BMI's DB12R

#5086

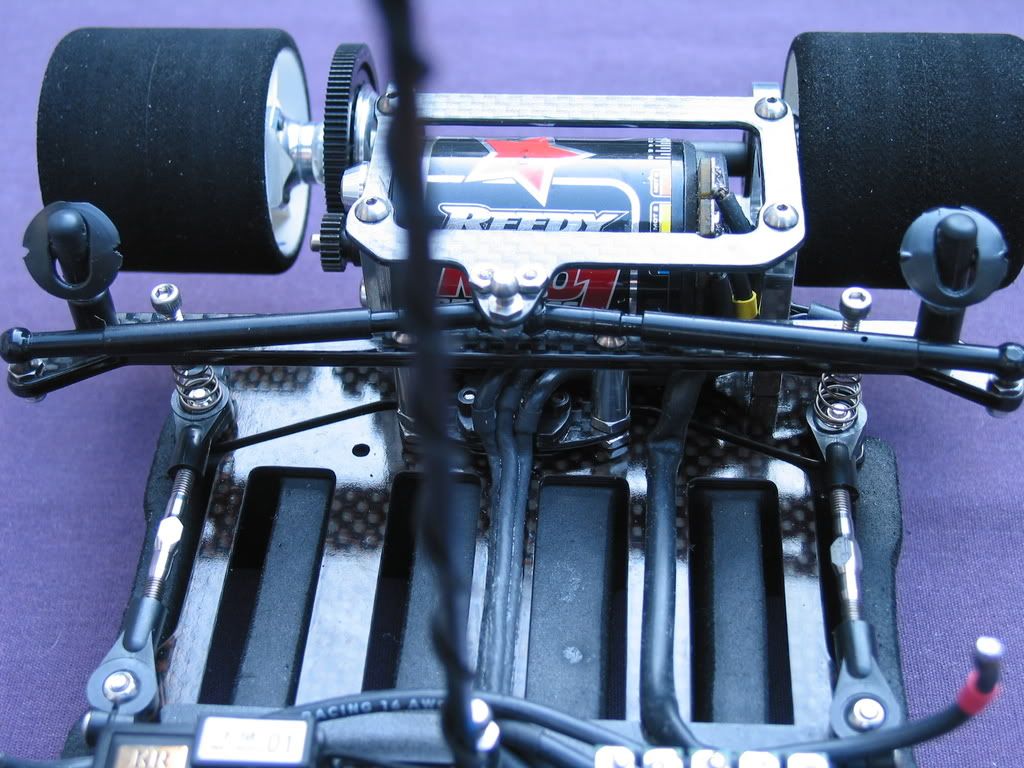

We run asphault. All the BMIs here run with their batteries all the back except for mine. I run mine in the mid position but that's only because I have to run a flat servo due to my servo case having no mounting ears on it. Here's my car:

#5087

For those who know the GTB better thank I...I'm really not liking how thick the wires are leading to the cap...It makes it a real pain to place the cap where I like. Will it effect the performance noticably if I put a Dean's connector on it to make wiring easier or if I change out the wires to 16awg like the rest of the wires?

#5088

Thanks OD that's what I was looking for. I was originally looking to put the capacitor up front by the transponder due to the size of the reciever...But I was having fits working with that hugely thick wire on the capacitor.

I've seen a few of your great wiring jobs here on RC Tech and was wondering...on chassis where you run the motor wires on the chassis, what do you use to hold it there? I've been using the sticker sheets that look like graphite but I haven't really been happy with that.

I've seen a few of your great wiring jobs here on RC Tech and was wondering...on chassis where you run the motor wires on the chassis, what do you use to hold it there? I've been using the sticker sheets that look like graphite but I haven't really been happy with that.

#5089

I always replace the capacitor wires on the GTB with 18ga. I usually place the cap on the side of the chassis opposite the esc to help balance the car, so the wires need to be a touch longer. I've never seen any performance difference on any of the cars I've done this to...I'm not sure why you would want to put a plug on, I just replace the wires all the way from the esc to the cap

Inspector--are you underweight and NEED the weight of the nickel? If not (and I doubt you are) why not move your receiver and cap out to the right edge of the chassis and leverage their existing (and required) mass? Not sure it would get you ALL the way there (though I'm able to balance out my monster GTB) but at least maybe it gets you down to a dime (or less).

#5090

+1

Inspector--are you underweight and NEED the weight of the nickel? If not (and I doubt you are) why not move your receiver and cap out to the right edge of the chassis and leverage their existing (and required) mass? Not sure it would get you ALL the way there (though I'm able to balance out my monster GTB) but at least maybe it gets you down to a dime (or less).

Inspector--are you underweight and NEED the weight of the nickel? If not (and I doubt you are) why not move your receiver and cap out to the right edge of the chassis and leverage their existing (and required) mass? Not sure it would get you ALL the way there (though I'm able to balance out my monster GTB) but at least maybe it gets you down to a dime (or less).

The servo I'm running is a bit lighter and more narrow then what most people run in 1/12th so it's likely not adding as much weight to that side as other servos. So it probably needed the nickle where people running a more common servo wouldn't need it.

The servo I'm running is a bit lighter and more narrow then what most people run in 1/12th so it's likely not adding as much weight to that side as other servos. So it probably needed the nickle where people running a more common servo wouldn't need it.

#5091

#5092

...I've seen a few of your great wiring jobs here on RC Tech and was wondering...on chassis where you run the motor wires on the chassis, what do you use to hold it there? I've been using the sticker sheets that look like graphite but I haven't really been happy with that.

