Project: Team Associated TC9

#1

Team Kassanova presents...

Project: Team Associated TC9

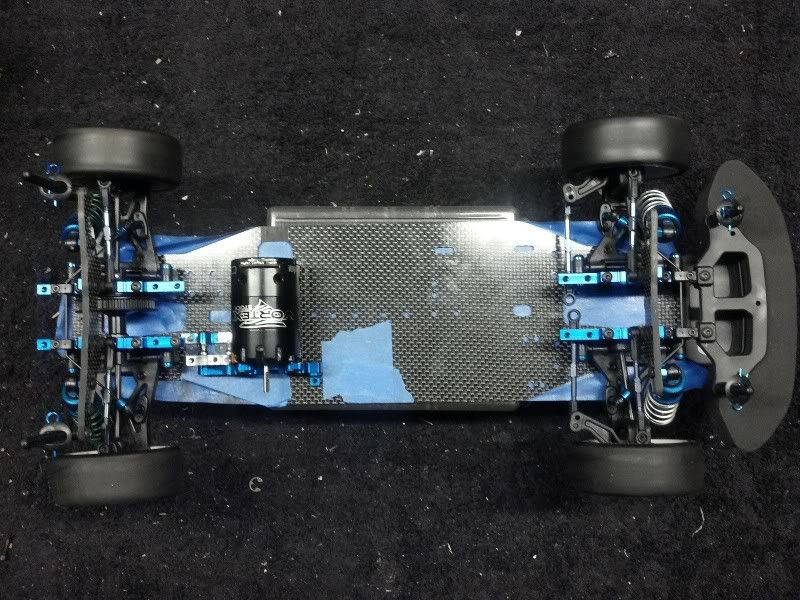

As you guys look through this thread you will see I have changed my design from a Two-belt and a shaft design, to a single belt design with centralized motor and battery , to a single belt or dual belt design with a centralized motor, and an offset shorty lipo. These types of revisions come naturally in the design process and more changes will probably come. But, I believe all changes are for the better and are steps towards creating a better design.

As many of us look into the touring car market we see many 1/10th touring cars which look very similar to each other. Small differences in the suspension , materials, and brand names make them different ,but the general electronic layout is the same. Of course there are a couple of exceptions to this such as the Team Losi JRX-S, Awesomatix A700, and the Team Magic E4. But, for the most part 1/10th electric touring cars has become a cookie cutter class.

