My clutch

#1

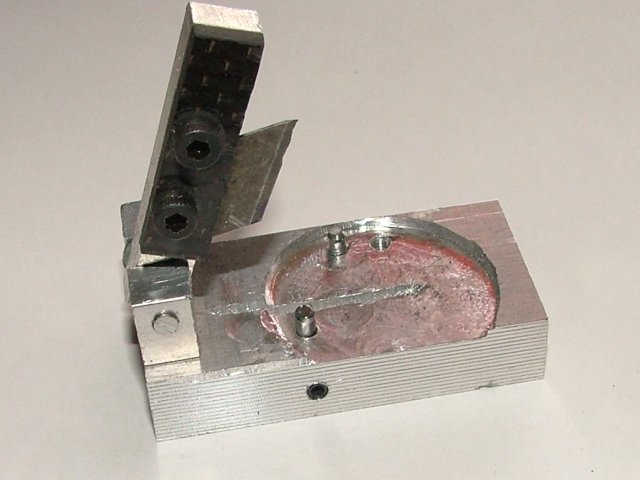

I know the new MRX5 clutch is affordable but with my own lathe it is just fun to give it a try to create one.

I have started to messure up all thickness of all the parts and imagined to take off the angled side of the flywheel and mounted it at the pressureplate. All drawed out and determed the messurements I started up the lathe with 7075 material.

The only thing to do are the 3 pins, next week I will go to a friend who has the tools to do that precisely.

The pics:

I have started to messure up all thickness of all the parts and imagined to take off the angled side of the flywheel and mounted it at the pressureplate. All drawed out and determed the messurements I started up the lathe with 7075 material.

The only thing to do are the 3 pins, next week I will go to a friend who has the tools to do that precisely.

The pics:

#2

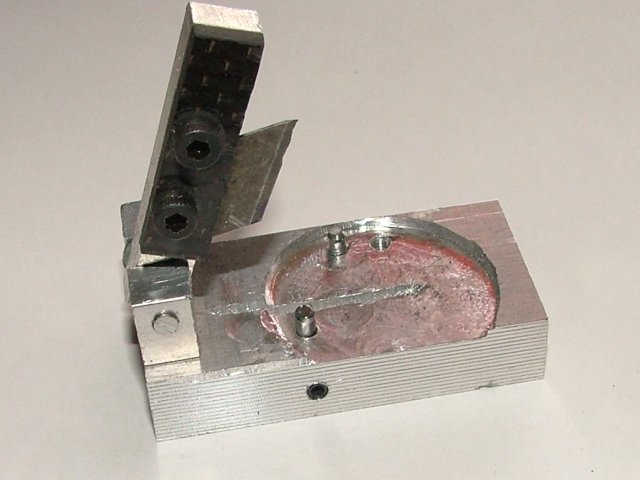

I know the new MRX5 clutch is affordable but with my own lathe it is just fun to give it a try to create one.

I have started to messure up all thickness of all the parts and imagined to take off the angled side of the flywheel and mounted it at the pressureplate. All drawed out and determed the messurements I started up the lathe with 7075 material.

The only thing to do are the 3 pins, next week I will go to a friend who has the tools to do that precisely.

The pics:

I have started to messure up all thickness of all the parts and imagined to take off the angled side of the flywheel and mounted it at the pressureplate. All drawed out and determed the messurements I started up the lathe with 7075 material.

The only thing to do are the 3 pins, next week I will go to a friend who has the tools to do that precisely.

The pics:

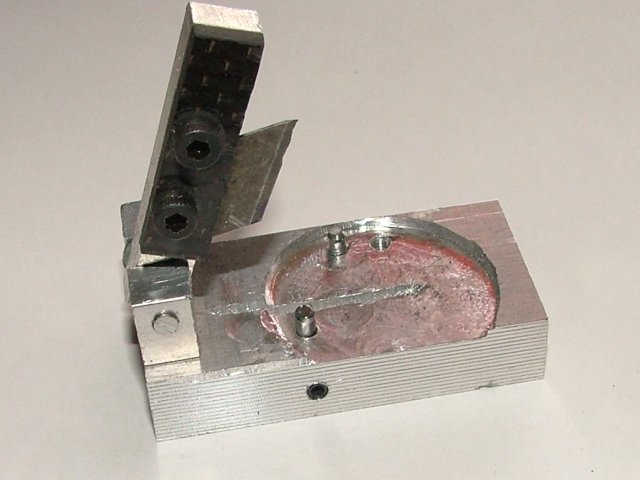

#3

Weight difference flywheel + pressure plate

Total difference clutch standard vs. my clutch and aluminoum bell (with shoes but no mounting material)

Lightened + pins

Final:

Total difference clutch standard vs. my clutch and aluminoum bell (with shoes but no mounting material)

Lightened + pins

Final:

#4

Tech Regular

#5

#6

#7

I am amazed!

