Mid-Corner Hop - Technical Investigation

#1

Hi all,

I'm starting this thread to discuss a very peculiar, and not very common, handling phenomenon.

On high grip tracks, the behaviour of a car in the middle of the corner is obviously very important to get right in order to maximize corner speed without grip rolling. It's quite easy to understand what's happening in a grip roll situation; the lateral grip force pushing on the outside tyres of the car is sufficiently higher than the downward force of gravity/aero on the cars centre of gravity to make the CofG rise up. The more the CofG rises the more leverage the outside tyre is putting on it so it quickly gets higher and higher until the tyres break traction or the car flips over.

Grip roll can be combatted by softening the cars roll stiffness so the suspension absorbs more of the roll - pretty simple really.

The strange problem I'm encountering is not grip roll. In fact I don't recall ever having grip rolled this particular chassis. The problem is, when the grip comes up (it's fine in low grip conditions) the car will simply bounce and skip across the track resulting in sudden loss of control.

It's particularly bad when there are any bumps in the corner, no matter how slight. It's almost like the suspension is losing any ability to absorb bumps whilst it's already under load 🤔 I've never seen other cars respond in this way - at least to this extent and I'm desperate to work out what's happening.

It's a problem which has been really bugging me for ages but it's hard to analyze it with out a high speed video camera and a day at the track.

Has anyone else ever experienced this problem and how did you solve it?

I'm currently running a setup which seems pretty generic for grey carpet:

I'm starting this thread to discuss a very peculiar, and not very common, handling phenomenon.

On high grip tracks, the behaviour of a car in the middle of the corner is obviously very important to get right in order to maximize corner speed without grip rolling. It's quite easy to understand what's happening in a grip roll situation; the lateral grip force pushing on the outside tyres of the car is sufficiently higher than the downward force of gravity/aero on the cars centre of gravity to make the CofG rise up. The more the CofG rises the more leverage the outside tyre is putting on it so it quickly gets higher and higher until the tyres break traction or the car flips over.

Grip roll can be combatted by softening the cars roll stiffness so the suspension absorbs more of the roll - pretty simple really.

The strange problem I'm encountering is not grip roll. In fact I don't recall ever having grip rolled this particular chassis. The problem is, when the grip comes up (it's fine in low grip conditions) the car will simply bounce and skip across the track resulting in sudden loss of control.

It's particularly bad when there are any bumps in the corner, no matter how slight. It's almost like the suspension is losing any ability to absorb bumps whilst it's already under load 🤔 I've never seen other cars respond in this way - at least to this extent and I'm desperate to work out what's happening.

It's a problem which has been really bugging me for ages but it's hard to analyze it with out a high speed video camera and a day at the track.

Has anyone else ever experienced this problem and how did you solve it?

I'm currently running a setup which seems pretty generic for grey carpet:

- 2.6 springs all round

- 450 or 400 CST oil depending on temperature

- Vented shock caps (outer section is vented but looks like inner part gets sealed off under compression??)

- 1.4 front 1.3 rear ARB

- 2.5mm front, 3mm rear droop

- 5mm front 5.2mm rear ride height.

- -2° or -1.5° camber all round

- -2.5° rear toe +1° front.

- Roll centres are fairly equal height front to rear at about -6.5mm.

- Carbon chassis (quite flexible especially just behind front bulkhead but have experimented with stiffening - doesn't seem to have much effect on the bouncing).

- Graphite suspension arms (stiff)

- Car is well balanced left to right and front to rear (within 0.5%) and not tweaked. Body shell has plenty of clearance and up travel.

#2

This page (for full size vehicles)

Vehicle Dynamics - Cause And Effect Guide - Race & Track Driving (formerly Win HPDE)

Suggests it could be too much ARB ("car may dart over one wheel bumps") or too much high speed damping?

Vehicle Dynamics - Cause And Effect Guide - Race & Track Driving (formerly Win HPDE)

Suggests it could be too much ARB ("car may dart over one wheel bumps") or too much high speed damping?

#3

Remember me?

You're running out of shock travel, almost everyone does and some cars handle that situation better than others depending on the flex.

The springs are too soft particularly the front ones let's do the math shall we?

Let's pick 2.6 xray springs which were tested to be 260gr per mm. The car weights 1350 and each wheel has 25% of the total weight, assuming common motion ratios and shock angle.

Each wheel has 337.5gr, motion ratio on the front is 0.55 and cosine of 35* shock angle is 0.82. 260x.55x0.82=approx. 117.3gr.mm wheel rate, 337.5/117.3=approx. 2.9mm of deflection at rest.

Being that on high grip tracks 2G are possible and this is the limit before traction roll, let's simplify calculations and say all the load of the inner tyres was transferred to the outside tyres, 337.5gr +337.5gr=675gr. The roll bar contributes with 25gm.mm so 117.3+25=142.3gr.mm during roll. 675/142.3=4.74mm shock travel used.

Droop changes when you reach the point of transferring all the inside tyre load so that can happen at 1.5G or lower at combined lateral and longitudinal acceleration, for example corner entry where you steer and decelerate. Braking acceleration can exceed 2G easily.

Hope it helps.

You're running out of shock travel, almost everyone does and some cars handle that situation better than others depending on the flex.

The springs are too soft particularly the front ones let's do the math shall we?

Let's pick 2.6 xray springs which were tested to be 260gr per mm. The car weights 1350 and each wheel has 25% of the total weight, assuming common motion ratios and shock angle.

Each wheel has 337.5gr, motion ratio on the front is 0.55 and cosine of 35* shock angle is 0.82. 260x.55x0.82=approx. 117.3gr.mm wheel rate, 337.5/117.3=approx. 2.9mm of deflection at rest.

Being that on high grip tracks 2G are possible and this is the limit before traction roll, let's simplify calculations and say all the load of the inner tyres was transferred to the outside tyres, 337.5gr +337.5gr=675gr. The roll bar contributes with 25gm.mm so 117.3+25=142.3gr.mm during roll. 675/142.3=4.74mm shock travel used.

Droop changes when you reach the point of transferring all the inside tyre load so that can happen at 1.5G or lower at combined lateral and longitudinal acceleration, for example corner entry where you steer and decelerate. Braking acceleration can exceed 2G easily.

Hope it helps.

#4

The wheels could be binding against something. Check that it isn't rubbing against suspension components by reducing EPA.

Try taking the corner slower and see if it happens

Try running without the bodyshell

Or try a different shell

Check UJs for wear/loose pins and drivebelts.

Run different tyres. It could entirely be down to a quirk in the rubber compound.

Try taking the corner slower and see if it happens

Try running without the bodyshell

Or try a different shell

Check UJs for wear/loose pins and drivebelts.

Run different tyres. It could entirely be down to a quirk in the rubber compound.

#7

Hi! good to see you replying. One of the most knowledgeable people out there!

Right. I couldn't work out if the car was just bottoming out or I was running out of travel. I've tried using o-ring bump stops on the shock shafts to calm it down in the past; it didn't really help a lot but 'the problem' happened more gradually. Just measured the shocks on the car (front end)

Total travel off the car = 8.8mm (irrelevant as it's longer than when at full droop but it does mean the piston isn't resting at the bottom of the shock body)

Spring length at full droop = 20.25 mm (slightly compressed)

At ride height ready to go = 1.65mm compressed

Compression at max wheel travel = 6.43 mm

so total shock travel availble from ride height = 4.78 mm (pretty close to what you calculated!!)

