LOSI Micro Brushless SCT

#16

I pulled the trigger on the chassis and got the "Derlin".

I heard the Micro Rally tires will fit the SCT and they are a little bigger. Is this true? I'm thinking of picking these up since they're on sale right now.

I heard the Micro Rally tires will fit the SCT and they are a little bigger. Is this true? I'm thinking of picking these up since they're on sale right now.

#17

I pulled the trigger on the chassis and got the "Derlin".

I heard the Micro Rally tires will fit the SCT and they are a little bigger. Is this true? I'm thinking of picking these up since they're on sale right now.

I heard the Micro Rally tires will fit the SCT and they are a little bigger. Is this true? I'm thinking of picking these up since they're on sale right now.

#18

Good point about the truggy tires! So are these bigger than the stock Micro SCT tires or smaller since they are the 1/36 scale (ooops....edit, I thought it was 1/36 but it's 1/24...hmmm, very cool!)? They definitely look like they have more grip but I'm hoping to get bigger tires than what I have now.

#19

Tech Apprentice

The larger wheels/tires may require you raise and or mod the body to keep them from rubbing. This is especially true with the truggy tires. Also, unless Losi has changed something you want to avoid the white rally wheels. The D shaped hole in the wheel strips easily.

#20

Hey Dialed-In and anyone else that can help...

I bought the Derlin chassis and made to use the stock Micro SCT servo but it was fitting without causing it to rub and stress the servo. It doesn't turn freely. It seems to turn to one side faster than the other and you can hear the stressed servo.

Or do I just need a stronger servo with more torque?

Below is a link to a video. Hope anyone can help as this has been a big pain to mod. The servo didn't fit like it should and the servo horn is nearly popping out of the mount when it turns to the left. ARG!!!!

Let me know if the video link works...

Video...

I bought the Derlin chassis and made to use the stock Micro SCT servo but it was fitting without causing it to rub and stress the servo. It doesn't turn freely. It seems to turn to one side faster than the other and you can hear the stressed servo.

Or do I just need a stronger servo with more torque?

Below is a link to a video. Hope anyone can help as this has been a big pain to mod. The servo didn't fit like it should and the servo horn is nearly popping out of the mount when it turns to the left. ARG!!!!

Let me know if the video link works...

Video...

Last edited by Nickerz; 08-19-2015 at 06:00 PM. Reason: Fixed Video Link (Photobucket Is Horrible...I Used Youtube, Worked Perfectly!)

#21

Tech Apprentice

I don't see your video.

The servo might take a little work to get right. I had to remove and re-align the servo horn. I also had to raise the servo a bit so the horn wasn't pushing down on the steering link when the horn was at its lowest position.

Here is how I realigned the horn. Start with the 2nd pic.

http://www.microtforum.com/viewtopic...151980#p151980

If your upper or lower chassis' plates are grooved for the servo to fit you might not be able to raise it up if it needs it.

The servo might take a little work to get right. I had to remove and re-align the servo horn. I also had to raise the servo a bit so the horn wasn't pushing down on the steering link when the horn was at its lowest position.

Here is how I realigned the horn. Start with the 2nd pic.

http://www.microtforum.com/viewtopic...151980#p151980

If your upper or lower chassis' plates are grooved for the servo to fit you might not be able to raise it up if it needs it.

#22

I don't see your video.

The servo might take a little work to get right. I had to remove and re-align the servo horn. I also had to raise the servo a bit so the horn wasn't pushing down on the steering link when the horn was at its lowest position.

Here is how I realigned the horn. Start with the 2nd pic.

http://www.microtforum.com/viewtopic...151980#p151980

If your upper or lower chassis' plates are grooved for the servo to fit you might not be able to raise it up if it needs it.

The servo might take a little work to get right. I had to remove and re-align the servo horn. I also had to raise the servo a bit so the horn wasn't pushing down on the steering link when the horn was at its lowest position.

Here is how I realigned the horn. Start with the 2nd pic.

http://www.microtforum.com/viewtopic...151980#p151980

If your upper or lower chassis' plates are grooved for the servo to fit you might not be able to raise it up if it needs it.

