Team Associated TC6.2 Touring Car

#1261

Someone about 10 posts up asked the same question for USGT. Probably a good starting point.

http://www.rctech.net/forum/13430277-post1248.html

http://www.rctech.net/forum/13430277-post1248.html

#1262

Hi Guys,

just finished building my TC6.2, my first Associated TC in 15 years. Very nice build, had a few small issues, but all taken care of. I am curious if anyone had trouble/breakage with the stock turnbuckle ends? I cracked one while snapping it into the ballstuds (it was the only one that did that....so maybe a fluke).

Very nice build, had a few small issues, but all taken care of. I am curious if anyone had trouble/breakage with the stock turnbuckle ends? I cracked one while snapping it into the ballstuds (it was the only one that did that....so maybe a fluke).

Thanks in advance

Steve

just finished building my TC6.2, my first Associated TC in 15 years.

Very nice build, had a few small issues, but all taken care of. I am curious if anyone had trouble/breakage with the stock turnbuckle ends? I cracked one while snapping it into the ballstuds (it was the only one that did that....so maybe a fluke).

Very nice build, had a few small issues, but all taken care of. I am curious if anyone had trouble/breakage with the stock turnbuckle ends? I cracked one while snapping it into the ballstuds (it was the only one that did that....so maybe a fluke). Thanks in advance

Steve

#1263

Hi Guys,

just finished building my TC6.2, my first Associated TC in 15 years. Very nice build, had a few small issues, but all taken care of. I am curious if anyone had trouble/breakage with the stock turnbuckle ends? I cracked one while snapping it into the ballstuds (it was the only one that did that....so maybe a fluke).

Very nice build, had a few small issues, but all taken care of. I am curious if anyone had trouble/breakage with the stock turnbuckle ends? I cracked one while snapping it into the ballstuds (it was the only one that did that....so maybe a fluke).

Thanks in advance

Steve

just finished building my TC6.2, my first Associated TC in 15 years.

Very nice build, had a few small issues, but all taken care of. I am curious if anyone had trouble/breakage with the stock turnbuckle ends? I cracked one while snapping it into the ballstuds (it was the only one that did that....so maybe a fluke).

Very nice build, had a few small issues, but all taken care of. I am curious if anyone had trouble/breakage with the stock turnbuckle ends? I cracked one while snapping it into the ballstuds (it was the only one that did that....so maybe a fluke). Thanks in advance

Steve

#1265

Ok lay the eyelet flat. The hole should be facing up. That would be the top. Most of the eyelets that have been broken around my track have been on the side of it. Where the line is in the plastic. There is one on both sides. My apologies, I did not see the pictures (i was on my phone). But Samnelso is correct.

Last edited by thecaptain; 08-03-2014 at 05:27 AM.

#1266

Tech Master

iTrader: (1)

Steve, looks like you threaded that eyelet in a bit too far and it pushed up against the eyelet opening, overstraining it and causing it to crack. The eyelets should be installed so an equal amount of thread is showing on each turnbuckle . This will prevent what you're experiencing. Additionally, be cognizant to not thread one eyelet in too far and bind up the ball stud. Make sure the turnbuckle is free once it's installed.

#1267

Tech Addict

iTrader: (5)

^^^ What samnelso said. Looking at the picture the the threads showing are not symmetrical in exposure.

I finished constructing my TC6.2 Roller last night. I have a Sanwa servo coming, just need to sort out the ESC and motor. I was mildly disappointed to discover the body post spacing is different from the TC6.1.... That means no transferring of bodies, unless I want extra holes