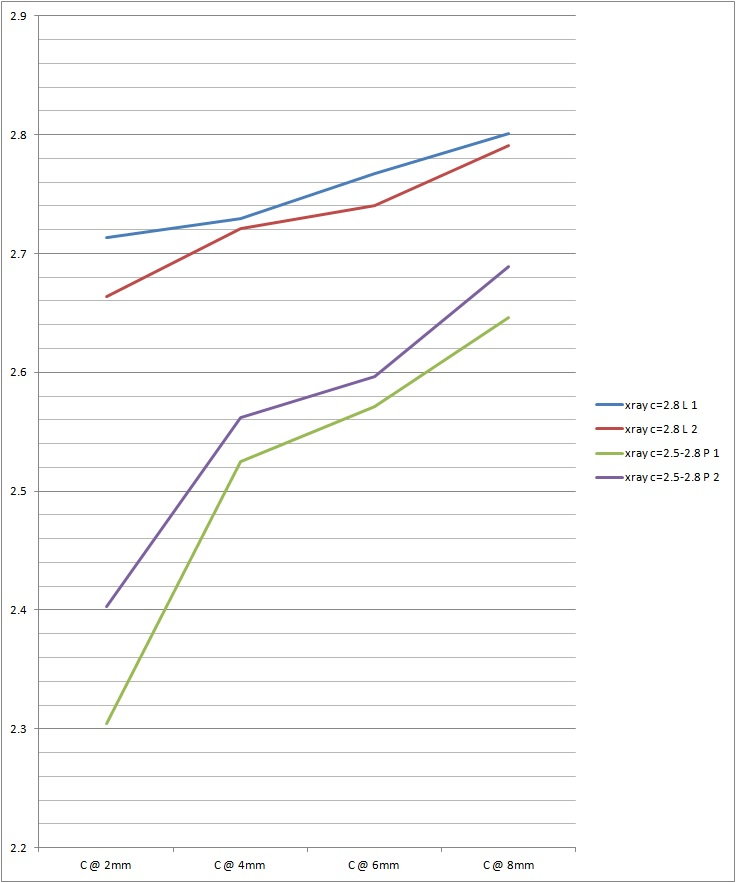

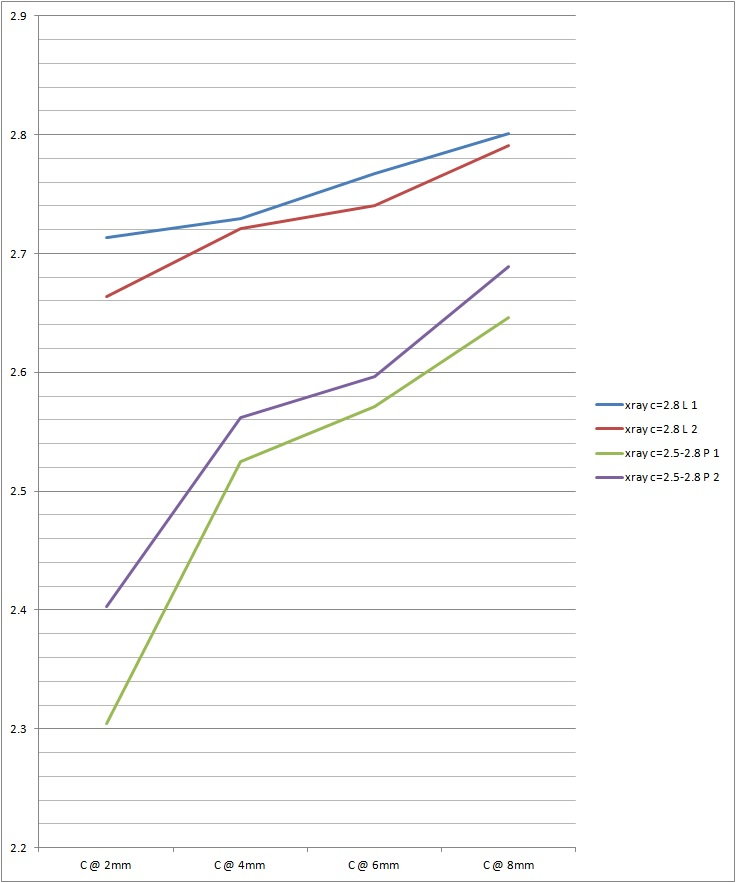

It's worse than that; all the springs I have measured are softer in the first half of their range, with the quoted rate being applicable at full compression (which will never be reached before runnin out of shock travel)

The springs I am currently running (3 racing white) measure C=2.35 N/mm at 4mm compression. I was, however using the outer hole on the front shock tower to make it a little stiffer.

