Unusual Clutch Bell vs. Standard-Length Crankshaft -- WHO WILL WIN?

#1

Spoiler: I won.

So I'm building a vintage RS4 SS chassis, which came with a vintage HPI .12R SS engine. It has a short crankshaft with a screw-on extender that doubles as the flywheel nut, the same setup as the current RS4, but I wanted to use a vintage HPI steel 2-speed clutch bell that I managed to get my hands on a while back.

This clutch bell is very strange, and I haven't been able to find any information whatsoever about how to make it fit properly. It's listed as an option part for a couple discontinued vehicles, but nowhere in their user manuals is it explained how to make the darn thing fit. The clutch bell has no shoulders inside the central bore for bearings to sit, it's just an 8mm-diameter bore all the way through. That problem was easy enough to solve by using flanged bearings to hold the clutch bell in-place, but the crankshaft was too short even with the extender screwed-on.

I puzzled over how to solve this problem for a while, and then while digging through my spare parts bags, I came across a 5mm internally-threaded servo-saver post from a different vehicle. Suddenly I had an idea: I could get another servo-saver post, measure how much of it I actually need to make the crankshaft the length I need, and then cut it off and attach it with a set-screw down the middle of the post, with some red Loctite to make sure it never comes loose.

Well, almost. As it turns out, I only needed about 5mm extra length, so what I ended up doing instead was cutting the end off the servo-saver post and then threading the cut-off piece onto a long bolt to make a homemade shoulder-screw that would fit snugly against the end of the crankshaft. It looks like this:

I cut it slightly too long on purpose, so I could precisely fit the clutch bell in-place with shims. 0.6mm of shims and a couple drops of blue Loctite later, it fits perfectly:

Now I won't have to worry about this RS4 chewing up aluminum pinion gears constantly.

So I'm building a vintage RS4 SS chassis, which came with a vintage HPI .12R SS engine. It has a short crankshaft with a screw-on extender that doubles as the flywheel nut, the same setup as the current RS4, but I wanted to use a vintage HPI steel 2-speed clutch bell that I managed to get my hands on a while back.

This clutch bell is very strange, and I haven't been able to find any information whatsoever about how to make it fit properly. It's listed as an option part for a couple discontinued vehicles, but nowhere in their user manuals is it explained how to make the darn thing fit. The clutch bell has no shoulders inside the central bore for bearings to sit, it's just an 8mm-diameter bore all the way through. That problem was easy enough to solve by using flanged bearings to hold the clutch bell in-place, but the crankshaft was too short even with the extender screwed-on.

I puzzled over how to solve this problem for a while, and then while digging through my spare parts bags, I came across a 5mm internally-threaded servo-saver post from a different vehicle. Suddenly I had an idea: I could get another servo-saver post, measure how much of it I actually need to make the crankshaft the length I need, and then cut it off and attach it with a set-screw down the middle of the post, with some red Loctite to make sure it never comes loose.

Well, almost. As it turns out, I only needed about 5mm extra length, so what I ended up doing instead was cutting the end off the servo-saver post and then threading the cut-off piece onto a long bolt to make a homemade shoulder-screw that would fit snugly against the end of the crankshaft. It looks like this:

I cut it slightly too long on purpose, so I could precisely fit the clutch bell in-place with shims. 0.6mm of shims and a couple drops of blue Loctite later, it fits perfectly:

Now I won't have to worry about this RS4 chewing up aluminum pinion gears constantly.

#2

Tech Rookie

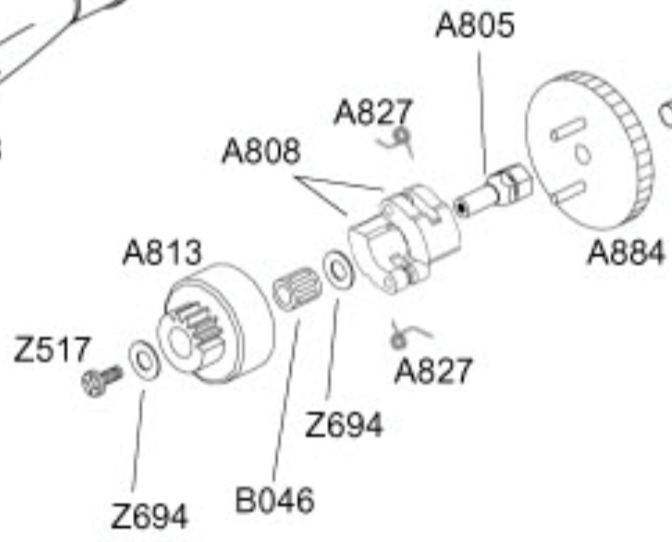

I became curious of your shelf queen project and decided to investigate this further as I'm also not too fond of aluminum pinions. As I understand your clutchbell is part #A824 CLUTCH BELL 15/21 TOOTH (1M) from Super Nitro - in the manual the mystery part you were missing is one #B046 CLUTCH NEEDLE BEARING 5x8mm:

Here it is in the manual (BTW, its length is 10mm and the accompanying washers are 10x5x0.5mm - same ones are used on RS4 3):

This part is listed as replaced by #B019 BALL BEARING 5x8x2.5mm - flanged bearing, probably similar to the one you ended up using, but used on R40 which has much more complicated clutch setup so not sure why HPI lists it as such.

