Project: Team Associated TC9

#91

Looks great!

#93

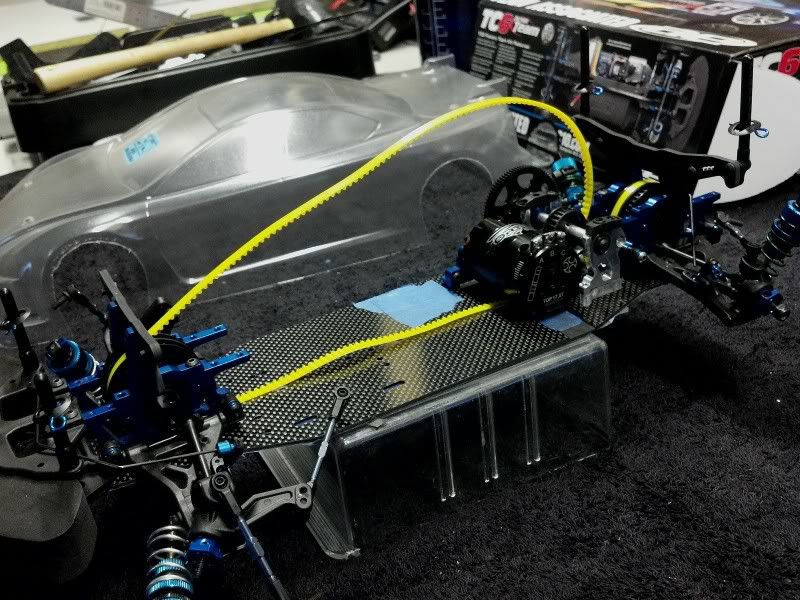

eds - awesome. i hadn't thought to put the idler ahead of the layshaft in terms of the direction of rotation. this will be killer. in fact, i predict that this transmission design will get ripped off by a major player in the next revision or two. that's how good it is ...

imagine how slick it could look if you were going from the ground up, with purpose built bulkheads that integrated the layshaft..

mmm, mmm, good.

imagine how slick it could look if you were going from the ground up, with purpose built bulkheads that integrated the layshaft..

mmm, mmm, good.

#94

Taking today off from working on this.. due to the holidays.. work will start back up monday or tuesday.

Thank you!

This is true.. but not by much. After thinking about it.. I agree that depending on where the motor and battery are positioned the car could have 50/50 weight bias. I suppose it could work.. not sure if any company would want to try it after the Losi JRX-S debacle though. It might work though.

Wow! Thank you very much..we will just have to see how the transmission fairs in real world testing.. I would be more than happy if a company stole my idea.. I like doing these projects for fun..but at the same time I do them and post them on forums and submit them to the magazines for articles.. so that I can get my name and my ideas out there.. I'm current in college working towards a mechanical engineering degree and hope to work for Team Associated or Losi once I graduate.

This would definitely would be slick if I was building it from the ground up. Unfortunately, I don't have the equipment or the money to do that. Plus TONS of people have the Tc5/Tc6.. so a conversion makes sense and draws attention.

Thank you for you very nice comments.. they were the cherry on top of my christmas

Thank you!

This is true.. but not by much. After thinking about it.. I agree that depending on where the motor and battery are positioned the car could have 50/50 weight bias. I suppose it could work.. not sure if any company would want to try it after the Losi JRX-S debacle though. It might work though.

eds - awesome. i hadn't thought to put the idler ahead of the layshaft in terms of the direction of rotation. this will be killer. in fact, i predict that this transmission design will get ripped off by a major player in the next revision or two. that's how good it is ...

imagine how slick it could look if you were going from the ground up, with purpose built bulkheads that integrated the layshaft..

mmm, mmm, good.

imagine how slick it could look if you were going from the ground up, with purpose built bulkheads that integrated the layshaft..

mmm, mmm, good.

This would definitely would be slick if I was building it from the ground up. Unfortunately, I don't have the equipment or the money to do that. Plus TONS of people have the Tc5/Tc6.. so a conversion makes sense and draws attention.

Thank you for you very nice comments.. they were the cherry on top of my christmas

#95

Tech Regular

iTrader: (1)

Superb work Eds, can't wait to see more.

Just a couple of tihngs to consider...

What if you change the cell orientation to West/East as opposed to North/South - this would compress the spread of the main bulk of the weight (battery/motor) even more and palce a little more weight outwards which, if done right, isn't a bad thing.