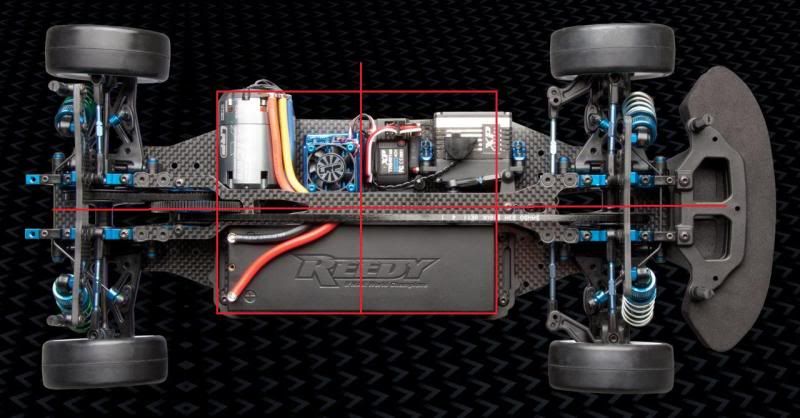

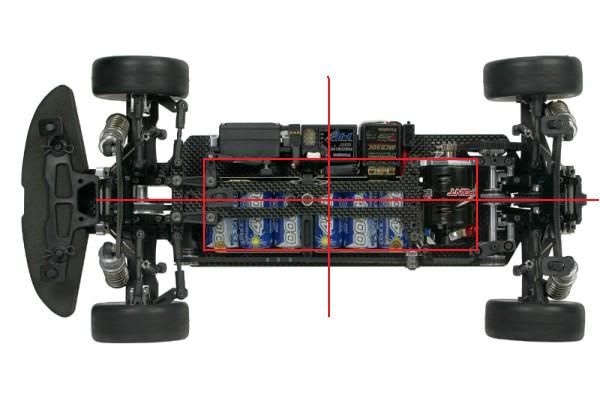

The popular modern layout used on a touring car is well balanced and is proven to be a great layout. But the two heaviest components on the car, the battery and the motor, aren't near the center of the car wither it be in the X direction or in the Y direction. This layout was designed around a standard nimh/nicd/lipo stick battery and works well with those batteries. With the emergence of the new "shorty" style battery packs I believe that touring car layouts can be optimized to better the balance..and inertia of the car.

And so I have decided to build a conversion kit for the Team Associated TC6 that is designed around the new shorty battery packs. The conversion will centralize the motor and move the battery closer to the center of the car. With more centralized weight the car should be able transition in between turns faster and easier and also be able to carry more corner speed.

The drive train will have the ability to switch between a one-belt system (preferred for modified motors or low traction) or a two-belt system (preferred for stock motors or high traction) while keeping the motor and battery centralized. This has been done before with the Kawada and the Kyosho Kx-One.. but those cars were designed for regular stick nimh packs.. and their suspension systems are outdated. Originally I was going to use two-belts (one in the front and one in the rear) and a shaft to connect the two..but I believe this would make the drive train two complicated and would yield inefficiency.

Once I complete the car I hope to compare its performance to a normal TC6 and get the opinions of local racers to see if they feel it performs better. If everything goes as planned my hope is to debut it at IIC in 2012.

I started off buy picking up a brand new Team Associated TC6. This is my first kit and so I was very excited to put it together. I usually buy used rollers but I figured I would be using this car for awhile so I should start new.

Some features I hope to implement into this car:

- Utilization of a single belt or dual belt

- Centralized motor

- Battery moved towards the center 10mm

- ROAR LEGAL

- Perfect balance left/right and front/rear

- Allowance to use "Shorty" lipo batteries

- Use of the stock chassis instead of a custom chassis

- Side loading battery

- Stock Tc6 steering system

- Partial channel in the chassis instead of a full channel

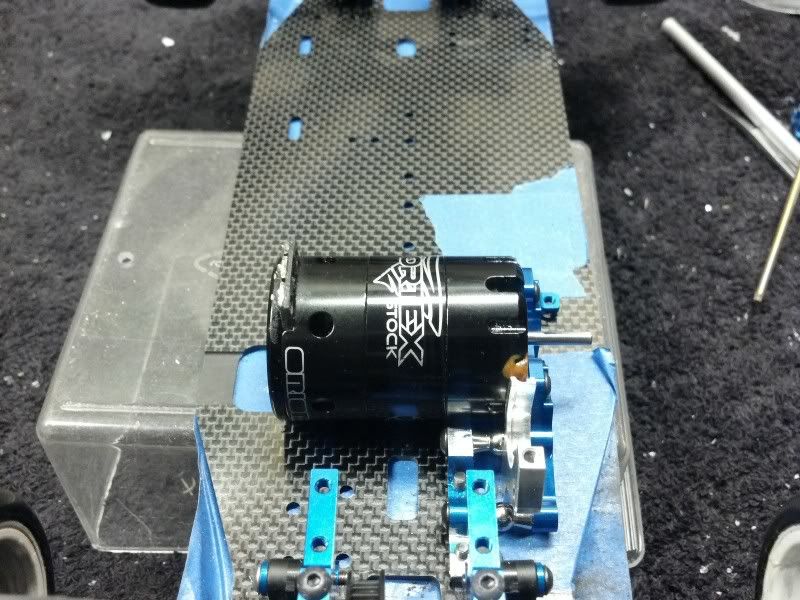

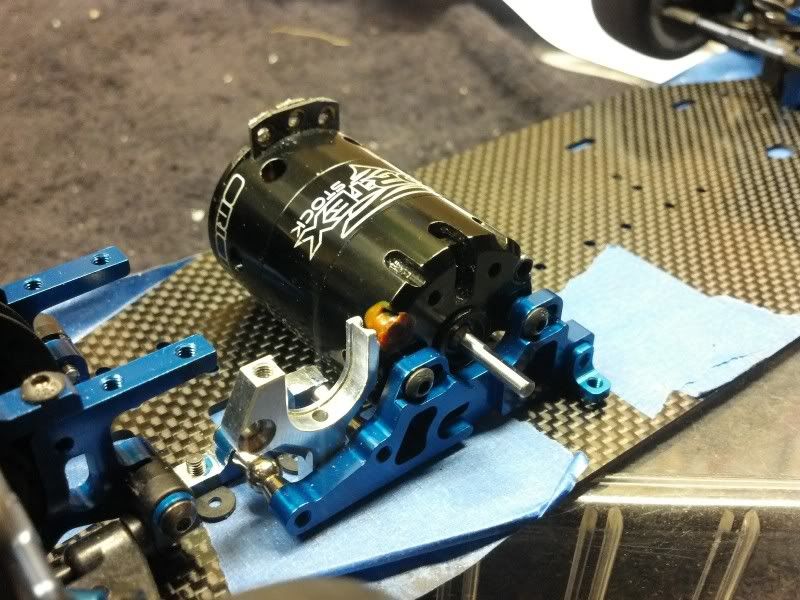

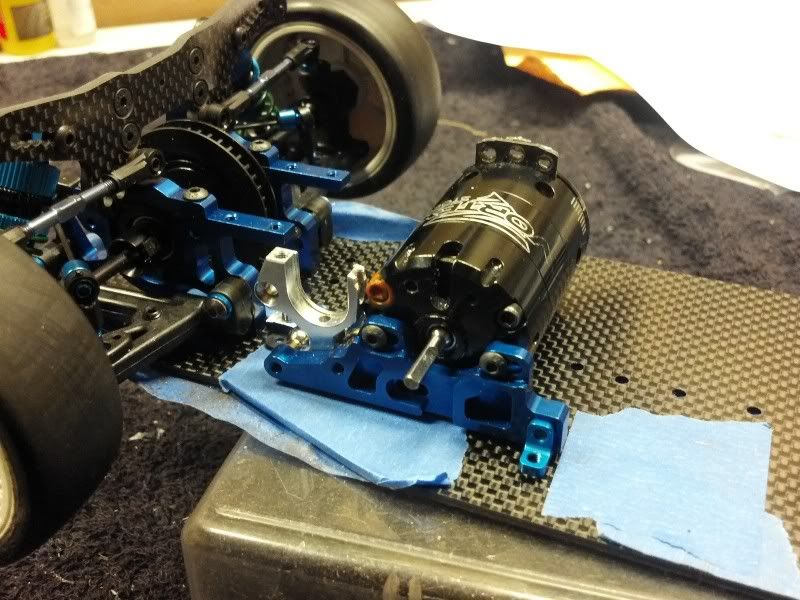

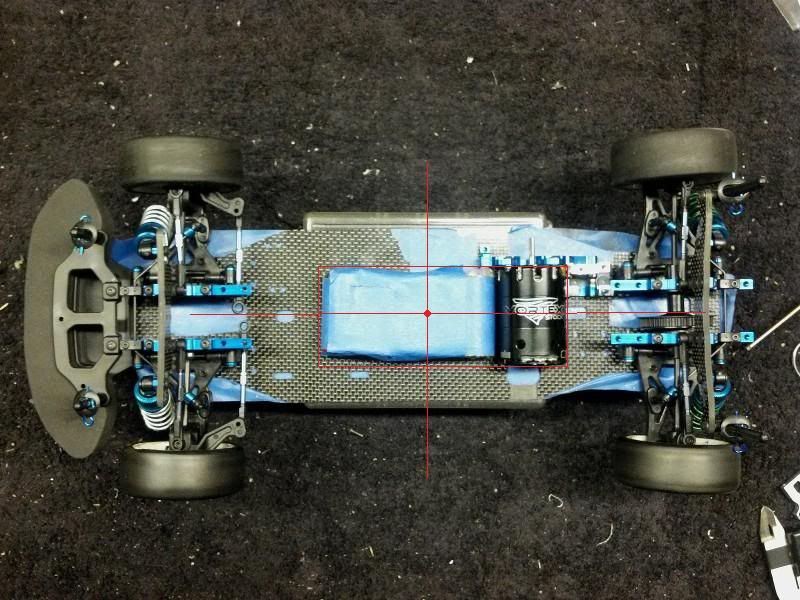

I enjoyed building most of the kit. After I finished, I noticed that I could very easily make a few modifications in order to mount the motor in the center of the chassis. Luckily, I was able to use the stock motor mount. (One last hole needs to be drilled for the motor mount support) I also modified a Team Magic E4 aluminum piece used to support the rear pulley shaft. I still have to modify the aluminum support that goes other side of the motor.

Look for updates soon

Ethan

Last edited by eds24; 01-11-2012 at 12:58 AM.

#2

tc6 has a pretty good left/right weight balance out of the box, so this seems like a waste of a good tc6. THOUGH. i cant fault you, as if i had a spare car around id prob do something similar. ie, my one day to be, nitro tc5 lol.

seems to me the least amount of work for you is to copy the team magic design and transplant as much of the drivetrain to your tc6. you will have to make a layshaft support for the other side, but id just use a e4 layshaft, pully set, side belt and front pully set. much easier than trying to make stuff.

I also hope you have an idea of how you plan to do the steering.

looks to me like your motor will be too far forward to accomodate the battery. unless you start cutting the front bulkheads to make room, and does your top deck fit over the motor without spacers?

seems to me the least amount of work for you is to copy the team magic design and transplant as much of the drivetrain to your tc6. you will have to make a layshaft support for the other side, but id just use a e4 layshaft, pully set, side belt and front pully set. much easier than trying to make stuff.

I also hope you have an idea of how you plan to do the steering.

looks to me like your motor will be too far forward to accomodate the battery. unless you start cutting the front bulkheads to make room, and does your top deck fit over the motor without spacers?

#3

Tech Adept

Nice Project !