Last saturday I had the time to give it a test. First I rebuilded the clutch because the 3 pins were not pressed straight so I had to bend them a tiny bit and a tip of the conus on the crankschaft was sticking out the flywheel preventing the flywheel nut to tighten the flywheel. (I know the cause so it is no issue)

I have used new ordered disc springs which can stand higher temperatures and tightened the spring nut with an half turn.

After starting the engine on the table it showed a very good engage point so without further adjusting I did put the car on the track and drove it.

I have never feeled such a smooth clutch and at the same time very agrassive when the throttle went full open !!

I am already very pleased with the result but there is more to test/play like larger gaps (I can go up to 4mm if needed) and smaller fly weights like the ones I am using on the older 4 pin clutch (also rotating over the pin)

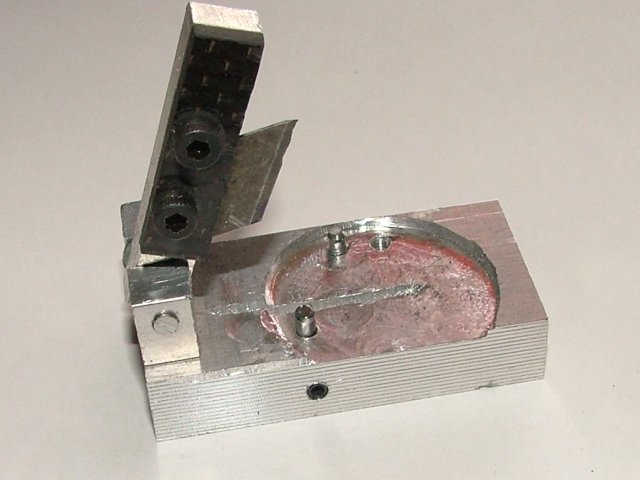

My flyweight cutter I use to cut older used shoes:

(for 3 and 4 pin setups)

Last saturday I had the time to give it a test. First I rebuilded the clutch because the 3 pins were not pressed straight so I had to bend them a tiny bit and a tip of the conus on the crankschaft was sticking out the flywheel preventing the flywheel nut to tighten the flywheel. (I know the cause so it is no issue)

I have used new ordered disc springs which can stand higher temperatures and tightened the spring nut with an half turn.

After starting the engine on the table it showed a very good engage point so without further adjusting I did put the car on the track and drove it.

I have never feeled such a smooth clutch and at the same time very agrassive when the throttle went full open !!

I am already very pleased with the result but there is more to test/play like larger gaps (I can go up to 4mm if needed) and smaller fly weights like the ones I am using on the older 4 pin clutch (also rotating over the pin)

My flyweight cutter I use to cut older used shoes:

(for 3 and 4 pin setups)

Last edited by Roelof; 11-21-2011 at 02:49 AM.

#8

I am amazed!

Last saturday I had the time to give it a test. First I rebuilded the clutch because the 3 pins were not pressed straight so I had to bend them a tiny bit and a tip of the conus on the crankschaft was sticking out the flywheel preventing the flywheel nut to tighten the flywheel. (I know the cause so it is no issue)

I have used new ordered disc springs which can stand higher temperatures and tightened the spring nut with an half turn.

After starting the engine on the table it showed a very good engage point so without further adjusting I did put the car on the track and drove it.

I have never feeled such a smooth clutch and at the same time very agrassive when the throttle went full open !!

I am already very pleased with the result but there is more to test/play like larger gaps (I can go up to 4mm if needed) and smaller fly weights like the ones I am using on the older 4 pin clutch (also rotating over the pin)

My flyweight cutter I use to cut older used shoes:

(for 3 and 4 pin setups)

Last saturday I had the time to give it a test. First I rebuilded the clutch because the 3 pins were not pressed straight so I had to bend them a tiny bit and a tip of the conus on the crankschaft was sticking out the flywheel preventing the flywheel nut to tighten the flywheel. (I know the cause so it is no issue)

I have used new ordered disc springs which can stand higher temperatures and tightened the spring nut with an half turn.

After starting the engine on the table it showed a very good engage point so without further adjusting I did put the car on the track and drove it.

I have never feeled such a smooth clutch and at the same time very agrassive when the throttle went full open !!

I am already very pleased with the result but there is more to test/play like larger gaps (I can go up to 4mm if needed) and smaller fly weights like the ones I am using on the older 4 pin clutch (also rotating over the pin)

My flyweight cutter I use to cut older used shoes:

(for 3 and 4 pin setups)

Nice work Roelof

#10

@blis

This cutter was made some years ago with less tools as I have now. It is functional and usefull to give used shoes a 2nd life.

@TomB

Well these kind of projecs are very usefull. Many drivers can only play with the equipment they can buy, creating and finding out your own stuff is cheap, does give more possibillities to make changes over the standard and for me it was also a learning proces how to use my lathe which is fun. The pressure plate is one of the things not easy to do without re-seating the part in the lathe but I did find out how to do it with a perfect re-seating.