The esc and servo can sit right in front of the cells - also although it is nice to keep as much of the donor car as possible, have you thought about the dual bellcrank system. Not knowing the tC6 very well i'm not sure if they have adopted this system (maybe on the TC6.1?) but every manufacturer seems to be going that route and in my experiance with the XRay it does seem to smooth out the steerings somewhat, it also enables you to use a low profile servo (facing frowards) that again allows you to compress the footprint of the electronics.

Just a couple of thoughts, hope you don't mind the input.

All the best mate.

Chris

Just a couple of tihngs to consider...

What if you change the cell orientation to West/East as opposed to North/South - this would compress the spread of the main bulk of the weight (battery/motor) even more and palce a little more weight outwards which, if done right, isn't a bad thing.

The esc and servo can sit right in front of the cells - also although it is nice to keep as much of the donor car as possible, have you thought about the dual bellcrank system. Not knowing the tC6 very well i'm not sure if they have adopted this system (maybe on the TC6.1?) but every manufacturer seems to be going that route and in my experiance with the XRay it does seem to smooth out the steerings somewhat, it also enables you to use a low profile servo (facing frowards) that again allows you to compress the footprint of the electronics.

Just a couple of thoughts, hope you don't mind the input.

All the best mate.

Chris

#96

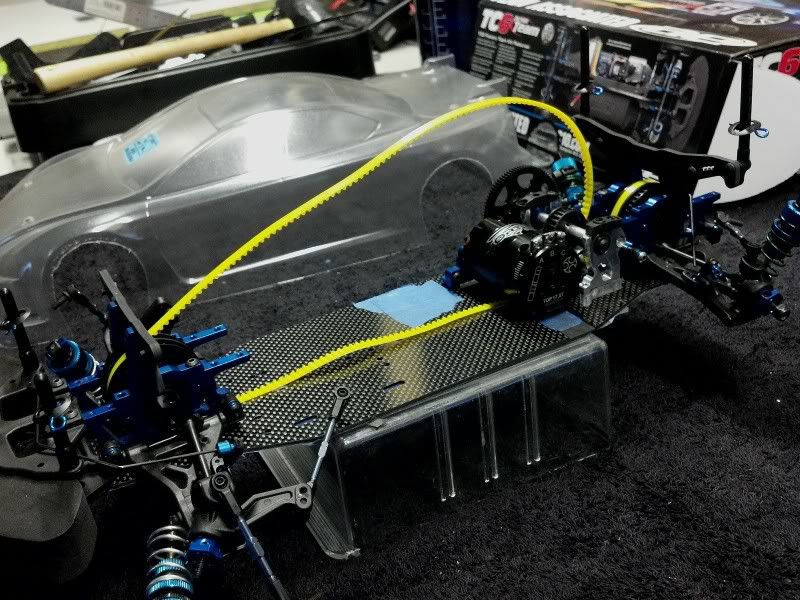

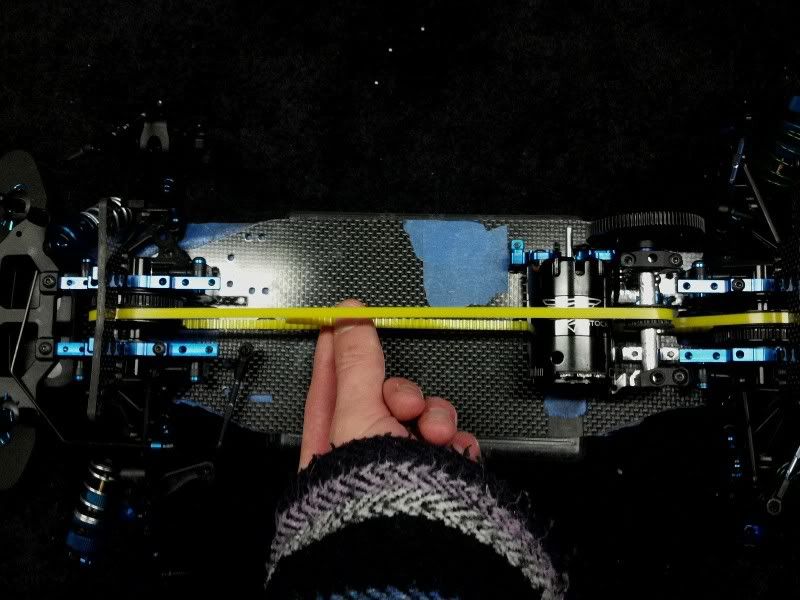

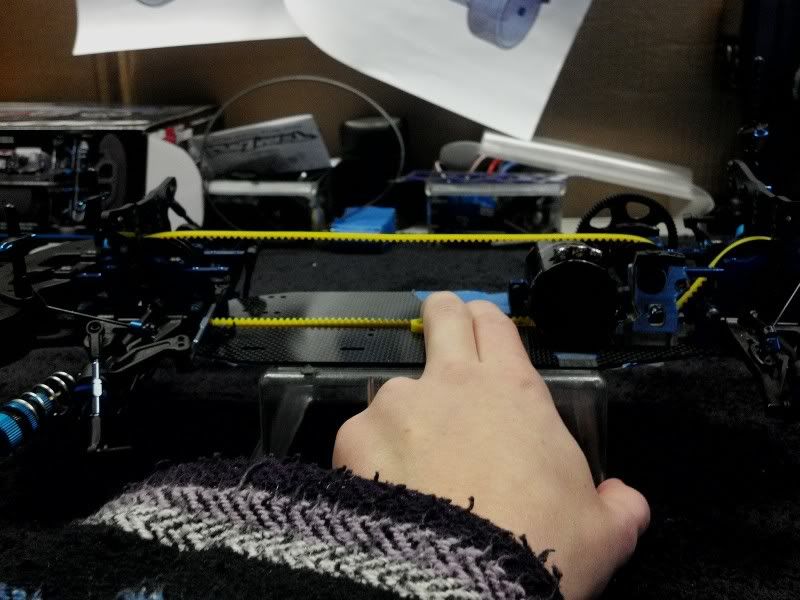

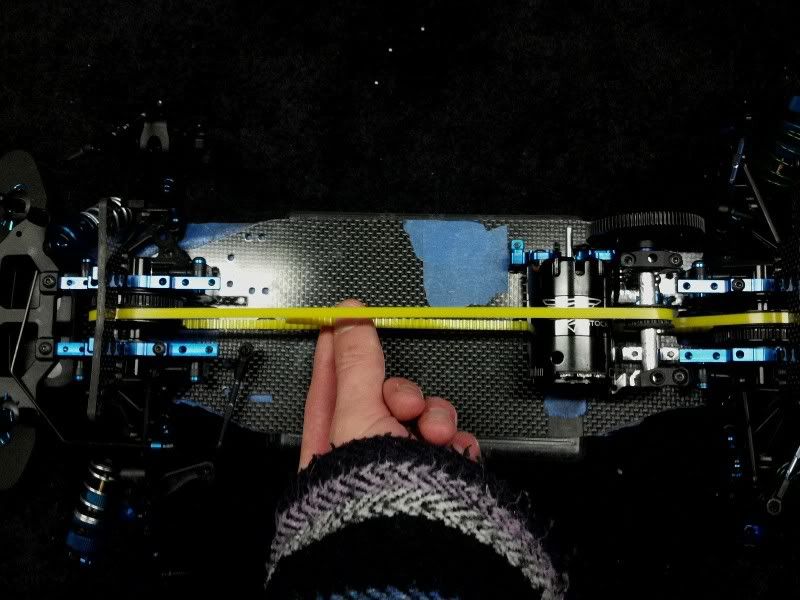

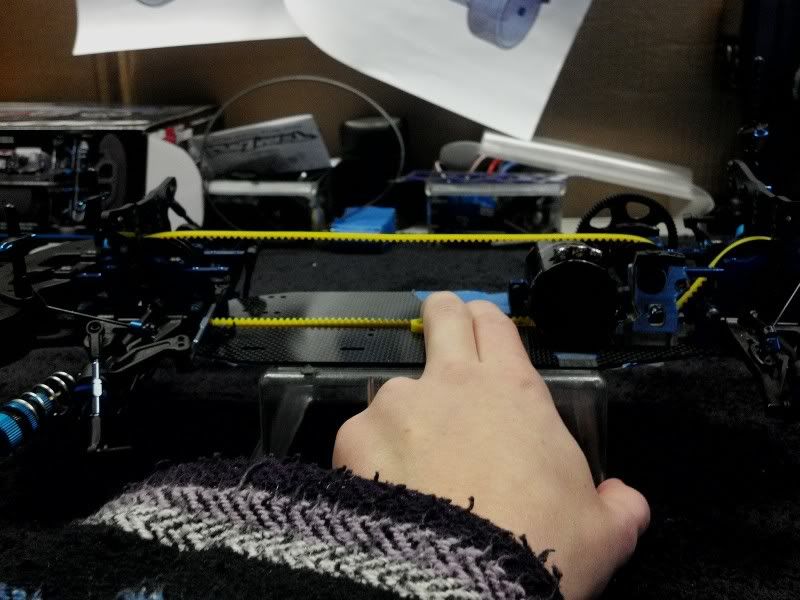

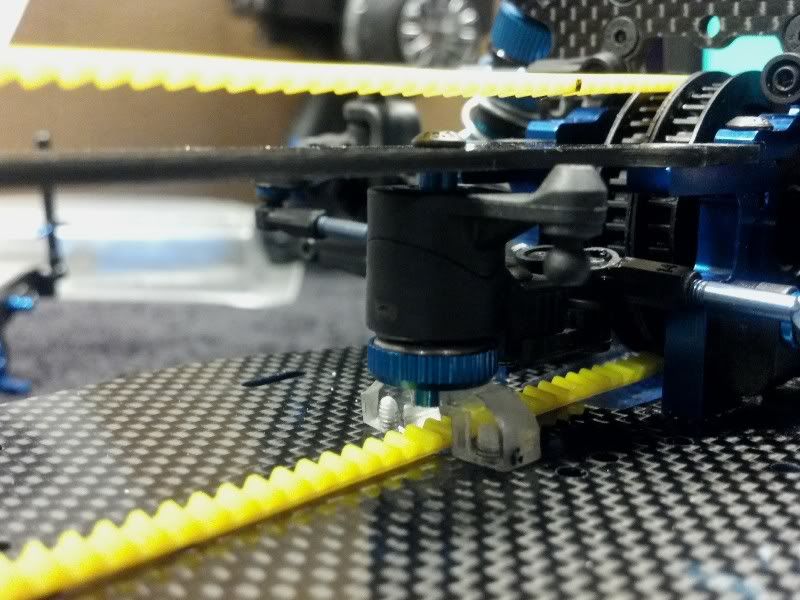

I received the Team Losi xxx-4 HD yellow belt yesterday and was eager to put it on the car and see how it fit.. as soon as I took it out of the package I realized how long it really is..and knew it would be too long for my car..  I still put it on the car anyway though..

I still put it on the car anyway though..

This belt obviously won't work..even if I put a larger idler and pulley.. it would still be too long. I'm not sure how to feel about the yellow.. part of me says its frickin awesome! and makes the drivetrain design stand out.. the other half of me thinks its ugly and a black belt would look better. I'm looking into the Team Losi xxx-s yellow belt that came stock on the G+... I can't seem to find anyone who knows how long that belt is.. my guess is that it will also be too long..but I already lost $17 on this xxx-4 belt so it would be nice to know if that belt is the right length before I buy it.. so if anyone with a xxx-s could measure the stock blue belt or the yellow that would be great..

If I can't get a xxx-s / xxx-4 belt I'm not exactly sure how well I can get this one-belt design to work simply because if I were to buy a custom belt from a manufacturer.. I don't think it would be flexible enough..maybe if I cut every other tooth off but even then I'm not sure.

Anyway.. if anyone could help me with the length of the xxx-s belts that would be great!

Thanks Chris

I have considered putting the battery across the chassis..the reason why I haven't gone with that design.. is that the goal is to get the heaviest components as centralized as possible. But, I should mention that with how I'm designing everything.. the battery and electronics can be changed very easily... so that I can test new layouts.

I have thought about doing a dual bell crank, unfortunately though with the design that I'm currently working on.. with a centralized battery a dual bell crank would push the servo out too far. If I do some testing on a different layout that'll be something I consider though.. thanks. It's interesting how the engineers started out with dual bell cranks.. then went to a single bell crank and now going back to dual.

I still put it on the car anyway though..

I still put it on the car anyway though..