My Club Mate, Marcel Geiger (also known for his excellent Chassis as MacGeiger or GTech, completed the same project based on the Hot Bodies TCX and run it succesfull to the B-main at the ETS Opening race in Germany a couple weeks back. Check the gallery on the ETS Home page for pictures

My Club Mate, Marcel Geiger (also known for his excellent Chassis as MacGeiger or GTech, completed the same project based on the Hot Bodies TCX and run it succesfull to the B-main at the ETS Opening race in Germany a couple weeks back. Check the gallery on the ETS Home page for pictures

#4

Nice project.

The brushless motors put their centre of mass a long way out in the current car designs, so I feel it is worth investigating the central motor layout again.

Unfortunately, despite the advantages in side-to-side weight distribution, the central-motor-inline-pack layouts of the past have always been perceived as a failure - HPI Pro3, Losi JRX-S, Team Magic E4 - so I don't know whether the new generation of prototypes and the Tamiya TA-06 will manage to convince people otherwise.

Unless they win a worlds, of course...

The brushless motors put their centre of mass a long way out in the current car designs, so I feel it is worth investigating the central motor layout again.

Unfortunately, despite the advantages in side-to-side weight distribution, the central-motor-inline-pack layouts of the past have always been perceived as a failure - HPI Pro3, Losi JRX-S, Team Magic E4 - so I don't know whether the new generation of prototypes and the Tamiya TA-06 will manage to convince people otherwise.

Unless they win a worlds, of course...

#5

Tech Adept

Nice project.

Keep going...

Attached photo of another car in other design........for your interest.

Keep going...

Attached photo of another car in other design........for your interest.

#6

Smart use of the shorty pack widthways to keep the weight narrow and well distributed.

#7

tc6 has a pretty good left/right weight balance out of the box, so this seems like a waste of a good tc6. THOUGH. i cant fault you, as if i had a spare car around id prob do something similar. ie, my one day to be, nitro tc5 lol.

seems to me the least amount of work for you is to copy the team magic design and transplant as much of the drivetrain to your tc6. you will have to make a layshaft support for the other side, but id just use a e4 layshaft, pully set, side belt and front pully set. much easier than trying to make stuff.

