Project: Team Associated TC9

#106

Tech Regular

just found their phone number. Called them they don't have 234t, but do have 233t, 237 and 240T. You wants me to go pickup some for you? PM me you address I will send it to you.

#107

have you tried SDPSI?

Here is a link to a 234 tooth belt 3m pitch.

https://sdp-si.com/eStore/PartDetail...55&GroupID=342

They carry a bunch of belts and I have personally used them on many of my car projects. They are mostly neoprene with fiberglass belts so they are pretty flexible.

just cut to the width you need and there you go. It's not too hard with a sharp xacto knife.

Here is a link to a 234 tooth belt 3m pitch.

https://sdp-si.com/eStore/PartDetail...55&GroupID=342

They carry a bunch of belts and I have personally used them on many of my car projects. They are mostly neoprene with fiberglass belts so they are pretty flexible.

just cut to the width you need and there you go. It's not too hard with a sharp xacto knife.

#108

Tech Master

iTrader: (7)

I am enjoying seeing this project come together... and I am gaining some ideas for when the time comes for my own project

The Tigermoth IS a brilliant design but is very poorly applied... I know as I've been persevering with mine for far too long... but it will be the basis for some extensive mods I have been planning for some time. I am hoping to fix some of the issues I have had with the car while not destroying the handling which is the best I've had in a car for some years...

Keep up the good work

Keep up the good work

#109

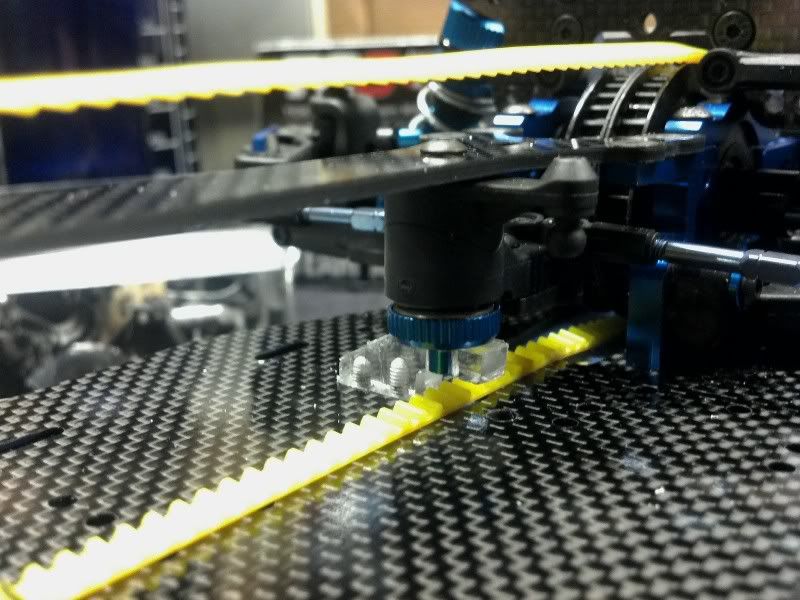

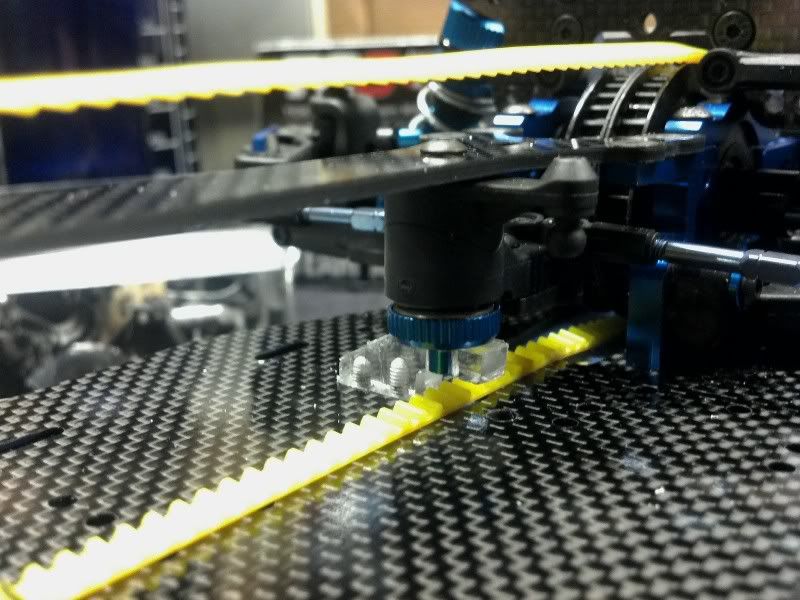

Last night I tried to mount the belt guide.. right in front of the motor.. and because of how small the bearings are and the shaft to hold them are I decided just to use CA to hold it in place.. I slipped up with the CA though and instead of applying it with a tooth pick to the shaft I applied it straight from the bottle to the chassis.. this ended up being too much and when I place the guide in place the CA got into all the bearings and seized them. So now I have to order more and try it again with abit less CA next time haha

