Mid-Corner Hop - Technical Investigation

#16

Yes, it happens because the carpet folds on the edge of the tire. When the car is under dampened the acceleration of the roll is fast and it will dip really fast into the surface. Once it starts oscillating as it goes into the carpet it will release and catch over and over.

I would try heavier oil. High grip on carpet requires more damping than on black carpet.

I would try heavier oil. High grip on carpet requires more damping than on black carpet.

#18

Yes, it happens because the carpet folds on the edge of the tire. When the car is under dampened the acceleration of the roll is fast and it will dip really fast into the surface. Once it starts oscillating as it goes into the carpet it will release and catch over and over.

I would try heavier oil. High grip on carpet requires more damping than on black carpet.

I would try heavier oil. High grip on carpet requires more damping than on black carpet.

I'm curious as to why no-one else at the same tracks seems to suffer the same problem even though they are running similar set-ups?

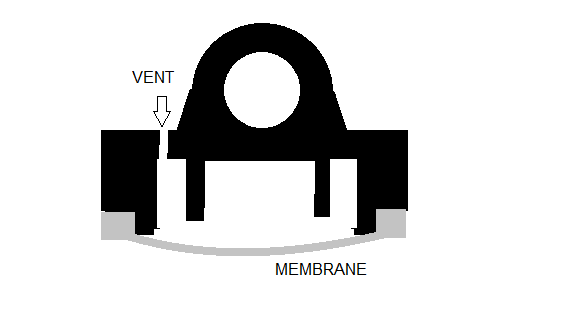

Could it possibly be something to do with the design of the shock cap? ( see pic)

#19

I donít think that the statement is an absolute meaning higher grip needing more damping, but this is often the case when I have run before. The situation described by LZR is similar to what I have experiences in my TC6 days and I even wrote an article about it on our blog a long time ago.

I know as well that MHIC I always ran heavier oil in my car than at my local track and their grip was always higher compared to what I was used to.

#20

Tech Master

If the car jumps from a bump it could be over damped unless you are hitting the end stop.

if the suspension compresses and then loses grip it could be the piston reversal is has a wide hysteresis. Sealing the shock or foam in the membrane will help.

if it is underdamped it will oscillate which could cause the loss of traction and then a regain of traction.

its tough to determine. i dont run conventional shocks but taking my experience from motorcycles...can you turn the shocks upside down? This might isolate membrane issues.

there is an app for the iphone that is a high speed camera. Ive used it and dropping the car on the ground on record makes it pretty easy to get close to proper damping.

if the suspension compresses and then loses grip it could be the piston reversal is has a wide hysteresis. Sealing the shock or foam in the membrane will help.

if it is underdamped it will oscillate which could cause the loss of traction and then a regain of traction.

its tough to determine. i dont run conventional shocks but taking my experience from motorcycles...can you turn the shocks upside down? This might isolate membrane issues.

there is an app for the iphone that is a high speed camera. Ive used it and dropping the car on the ground on record makes it pretty easy to get close to proper damping.

#21

Not sure I understand what you mean by the statement, but sure everything is debatable.

I donít think that the statement is an absolute meaning higher grip needing more damping, but this is often the case when I have run before. The situation described by LZR is similar to what I have experiences in my TC6 days and I even wrote an article about it on our blog a long time ago.

I know as well that MHIC I always ran heavier oil in my car than at my local track and their grip was always higher compared to what I was used to.

My tc6 uses many of your tricks.

#22

Just wanted to find a trend or something. As you said, stiffer springs need more damping, so if I take my example above with a spring that's good enough up to 2Gs (if I'm trying to use same spring on med and high grip tracks) I could use the same damping because I didn't change spring or mass, right?

My tc6 uses many of your tricks.

My tc6 uses many of your tricks.

I think I know where you are going to. My take on it is yes, you could run the same spring and damping, but perhaps that is not the best way to optimize set up. Carpet is many times against ďtheoreticalĒ standard ways of set up. Higher grip usually requires softer springs on carpet to take away a bit of grip and response (potentially traction rolling). Sometimes this can be done with just a spring, because as long as you are within a proper damping envelope, it makes a bigger difference, but many times an increase in damping can go along well with the change to mellow out the car.

My take is, springs are easy to change and make a huge difference. Itís easier than damping changes, so often my first change is to find the right springs for the car. Most of the time, only if I need something else will I mess with damping. Usually the spring envelope that is optimal is within 0.2-0.3 C so matching the oil is often not too important to get around the track.

#24

If the car jumps from a bump it could be over damped unless you are hitting the end stop.

if the suspension compresses and then loses grip it could be the piston reversal is has a wide hysteresis. Sealing the shock or foam in the membrane will help.

if it is underdamped it will oscillate which could cause the loss of traction and then a regain of traction.

its tough to determine. i dont run conventional shocks but taking my experience from motorcycles...can you turn the shocks upside down? This might isolate membrane issues.

there is an app for the iphone that is a high speed camera. Ive used it and dropping the car on the ground on record makes it pretty easy to get close to proper damping.

if the suspension compresses and then loses grip it could be the piston reversal is has a wide hysteresis. Sealing the shock or foam in the membrane will help.

if it is underdamped it will oscillate which could cause the loss of traction and then a regain of traction.

its tough to determine. i dont run conventional shocks but taking my experience from motorcycles...can you turn the shocks upside down? This might isolate membrane issues.

there is an app for the iphone that is a high speed camera. Ive used it and dropping the car on the ground on record makes it pretty easy to get close to proper damping.