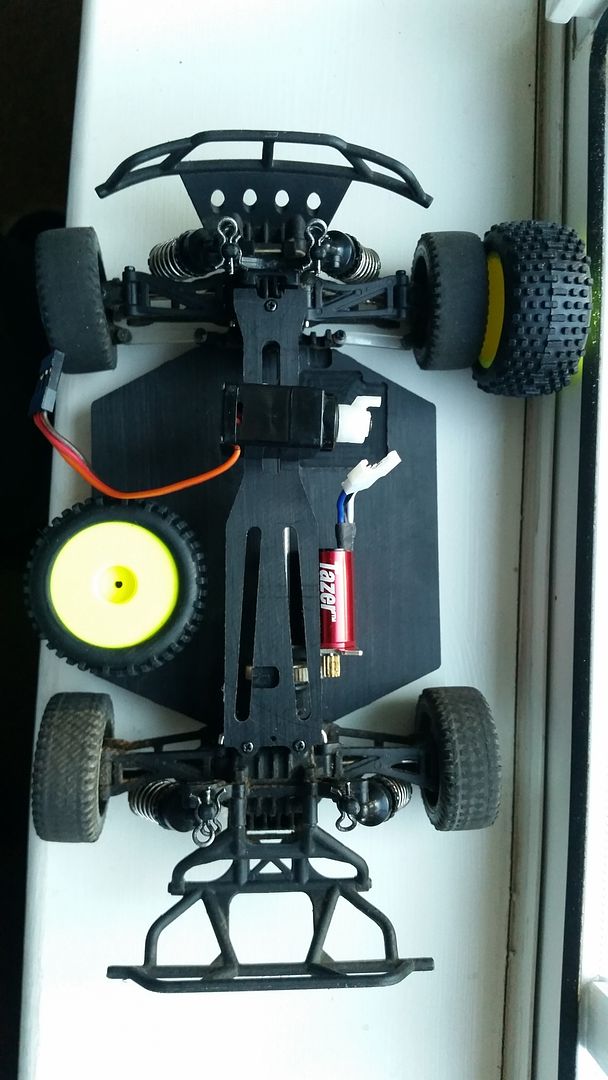

After some mods to the servo horn (I cut the plastic bar down), it still doesn't turn freely as you can hopefully now see in the video. The maker of the Derlin chassis emailed me today offering a full refund (which was nice) or an upgraded chassis that is supposed to fit the stock servo. Problem is, I don't know if my cutting down the servo horn will still work on his "upgraded" chassis. Also, his chassis would require trimming to fit the Truggy tires and allow them to turn. (See pic below)...

So now I'm thinking if I should get the Druonu chassis since the truggy tires will have no issue fitting (according to his pics he's got even bigger tires ("HSP MT 24 Wheels and tires, custom foams and truggy wheels and tires") http://www.rctech.net/forum/attachme..._093844-1-.jpg plus the bellcrank steering should be more accurate.

Also, did you notice the servo wire in the pic? I took off the case, cut a small hole and re-directed the wire so the servo can lay horizontally! Maybe I should fill the old hole so dirt, water, etc. can't get in.

Dialed in...will the bellcrank streering setup work with my stock servo? Or do I need to buy a new servo? If so, this is getting expensive - lol! You wanna sell me your chassis?

Last edited by Nickerz; 08-19-2015 at 06:50 PM. Reason: added another pic...

#23

Tech Apprentice

The stock servo isn't that great. A $3 Hextronik HXT500 servo from China will be faster and stronger. Someone is actually selling them on ebay for $5.59. The only thing is you have to make your own horn or adapt the Losi servo saver to work on the new servo. You really don't need a saver on a $3 servo. 5 and 6 in the post shows several methods to accomplish this. http://www.microtforum.com/viewtopic.php?f=45&t=21711

You know how you said the horn almost pops out in one direction. It's because the U-shape in the steering rack is lower on one side. I was actually going to build mine up on the low side but realigning the top gear of the servo helped. Did you realign the top gear like in the link in my last post? Also, when it almost pops out and you you happen to hit something or the front tire digs in the horn will pop out.

On your current chassis. If you straighten the front wheels, put the servo in the cut out does the center of the saver screw align perfectly with the steering rack groove? It looks like it does. Does the servo just need shimmed up or down? Would it help to build up the one side of the steering rack? Also, when you are testing it helps to hold the servo perfectly still. For permanent mount servo tape with a bead of hot glue along the sides should hold it still and still make it easy to remove.

Your goal should be to align the horn so it has the same throw in both directions when laying on the side it will be mounted. When the horn is at it's lowest point in the rack it shouldn't be pushing down on the rack. Shim up or down a hair to make it perfect.

A bellcrank setup will be superior in every way. The only downsides are the cost and you have to hunt down the bearings and parts for ball steering links.

The servo wire looks good. A little bit of silicone or rtv sealant in the hole should keep any dirt out.

You know how you said the horn almost pops out in one direction. It's because the U-shape in the steering rack is lower on one side. I was actually going to build mine up on the low side but realigning the top gear of the servo helped. Did you realign the top gear like in the link in my last post? Also, when it almost pops out and you you happen to hit something or the front tire digs in the horn will pop out.

On your current chassis. If you straighten the front wheels, put the servo in the cut out does the center of the saver screw align perfectly with the steering rack groove? It looks like it does. Does the servo just need shimmed up or down? Would it help to build up the one side of the steering rack? Also, when you are testing it helps to hold the servo perfectly still. For permanent mount servo tape with a bead of hot glue along the sides should hold it still and still make it easy to remove.

Your goal should be to align the horn so it has the same throw in both directions when laying on the side it will be mounted. When the horn is at it's lowest point in the rack it shouldn't be pushing down on the rack. Shim up or down a hair to make it perfect.

A bellcrank setup will be superior in every way. The only downsides are the cost and you have to hunt down the bearings and parts for ball steering links.

The servo wire looks good. A little bit of silicone or rtv sealant in the hole should keep any dirt out.