivers strip the heads of JIS screws.

The tapping thread of the kit screws is ideal for the ABS plastic most of the car is made out of, the screw hole tolerances are engineered for tapping screws as well. You'll find that machine screws strip out the ABS a lot more often because they don't cut very deep into the relatively soft material.

I picked up one a long time ago on sale for little over $10. Perfect fit on the heads. The hex is meh though.

The advantage is basically that the complete arm is a single piece.

288Likes

288Likes