Motiv RC

|

|||

#166

I talked with Paul today, he mentioned that the fit is supposed to be tight in order to keep the bearings lined up perfectly. He seemed to be aware of the tool Vex made. He didn't really have any feedback on it at this time though. He recommended backing off the countersunk screw 3 turns and sliding the plate out, then adjusting the timing.

#167

Hello my friends!!!

THanks for the plug adam b. your shirts should be with you soon enough

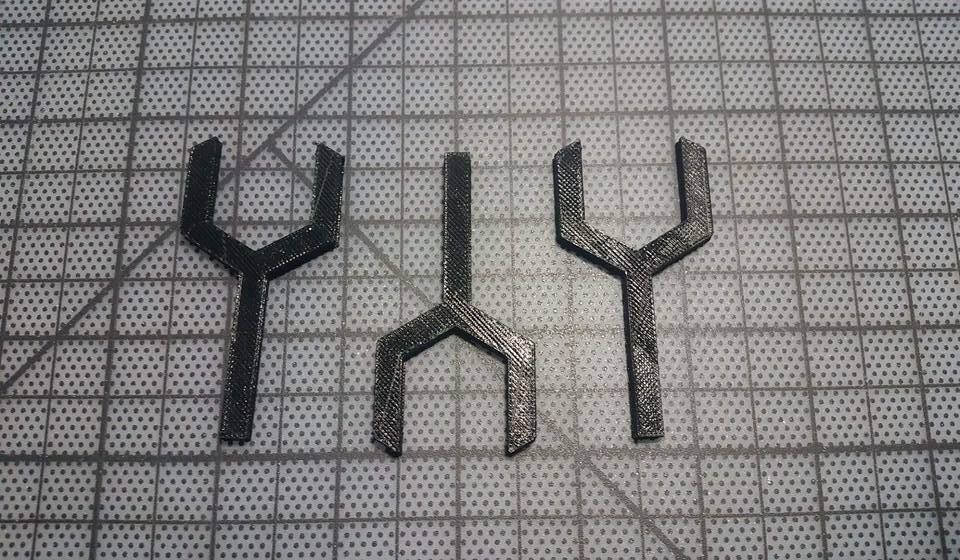

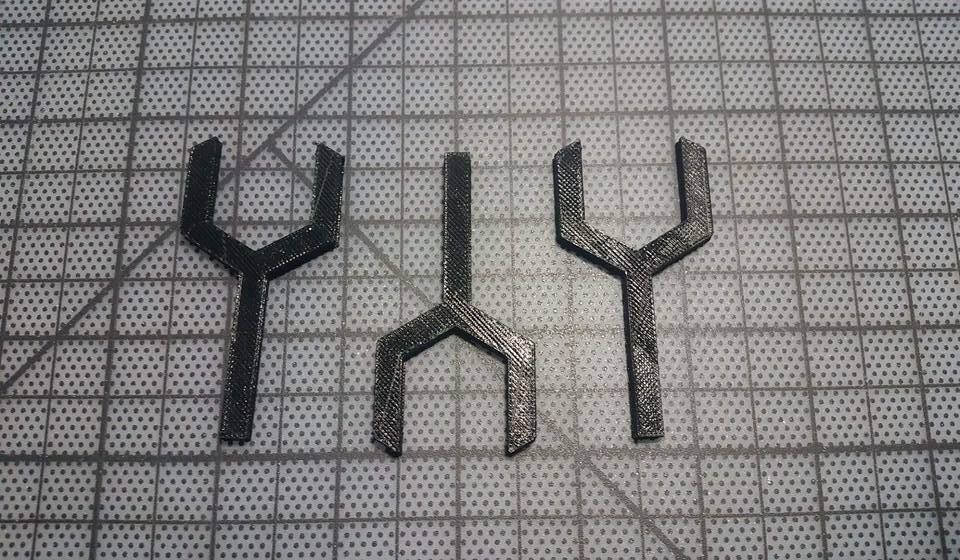

As for the tool, its simple tool that was actually Courtney Townend's idea. I was done to help simplify making minute changes to the motors timing. in his own words...

Anyways here are some pics of the tool as well as a link to the download site for those who have access to a 3d printer. To the Motiv crew, you can go ahead and take this design and make changes, reprint, sell, or even give away to your customers if you chooses to do so.

Enjoy my friends

and download link : http://www.thingiverse.com/thing:1423431

THanks for the plug adam b. your shirts should be with you soon enough

As for the tool, its simple tool that was actually Courtney Townend's idea. I was done to help simplify making minute changes to the motors timing. in his own words...

""i have noticed that the difference between 45 and 55 is very small when setting timing... with vex help this little doo dad should make setting small timing changes less challenging. basically a motiv timing wrench" - CJ Townend"

Enjoy my friends

and download link : http://www.thingiverse.com/thing:1423431

#168

Great job Coach&Vex... Nice tool..... See you guys soon....

#169

Hey Vex & CJ, I shared this with Paul and he appreciates your work and the kind offer. So on behalf of Paul and everyone with Motiv, thank you!