#25

Tech Master

I have rotary dampers.

when the suspension compresses it should rebound about 3 times faster than it compressed so that the tire maintains traction.

Visualize your damper. When it compresses the bladder compresses and vents air. The rebound is potentially restricted by a deflated diaphragm and an orifice that will limit the refill of the bladder. Its all speculation without a camera or proof but it is rooted in experience and science. But you can flip the shock over and the diaphragm will not be a factor in the reversal from compression to rebound. If i thought long and hard about it I could probably say something about sprung versus unsprung mass as well.

nope...i take it al back, sorry. You cant isolate the membrane by flipping the shock. I didnt think hard enough about that. You will change the frequency of the arm which might show you something. Some shocks have a piece of foam for the diaphragm so that it expands quickly.

You have 3 things to isolate. Sealing the hole or a piece of foam in the bladder might help if you suspect the issue is in the revearsal. But a high speed app on a phone would help you with that.

I know guys like to vent the shocks. If it works go for it. There are shock dyno results on here that shows a vented bladder taking much longer to reverse if it collapses. Your design doesnt look like the conventional bubble and it looks resistant to collapse. Sorry, other than the app I cant offer much on isolating the bladder.

when the suspension compresses it should rebound about 3 times faster than it compressed so that the tire maintains traction.

Visualize your damper. When it compresses the bladder compresses and vents air. The rebound is potentially restricted by a deflated diaphragm and an orifice that will limit the refill of the bladder. Its all speculation without a camera or proof but it is rooted in experience and science. But you can flip the shock over and the diaphragm will not be a factor in the reversal from compression to rebound. If i thought long and hard about it I could probably say something about sprung versus unsprung mass as well.

nope...i take it al back, sorry. You cant isolate the membrane by flipping the shock. I didnt think hard enough about that. You will change the frequency of the arm which might show you something. Some shocks have a piece of foam for the diaphragm so that it expands quickly.

You have 3 things to isolate. Sealing the hole or a piece of foam in the bladder might help if you suspect the issue is in the revearsal. But a high speed app on a phone would help you with that.

I know guys like to vent the shocks. If it works go for it. There are shock dyno results on here that shows a vented bladder taking much longer to reverse if it collapses. Your design doesnt look like the conventional bubble and it looks resistant to collapse. Sorry, other than the app I cant offer much on isolating the bladder.

Last edited by Bry195; 11-11-2019 at 07:56 PM.

#26

Man, I wish I was smart enough to measure gís. 😜. John Stranahan used to run tests on it.

I think I know where you are going to. My take on it is yes, you could run the same spring and damping, but perhaps that is not the best way to optimize set up. Carpet is many times against ďtheoreticalĒ standard ways of set up. Higher grip usually requires softer springs on carpet to take away a bit of grip and response (potentially traction rolling). Sometimes this can be done with just a spring, because as long as you are within a proper damping envelope, it makes a bigger difference, but many times an increase in damping can go along well with the change to mellow out the car.

My take is, springs are easy to change and make a huge difference. Itís easier than damping changes, so often my first change is to find the right springs for the car. Most of the time, only if I need something else will I mess with damping. Usually the spring envelope that is optimal is within 0.2-0.3 C so matching the oil is often not too important to get around the track.

About the membrane I don't think there's enough force on it to cause collapse but try a piece of foam to support it, plus vented.

#27

Does anyone have an effective method for an up-stop in the suspension . When i used to run

offroad with longer shocks we would put (1/8" id) silicone tubing on the shock pistons to limit

the travel & prevent bottoming. Are there any other more consistent & precise methods ?

offroad with longer shocks we would put (1/8" id) silicone tubing on the shock pistons to limit

the travel & prevent bottoming. Are there any other more consistent & precise methods ?

#28

Does anyone have an effective method for an up-stop in the suspension . When i used to run

offroad with longer shocks we would put (1/8" id) silicone tubing on the shock pistons to limit

the travel & prevent bottoming. Are there any other more consistent & precise methods ?

offroad with longer shocks we would put (1/8" id) silicone tubing on the shock pistons to limit

the travel & prevent bottoming. Are there any other more consistent & precise methods ?

#30

Ah I miss-read it. I bought a bag of 0.5mm rubber shims for that very purpose - they can help slightly on tracks with big kerbs; the car doesn't launch so violently off them. However I haven't used them in any precise way before, just chucked one on each shock shaft.

There is probably an ideal amount of uptravel to have before hitting the bumpstop?

I never see anyone else using bumpstops on TC.

There is probably an ideal amount of uptravel to have before hitting the bumpstop?

I never see anyone else using bumpstops on TC.

24Likes

24Likes