And yes, I do love the hobby and also the sport with it, it is only a sad thing that the factories and payed drivers are loosing the hobby more and more and making things and rules more difficult for the hobby drivers.

This cutter was made some years ago with less tools as I have now. It is functional and usefull to give used shoes a 2nd life.

@TomB

Well these kind of projecs are very usefull. Many drivers can only play with the equipment they can buy, creating and finding out your own stuff is cheap, does give more possibillities to make changes over the standard and for me it was also a learning proces how to use my lathe which is fun. The pressure plate is one of the things not easy to do without re-seating the part in the lathe but I did find out how to do it with a perfect re-seating.

And yes, I do love the hobby and also the sport with it, it is only a sad thing that the factories and payed drivers are loosing the hobby more and more and making things and rules more difficult for the hobby drivers.

#11

@blis

This cutter was made some years ago with less tools as I have now. It is functional and usefull to give used shoes a 2nd life.

@TomB

Well these kind of projecs are very usefull. Many drivers can only play with the equipment they can buy, creating and finding out your own stuff is cheap, does give more possibillities to make changes over the standard and for me it was also a learning proces how to use my lathe which is fun. The pressure plate is one of the things not easy to do without re-seating the part in the lathe but I did find out how to do it with a perfect re-seating.

And yes, I do love the hobby and also the sport with it, it is only a sad thing that the factories and payed drivers are loosing the hobby more and more and making things and rules more difficult for the hobby drivers.

This cutter was made some years ago with less tools as I have now. It is functional and usefull to give used shoes a 2nd life.

@TomB

Well these kind of projecs are very usefull. Many drivers can only play with the equipment they can buy, creating and finding out your own stuff is cheap, does give more possibillities to make changes over the standard and for me it was also a learning proces how to use my lathe which is fun. The pressure plate is one of the things not easy to do without re-seating the part in the lathe but I did find out how to do it with a perfect re-seating.

And yes, I do love the hobby and also the sport with it, it is only a sad thing that the factories and payed drivers are loosing the hobby more and more and making things and rules more difficult for the hobby drivers.

So what you say about the pro racers is true. The upper echelon of racers spend more and more money (or their sponsor companies do anyway) to find speed. This attitude towards racing has a trickle down effect. You could argue that the very large majority of people on RCtech are racers who have been the recipients of this trickle down effect from the top echelon of racers.

Mix into this, the increasing accessability of information on the web, and you also have increased knowledge of the general racer. Increased knowledge breeds an attitude of pushing for quicker lap times, more professional setups etc...

all of this means that, when a racer begins in this hobby they become daunted at the cost to keep up and race with the average established guy. the new person therfore is less likely to stay in the hobby, and thus, it's the hobby that suffers in the long term as there are no new people coming in. this is very evident in Australia. The hobby has shrunken in the last 4 years, and it is a significant decrease in numbers.

On the flip side, manufacturers are increasingly trying to appeal to this newer emerged "racing market". Although there are less people racing nitro in general, those who have remained are spending more than their counterparts 5 or 6 years ago. This hobby is not growing, but those who are still here spend more. This, in the long term doesn't bode well for the hobby or manufacturers.

So what does this have to do with you, Roelof? well i think it's great that you do what you do, as it brings back the cheaper ingenuity that the hobby had a few years ago. Not everyone has a lathe, but seeing you make stuff might inspire people to try and tinker and enjoy the hobby in a cheaper way. In a metaphorical sense, people should try to enjoy the process of getting somewhere, making something, instead of the act of reaching the finish line.

#12

Started with RC far back in the 80's and started with 1/8 in 1990 I can say that I have seen much. I had the right people arround me who were into creating things instead of endless buying and I did grow up with them as me myself had already some technical sight on things.

For many years I had the wish to get my own lathe and today they can be found for very good prices and so I did get one a few months ago and I am very happy with it but until that time (and still) I can go to a friend who has also a milling machine on his lathe with all kind of tools.

This is my lathe:

http://buitelaar.nl/comasy/templates...productid=4379

I did get it with digital distance meters and some tools.

For many years I had the wish to get my own lathe and today they can be found for very good prices and so I did get one a few months ago and I am very happy with it but until that time (and still) I can go to a friend who has also a milling machine on his lathe with all kind of tools.

This is my lathe:

http://buitelaar.nl/comasy/templates...productid=4379

I did get it with digital distance meters and some tools.

#13

is it with belts or gears Roelof?

something more.have you mill the contact area of the shoe before cutting it and use it like a flywheel?

something more.have you mill the contact area of the shoe before cutting it and use it like a flywheel?

#14

btw great job!!

#15

There is no need to mill the contact area of the shoe, the yellow shoe has a small hard surface from the burning marks when used which will help in his new function.

Will the lighter flywheel slower the top speed?

Will the lighter flywheel slower the top speed?