Here it is in the manual (BTW, its length is 10mm and the accompanying washers are 10x5x0.5mm - same ones are used on RS4 3):

This part is listed as replaced by #B019 BALL BEARING 5x8x2.5mm - flanged bearing, probably similar to the one you ended up using, but used on R40 which has much more complicated clutch setup so not sure why HPI lists it as such.

#3

This is a two-speed clutch bell, which as far as I can tell would've used a longer bearing. I know it used a longer stub-shaft (or whatever they're called) screwed onto the end of the crankshaft (part A806 instead of A805), but I didn't know that longer stub-shaft existed until recently. In any event, you're correct about the flange bearings being the official replacement for the needle-bearing; I'm glad I guessed correctly.

On my 2-speed runner, I *am* using aluminum pinions, though. The anodizing wore off fast, but after that they seem to be holding up well. It no doubt helps that I covered the hole under the center gearbox with a carefully trimmed piece of Coke-can, to keep grit from bouncing up into the gears.

On my 2-speed runner, I *am* using aluminum pinions, though. The anodizing wore off fast, but after that they seem to be holding up well. It no doubt helps that I covered the hole under the center gearbox with a carefully trimmed piece of Coke-can, to keep grit from bouncing up into the gears.

#4

Tech Rookie

As I was writing my findings I realized this 1S/2S difference as well but decided to post anyway for future reference. Now I see your mirror post at URC with the suggestion about #A806 - that's the part I couldn't deduce.

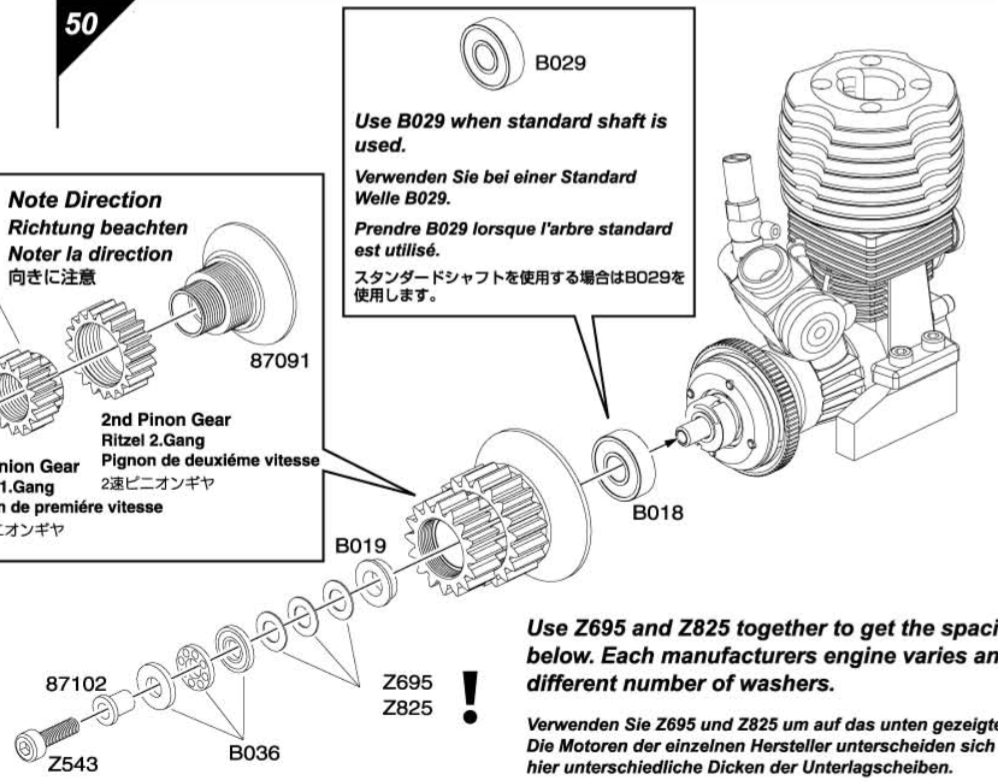

BTW, here is the diagram with said sleeve bearing #B019 in R40's 2-speed clutch:

BTW, here is the diagram with said sleeve bearing #B019 in R40's 2-speed clutch: