Awesomatix EP Touring Car (A700 Shaft Drive)

#5686

If the gearbox has more travel one way, you might not have it on straight. I would double check first that the tube is straight via where it mounts on the rear bulkhead, and then check that the front gearbox is straight relative to that where the front gearbox bolts on. It should travel about the same both ways, at least mine does

I have not run a topdeck and I have had 0 issues with anything happening with 0 precautions to prevent it, other than having no shims under the am06s. Anyone who saw me last week when I was a little sick knows I hit some crap hard too

I have not run a topdeck and I have had 0 issues with anything happening with 0 precautions to prevent it, other than having no shims under the am06s. Anyone who saw me last week when I was a little sick knows I hit some crap hard too

#5687

Tech Fanatic

Well, I thought I knew what FFG stood for until this weekend. Under peer pressure I installed a FFG set up on my 700L, now I know it means F'ing frustrated guy. The right dog bone would pop out, even after doing the pin fix. The gearbox has more travel to the left then right for sure. The set up didn't have the top deck, would a top deck help solve this also?

P10 is very important element of FFG design and cinematics!

P10:

1. Restricts both the twist and the side movement of the front gearbox to the optimal level.

2. Provides the necessary link between the twist and the side movement of the front gearbox.

#5688

Ha, it's like Oleg is looking at my car. I took the FFG off another car and put it on mine. It did not have the covers on it. I will try to install them tonight.

#5689

Tech Adept

When I don't use the covers it works free but once I did put them on it it's blocked on one side and free on the other one... Can anybody tell me what to do to fix it?

Cheers

Cheers

#5690

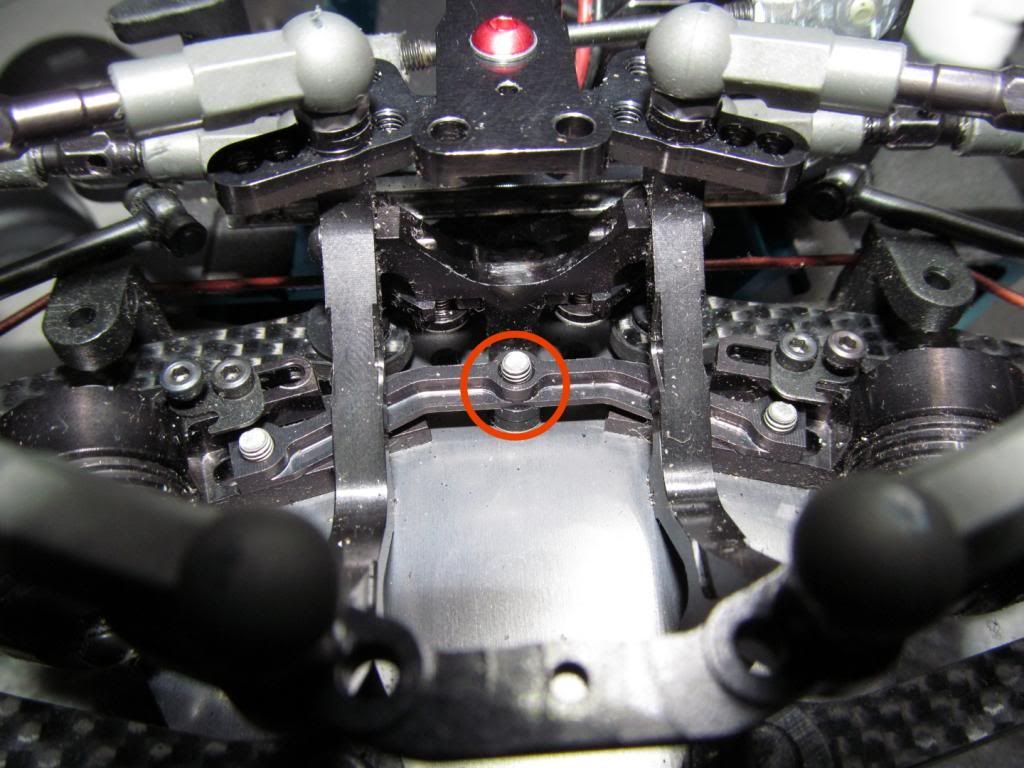

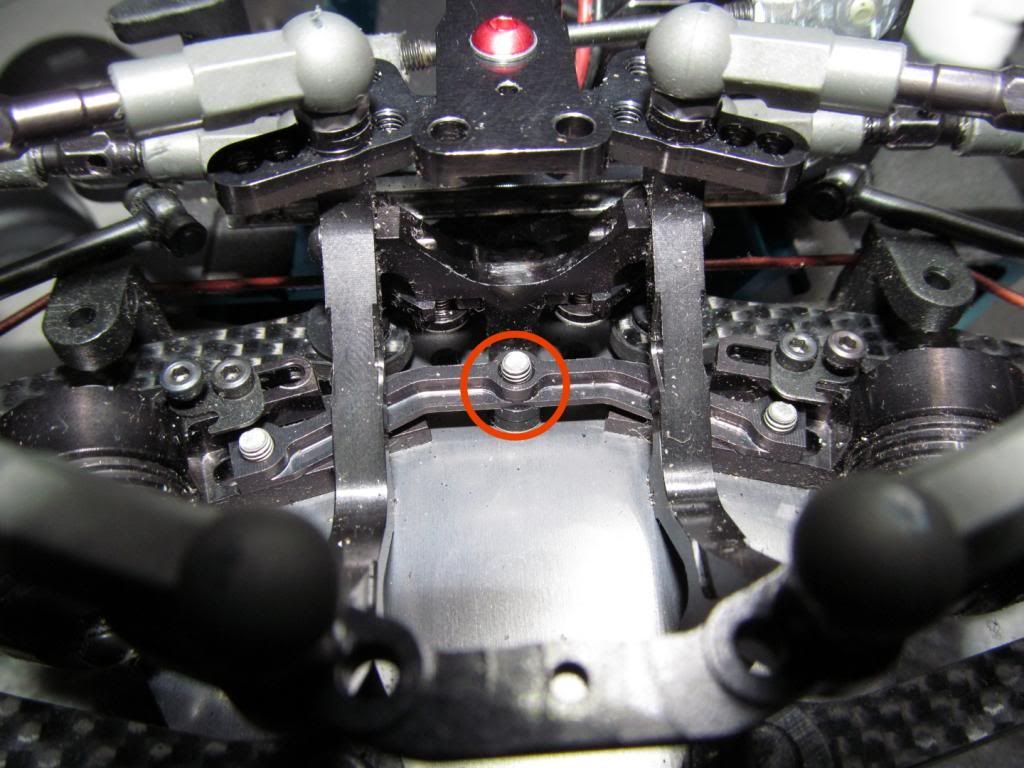

Here is a tip for anyone who is finding their FFG binds up after installing the diff cover.

Make sure the screw I show in the picture here is not too long (it is too long in the picture). If it is too long it will foul the diff cover. This is a problem with the alloy chassis and might be for carbon too but I don't know.

If the FFG moves more one way than the other then it is likely not centered properly. Undo the screws holding the FFG at the rear and carefully reposition it and ensure it remains central whilst tightening the screws.

Also check your battery is not too far inboard. It can foul the FFG also.

Make sure all the stops are not pressed tightly or this will restrict movement.

Ensure that where the gearbox goes through the bulkhead is free from dirt and debris and that whatever tape you have used here is still smooth and clean. I am replacing this tape after every meeting so far. To make this easier I am now putting the tape on the gearbox not the bulk head.

Hope this helps!

EDIT: Forgot to mention make sure the diff cover is closed properly once installed on the front gear box. Mine took a little wiggling before they snapped shut properly and it was possible to tighten everything up with the diff cover not closed properly.

Make sure the screw I show in the picture here is not too long (it is too long in the picture). If it is too long it will foul the diff cover. This is a problem with the alloy chassis and might be for carbon too but I don't know.

If the FFG moves more one way than the other then it is likely not centered properly. Undo the screws holding the FFG at the rear and carefully reposition it and ensure it remains central whilst tightening the screws.

Also check your battery is not too far inboard. It can foul the FFG also.

Make sure all the stops are not pressed tightly or this will restrict movement.

Ensure that where the gearbox goes through the bulkhead is free from dirt and debris and that whatever tape you have used here is still smooth and clean. I am replacing this tape after every meeting so far. To make this easier I am now putting the tape on the gearbox not the bulk head.

Hope this helps!

EDIT: Forgot to mention make sure the diff cover is closed properly once installed on the front gear box. Mine took a little wiggling before they snapped shut properly and it was possible to tighten everything up with the diff cover not closed properly.

#5691

two c01al setups we used at Snowbirds were--

AM30 -- center screw hole w/ flat head screw -- front and rear screw holes w/ a set screw [i.e. the fairtrace in 17.5/13.5]

AM30 -- all holes filled minus the rear most screw w/ flat heads -- brace 'jb weld'd' once we've verified the screws allowed for a flat chassis [i.e. the cyrul and hanulec in mod]

AM30 -- center screw hole w/ flat head screw -- front and rear screw holes w/ a set screw [i.e. the fairtrace in 17.5/13.5]

AM30 -- all holes filled minus the rear most screw w/ flat heads -- brace 'jb weld'd' once we've verified the screws allowed for a flat chassis [i.e. the cyrul and hanulec in mod]

Currently I have mine screwed on with all screws, no glue. It took some messing with screw tensions and tightening order to get the chassis flat. Removing the rear most screw makes it a lot easier to get flat.

EDIT: Sorry I'm making a lot of posts. I'll put this one as an edit to minimise spam!

Just noticed this AM30-1 http://shop.awesomatixusa.com/a700-am30-1.html

Has AM30 been updated already? Can anyone tell me the difference between AM30 and AM30-1 please? Or even better have a photo?

#5692

Tech Fanatic

AM30-1 is stiffer, higher, narrower (5mm) and easy for installation (the gluing is not important).

The first photo of AM30-1.

The first photo of AM30-1.

