Losi Truggy

#1501

from playing with Multiple differnt motor's and Countless clutch set-ups...ive found that every motor brand fits a little differently and needs its own shimming....1 shim behind the collet to sit the flywheel center'd in the cutout.....or couple under the 5x13 to get the "air gap" as LOW ET liked to put it.......and i have even gone as far as to use the Ofna Style bushing and shave it down to the specs needed....what ever it takes.

#1502

I've been running the last couple of races without the Front swaybar. I like the feel of it. But there are moments the front will bite too hard and the truck wants to spin. Easily correctable though. Without the front swaybar I really like how the truck reacts and behaves.

#1503

x2...i recently went down to the thin bar up front and noticed a slight difference in how the truck came off little roller's and step down's....i might try No bar next time.

#1504

i got my clutch issues fixed and my truggy is back in action  . it seems i got my top end running ok (smoke, 230*) but i think the bottom end needs a little work. should i see smoke when i hit the throttle before the truck moves? at the crack of the throttle it seems lazy until it clears out then it hauls the mail. sometimes at idle i can tap the throttle and the rpm doesn't change until it clears out, also after running it around the rpm seems to hang slightly until i blip the throttle and then it comes down to normal. any suggestions?

. it seems i got my top end running ok (smoke, 230*) but i think the bottom end needs a little work. should i see smoke when i hit the throttle before the truck moves? at the crack of the throttle it seems lazy until it clears out then it hauls the mail. sometimes at idle i can tap the throttle and the rpm doesn't change until it clears out, also after running it around the rpm seems to hang slightly until i blip the throttle and then it comes down to normal. any suggestions?

. it seems i got my top end running ok (smoke, 230*) but i think the bottom end needs a little work. should i see smoke when i hit the throttle before the truck moves? at the crack of the throttle it seems lazy until it clears out then it hauls the mail. sometimes at idle i can tap the throttle and the rpm doesn't change until it clears out, also after running it around the rpm seems to hang slightly until i blip the throttle and then it comes down to normal. any suggestions?

. it seems i got my top end running ok (smoke, 230*) but i think the bottom end needs a little work. should i see smoke when i hit the throttle before the truck moves? at the crack of the throttle it seems lazy until it clears out then it hauls the mail. sometimes at idle i can tap the throttle and the rpm doesn't change until it clears out, also after running it around the rpm seems to hang slightly until i blip the throttle and then it comes down to normal. any suggestions?

#1505

i got my clutch issues fixed and my truggy is back in action  . it seems i got my top end running ok (smoke, 230*) but i think the bottom end needs a little work. should i see smoke when i hit the throttle before the truck moves? at the crack of the throttle it seems lazy until it clears out then it hauls the mail. sometimes at idle i can tap the throttle and the rpm doesn't change until it clears out, also after running it around the rpm seems to hang slightly until i blip the throttle and then it comes down to normal. any suggestions?

. it seems i got my top end running ok (smoke, 230*) but i think the bottom end needs a little work. should i see smoke when i hit the throttle before the truck moves? at the crack of the throttle it seems lazy until it clears out then it hauls the mail. sometimes at idle i can tap the throttle and the rpm doesn't change until it clears out, also after running it around the rpm seems to hang slightly until i blip the throttle and then it comes down to normal. any suggestions?

. it seems i got my top end running ok (smoke, 230*) but i think the bottom end needs a little work. should i see smoke when i hit the throttle before the truck moves? at the crack of the throttle it seems lazy until it clears out then it hauls the mail. sometimes at idle i can tap the throttle and the rpm doesn't change until it clears out, also after running it around the rpm seems to hang slightly until i blip the throttle and then it comes down to normal. any suggestions?

. it seems i got my top end running ok (smoke, 230*) but i think the bottom end needs a little work. should i see smoke when i hit the throttle before the truck moves? at the crack of the throttle it seems lazy until it clears out then it hauls the mail. sometimes at idle i can tap the throttle and the rpm doesn't change until it clears out, also after running it around the rpm seems to hang slightly until i blip the throttle and then it comes down to normal. any suggestions?I come across many people that say something like this, "I don't know what's wrong, it was running great last weekend. I haven't changed any of the needles."

I'd suggest leaning the bottom a bit, and you might have to back out the high speed needle a little. But it's hard to say without being there and hearing your engine.

#1506

#1507

LOL. How often do you hear it? I'm sure at least once every month or two. Just guessing though.

I'm not trying to put anyone down guys. So please don't take my suggestions like that. I'm simply saying your carb WILL need adjusted each time out. And if you get lost on your settings or you don't quite understand what's going on, just back the needles out and slowly work your way back in. Make small 1/8 turns adjustments, or use the clock face hours as an adjustment. 1 hour, or 2 hour adjustments.

I'm not trying to put anyone down guys. So please don't take my suggestions like that. I'm simply saying your carb WILL need adjusted each time out. And if you get lost on your settings or you don't quite understand what's going on, just back the needles out and slowly work your way back in. Make small 1/8 turns adjustments, or use the clock face hours as an adjustment. 1 hour, or 2 hour adjustments.

#1509

http://www.osengines.com/engines/osmg2068.html

In this link the, picture shows the low speed needle closest to the camera. I would call this linkage side.

At the bottom, rear of the carb is the idle needle.

And then of course the brass guide sticking straight up is the high speed.