Today I ordered this belt..Bando belt that is 233T long..

https://www.mrosupply.com/product/71...elts_3MM_Pitch

I think that I possibly can make it flexible enough by cutting every other tooth out of it.. I searched and searched for a place that has Polyurethane belts in STS profile or even HTD profile.. but Mitsuboshi is the only company I could find that makes belts like the Losi belts and I would have to special order belts from Mitsuboshi so I'm just going to try the Bando belt.

Thanks GPM-parts.. unfortunatly, I need the belt very soon so I have to order it from inside the country.

I'm not sure about that.. haha I still have a bit to go.. but its coming together.

Thanks for the link! I think I might have to try them if the Bando belts I'm ordering aren't flexible enough.

I'm glad you enjoying the build!

Yea I agree, that will be very interesting.. make sure to post a project thread up so we can see you modifications and progress! I would love to see that.

Today I ordered this belt..Bando belt that is 233T long..

https://www.mrosupply.com/product/71...elts_3MM_Pitch

I think that I possibly can make it flexible enough by cutting every other tooth out of it.. I searched and searched for a place that has Polyurethane belts in STS profile or even HTD profile.. but Mitsuboshi is the only company I could find that makes belts like the Losi belts and I would have to special order belts from Mitsuboshi so I'm just going to try the Bando belt.

I'm not sure about that.. haha I still have a bit to go.. but its coming together.

have you tried SDPSI?

Here is a link to a 234 tooth belt 3m pitch.

https://sdp-si.com/eStore/PartDetail...55&GroupID=342

They carry a bunch of belts and I have personally used them on many of my car projects. They are mostly neoprene with fiberglass belts so they are pretty flexible.

just cut to the width you need and there you go. It's not too hard with a sharp xacto knife.

Here is a link to a 234 tooth belt 3m pitch.

https://sdp-si.com/eStore/PartDetail...55&GroupID=342

They carry a bunch of belts and I have personally used them on many of my car projects. They are mostly neoprene with fiberglass belts so they are pretty flexible.

just cut to the width you need and there you go. It's not too hard with a sharp xacto knife.

I am enjoying seeing this project come together... and I am gaining some ideas for when the time comes for my own project

The Tigermoth IS a brilliant design but is very poorly applied... I know as I've been persevering with mine for far too long... but it will be the basis for some extensive mods I have been planning for some time. I am hoping to fix some of the issues I have had with the car while not destroying the handling which is the best I've had in a car for some years...

Keep up the good work

The Tigermoth IS a brilliant design but is very poorly applied... I know as I've been persevering with mine for far too long... but it will be the basis for some extensive mods I have been planning for some time. I am hoping to fix some of the issues I have had with the car while not destroying the handling which is the best I've had in a car for some years...

Keep up the good work

Yea I agree, that will be very interesting.. make sure to post a project thread up so we can see you modifications and progress! I would love to see that.

#110

Tech Regular

#112

Great project. Keep it up!

I have a concern though with your design and that's the layshaft pulley and how much of the belt is wrapped around. I was a keen runner of the XXXS and the tensioner was designed so that it wrapped the belt around the pulley a full 180 degrees. Looking at yours I can see that it's possibly only about 120?

The XXXS belt slipped under high loads especially under braking I'm concerned that yours may slip under lesser loads. I've been working on a single belt tourer too and this has been a major issue.

I'm sure you will find a solution.

I have a concern though with your design and that's the layshaft pulley and how much of the belt is wrapped around. I was a keen runner of the XXXS and the tensioner was designed so that it wrapped the belt around the pulley a full 180 degrees. Looking at yours I can see that it's possibly only about 120?

The XXXS belt slipped under high loads especially under braking I'm concerned that yours may slip under lesser loads. I've been working on a single belt tourer too and this has been a major issue.

I'm sure you will find a solution.

