Team Associated TC5

Protoform Mazda 6 or speed 6, LTC RF-9, all 190mm bodies will work

Tech Regular

iTrader: (7)

Tech Regular

iTrader: (7)

What's a good gear ratio to run in the TC5 for street driving?

Thanks

Erik

Thanks

Erik

Tech Regular

iTrader: (7)

Whats the best way to get more turn in out of the car? I've running the IIC 2009 setup and having it push in and little loose off. On the straight the inside rear will spin before the car takes off.

Tech Master

iTrader: (15)

Depends on your class. 190mm for the standard touring classes. Things change if you decide to run VTA or RCGT.

Tech Fanatic

iTrader: (13)

After street racing last night with my tc5r, I cleaned it and noticed a

thin long twig got caught between the steering block and the aluminum

hex hub. The curled twig damaged the bearing seal. And I dont have a

spare, I just cleaned it and flipped it. Will take weeks for our LHS to have

replacement axle bearing.

Can I use a metal shielded axle bearing from any Tamiya RC kits?

Some hobby shop carry more Tamiya stuff so that is my option

Thanks in advance

thin long twig got caught between the steering block and the aluminum

hex hub. The curled twig damaged the bearing seal. And I dont have a

spare, I just cleaned it and flipped it. Will take weeks for our LHS to have

replacement axle bearing.

Can I use a metal shielded axle bearing from any Tamiya RC kits?

Some hobby shop carry more Tamiya stuff so that is my option

Thanks in advance

Tech Master

iTrader: (42)

Anything Tamiya will probably be metric, so it won't fit, but if something does then go for it.

Tech Fanatic

iTrader: (13)

I have the TC5R which uses metric screws and totally different from what

my TC4 is using (well except for the 3-32 diff balls). In the manual it says

6x10 bearings. I believe that's metric. Any Tamiya counterpart axle bearing?

my TC4 is using (well except for the 3-32 diff balls). In the manual it says

6x10 bearings. I believe that's metric. Any Tamiya counterpart axle bearing?

Tech Master

iTrader: (89)

Tech Fanatic

iTrader: (13)

Found it, thanks ü

Ask some of the guys at the track you will be racing at, but you can try 9 or 10 fdr. Do a few laps and check temps. www.gearchart.com

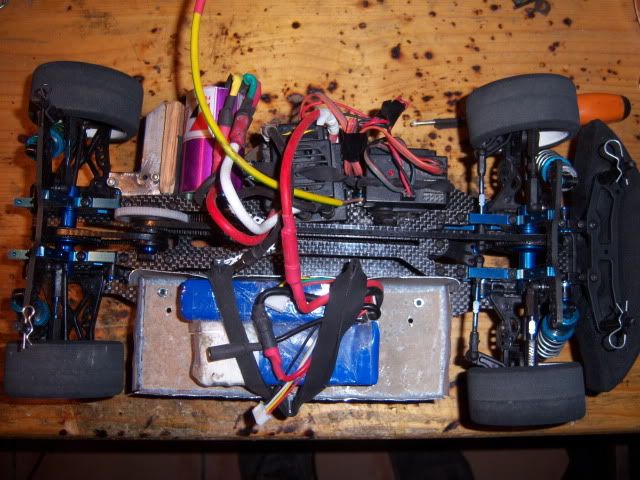

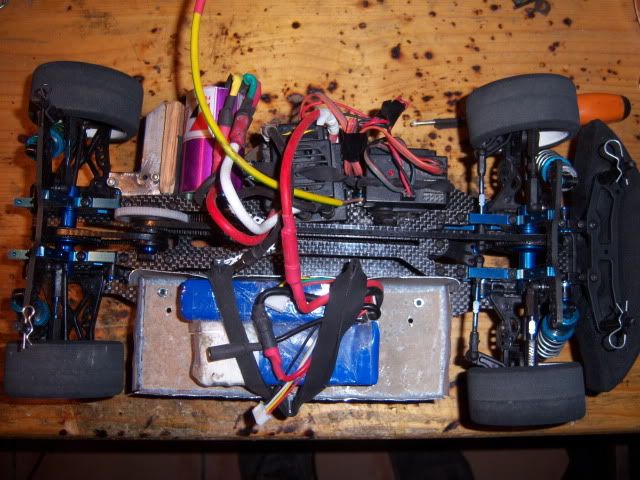

this is my "suicide tc5":

Tech Adept

I'm having some problems getting the rebound set right on 2 of my TC5r shocks. I changed the weight of the oil and now I can't get 2 of the shocks to rebound evenly. I've got small holes drilled in the caps already. I've never had this problem before.

The procedure I use is as follows:

1) fill the shocks with oil, move pistons up and down to get the air bubbles out. Let sit for a while then top up with oil so that oil is level with the top of the shock.

2) Fit bladder into shock cap (with no foam above).

3) Push shock shaft right into the shock slowly so that the ball stud is flush with the bottom of the shock body. There is very little oil above the shock piston but no air bubbles if done slowly.

4) screw on shock cap and displace oil.

This worked fine for 2 shocks but the other 2 I can't get to not rebound. They don't even rebound at the same rate. This procedure has worked fine for me in the past but for some reason I'm having no end of trouble this time around.

Do I need to drill bigger holes in the caps? I used a really small drill to do it last time but the hole is not blocked by anything.

Any ideas on how I can get these shocks to not rebound or at least to rebound evenly would be great.

The procedure I use is as follows:

1) fill the shocks with oil, move pistons up and down to get the air bubbles out. Let sit for a while then top up with oil so that oil is level with the top of the shock.

2) Fit bladder into shock cap (with no foam above).

3) Push shock shaft right into the shock slowly so that the ball stud is flush with the bottom of the shock body. There is very little oil above the shock piston but no air bubbles if done slowly.

4) screw on shock cap and displace oil.

This worked fine for 2 shocks but the other 2 I can't get to not rebound. They don't even rebound at the same rate. This procedure has worked fine for me in the past but for some reason I'm having no end of trouble this time around.

Do I need to drill bigger holes in the caps? I used a really small drill to do it last time but the hole is not blocked by anything.

Any ideas on how I can get these shocks to not rebound or at least to rebound evenly would be great.