This belt obviously won't work..even if I put a larger idler and pulley.. it would still be too long. I'm not sure how to feel about the yellow.. part of me says its frickin awesome! and makes the drivetrain design stand out.. the other half of me thinks its ugly and a black belt would look better. I'm looking into the Team Losi xxx-s yellow belt that came stock on the G+... I can't seem to find anyone who knows how long that belt is.. my guess is that it will also be too long..but I already lost $17 on this xxx-4 belt so it would be nice to know if that belt is the right length before I buy it.. so if anyone with a xxx-s could measure the stock blue belt or the yellow that would be great..

If I can't get a xxx-s / xxx-4 belt I'm not exactly sure how well I can get this one-belt design to work simply because if I were to buy a custom belt from a manufacturer.. I don't think it would be flexible enough..maybe if I cut every other tooth off but even then I'm not sure.

Anyway.. if anyone could help me with the length of the xxx-s belts that would be great!

Superb work Eds, can't wait to see more.

Just a couple of tihngs to consider...

What if you change the cell orientation to West/East as opposed to North/South - this would compress the spread of the main bulk of the weight (battery/motor) even more and palce a little more weight outwards which, if done right, isn't a bad thing.

The esc and servo can sit right in front of the cells - also although it is nice to keep as much of the donor car as possible, have you thought about the dual bellcrank system. Not knowing the tC6 very well i'm not sure if they have adopted this system (maybe on the TC6.1?) but every manufacturer seems to be going that route and in my experiance with the XRay it does seem to smooth out the steerings somewhat, it also enables you to use a low profile servo (facing frowards) that again allows you to compress the footprint of the electronics.

Just a couple of thoughts, hope you don't mind the input.

All the best mate.

Chris

Just a couple of tihngs to consider...

What if you change the cell orientation to West/East as opposed to North/South - this would compress the spread of the main bulk of the weight (battery/motor) even more and palce a little more weight outwards which, if done right, isn't a bad thing.

The esc and servo can sit right in front of the cells - also although it is nice to keep as much of the donor car as possible, have you thought about the dual bellcrank system. Not knowing the tC6 very well i'm not sure if they have adopted this system (maybe on the TC6.1?) but every manufacturer seems to be going that route and in my experiance with the XRay it does seem to smooth out the steerings somewhat, it also enables you to use a low profile servo (facing frowards) that again allows you to compress the footprint of the electronics.

Just a couple of thoughts, hope you don't mind the input.

All the best mate.

Chris

I have considered putting the battery across the chassis..the reason why I haven't gone with that design.. is that the goal is to get the heaviest components as centralized as possible. But, I should mention that with how I'm designing everything.. the battery and electronics can be changed very easily... so that I can test new layouts.

I have thought about doing a dual bell crank, unfortunately though with the design that I'm currently working on.. with a centralized battery a dual bell crank would push the servo out too far. If I do some testing on a different layout that'll be something I consider though.. thanks. It's interesting how the engineers started out with dual bell cranks.. then went to a single bell crank and now going back to dual.

Last edited by eds24; 12-28-2011 at 09:46 AM.

#97

this (225T) will cover your span, but will probably require you to back out/raise your idler pulley some. this change will only help your efficiency (which is a relatively insignificant byproduct - but still in the right direction).

if you haven't come across this yet, this will also serve as a good tool.

Last edited by seaball; 12-28-2011 at 04:07 PM.

#98

a local here needed a special belt for his prodject...I think he said he went with a vacum cleaner co. and cut it down...whatever he did it worked very well...he finished 2nd at the last race, and the belt held up nice...

I will get him to check out the thread and see if he can give more info...

I will get him to check out the thread and see if he can give more info...

#99

Tech Rookie

Your project finally made me post up, I've been lurking rctech off and on for years!

I just posted in the xxx-s thread, the length of the standard xxx-s belt. If memory serves me correctly, the industry number is s3m750-03.

Keep up the good work!!

I just posted in the xxx-s thread, the length of the standard xxx-s belt. If memory serves me correctly, the industry number is s3m750-03.

Keep up the good work!!

#100

Hi Eds24,

Cut that belt to size and rejoin. Here's what I do, hope it works for you.

http://www.rccartips.com/cut-joining-belts.htm

Cut that belt to size and rejoin. Here's what I do, hope it works for you.

http://www.rccartips.com/cut-joining-belts.htm

#101

I have thought about doing a dual bell crank, unfortunately though with the design that I'm currently working on.. with a centralized battery a dual bell crank would push the servo out too far. If I do some testing on a different layout that'll be something I consider though.. thanks. It's interesting how the engineers started out with dual bell cranks.. then went to a single bell crank and now going back to dual.