#113

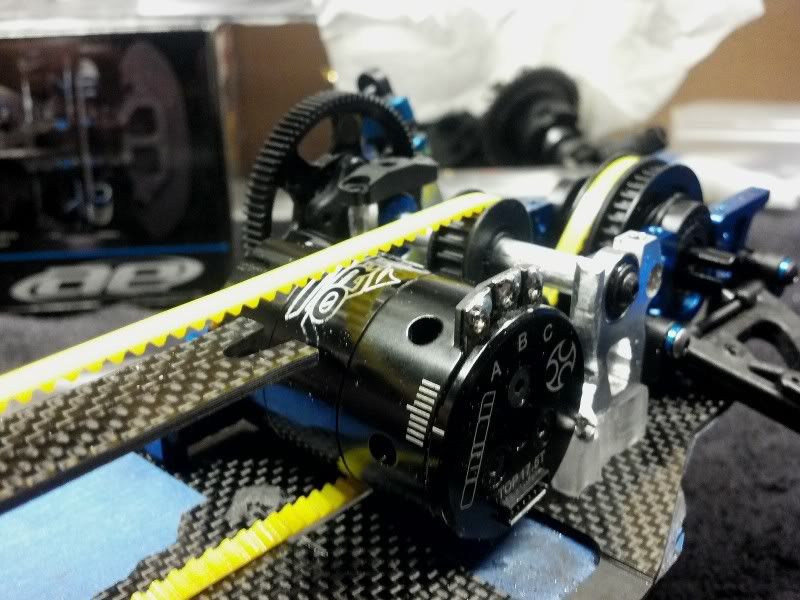

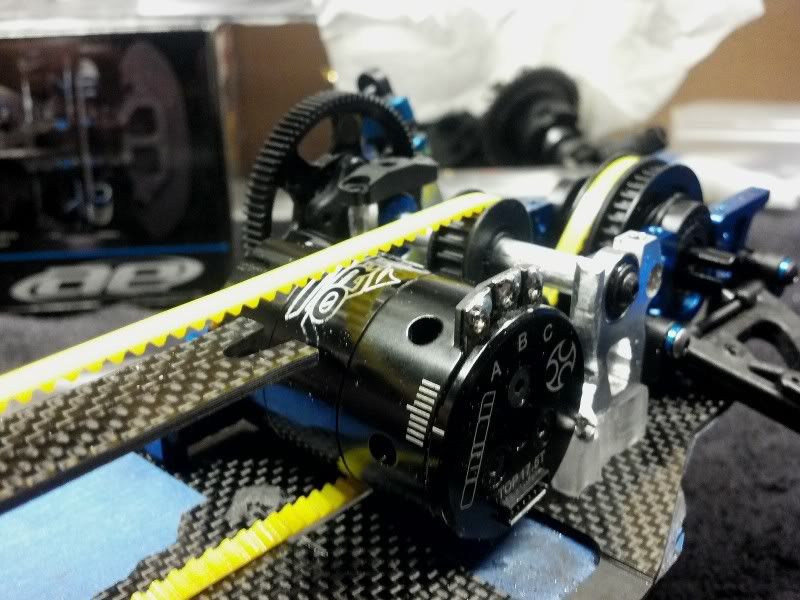

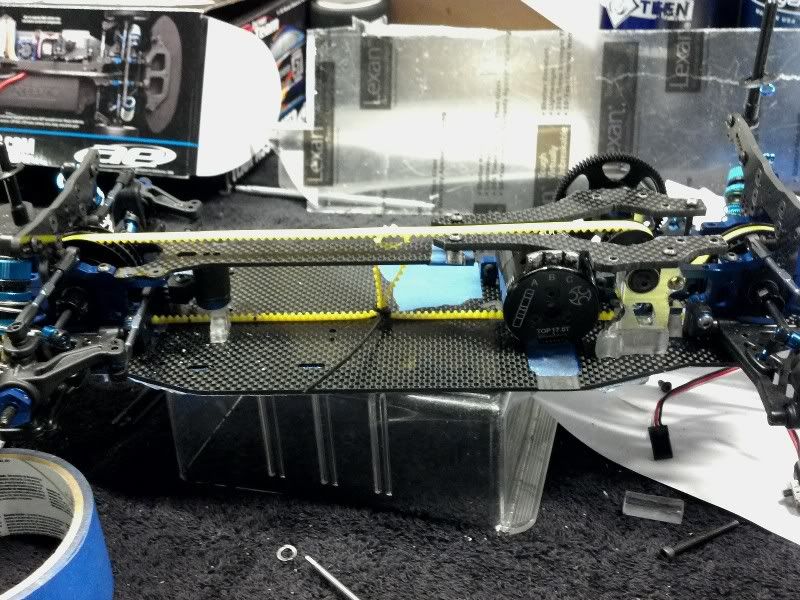

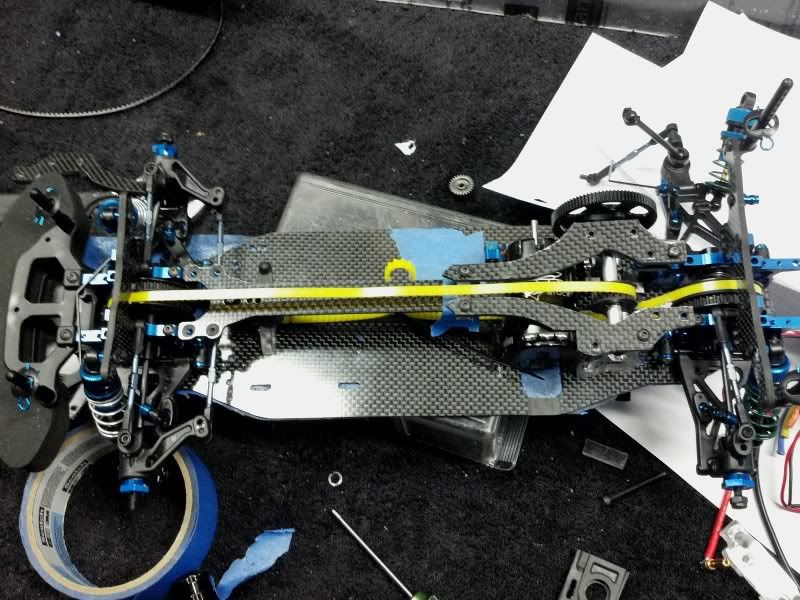

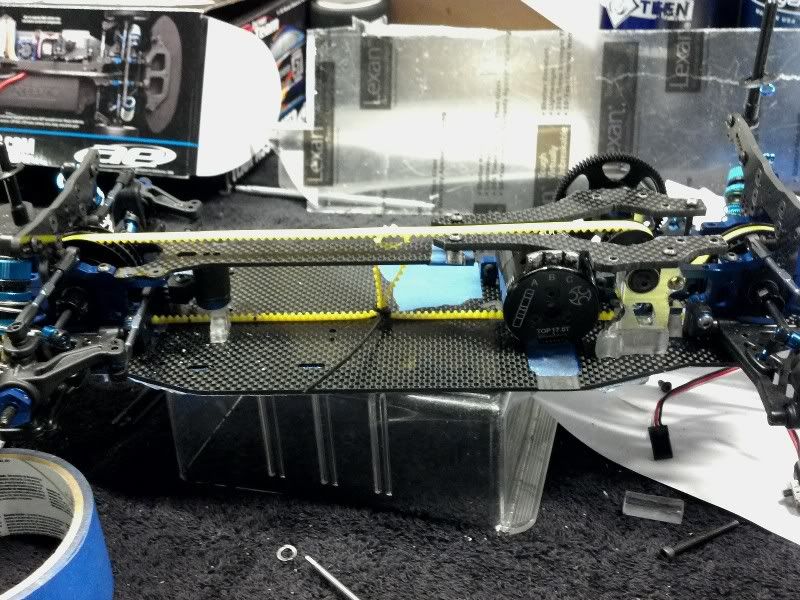

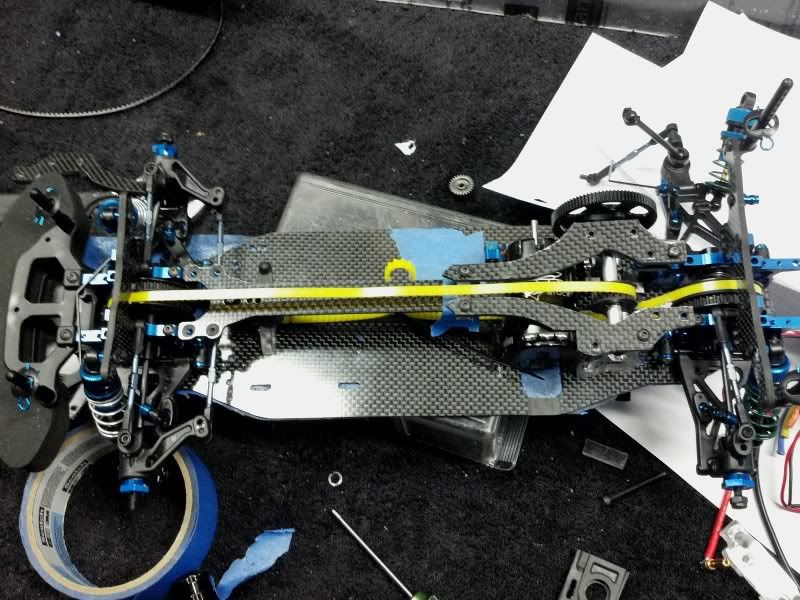

I raised the Layshaft to its final position in order for the belt to clear the motor and have a couple mm's of clearance. The final height is 31.5mm. This is 8.5 mm higher than the TC6 layshaft which is at 23 mm. A substantial amount of height has been added.. but nothing like the layshaft height of designs where the entire belt has to run over the motor.

This layshaft height is only required when using the single belt.. if using two belts.. the layshaft can be lowered to 23-26mm (depending on spur) which is only 0-3mm mm above the TC6's layshaft height.

I also redesigned the steering bellcrank support. Now the belt can be removed without having to take off the support.. one less thing that has to be disassembled in order to get the belt off.

The Bando belt I order should be here in the next couple of days.. in the meantime I'm going to be working on two different upper deck designs..those are too hard to explain without pictures.

Updates coming soon.

I don't blame you.. doing parts by hand is a lot of work and the final results aren't nearly as great as when using a mill. Unfortunately, I can't afford such tools.. so I'm stuck with doing everything by hand.

Thanks for you concern.. After looking at how I have it set-up with a larger idler..I'm at around 145-150 degrees..of contact.. I can easily bring this up to 180 or so by putting a slightly smaller idler on it..and extending the slots I have drilled in the chassis for the idler/tensioner to slide along. This in-turn slides the idler further under the drive pulley. I think this is something I will go ahead and do. Thanks!