All that being said, the wires mostly only need to be held in place until the batteries are installed

#5093

Hmmmm...not sure I'd like epoxy, that would be difficult to remove from the chassis. The wire may come off the epoxy fine but the epoxy off the chassis I just don't know if I want ti be that permanent. I've tried shoe goo since that works so well for electronics but with the small amount of contact area on wires it just doesn't work. I just had an idea though...I wonder how well Shoe Goo or another Silicone glue would work with a straw...maybe I can find some sort of plastic straw that the wire fits a bit tight into and Shoe Goo the straw to the chassis. Hmmmm

#5094

Well your really talking about 2 different cars...the cap I've been asking about is on a Novak GTB on a customer car. The car with the nickle on it is mine and the cap is the very small and light Tekin cap. Originally I had my PTX transponder where the nickle is so my electronics pretty much were all the way over and I still needed to add a little weight to balance it. Note I balanced it without the rear pod...trying that idea out too  The servo I'm running is a bit lighter and more narrow then what most people run in 1/12th so it's likely not adding as much weight to that side as other servos. So it probably needed the nickle where people running a more common servo wouldn't need it.

The servo I'm running is a bit lighter and more narrow then what most people run in 1/12th so it's likely not adding as much weight to that side as other servos. So it probably needed the nickle where people running a more common servo wouldn't need it.

The servo I'm running is a bit lighter and more narrow then what most people run in 1/12th so it's likely not adding as much weight to that side as other servos. So it probably needed the nickle where people running a more common servo wouldn't need it.

The servo I'm running is a bit lighter and more narrow then what most people run in 1/12th so it's likely not adding as much weight to that side as other servos. So it probably needed the nickle where people running a more common servo wouldn't need it.I think you're DEAD on with the balancing sans rear pod. I've been doing that on my cars for a while now and am very pleased with the results. Nothing like building a brand new car, aligning it with my Niftech bars, throwing it on the track and not even needing to adjust steering trim. I LOVE these cars!!

#5095

Nope...just talking about your car. You have a cap. You have a receiver. Move 'em as far as you can to the right. Eliminate need for nickel. Leverage, my friend, leverage.

I think you're DEAD on with the balancing sans rear pod. I've been doing that on my cars for a while now and am very pleased with the results. Nothing like building a brand new car, aligning it with my Niftech bars, throwing it on the track and not even needing to adjust steering trim. I LOVE these cars!!

I think you're DEAD on with the balancing sans rear pod. I've been doing that on my cars for a while now and am very pleased with the results. Nothing like building a brand new car, aligning it with my Niftech bars, throwing it on the track and not even needing to adjust steering trim. I LOVE these cars!!

I really like my old Holeshot alignment board...it's kind of an early Hudy type setup but with the toe gauge on the bottom instead of on the top.

#5096

Hmmmm...not sure I'd like epoxy, that would be difficult to remove from the chassis. The wire may come off the epoxy fine but the epoxy off the chassis I just don't know if I want ti be that permanent. I've tried shoe goo since that works so well for electronics but with the small amount of contact area on wires it just doesn't work. I just had an idea though...I wonder how well Shoe Goo or another Silicone glue would work with a straw...maybe I can find some sort of plastic straw that the wire fits a bit tight into and Shoe Goo the straw to the chassis. Hmmmm

Your straw idea can work as long as you are only running one wire under the battery, otherwise it may not fit in that little space between the batteries.

There is another way to do it that I use but it is almost too much work

By using this method I can get all three motor wires under the one middle battery space. First lay the wires out in their approximate final positions, then strip the insulation off of the wires the entire length of where they pass under the batteries (plus a little bit on either end) Then shrink wrap them (individually, duh) with the smallest diameter wrap you can get around them. Then glue two of them to the chassis right next to each other the distance of the battery slot. After that glue the third wire on top of the first two, like a little log pile. The glue, ca or shoo goo will stick to the shrink wrap really well. Too much work but it will amaze your friends

By using this method I can get all three motor wires under the one middle battery space. First lay the wires out in their approximate final positions, then strip the insulation off of the wires the entire length of where they pass under the batteries (plus a little bit on either end) Then shrink wrap them (individually, duh) with the smallest diameter wrap you can get around them. Then glue two of them to the chassis right next to each other the distance of the battery slot. After that glue the third wire on top of the first two, like a little log pile. The glue, ca or shoo goo will stick to the shrink wrap really well. Too much work but it will amaze your friends

I think I have a pic

I think I have a pic

#5097

I like that...but given the DB12R has the battery locater in the middle the wires won't fit there

However...it might work on one of the other slots if I do it right...hmmmm

However...it might work on one of the other slots if I do it right...hmmmm

#5098

So I have a solution, but only if you run your batteries in the same position all the time

1. chassis, plugs and carbon fiber strip (.007)

2. plugs glued in with epoxy

3. carbon fiber strip glued on top

#5099

interesting idea...could probably get away with shoe goo'ing in the spacers so that they are still removeable. I've been thinking along a different line...I'm always frustrated with my cell shrink wrap getting ripped up over time running on outdoor asphault. I've been thinking about building a small vaccuum form machine and making lexan trays for the battery to sit in to protect them. Possibly I could incorporate the 2 ideas and have the tray serve as the battery positioner as well.

Why not shrink the whole wire? The silicone is more flexible but with the heat shrink being so much thinner it shouldn't sacrafice flexability.

Why not shrink the whole wire? The silicone is more flexible but with the heat shrink being so much thinner it shouldn't sacrafice flexability.

#5100

InspGadgt...

This is the layout of my car. see attached file.

E

This is the layout of my car. see attached file.

E