I'm also working on a custom-build TC at the moment and have been looking around at belts. The most common belts in RC are made by Bando (you'll see the TC6 belts are Bando if you look at the writing on them), in S3M profile. If you purchase a Bando belt in the length you need it should be as flexible as the kit TC6 belts.

The only difficulty is width; the stock widths are 6, 9 and 12mm. So you'll either have to cut the width down yourself (totally possible, and much easier than cutting and shutting a belt thats too long!). Or try to find a belt supplier who can get Bando belts and offer a cutting service, which should just take a few phonecalls to local belt suppliers.

You can buy Bando belts here:

https://www.mrosupply.com/products/1171-3MM_Pitch

Should be easy enough to work out the length now; you could try cutting the XXX4 belt to length just to get an exact idea of what length you need.

Good luck; it looks like you're pretty much there once a belt is sorted.

#102

Tech Apprentice

WOW, NICE JOB . JUST WANT TO SHARE WITH YOU WHAT OTHERS ARE DO TOO ...

#103

On the issue of the belt.. thanks to paraletic and railmagnet I found out that the xxx-s belt is somewhere between 250T and 253T. This is still far too long for my project. I'm looking for a belt that is around 232T-236T (234T is ideal). Right now i'm thinking my best option is just to buy a custom Bando belt.. and then cutting every other tooth out of it to see if I can make it flexible enough for the idler system I have. Unfortunatly, there is a noticable difference in the flexibility of the Losi belt compared to the Associated Bando belt. After doing some research I found that Losi gets their belts custom made by Mitsuboshi. I don't believe I would be able to get a belt like the Losi one except shorter without having to have Mitsuboshi custom make me a ton. I might also try splicing and rejoining the xxx-4 belt like rccartips has suggested.