This layshaft height is only required when using the single belt.. if using two belts.. the layshaft can be lowered to 23-26mm (depending on spur) which is only 0-3mm mm above the TC6's layshaft height.

I also redesigned the steering bellcrank support. Now the belt can be removed without having to take off the support.. one less thing that has to be disassembled in order to get the belt off.

The Bando belt I order should be here in the next couple of days.. in the meantime I'm going to be working on two different upper deck designs..those are too hard to explain without pictures.

Updates coming soon.

Great project. Keep it up!

I have a concern though with your design and that's the layshaft pulley and how much of the belt is wrapped around. I was a keen runner of the XXXS and the tensioner was designed so that it wrapped the belt around the pulley a full 180 degrees. Looking at yours I can see that it's possibly only about 120?

The XXXS belt slipped under high loads especially under braking I'm concerned that yours may slip under lesser loads. I've been working on a single belt tourer too and this has been a major issue.

I'm sure you will find a solution.

I have a concern though with your design and that's the layshaft pulley and how much of the belt is wrapped around. I was a keen runner of the XXXS and the tensioner was designed so that it wrapped the belt around the pulley a full 180 degrees. Looking at yours I can see that it's possibly only about 120?

The XXXS belt slipped under high loads especially under braking I'm concerned that yours may slip under lesser loads. I've been working on a single belt tourer too and this has been a major issue.

I'm sure you will find a solution.

#114

Tech Master

iTrader: (7)

#115

More bad belt news.. I got an email from the place that I ordered my Bando belt from saying that the manufacturer has a lead time of 8-10 weeks and that my credit card hadn't been charged  I don't understand this because on their website it was shown in stock..

I don't understand this because on their website it was shown in stock..  Oh well... I guess I'm going to have to order my belt from some where else.

Oh well... I guess I'm going to have to order my belt from some where else.

I checked out that mill and it looks pretty nice.. idk though I think after this project.. I might just start concentrating on racing and doing solidworks. Possibly a couple projects down the road..but i'm not sure.

I don't understand this because on their website it was shown in stock..

I don't understand this because on their website it was shown in stock..  Oh well... I guess I'm going to have to order my belt from some where else.

Oh well... I guess I'm going to have to order my belt from some where else. You should check out the acra mill... its designed to hold a dremel and its pretty cheap for what it provides... I've seen some work done with one and it will do aluminum for the sort of work done on RC etc... the main reason I balk at it is because freighting it to Australia almost doubles the price

#117

I took Yodog's advice and ordered a belt from SDPSI... hopefully it will arrive next week..

