Hit and miss versus hand picked.

#1

I've been really lucky lately getting older model NOS (new old stock) 353 engines that run in with a tank on the bench and a few minutes on track. They've performed tirelessy and while perhaps not as fast, the reliability and tuning response makes them favourites.

I've also had really tight engines and a good friend bought some hand picked Novas and said they performed magnificently. He's a top 3 driver in the country and driven modified engines before and his results were outstanding double podium at our national champs, 1st in 1/8th onr.

So the question is, how much harm are we doing when running in and is there a point where you'll hurt the engine before you've even got a chance to run it?

I hope there'll be differing opinions, might make me feel better about my own indecisions.

cheers

h

I've also had really tight engines and a good friend bought some hand picked Novas and said they performed magnificently. He's a top 3 driver in the country and driven modified engines before and his results were outstanding double podium at our national champs, 1st in 1/8th onr.

So the question is, how much harm are we doing when running in and is there a point where you'll hurt the engine before you've even got a chance to run it?

I hope there'll be differing opinions, might make me feel better about my own indecisions.

cheers

h

#2

Tech Master

iTrader: (2)

The difference between a standard and a truly hand picked engine is pretty big.

A hand picked or blueprinted engine fits together perfectly, crank goes in under it's own weight, sleeve can be removed without having to press it out using a ty-rap etc.

Hand picked engines are also much easier to break in and they last quite a bit longer.

The only truly hand picked engines I know off which are easily available to the normal racer are Orcan engines, the MH versions.

Regarding running in the engine,

A average motor can be made fast using a proper break in, or a fast motor can be made into an average or bad motor when break in isn't done properly.

Two things are the most important for break in: heat and lubrication. You need enough heat to make sure the engine breaks in on the temperature it will be raced at and you need lubrication to have a nicely polished sealing area to have the best possible seal with the least amount of friction.

I use my own method, with my self developed break in oil:

http://www.capricornrc.nl/ExportBest...20Oil&Type=pdf

Since I've been using the method listed above every single one of my engines has been a lot faster than average.

A hand picked or blueprinted engine fits together perfectly, crank goes in under it's own weight, sleeve can be removed without having to press it out using a ty-rap etc.

Hand picked engines are also much easier to break in and they last quite a bit longer.

The only truly hand picked engines I know off which are easily available to the normal racer are Orcan engines, the MH versions.

Regarding running in the engine,

A average motor can be made fast using a proper break in, or a fast motor can be made into an average or bad motor when break in isn't done properly.

Two things are the most important for break in: heat and lubrication. You need enough heat to make sure the engine breaks in on the temperature it will be raced at and you need lubrication to have a nicely polished sealing area to have the best possible seal with the least amount of friction.

I use my own method, with my self developed break in oil:

http://www.capricornrc.nl/ExportBest...20Oil&Type=pdf

Since I've been using the method listed above every single one of my engines has been a lot faster than average.

#3

The difference between a standard and a truly hand picked engine is pretty big.

A hand picked or blueprinted engine fits together perfectly, crank goes in under it's own weight, sleeve can be removed without having to press it out using a ty-rap etc.

Hand picked engines are also much easier to break in and they last quite a bit longer.

The only truly hand picked engines I know off which are easily available to the normal racer are Orcan engines, the MH versions.

Regarding running in the engine,

A average motor can be made fast using a proper break in, or a fast motor can be made into an average or bad motor when break in isn't done properly.

Two things are the most important for break in: heat and lubrication. You need enough heat to make sure the engine breaks in on the temperature it will be raced at and you need lubrication to have a nicely polished sealing area to have the best possible seal with the least amount of friction.

I use my own method, with my self developed break in oil:

http://www.capricornrc.nl/ExportBest...20Oil&Type=pdf

Since I've been using the method listed above every single one of my engines has been a lot faster than average.

A hand picked or blueprinted engine fits together perfectly, crank goes in under it's own weight, sleeve can be removed without having to press it out using a ty-rap etc.

Hand picked engines are also much easier to break in and they last quite a bit longer.

The only truly hand picked engines I know off which are easily available to the normal racer are Orcan engines, the MH versions.

Regarding running in the engine,

A average motor can be made fast using a proper break in, or a fast motor can be made into an average or bad motor when break in isn't done properly.

Two things are the most important for break in: heat and lubrication. You need enough heat to make sure the engine breaks in on the temperature it will be raced at and you need lubrication to have a nicely polished sealing area to have the best possible seal with the least amount of friction.

I use my own method, with my self developed break in oil:

http://www.capricornrc.nl/ExportBest...20Oil&Type=pdf

Since I've been using the method listed above every single one of my engines has been a lot faster than average.

Have you ever had an engine that was TOO tight?