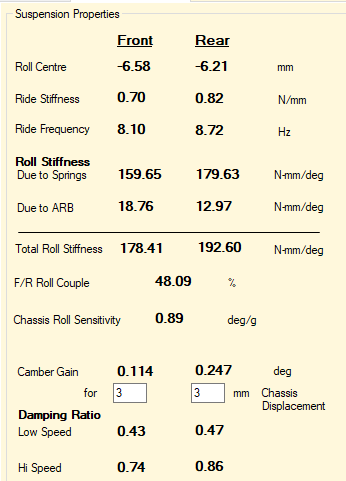

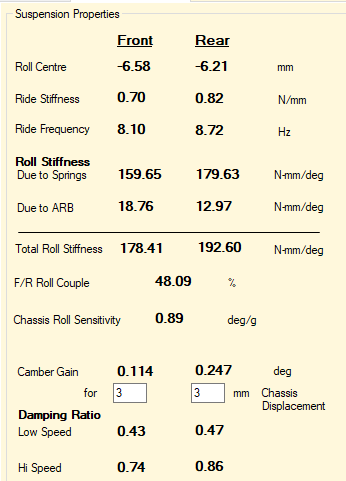

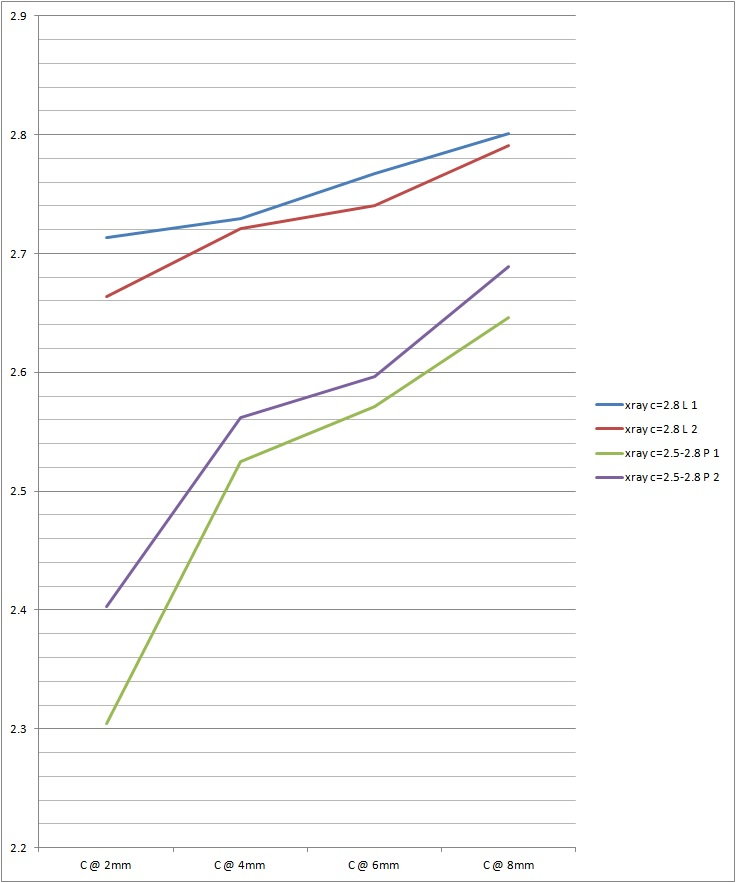

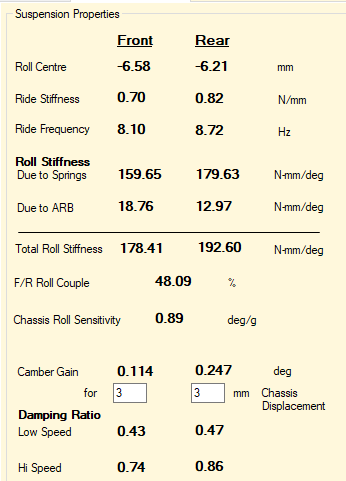

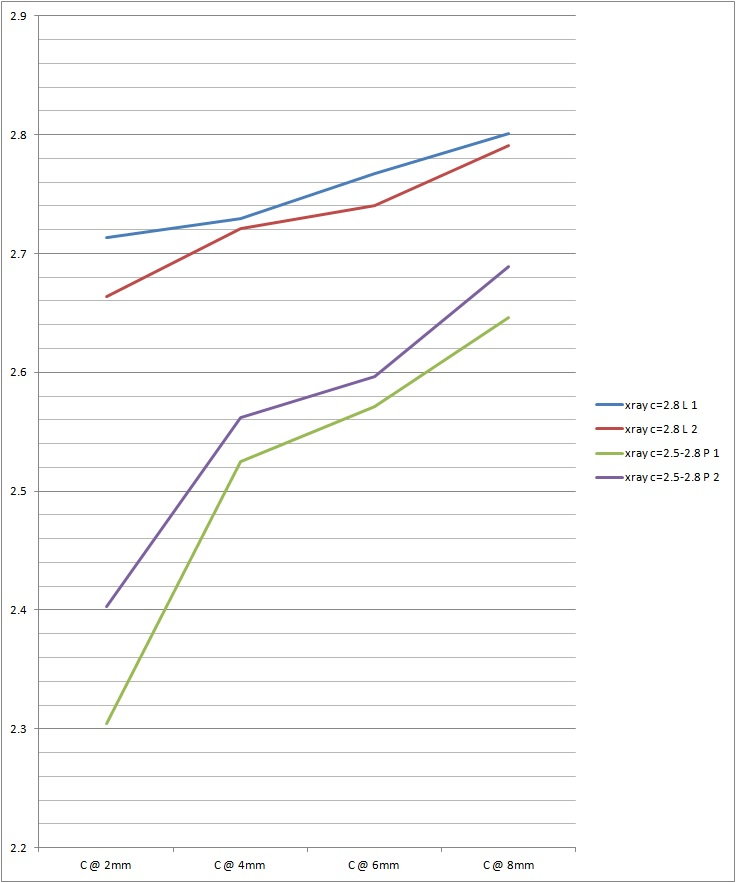

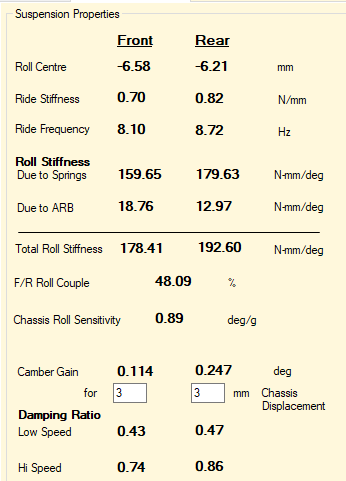

FYI here's the numbers from RC3 for this setup

I think that's even softer than you were basing your calculations on, or is it just the difference in units between grams and Newtons?

Total travel off the car = 8.8mm (irrelevant as it's longer than when at full droop but it does mean the piston isn't resting at the bottom of the shock body)

Spring length at full droop = 20.25 mm (slightly compressed)

At ride height ready to go = 1.65mm compressed

Compression at max wheel travel = 6.43 mm

so total shock travel availble from ride height = 4.78 mm (pretty close to what you calculated!!)

The springs I am currently running (3 racing white) measure C=2.35 N/mm at 4mm compression. I was, however using the outer hole on the front shock tower to make it a little stiffer.

The car weights 1350 and each wheel has 25% of the total weight, assuming common motion ratios and shock angle.

Each wheel has 337.5gr, motion ratio on the front is 0.55 and cosine of 35* shock angle is 0.82. 260x.55x0.82=approx. 117.3gr.mm wheel rate, 337.5/117.3=approx. 2.9mm of deflection at rest.

Being that on high grip tracks 2G are possible and this is the limit before traction roll, let's simplify calculations and say all the load of the inner tyres was transferred to the outside tyres, 337.5gr +337.5gr=675gr. The roll bar contributes with 25gm.mm so 117.3+25=142.3gr.mm during roll. 675/142.3=4.74mm shock travel used.

Each wheel has 337.5gr, motion ratio on the front is 0.55 and cosine of 35* shock angle is 0.82. 260x.55x0.82=approx. 117.3gr.mm wheel rate, 337.5/117.3=approx. 2.9mm of deflection at rest.