I also hope you have an idea of how you plan to do the steering.

looks to me like your motor will be too far forward to accomodate the battery. unless you start cutting the front bulkheads to make room, and does your top deck fit over the motor without spacers?

seems to me the least amount of work for you is to copy the team magic design and transplant as much of the drivetrain to your tc6. you will have to make a layshaft support for the other side, but id just use a e4 layshaft, pully set, side belt and front pully set. much easier than trying to make stuff.

I also hope you have an idea of how you plan to do the steering.

looks to me like your motor will be too far forward to accomodate the battery. unless you start cutting the front bulkheads to make room, and does your top deck fit over the motor without spacers?

As a general rule of thumb you want the heaviest components of the car as close to the center of the car as you can get in BOTH the x direction and the y direction (looking at the car from the side). The more compact the battery and motor are and the shorter the length of the two combined in the x-direction and the closer these components are to the center of the chassis the faster the car will rotate in the turns. The closer the battery and the motor are to the center of the car in the Y-direction the better as this will also allow for a quicker rotating car in the turns. Both of these items put together will allow the car to carry more corner speed and change directions quicker.

The TC6's motor and battery are compressed in a small package in the X direction but are spread out and far from the center in the Y direction. By centralizing the motor and battery theoretically the car will handle better and carry more corner speed and will be easier to maneuver around the turns. That's the whole reason of this project..to create a better handling car. If I can improve the handling of the TC6 then I don't think its a waste of a TC6 at all.

As far as useing components from the E4.. I will be using another E4 lay shaft on the other side. Unfortunately.. I cannot use the E4 lay-shaft, pulley, belt, etc. You'll see why later. I do have a plan for the steering.

Remember I'm using a short 95mm long lipo battery.. not a full 140mm long lipo battery..so there is plenty of room for the battery with how far the motor is forward. The top deck won't fit over the motor and so of putting spacers under it and raising the cog I will be making a custom upper chassis to fit around the motor.

Nice Project !

My Club Mate, Marcel Geiger (also known for his excellent Chassis as MacGeiger or GTech, completed the same project based on the Hot Bodies TCX and run it succesfull to the B-main at the ETS Opening race in Germany a couple weeks back. Check the gallery on the ETS Home page for pictures

My Club Mate, Marcel Geiger (also known for his excellent Chassis as MacGeiger or GTech, completed the same project based on the Hot Bodies TCX and run it succesfull to the B-main at the ETS Opening race in Germany a couple weeks back. Check the gallery on the ETS Home page for pictures

Nice project.

The brushless motors put their centre of mass a long way out in the current car designs, so I feel it is worth investigating the central motor layout again.

Unfortunately, despite the advantages in side-to-side weight distribution, the central-motor-inline-pack layouts of the past have always been perceived as a failure - HPI Pro3, Losi JRX-S, Team Magic E4 - so I don't know whether the new generation of prototypes and the Tamiya TA-06 will manage to convince people otherwise.

Unless they win a worlds, of course...

The brushless motors put their centre of mass a long way out in the current car designs, so I feel it is worth investigating the central motor layout again.

Unfortunately, despite the advantages in side-to-side weight distribution, the central-motor-inline-pack layouts of the past have always been perceived as a failure - HPI Pro3, Losi JRX-S, Team Magic E4 - so I don't know whether the new generation of prototypes and the Tamiya TA-06 will manage to convince people otherwise.

Unless they win a worlds, of course...

As far as the cars which have had centralized batteries and motors in the past...

The Losi JRX-S decided to use two-belts , but how they layed everything out it caused the a-arms to be very short..which I have heard had a negative effect.

I have heard numerous things about the E4.. but part of it was that it uses 3 belts and the battery is bottom loaded.

Not sure why the Pro 3 wasn't popular other than the the reason stated below..

The problem with ALL three of these cars and even the TA06 is they were designed with a full size battery in mind. The centralized layout in these cars with a full size battery spreads out the weight of the battery and motor on the x-axis... this makes it more difficult for the car to turn and transition. Unfortunately, its not as simple as sticking a short lipo in one of those cars though that would help. Since they all had to fit the long batteries in them they had to push the motor back.. I believe that if you put a shorty battery in one of those cars it would be harder to balance front and rear.