#4

Tech Master

iTrader: (2)

I've had one which was extremely tight, even at 100�C it kept getting stuck.

Luckily I've got the tooling to lap and hone the liner so I can adjust the fit of a piston/sleeve set.

#5

Yes, over here we race with a spec engine in the nationals and clubraces. Spec engine is the Novarossi N12T1 which is a perfect engine for it's price but there can be some differences between batches.

I've had one which was extremely tight, even at 100�C it kept getting stuck.

Luckily I've got the tooling to lap and hone the liner so I can adjust the fit of a piston/sleeve set.

I've had one which was extremely tight, even at 100�C it kept getting stuck.

Luckily I've got the tooling to lap and hone the liner so I can adjust the fit of a piston/sleeve set.

When lapping a liner, your thinning out the hard Cr coating, doesnt make me happy. I do understant the N12T1 class, we use an OS TG / JAMMING < 1 HP in our "gas touring" and they are budget engines. They proved too fast for the "choked" 4mm OSTG class and we cant use them unfortunately.

Does anyone ever do work on their pistons to make them fit. Precision lathes etc, or are the tolerances so small it's not viable?

h

More Google.

Other types (and OS is the worst example) is ABN where N is for nickel plating, AAO (as used by Norvell and I think will be the next big thing) which is Aluminium piston with an Aluminium Oxide coating on the aluminium liner. Al Oxide is somewhere between chrome and diamond for hardness

I think

#6

Hey DS, where can I get the ORCAN motors?

I'm running a murnan modified RBM3 and I'm more than satisfied.

Also my backup at the moment is a RB T10rc and I'm also happy with that too, just a little heavy IMO. looking for a good motor for next year and have broken it down to a capricorn or murnan keep on, both engines .12

I'm running a murnan modified RBM3 and I'm more than satisfied.

Also my backup at the moment is a RB T10rc and I'm also happy with that too, just a little heavy IMO. looking for a good motor for next year and have broken it down to a capricorn or murnan keep on, both engines .12

#7

Tech Fanatic

iTrader: (12)

I use my own method, with my self developed break in oil:

http://www.capricornrc.nl/ExportBest...20Oil&Type=pdf

Since I've been using the method listed above every single one of my engines has been a lot faster than average.

I have been using a very similar breakin procedure for about 2 years & with the same results. Very pleased with this method

Breaking in a engine used to be such a pain in the azz but this method has made it a lot less of a chore and a lot more rewarding

.

#8

The chrome layer is very hard and many microns thick, with very tight engines after one or 2 races I sometimes use a brake cilinder hone stone to work on the sleeve. I makes the sleeve a tiny bit larger but it also makes a fresh hone profile (scratches) what will hold the oil much better for a better lubrication and compression build.

#9

Take a search in the Offroad engine section to "hand lapping", is is a common thing to do. When I do it I use a Scotch brite pad which is a kind of polishing pad. Some have made an holder with an hole where you can put in the polishing pad and the piston and an adaptor so you can connect the rod to an electric dril/screwdriver

The chrome layer is very hard and many microns thick, with very tight engines after one or 2 races I sometimes use a brake cilinder hone stone to work on the sleeve. I makes the sleeve a tiny bit larger but it also makes a fresh hone profile (scratches) what will hold the oil much better for a better lubrication and compression build.

The chrome layer is very hard and many microns thick, with very tight engines after one or 2 races I sometimes use a brake cilinder hone stone to work on the sleeve. I makes the sleeve a tiny bit larger but it also makes a fresh hone profile (scratches) what will hold the oil much better for a better lubrication and compression build.

#10

Handpicking is nothing more than fitting pistons into sleeves. A certain distance is determed of how far the piston must go into the sleeve as a perfect fit for a perfect end result after running in. A simple way to see is it is locating the piston pin in the exhaust port to see how high it goes.

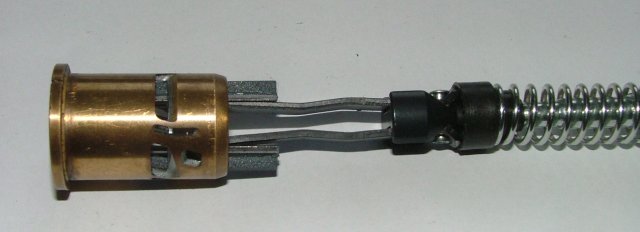

Using a hone tool like mine is more acurate than hand lapping the piston without special tools. The spring type shaft as also the spring tension on the stones does give a stable pressure on the chrome layer at any time at any position. If you want to do it more acurate you can use a drillpress but is is not needed.