Being that on high grip tracks 2G are possible and this is the limit before traction roll, let's simplify calculations and say all the load of the inner tyres was transferred to the outside tyres, 337.5gr +337.5gr=675gr. The roll bar contributes with 25gm.mm so 117.3+25=142.3gr.mm during roll. 675/142.3=4.74mm shock travel used.

I think that's even softer than you were basing your calculations on, or is it just the difference in units between grams and Newtons?

#8

In yesterday's case the tyres were fairly equal in terms of temperature and tackyness. The balance of the car when it was on the track was actually really good, but it would suddenly hit a limit point and bounce up into the air obviously loosing all grip as it does so.

#9

The wheels could be binding against something. Check that it isn't rubbing against suspension components by reducing EPA.

Try taking the corner slower and see if it happens

Try running without the bodyshell

Or try a different shell

Check UJs for wear/loose pins and drivebelts.

Run different tyres. It could entirely be down to a quirk in the rubber compound.

Try taking the corner slower and see if it happens

Try running without the bodyshell

Or try a different shell

Check UJs for wear/loose pins and drivebelts.

Run different tyres. It could entirely be down to a quirk in the rubber compound.

#11

The car can be a bit oversteery on exit but this only happens if i'm over correcting for the erratic behaviour in the mid corner.

#12

Tech Initiate

You’d think a stiffer chassis would help stop it from loading up and ‘springing’ back, but you said you already tried that.

Wider front track width to put less weight over the outside tyre?

Maybe freeing the rear up would help the front tyres out? You say it’s mid corner, is it mostly off power or on or both? If it’s off power and you have some oversteer when you get on power at exit anyway, a thinner diff might help rotate the car without asking so much of the front tyres?

Wider front track width to put less weight over the outside tyre?