I have to agree though..until a centralized car wins races people will want to stick with the normal layout.

Here are some pictures to help explain what I was saying about how if the heaviest components on the car are compact in the x direction and close to the center of the car in the y direction then the car will rotate quicker...

(Sorry I haven't order my shorty lipos yet so I'm just using a mock battery for demonstration purposes.

As you can see the rectangle is by far the smallest on the TC9

I hope that helps with you guys trying to wrap your head around why I'm doing this and why using a shorty lipo makes the world of difference with a centralized motor and battery.

Last edited by eds24; 11-20-2011 at 09:13 PM.

#9

i didnt actually see that you planned to use the shorty batteries. are you leaving enough room to fit a full size one per roar rules?

if not, id be curious to see the servo placed in the extra spare the battery isnt taking up.

ill keep an eye on your thread though. i want to convert my tc5 to nitro sometime for fun, so how you get this to work will simplify my project too ha.

if not, id be curious to see the servo placed in the extra spare the battery isnt taking up.

ill keep an eye on your thread though. i want to convert my tc5 to nitro sometime for fun, so how you get this to work will simplify my project too ha.

#10

A couple things to think about.

1. The car doesn't have to be raceable with a standard pack, it just has to fit without modifications. If you can stick it in crosswise, it would be legal and you wouldn't have to actually run it like that.

2. One small problem with a motor mount bolted to the chassis way off to one side (to center the motor) is that it could create an asymmetric flex. You might want to keep that in mind in the design as there are ways to work around it.

1. The car doesn't have to be raceable with a standard pack, it just has to fit without modifications. If you can stick it in crosswise, it would be legal and you wouldn't have to actually run it like that.

2. One small problem with a motor mount bolted to the chassis way off to one side (to center the motor) is that it could create an asymmetric flex. You might want to keep that in mind in the design as there are ways to work around it.

#13

Tech Regular

Interesting project. I run a TC6 and it's a fast and good to drive car, but I'm going to follow this project purely to see new ideas on (already) a good chassis.

#14

This is something I have talked about with some of my friends, and maybe it's a dumb idea, but what about an FK04 or 414MII with proper modern suspension on it? I have a hard time believing that the layshaft being high is a huge disadvantage. With lipos, you could use a shorty battery and still remain legal by claiming it is a "saddle pack" or "transverse mounted stick" car. The chassis could even be pretty narrow...

Obviously it may require moving the motor a bit, but you get the idea..

Obviously it may require moving the motor a bit, but you get the idea..

#15

I'm working on ordering some parts so that I can lathe the layshaft and get that mounted with the spur..once I get that mounted you guys will see how I plan on transferring the power from the back to front. I've already given you guys a hint...just look at the title ; )

Oh ok. I don't plan on racing this in ROAR sanctioned events..and I feel like the ROAR rule won't be around for a long time. Plus...it seems like a lot of places are moving away from ROAR rules.. i don't maybe it is just where I am.

I have looked into putting a low profile servo in front of the battery but I don't think that will be possible because of the front pulley. I'm going to be using a electronic/battery layout similar to the E4 where the battery is slightly offset. I have a an interesting idea about how to get around using a bottom loading battery because that seems to yield negative results.

Haha that sounds fun

I suppose if I ever had to race this at a Roar event or if I ever ended up sponsoring someone I bet I could figure out a way to mount a saddle or stick pack...there is a lot of room on the bumper  I feel like some would view that as cheating though.

I feel like some would view that as cheating though.

You make an interesting point about the chassis flex. The chassis will only bolted directly to the chassis with the motor mount support..on the opposite side of the chassis I have a feeling that the chassis flex should be equaled out by a stand-off used as a part of the power transfer system. Since the motor is mainly mounted with a trimmed down aluminum piece that used to be used to mount the spur on the TC6 I will trim down the other spur mount to try and offset the flex. Thank you for mentioning chassis flex as it will certainly be something I need to take into consideration.