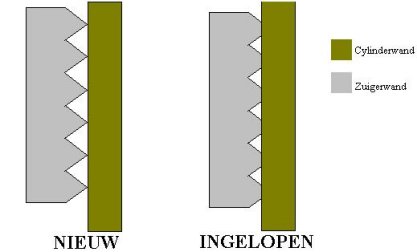

Be aware with running in the piston will always shape to the sleeve. The piston is made on a lathe so it has a kind of microscopic screwthread on it which is actually used to be polished away during running in. This thread creates a surface roughness. The speed of the lathe is determing the depth of the screwthread/roughness.

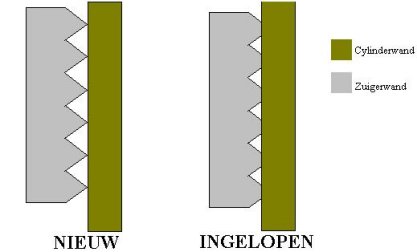

On the left a fresh P/S set (gray is the piston). on the right what happens when running in. It is essential to make an reasy start, you must not damage the fragile sharp edges of the "thread"

In the attachement a piston and a zoomed in picture where you can see the lines of the microscopic thread.

We do believe some tightness is needed because mass production with cost reduction does not create perfect shaped pistons and sleeves where the break in process will take care off.

The perfect sleeve is made with a precision grinder working on the chrome layer to make it perfect round, that together with a pistons made on slow speed with perfect sharp toolbits will make P/S sets with a loose fit creating a fast break in process without affecting the performance.

Using a hone tool like mine is more acurate than hand lapping the piston without special tools. The spring type shaft as also the spring tension on the stones does give a stable pressure on the chrome layer at any time at any position. If you want to do it more acurate you can use a drillpress but is is not needed.

Be aware with running in the piston will always shape to the sleeve. The piston is made on a lathe so it has a kind of microscopic screwthread on it which is actually used to be polished away during running in. This thread creates a surface roughness. The speed of the lathe is determing the depth of the screwthread/roughness.

On the left a fresh P/S set (gray is the piston). on the right what happens when running in. It is essential to make an reasy start, you must not damage the fragile sharp edges of the "thread"

In the attachement a piston and a zoomed in picture where you can see the lines of the microscopic thread.

We do believe some tightness is needed because mass production with cost reduction does not create perfect shaped pistons and sleeves where the break in process will take care off.

The perfect sleeve is made with a precision grinder working on the chrome layer to make it perfect round, that together with a pistons made on slow speed with perfect sharp toolbits will make P/S sets with a loose fit creating a fast break in process without affecting the performance.

#11

Good information, so it's the fine machining that is the tolerance allowed for the run it, so...

If it's too tight you will see it on a piston and your diagrams would mean there are no teeth left (cross section of spiral). Also, your hone, does it finely polish the liner? How do you prevent the same groove on liner... Or is that a secret you are keeping from, double grooved lubriicaton?

If it's too tight you will see it on a piston and your diagrams would mean there are no teeth left (cross section of spiral). Also, your hone, does it finely polish the liner? How do you prevent the same groove on liner... Or is that a secret you are keeping from, double grooved lubriicaton?

#12

Tech Apprentice

The difference between a standard and a truly hand picked engine is pretty big.

A hand picked or blueprinted engine fits together perfectly, crank goes in under it's own weight, sleeve can be removed without having to press it out using a ty-rap etc.

Hand picked engines are also much easier to break in and they last quite a bit longer.

The only truly hand picked engines I know off which are easily available to the normal racer are Orcan engines, the MH versions.

Regarding running in the engine,

A average motor can be made fast using a proper break in, or a fast motor can be made into an average or bad motor when break in isn't done properly.

Two things are the most important for break in: heat and lubrication. You need enough heat to make sure the engine breaks in on the temperature it will be raced at and you need lubrication to have a nicely polished sealing area to have the best possible seal with the least amount of friction.

I use my own method, with my self developed break in oil:

http://www.capricornrc.nl/ExportBest...20Oil&Type=pdf

Since I've been using the method listed above every single one of my engines has been a lot faster than average.

A hand picked or blueprinted engine fits together perfectly, crank goes in under it's own weight, sleeve can be removed without having to press it out using a ty-rap etc.

Hand picked engines are also much easier to break in and they last quite a bit longer.

The only truly hand picked engines I know off which are easily available to the normal racer are Orcan engines, the MH versions.

Regarding running in the engine,

A average motor can be made fast using a proper break in, or a fast motor can be made into an average or bad motor when break in isn't done properly.

Two things are the most important for break in: heat and lubrication. You need enough heat to make sure the engine breaks in on the temperature it will be raced at and you need lubrication to have a nicely polished sealing area to have the best possible seal with the least amount of friction.

I use my own method, with my self developed break in oil:

http://www.capricornrc.nl/ExportBest...20Oil&Type=pdf

Since I've been using the method listed above every single one of my engines has been a lot faster than average.

Doesn't it go too high?