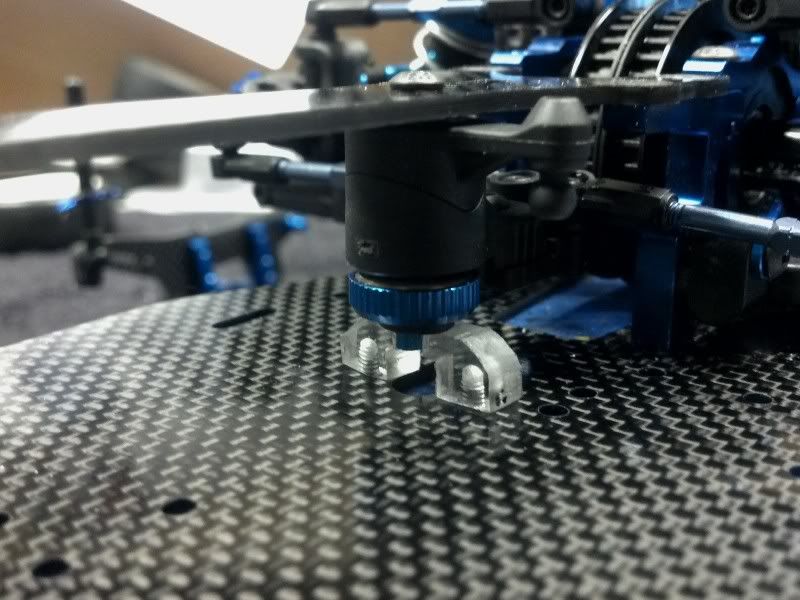

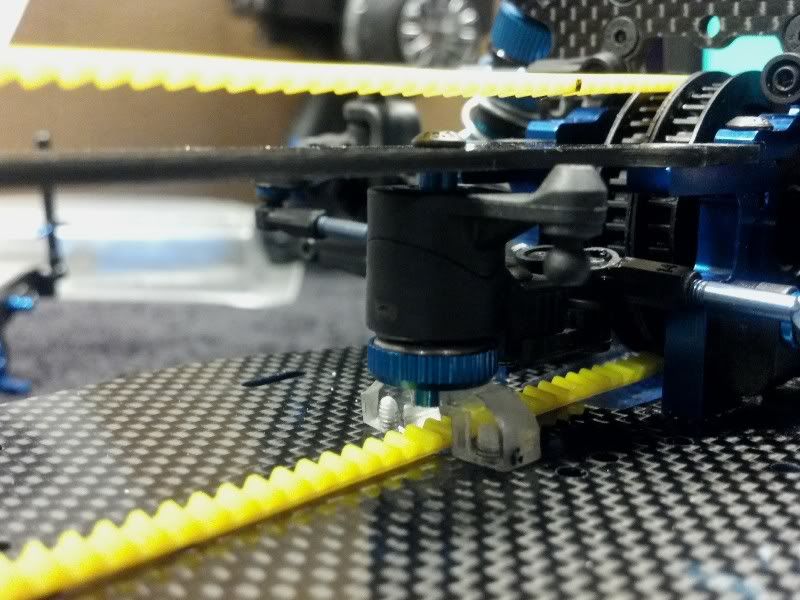

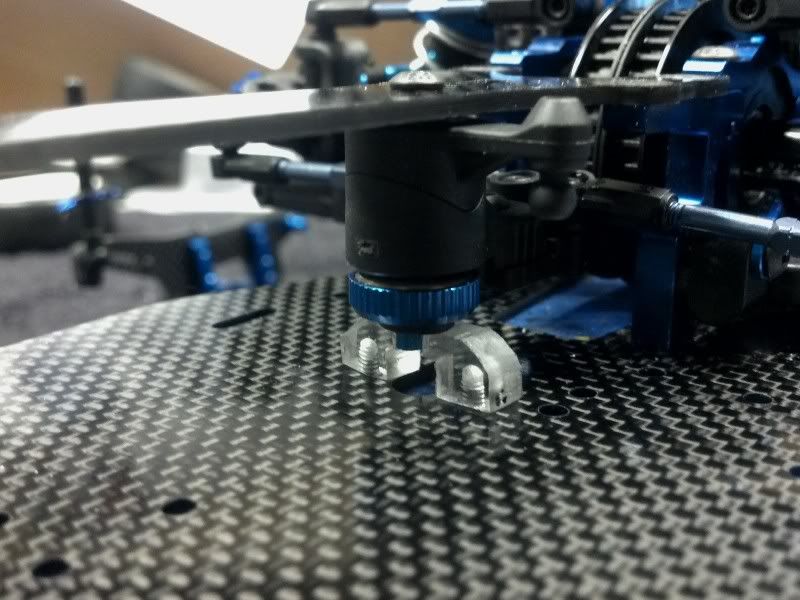

Today I started working on the bellcrank mount.. because I wanted to show Daleburr how I planned on going about mounting a single bellcrank with a one-belt system..

Everything went great.. and the slot I cut in the lexan keys up to the rectangle part on the steering post.. this allows me to unscrew the post without the post turning.. I was also able to eliminate the pesky e-clip that goes on the bottom of the bellcrank!

Once I started installing the belt.. I found out this design wasn't very good.. because it requires me to take the bellcrank mount off in order to get the belt on and off.. so I will be re-designing this mount so that the belt can slide out one side. That should be simple.. instead of having a screw on each side.. I will just have two screws on one side.. and the other side won't connect to the chassis.

I also received the micro bearings from China today for the belt guide that will be guide the belt from being under the motor to on top of the chassis. I have to say these are the tiniest bearings I have EVER seen! 1x3x1 is their dimensions.. they will life the belt 1-2mm off of the chassis.

Thanks Seaball!

That belt is very close to the size I'm needing.. but about 9 teeth short.. I'm currently trying to figure out how I could get it to work.

Also, thanks for the link to the pulley/belt calculator!

Thanks Darkside for the information. I suppose I could look up the number of some vacuum cleaner companies.. my first thought is that it might be difficult to find the exact type of belt I need at one of those places.. but I will check it out.

I'm glad to see that you have signed up!

Thank you so much for that information! You have saved me some money because I now know a xxx-s belt would be far too long for my project! Thanks again for the information!

That is a very interesting technique! How was the durability been of your custom spliced belts??

I'm glad you asked about the single bellcrank system.. see the pictures above as to how I'm working around the belt..

I have been looking around for Bando belts.. and I would like to thank you greatly for that link to a place where I can get Bando belts!! Their prices are the best I have seen... excellent.. I'm thinking my best option is just to cut the belts myself.

Thanks again for that link!

Hmm that's interesting.. it looks like a three belt layout?

Today I started working on the bellcrank mount.. because I wanted to show Daleburr how I planned on going about mounting a single bellcrank with a one-belt system..