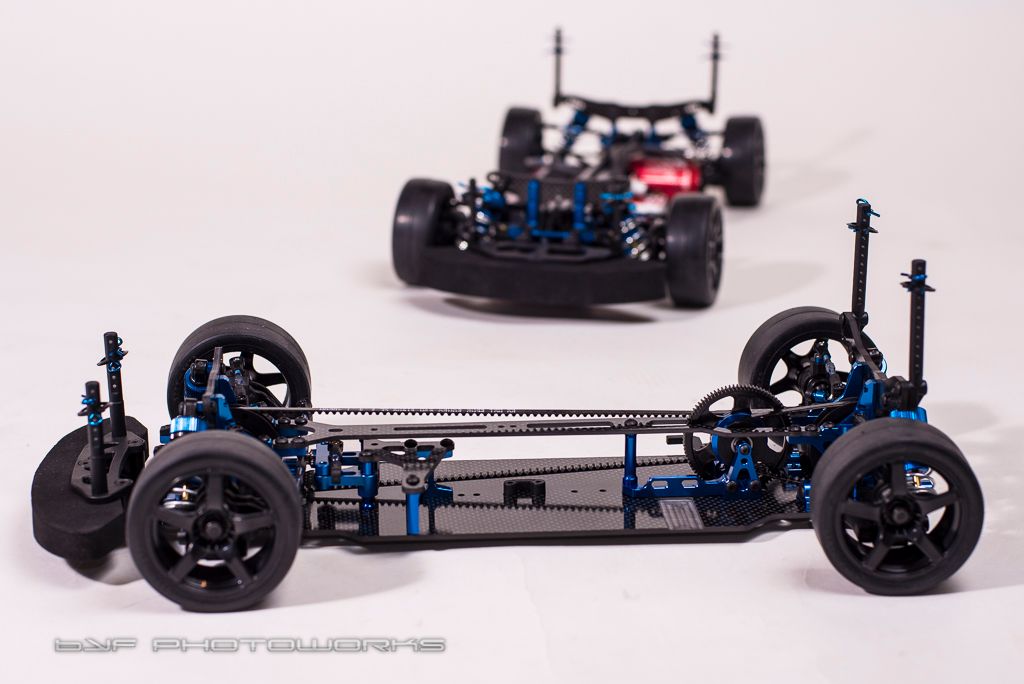

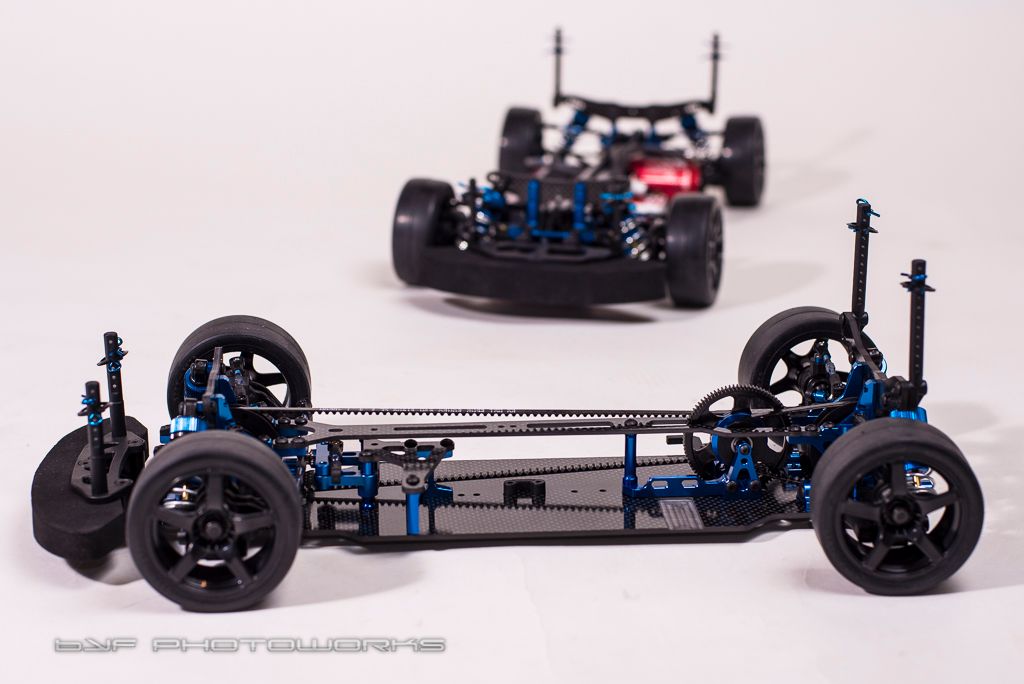

TC6.1 (left), TC6.2 (right)

TC6.1 (left), TC6.2 (right)

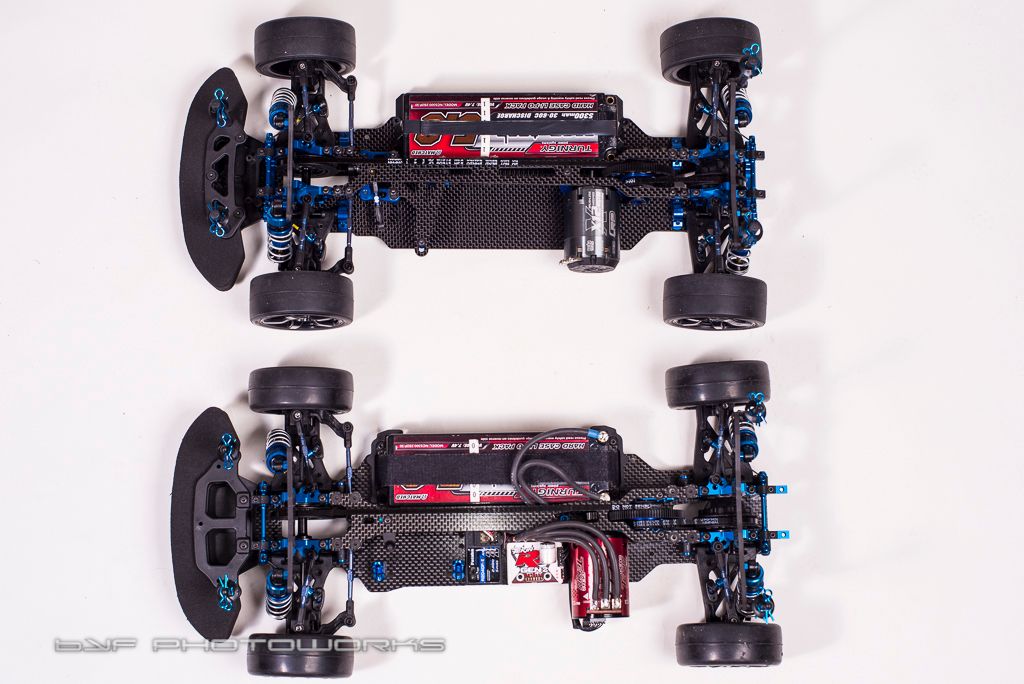

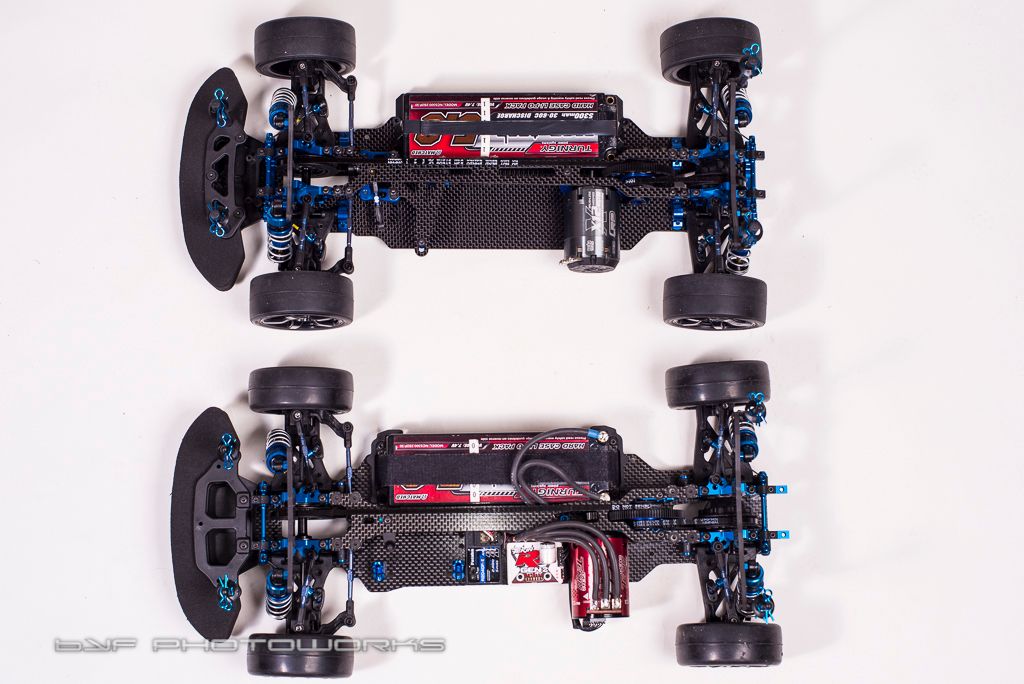

TC6.2 (top), TC6.1 (bottom)

I finished constructing my TC6.2 Roller last night. I have a Sanwa servo coming, just need to sort out the ESC and motor. I was mildly disappointed to discover the body post spacing is different from the TC6.1.... That means no transferring of bodies, unless I want extra holes

TC6.1 (left), TC6.2 (right)

TC6.1 (left), TC6.2 (right)

TC6.2 (top), TC6.1 (bottom)

#1268

Thanks for the input guys. Haven't build a TC in about two years so I will take full credit for that "operator error"  I will still stock up on some of these ends just in case.

I will still stock up on some of these ends just in case.

Thanks again

Steve

I will still stock up on some of these ends just in case.

I will still stock up on some of these ends just in case.Thanks again

Steve

#1269

any tips from the pro's on how the free up their 6.2's for more corner speed and less pushy on a large parking lot track?

I am running Yokomo yellow front and rear blues with basically the kit setup except for inner holes on the bulkheads for camber links (long link)

Thanks

I am running Yokomo yellow front and rear blues with basically the kit setup except for inner holes on the bulkheads for camber links (long link)

Thanks

#1270

Tech Adept

iTrader: (1)

any tips from the pro's on how the free up their 6.2's for more corner speed and less pushy on a large parking lot track?

I am running Yokomo yellow front and rear blues with basically the kit setup except for inner holes on the bulkheads for camber links (long link)

Thanks

I am running Yokomo yellow front and rear blues with basically the kit setup except for inner holes on the bulkheads for camber links (long link)

Thanks

#1273

Tech Master

iTrader: (1)

They're certainly a good thing for tracks that run boards. With curbs or dots servo saver isn't needed. With that said, I run them on my cars as well, although I'm not sure if they actually help mitigate breakage. Today's servos certainly are not going anywhere and I probably run them more out of habit that anything. Note, offroad does not use them.

BTW your cars look good and nice camera work.

BTW your cars look good and nice camera work.

#1274

Everyone at our track broke their servos on the first few runs with the new car. Then we all got servo savers and no problems since. I agree they should have put one in the kit.

3Likes

3Likes