#13

In a simple explenation the depth of the spiral is giving the needed tolerance for the break in, if more is needed then it will take some time because after the spiral tops are gone a huge flat surface has to be polished away.....

If not much of the tops is needed then it explaines why the engine is quickly loosing compression because the small flat surface on rest of the tops can easilly wear off.

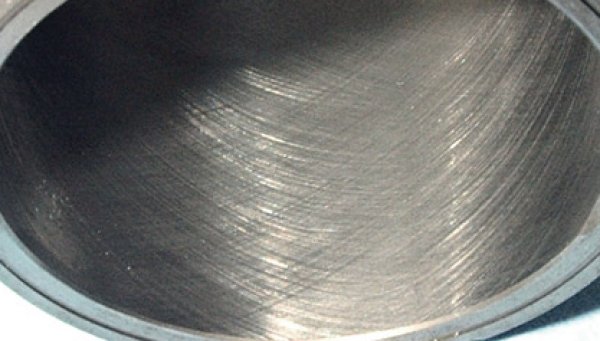

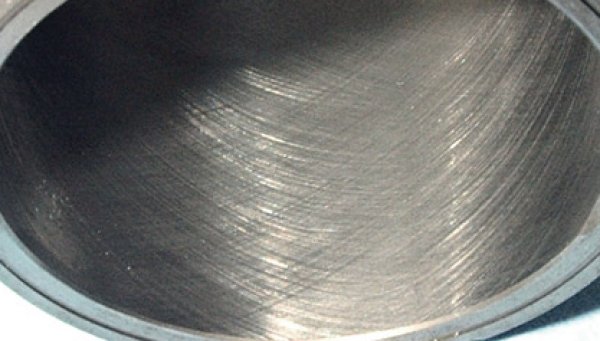

Honing is no secret, If you have a fresh P/S set you can see the crossed lines on the chrome layer. It is no polishing, it is more like grinding, it does smoothen the surface a bit but for sure no polishing.

http://en.wikipedia.org/wiki/Honing_(metalworking)

(A bit overdone but a good example how it is showed)

One of the many video's on youtube:

http://www.youtube.com/watch?v=o-mTsELG3Os

If not much of the tops is needed then it explaines why the engine is quickly loosing compression because the small flat surface on rest of the tops can easilly wear off.

Honing is no secret, If you have a fresh P/S set you can see the crossed lines on the chrome layer. It is no polishing, it is more like grinding, it does smoothen the surface a bit but for sure no polishing.

http://en.wikipedia.org/wiki/Honing_(metalworking)

A "cross-hatch" pattern is used to retain oil or grease to ensure proper lubrication and ring seal of pistons in cylinders. A smooth glazed cylinder wall can cause piston ring and cylinder scuffing. The "cross-hatch" pattern is used on brake rotors, and flywheels.

(A bit overdone but a good example how it is showed)

One of the many video's on youtube:

http://www.youtube.com/watch?v=o-mTsELG3Os

Good information, so it's the fine machining that is the tolerance allowed for the run it, so...

If it's too tight you will see it on a piston and your diagrams would mean there are no teeth left (cross section of spiral). Also, your hone, does it finely polish the liner? How do you prevent the same groove on liner... Or is that a secret you are keeping from, double grooved lubriicaton?

If it's too tight you will see it on a piston and your diagrams would mean there are no teeth left (cross section of spiral). Also, your hone, does it finely polish the liner? How do you prevent the same groove on liner... Or is that a secret you are keeping from, double grooved lubriicaton?

#14

Watched the video, what a delightful character who doesnt mind getting his hands dirty

Thanks for more good info, I'd never thought of the spiral making a cross hatch like that to be useful. I watched another video that stressed the need to clean out the hatches of debris left by the hone. I guess that's a lot easier in small scale than 1:1.

Yes that all makes good sense and I've got two Novas here, one run hard and well, the other new. If I get a chance I'll do some comparisons and take pics.

Thanks for more good info, I'd never thought of the spiral making a cross hatch like that to be useful. I watched another video that stressed the need to clean out the hatches of debris left by the hone. I guess that's a lot easier in small scale than 1:1.

Yes that all makes good sense and I've got two Novas here, one run hard and well, the other new. If I get a chance I'll do some comparisons and take pics.

#15

As you can see, it is no secret. For sure with tight engines after the break-in proces it an option. With inspecting the chrome layer you will see that the scratches at TDC are almost gone.

But be aware that the cold feeling of the pinch does not tell anything about the pinch during operating temperature. When running some castor oil the gray ring between the black carbon at the side of the piston will tell how tight the piston is.

But be aware that the cold feeling of the pinch does not tell anything about the pinch during operating temperature. When running some castor oil the gray ring between the black carbon at the side of the piston will tell how tight the piston is.