#172

Just want to say that I'm impessed with how smooth the power is with these motors and their ability to handle big pinions. Ran my 13.5 motor at 50 degrees and 3.9 ratio on a very large outdoor track and had the sme times as my best R1 ultra premium. However the sensor assemblies are just shit IMO. We had 2 out of 3 motors have sensors go bad at a big meet this weekend gone. Motors did not get above 60c or have any big accidents to shunt the motors. The screws holding the sensor assembly are also very poor as one is stripped after adjusting the timing only once. Using a mip driver with very little pressure it stripped and my motor is now suitable for the bin as I can't get it open. $150aud paper weights suck. As good as they seem I'll be selling my spare motor ASAP to buy something else!

#173

Tech Fanatic

I've been running a 17.5 D4ss for the last year in tc stock, but am looking for something with smoother power delivery. The D4ss feels like an on/off switch. A local racer is selling a Motiv 17.5 with the mid strength rotor installed. My next race is on a 60'x80' indoor carpet track at a club that typically runs open flowing layouts. Will the mid rotor be of any use on this layout, or should I order a high strength torque rotor?

Also looking for suggestions for a starting point for fdr and timing.

Thanks!

Also looking for suggestions for a starting point for fdr and timing.

Thanks!

#174

I've been running a 17.5 D4ss for the last year in tc stock, but am looking for something with smoother power delivery. The D4ss feels like an on/off switch. A local racer is selling a Motiv 17.5 with the mid strength rotor installed. My next race is on a 60'x80' indoor carpet track at a club that typically runs open flowing layouts. Will the mid rotor be of any use on this layout, or should I order a high strength torque rotor?

Also looking for suggestions for a starting point for fdr and timing.

Thanks!

Also looking for suggestions for a starting point for fdr and timing.

Thanks!

That being said the mid rotor still works great in stock touring. Usually set the timing from 45-47 with a motor checker or leave it where it was set from the factory and adjust gearing Accordingly.

#175

Just want to say that I'm impessed with how smooth the power is with these motors and their ability to handle big pinions. Ran my 13.5 motor at 50 degrees and 3.9 ratio on a very large outdoor track and had the sme times as my best R1 ultra premium. However the sensor assemblies are just shit IMO. We had 2 out of 3 motors have sensors go bad at a big meet this weekend gone. Motors did not get above 60c or have any big accidents to shunt the motors. The screws holding the sensor assembly are also very poor as one is stripped after adjusting the timing only once. Using a mip driver with very little pressure it stripped and my motor is now suitable for the bin as I can't get it open. $150aud paper weights suck. As good as they seem I'll be selling my spare motor ASAP to buy something else!

#176

Tech Adept

iTrader: (1)

Just want to say that I'm impessed with how smooth the power is with these motors and their ability to handle big pinions. Ran my 13.5 motor at 50 degrees and 3.9 ratio on a very large outdoor track and had the sme times as my best R1 ultra premium. However the sensor assemblies are just shit IMO. We had 2 out of 3 motors have sensors go bad at a big meet this weekend gone. Motors did not get above 60c or have any big accidents to shunt the motors. The screws holding the sensor assembly are also very poor as one is stripped after adjusting the timing only once. Using a mip driver with very little pressure it stripped and my motor is now suitable for the bin as I can't get it open. $150aud paper weights suck. As good as they seem I'll be selling my spare motor ASAP to buy something else!

Just drill it out pops head right off boom good as new

#177

Tech Regular

iTrader: (19)

I am surprised that you are having these issues with the motor, I personally have run 7 of them in various turns and have had no problems with the sensor boards. If there is an issue with sensor board variance contact your dealer or motiv RC direct and they should take care of you. As for the sensor board screws stripping that seems extremely odd. I know the first batch of motors the adjustment was really stiff but I haven't had any issues with the screws stripping. If you can get your hands on one try using an mip driver. Also the motors usually come at a good spot for timing so just throw it in the car and gear accordingly.

#178

I have not had any sensor related issues in any of my motors, and I have ran dozens of them. That said, if you contact Motiv RC (phone number is on the homepage of there website...top left corner), they will be sure to help you out in whatever way they can!

Thanks!

Thanks!

#179

Running a heatsink and it's comming off at 148 (ish) after a 6 minute heat. Indoor carpet.in

#180

I've been running a 17.5 D4ss for the last year in tc stock, but am looking for something with smoother power delivery. The D4ss feels like an on/off switch. A local racer is selling a Motiv 17.5 with the mid strength rotor installed. My next race is on a 60'x80' indoor carpet track at a club that typically runs open flowing layouts. Will the mid rotor be of any use on this layout, or should I order a high strength torque rotor?

Also looking for suggestions for a starting point for fdr and timing.

Thanks!

Also looking for suggestions for a starting point for fdr and timing.

Thanks!

I would agree with Alex. That said, I think a high rotor is your best option for carpet tracks, particularly of the size you mention, but a mid rotor would be more than fine. I have used both and prefer the bit of extra torque the HT gives coming out of the corner. I prefer the HT rotor in all carpet applications as my default.

240Likes

240Likes