#5693

Thanks for that Oleg, something else to add to my shopping list =]

Sadly I have to report I'm as stuck as many with getting the FFG moving freely with the diff cover installed.

Using the tips I posted above I have the FFG moving freely whilst the car is on the car stand but as soon as it is on it's wheels it binds up again. I can hear something rubbing but can't see what it is. I'm out of time/patience for today but will investigate it further when I do have more time/patience.

Some other things I had to take care of just to get it moving freely on the car stand was when tightening the 2 screws that hold the front gear box onto carbon rod assembly make sure the gear box does not twist and sits straight. Otherwise I found this limited the overall movement on one side.

For the same reason as above make sure the front bulkhead is square and straight.

After doing this I found the nub of plastic on the bottom of the diff cover was rubbing on the lower deck so I sanded a little material away. I think this nub might be what is limiting some of the movement and protecting the system so I don't think it's a good idea to entirely remove it or remove too much material just enough to get it moving freely.

Sadly I have to report I'm as stuck as many with getting the FFG moving freely with the diff cover installed.

Using the tips I posted above I have the FFG moving freely whilst the car is on the car stand but as soon as it is on it's wheels it binds up again. I can hear something rubbing but can't see what it is. I'm out of time/patience for today but will investigate it further when I do have more time/patience.

Some other things I had to take care of just to get it moving freely on the car stand was when tightening the 2 screws that hold the front gear box onto carbon rod assembly make sure the gear box does not twist and sits straight. Otherwise I found this limited the overall movement on one side.

For the same reason as above make sure the front bulkhead is square and straight.

After doing this I found the nub of plastic on the bottom of the diff cover was rubbing on the lower deck so I sanded a little material away. I think this nub might be what is limiting some of the movement and protecting the system so I don't think it's a good idea to entirely remove it or remove too much material just enough to get it moving freely.

#5694

Hi guys,

Something to share which will ensure the FFG moves more freely when car is on it's wheels.

You can use B74RS bearing + 1mm shim (ensure diameter is small enough to fit into rectangle cutout)+ ST08 nut instead of P31.

Some material may need to be removed from the right side steering link ball cup to ensure it does not rub on the bearing.

This solution also allows for tightening without the fear of stripping P31.

I have track tested this solution and found the FFG system needs less attention.

Something to share which will ensure the FFG moves more freely when car is on it's wheels.

You can use B74RS bearing + 1mm shim (ensure diameter is small enough to fit into rectangle cutout)+ ST08 nut instead of P31.

Some material may need to be removed from the right side steering link ball cup to ensure it does not rub on the bearing.

This solution also allows for tightening without the fear of stripping P31.

I have track tested this solution and found the FFG system needs less attention.

#5695

Tech Fanatic

#5696

Hi guys,

Something to share which will ensure the FFG moves more freely when car is on it's wheels.

You can use B74RS bearing + 1mm shim (ensure diameter is small enough to fit into rectangle cutout)+ ST08 nut instead of P31.

Some material may need to be removed from the right side steering link ball cup to ensure it does not rub on the bearing.

This solution also allows for tightening without the fear of stripping P31.

I have track tested this solution and found the FFG system needs less attention.

Something to share which will ensure the FFG moves more freely when car is on it's wheels.

You can use B74RS bearing + 1mm shim (ensure diameter is small enough to fit into rectangle cutout)+ ST08 nut instead of P31.

Some material may need to be removed from the right side steering link ball cup to ensure it does not rub on the bearing.

This solution also allows for tightening without the fear of stripping P31.

I have track tested this solution and found the FFG system needs less attention.

Thanks for clarifying that one Oleg. I'm pretty sure I just need to straighten the front bulkhead on my car to get everything moving sweetly again =]

#5697

Hi guys,

Something to share which will ensure the FFG moves more freely when car is on it's wheels.

You can use B74RS bearing + 1mm shim (ensure diameter is small enough to fit into rectangle cutout)+ ST08 nut instead of P31.

Some material may need to be removed from the right side steering link ball cup to ensure it does not rub on the bearing.

This solution also allows for tightening without the fear of stripping P31.

I have track tested this solution and found the FFG system needs less attention.

Something to share which will ensure the FFG moves more freely when car is on it's wheels.

You can use B74RS bearing + 1mm shim (ensure diameter is small enough to fit into rectangle cutout)+ ST08 nut instead of P31.

Some material may need to be removed from the right side steering link ball cup to ensure it does not rub on the bearing.

This solution also allows for tightening without the fear of stripping P31.

I have track tested this solution and found the FFG system needs less attention.

About the PTFE tape. I didn't have any to hand so I used a piece of foil backed plastic - a Kinder chocolate bar wrapper - and backed it with thin double sided tape. Then Tamiya AW grease top and bottom of the gearbox. Free movement, no wear. Works perfect.

#5698

Tech Fanatic

Guys,

Please explain what is the problem to find 3M Scotch Magic Tape for FFG?

We have this tape in every supermarket of my region ( in the departments of stationery/office products) !

Please explain what is the problem to find 3M Scotch Magic Tape for FFG?

We have this tape in every supermarket of my region ( in the departments of stationery/office products) !

143Likes

143Likes