In the meantime how about some pictures? I thought I would show you guys the upper deck design I have been working on.. it uses half of the regular TC6 upper chassis and then two custom car parts for the back.. The parts shown are made from 3mm Carbon.. I think that will be too thick and too stiff..as they don't flex hardly at all..so I won't actually be finishing these parts unless I find that car has too much flex with 2.5mm plates.

I think I'm going to order 2.5mm Carbon to make the actual rear upper chassis plates.. I think they will be a good stiffness.. not quiet as flexible as the 2mm but just a tad stiffer to make up for the slot made in the bottom of the chassis.

In the meantime how about some pictures? I thought I would show you guys the upper deck design I have been working on.. it uses half of the regular TC6 upper chassis and then two custom car parts for the back.. The parts shown are made from 3mm Carbon.. I think that will be too thick and too stiff..as they don't flex hardly at all..so I won't actually be finishing these parts unless I find that car has too much flex with 2.5mm plates.

I think I'm going to order 2.5mm Carbon to make the actual rear upper chassis plates.. I think they will be a good stiffness.. not quiet as flexible as the 2mm but just a tad stiffer to make up for the slot made in the bottom of the chassis.

#118

i dont have a tc6 so this might be a dumb question, but why did you have to double up the diff pullies like that? couldn't you have just placed the difs both on the same side? belt would be slightly offcenter but is that really that big a deal? also curious how your gonna mount the battery low with the belt arranged like that. kinda defeats the purpose of moving your motor to center if the battery is still sitting outboard to clear the belt.

even with a stubby lipo would have to add a lot of weight on the other side to balance with the battery. electronics wont be even close.

average brushless motor = 170gr average 7.4v hard lipo 280gr.

even with a stubby lipo would have to add a lot of weight on the other side to balance with the battery. electronics wont be even close.

average brushless motor = 170gr average 7.4v hard lipo 280gr.

#119

Tech Master

iTrader: (3)

Join Date: Nov 2001

Location: Land of high taxes and bad football

Posts: 1,807

Trader Rating: 3 (100%+)

Great project. Keep it up!

I have a concern though with your design and that's the layshaft pulley and how much of the belt is wrapped around. I was a keen runner of the XXXS and the tensioner was designed so that it wrapped the belt around the pulley a full 180 degrees. Looking at yours I can see that it's possibly only about 120?

The XXXS belt slipped under high loads especially under braking I'm concerned that yours may slip under lesser loads. I've been working on a single belt tourer too and this has been a major issue.

I'm sure you will find a solution.

I have a concern though with your design and that's the layshaft pulley and how much of the belt is wrapped around. I was a keen runner of the XXXS and the tensioner was designed so that it wrapped the belt around the pulley a full 180 degrees. Looking at yours I can see that it's possibly only about 120?

The XXXS belt slipped under high loads especially under braking I'm concerned that yours may slip under lesser loads. I've been working on a single belt tourer too and this has been a major issue.

I'm sure you will find a solution.

Thanks for you concern.. After looking at how I have it set-up with a larger idler..I'm at around 145-150 degrees..of contact.. I can easily bring this up to 180 or so by putting a slightly smaller idler on it..and extending the slots I have drilled in the chassis for the idler/tensioner to slide along. This in-turn slides the idler further under the drive pulley. I think this is something I will go ahead and do. Thanks!

With your current design the drive pulley is putting drive tension into the belt as it snakes its way around the tensioner.

Does this make any sense?

I like the way you have run the belt around the motor, but perhaps the layshaft would be better in front of the motor?

#120

i dont have a tc6 so this might be a dumb question, but why did you have to double up the diff pullies like that? couldn't you have just placed the difs both on the same side? belt would be slightly offcenter but is that really that big a deal? also curious how your gonna mount the battery low with the belt arranged like that. kinda defeats the purpose of moving your motor to center if the battery is still sitting outboard to clear the belt.

even with a stubby lipo would have to add a lot of weight on the other side to balance with the battery. electronics wont be even close.

average brushless motor = 170gr average 7.4v hard lipo 280gr.

even with a stubby lipo would have to add a lot of weight on the other side to balance with the battery. electronics wont be even close.

average brushless motor = 170gr average 7.4v hard lipo 280gr.

Servo = 50g

ESC = 80g (with wires)

Receiver = 10g

Transponder = 5g

TOTAL = 145g

So it's not that far off, especially as the car is likely to be light and require lead to get it upto any sort of minimum weight, so this can be put on the electronics side.