Maybe freeing the rear up would help the front tyres out? You say it’s mid corner, is it mostly off power or on or both? If it’s off power and you have some oversteer when you get on power at exit anyway, a thinner diff might help rotate the car without asking so much of the front tyres?

#13

I used to encounter this back in the day on gray carpet. Usually I would use the “chatter out point” as the point where my dampening was too light for the rear end. For me going up 1 rate in CST (50) or 2.5-5.0 wt would fix it and this would be my ideal oil to run with the specific spring I was running.

Heavier springs require heavier oil and vice versa.

Few things mechanically that could be wrong:

-check to see your pistons are not loose or that they have come undone.

-check your rear or front out drives. Are they worn out? Do they have notches on them? What material are they? Broken blades? Notches?

-are the tires glued properly?

Heavier springs require heavier oil and vice versa.

Few things mechanically that could be wrong:

-check to see your pistons are not loose or that they have come undone.

-check your rear or front out drives. Are they worn out? Do they have notches on them? What material are they? Broken blades? Notches?

-are the tires glued properly?

#14

Hi! good to see you replying. One of the most knowledgeable people out there!

Right. I couldn't work out if the car was just bottoming out or I was running out of travel. I've tried using o-ring bump stops on the shock shafts to calm it down in the past; it didn't really help a lot but 'the problem' happened more gradually. Just measured the shocks on the car (front end)

Total travel off the car = 8.8mm (irrelevant as it's longer than when at full droop but it does mean the piston isn't resting at the bottom of the shock body)

Spring length at full droop = 20.25 mm (slightly compressed)

At ride height ready to go = 1.65mm compressed

Compression at max wheel travel = 6.43 mm

so total shock travel availble from ride height = 4.78 mm (pretty close to what you calculated!!)

It's worse than that; all the springs I have measured are softer in the first half of their range, with the quoted rate being applicable at full compression (which will never be reached before runnin out of shock travel)

The springs I am currently running (3 racing white) measure C=2.35 N/mm at 4mm compression. I was, however using the outer hole on the front shock tower to make it a little stiffer.

FYI here's the numbers from RC3 for this setup

I think that's even softer than you were basing your calculations on, or is it just the difference in units between grams and Newtons?

Right. I couldn't work out if the car was just bottoming out or I was running out of travel. I've tried using o-ring bump stops on the shock shafts to calm it down in the past; it didn't really help a lot but 'the problem' happened more gradually. Just measured the shocks on the car (front end)

Total travel off the car = 8.8mm (irrelevant as it's longer than when at full droop but it does mean the piston isn't resting at the bottom of the shock body)

Spring length at full droop = 20.25 mm (slightly compressed)

At ride height ready to go = 1.65mm compressed

Compression at max wheel travel = 6.43 mm

so total shock travel availble from ride height = 4.78 mm (pretty close to what you calculated!!)

It's worse than that; all the springs I have measured are softer in the first half of their range, with the quoted rate being applicable at full compression (which will never be reached before runnin out of shock travel)

The springs I am currently running (3 racing white) measure C=2.35 N/mm at 4mm compression. I was, however using the outer hole on the front shock tower to make it a little stiffer.

FYI here's the numbers from RC3 for this setup

I think that's even softer than you were basing your calculations on, or is it just the difference in units between grams and Newtons?

No my calcs converted for Newton would be around 1.1N/mm must be the rate and any changes in motion ratio and shock angle. Don't worry we'll do the right way.

675/4.78=141.2-20(from roll bar)=121.2gr/mm would be a wheel rate stiff enough to get out of trouble. Use the equation above with your car motion ratio and shock angle cosine to find the spring rate.

Funny, if a 2.6 spring would provide a 110gr/mm wheel rate using the motion ratio and shock angle example I used above it would be very close to what you needed.

#15

I used to encounter this back in the day on gray carpet. Usually I would use the “chatter out point” as the point where my dampening was too light for the rear end. For me going up 1 rate in CST (50) or 2.5-5.0 wt would fix it and this would be my ideal oil to run with the specific spring I was running.

-check to see your pistons are not loose or that they have come undone.

-check your rear or front out drives. Are they worn out? Do they have notches on them? What material are they? Broken blades? Notches?

-are the tires glued properly?

-check to see your pistons are not loose or that they have come undone.

-check your rear or front out drives. Are they worn out? Do they have notches on them? What material are they? Broken blades? Notches?

-are the tires glued properly?

24Likes

24Likes