Thank you. I have to agree the TC6 is a great platform that performs greater. For some reason though I can't seem to keep a car stock..and I feel like improvements can be made.. but we will just have to see.

That is an interesting idea... and actually.. I vaguely remeber Hara being asked what he thinks cars of the future with lipo will look like and he described something similar to what you have come up with.

As far as the COG of the layshaft.. I think it probably would effect the car because the lay shaft if somewhat lite.. but you also have to factor in the spur and the bearings and the pulley and bulkheads. I'm not a physics major but it also doesn't seem to that it would be good to have rotating mass up so high.. but I don't know. Also, even if it doesn't have a huge effect on the COG people perceive it as something that makes the car handle poorly because everyone wants everything on touring cars to be low profile. Though, when trying to centralize the motor and the battery you have to compromised something else... wither it be by adding more friction in the drivetrain , or wither it be shorter a-arms, chassis flex, or raising the cog slightly. So I think your idea is pretty good.

i didnt actually see that you planned to use the shorty batteries. are you leaving enough room to fit a full size one per roar rules?

if not, id be curious to see the servo placed in the extra spare the battery isnt taking up.

ill keep an eye on your thread though. i want to convert my tc5 to nitro sometime for fun, so how you get this to work will simplify my project too ha.

if not, id be curious to see the servo placed in the extra spare the battery isnt taking up.

ill keep an eye on your thread though. i want to convert my tc5 to nitro sometime for fun, so how you get this to work will simplify my project too ha.

I have looked into putting a low profile servo in front of the battery but I don't think that will be possible because of the front pulley. I'm going to be using a electronic/battery layout similar to the E4 where the battery is slightly offset. I have a an interesting idea about how to get around using a bottom loading battery because that seems to yield negative results.

Haha that sounds fun

A couple things to think about.

1. The car doesn't have to be raceable with a standard pack, it just has to fit without modifications. If you can stick it in crosswise, it would be legal and you wouldn't have to actually run it like that.

2. One small problem with a motor mount bolted to the chassis way off to one side (to center the motor) is that it could create an asymmetric flex. You might want to keep that in mind in the design as there are ways to work around it.

1. The car doesn't have to be raceable with a standard pack, it just has to fit without modifications. If you can stick it in crosswise, it would be legal and you wouldn't have to actually run it like that.

2. One small problem with a motor mount bolted to the chassis way off to one side (to center the motor) is that it could create an asymmetric flex. You might want to keep that in mind in the design as there are ways to work around it.

I feel like some would view that as cheating though.

I feel like some would view that as cheating though. You make an interesting point about the chassis flex. The chassis will only bolted directly to the chassis with the motor mount support..on the opposite side of the chassis I have a feeling that the chassis flex should be equaled out by a stand-off used as a part of the power transfer system. Since the motor is mainly mounted with a trimmed down aluminum piece that used to be used to mount the spur on the TC6 I will trim down the other spur mount to try and offset the flex. Thank you for mentioning chassis flex as it will certainly be something I need to take into consideration.

This is something I have talked about with some of my friends, and maybe it's a dumb idea, but what about an FK04 or 414MII with proper modern suspension on it? I have a hard time believing that the layshaft being high is a huge disadvantage. With lipos, you could use a shorty battery and still remain legal by claiming it is a "saddle pack" or "transverse mounted stick" car. The chassis could even be pretty narrow...

Obviously it may require moving the motor a bit, but you get the idea..

Obviously it may require moving the motor a bit, but you get the idea..

As far as the COG of the layshaft.. I think it probably would effect the car because the lay shaft if somewhat lite.. but you also have to factor in the spur and the bearings and the pulley and bulkheads. I'm not a physics major but it also doesn't seem to that it would be good to have rotating mass up so high.. but I don't know. Also, even if it doesn't have a huge effect on the COG people perceive it as something that makes the car handle poorly because everyone wants everything on touring cars to be low profile. Though, when trying to centralize the motor and the battery you have to compromised something else... wither it be by adding more friction in the drivetrain , or wither it be shorter a-arms, chassis flex, or raising the cog slightly. So I think your idea is pretty good.