Everything went great.. and the slot I cut in the lexan keys up to the rectangle part on the steering post.. this allows me to unscrew the post without the post turning.. I was also able to eliminate the pesky e-clip that goes on the bottom of the bellcrank!

Once I started installing the belt.. I found out this design wasn't very good.. because it requires me to take the bellcrank mount off in order to get the belt on and off.. so I will be re-designing this mount so that the belt can slide out one side. That should be simple.. instead of having a screw on each side.. I will just have two screws on one side.. and the other side won't connect to the chassis.

I also received the micro bearings from China today for the belt guide that will be guide the belt from being under the motor to on top of the chassis. I have to say these are the tiniest bearings I have EVER seen! 1x3x1 is their dimensions.. they will life the belt 1-2mm off of the chassis.

i will have none of this nonsense!

this (225T) will cover your span, but will probably require you to back out/raise your idler pulley some. this change will only help your efficiency (which is a relatively insignificant byproduct - but still in the right direction).

if you haven't come across this yet, this will also serve as a good tool.

this (225T) will cover your span, but will probably require you to back out/raise your idler pulley some. this change will only help your efficiency (which is a relatively insignificant byproduct - but still in the right direction).

if you haven't come across this yet, this will also serve as a good tool.

That belt is very close to the size I'm needing.. but about 9 teeth short.. I'm currently trying to figure out how I could get it to work.

Also, thanks for the link to the pulley/belt calculator!

a local here needed a special belt for his prodject...I think he said he went with a vacum cleaner co. and cut it down...whatever he did it worked very well...he finished 2nd at the last race, and the belt held up nice...

I will get him to check out the thread and see if he can give more info...

I will get him to check out the thread and see if he can give more info...

Thank you so much for that information! You have saved me some money because I now know a xxx-s belt would be far too long for my project! Thanks again for the information!

Hi Eds24,

Cut that belt to size and rejoin. Here's what I do, hope it works for you.

http://www.rccartips.com/cut-joining-belts.htm

Cut that belt to size and rejoin. Here's what I do, hope it works for you.

http://www.rccartips.com/cut-joining-belts.htm

Mounting a single bellcrank when the belt is also in the centre of the car might be a bit tricky, but doable.

I'm also working on a custom-build TC at the moment and have been looking around at belts. The most common belts in RC are made by Bando (you'll see the TC6 belts are Bando if you look at the writing on them), in S3M profile. If you purchase a Bando belt in the length you need it should be as flexible as the kit TC6 belts.

The only difficulty is width; the stock widths are 6, 9 and 12mm. So you'll either have to cut the width down yourself (totally possible, and much easier than cutting and shutting a belt thats too long!). Or try to find a belt supplier who can get Bando belts and offer a cutting service, which should just take a few phonecalls to local belt suppliers.

You can buy Bando belts here:

https://www.mrosupply.com/products/1171-3MM_Pitch

Should be easy enough to work out the length now; you could try cutting the XXX4 belt to length just to get an exact idea of what length you need.

Good luck; it looks like you're pretty much there once a belt is sorted.

I'm also working on a custom-build TC at the moment and have been looking around at belts. The most common belts in RC are made by Bando (you'll see the TC6 belts are Bando if you look at the writing on them), in S3M profile. If you purchase a Bando belt in the length you need it should be as flexible as the kit TC6 belts.

The only difficulty is width; the stock widths are 6, 9 and 12mm. So you'll either have to cut the width down yourself (totally possible, and much easier than cutting and shutting a belt thats too long!). Or try to find a belt supplier who can get Bando belts and offer a cutting service, which should just take a few phonecalls to local belt suppliers.

You can buy Bando belts here:

https://www.mrosupply.com/products/1171-3MM_Pitch

Should be easy enough to work out the length now; you could try cutting the XXX4 belt to length just to get an exact idea of what length you need.

Good luck; it looks like you're pretty much there once a belt is sorted.

I have been looking around for Bando belts.. and I would like to thank you greatly for that link to a place where I can get Bando belts!! Their prices are the best I have seen... excellent.. I'm thinking my best option is just to cut the belts myself.

Thanks again for that link!

Hmm that's interesting.. it looks like a three belt layout?

Last edited by eds24; 12-29-2011 at 08:02 PM.

#104

Tech Regular

I know a place that sell industrial belt just down the street. Will drop by tomorrow to see if they have s3m702 belt.

#105

Your car is almost alive. Can't wait for the video of it running.