According to the picture in the link above, the carb would need to be facing the opposite way for 1/8 racing. Turned 180 degrees so the slide can be operated by the servo. This would put the idle needle at the front of the carb and very low. Access would become more difficult but shouldn't be an issue really.

In this link the, picture shows the low speed needle closest to the camera. I would call this linkage side.

At the bottom, rear of the carb is the idle needle.

And then of course the brass guide sticking straight up is the high speed.

According to the picture in the link above, the carb would need to be facing the opposite way for 1/8 racing. Turned 180 degrees so the slide can be operated by the servo. This would put the idle needle at the front of the carb and very low. Access would become more difficult but shouldn't be an issue really.

#1510

a good starting point for the low speed needle (linkage side as you say) is flush with the body and parallel to the chassis. You may have to go +1/-1 hour for a better tune, but i have run 3-4 specs and they all had good bottom at this general location.

Fot the mid needle (opposite of the low speed and under the high speed) yo want to go flush with the body and set it to 2 o'clock.

Fot the mid needle (opposite of the low speed and under the high speed) yo want to go flush with the body and set it to 2 o'clock.

#1512

Just got a .28 GRP mill with pipe  any suggestions for a really good starter box ? I purchased the losi one and have had nothing but problems with it. Only had it two days and one of the motors died so I replaced it, now on the third day and the other one just died. Needless to say I'm not very impressed

any suggestions for a really good starter box ? I purchased the losi one and have had nothing but problems with it. Only had it two days and one of the motors died so I replaced it, now on the third day and the other one just died. Needless to say I'm not very impressed  Just curious to know what starter boxes you guys are using?

Just curious to know what starter boxes you guys are using?

any suggestions for a really good starter box ? I purchased the losi one and have had nothing but problems with it. Only had it two days and one of the motors died so I replaced it, now on the third day and the other one just died. Needless to say I'm not very impressed

any suggestions for a really good starter box ? I purchased the losi one and have had nothing but problems with it. Only had it two days and one of the motors died so I replaced it, now on the third day and the other one just died. Needless to say I'm not very impressed  Just curious to know what starter boxes you guys are using?

Just curious to know what starter boxes you guys are using?

#1513

Just got a .28 GRP mill with pipe  any suggestions for a really good starter box ? I purchased the losi one and have had nothing but problems with it. Only had it two days and one of the motors died so I replaced it, now on the third day and the other one just died. Needless to say I'm not very impressed

any suggestions for a really good starter box ? I purchased the losi one and have had nothing but problems with it. Only had it two days and one of the motors died so I replaced it, now on the third day and the other one just died. Needless to say I'm not very impressed  Just curious to know what starter boxes you guys are using?

Just curious to know what starter boxes you guys are using?

any suggestions for a really good starter box ? I purchased the losi one and have had nothing but problems with it. Only had it two days and one of the motors died so I replaced it, now on the third day and the other one just died. Needless to say I'm not very impressed

any suggestions for a really good starter box ? I purchased the losi one and have had nothing but problems with it. Only had it two days and one of the motors died so I replaced it, now on the third day and the other one just died. Needless to say I'm not very impressed  Just curious to know what starter boxes you guys are using?

Just curious to know what starter boxes you guys are using?the losi...Modified a little.

PS that Pipe that comes with the promo pack somewhat tones down the power of that mill...try a 086 or MSR 1005 to really wake that thing up.

#1514

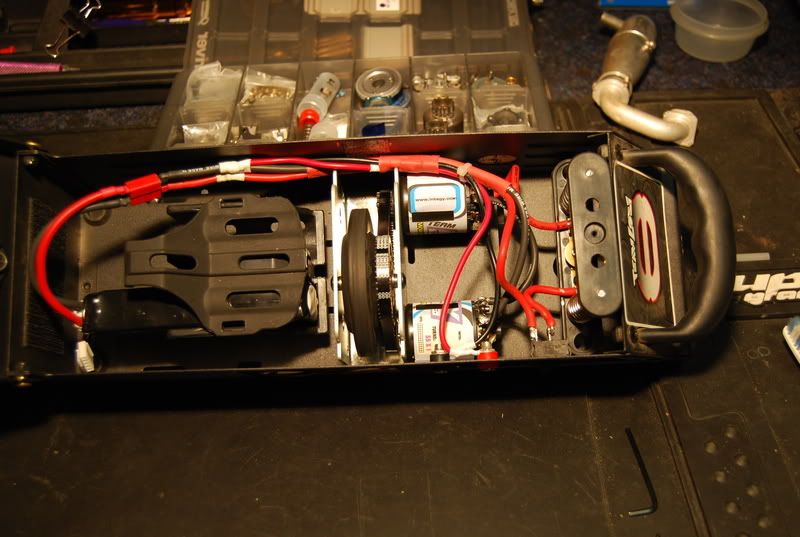

That looks pretty much what I was thinking of doing, I see you dealt with the too short wires that rub the wheel problem too ! ! What kind of motors did you put in there? Its a shame that all this work has to be done to it to make it good

#1515

i hear ya....but like anything....stock really never cuts it.

....there Integy 55's....a whopping 18$ a peice.....couple Ft of Deans and a Ebay 4 cell for around 40$.....its been workin like a Charm the last month or so since i did the swap.

....there Integy 55's....a whopping 18$ a peice.....couple Ft of Deans and a Ebay 4 cell for around 40$.....its been workin like a Charm the last month or so since i did the swap.