Team Associated B6 & B6D thread

|

|||

#4576

#4578

Tech Apprentice

I just started a BD6 build this morning. I threw in a Savox 1258tg with an Exotek Aluminum servo horn with the 2mm ball stud removed as well as spacers removed from behind the servo ears...im still getting just a little rub between the servo horn and the top plate...other than that, the rest of build has been on point, I stopped right before building the shocks to watch Penn St. vs Wisconsin...

#4579

Tech Apprentice

whats the deal with sanding and sealing the carbon fiber shock towers? I built a 1/10th sedan a few years ago and I sanded and sealed all of the carbon fiber in the kit...are people still doing this for the shock towers? I think I read something that said there is no need anymore, although I could be wrong...

#4580

Tech Regular

iTrader: (31)

I haven't sealed any shock towers so far. The first rear one that I had that came with the kit lasted around 6 weeks. The second (an x-factory one that was supposed to be stronger), about 2 weeks. Most recently, another AE one lasted less than one race day before coming apart.

I also just found out that I had a bent d-block....anybody else had this? (new on top, older bent one on bottom)

I also just found out that I had a bent d-block....anybody else had this? (new on top, older bent one on bottom)

Last edited by joncmack; 12-04-2016 at 05:46 AM.

#4581

Tech Apprentice

im gonna let mine rock without the sanding and sealing, if they fall apart, I will sand and seal the replacement towers...

#4582

Protek 160T

No servo spacers

Exotek horn 2mm spacer

Car 2

Protek 170SBL

No servo spacers

Associated horn no spacers

I will say the associated horn sits a couple MM higher than the exotek. I prefer the lower Exotek to keep the link level as possible

Here's a shot from the back so you can see the height diff

1st is exotek, 2nd is Associated

Last edited by abailey21; 12-03-2016 at 08:26 PM.

#4583

Is there a certain glue you guys like for sealing towers? I was used to just using what i had on hand, but this time had some HPI glue that for this purchase was not good. Anyway, curious what others like.

I do have a race report. we ran the first race of the winter series. Had about 60+ total entries which is really good for the area. Lots of 2wd and 4wd buggies, with the latter at points looking like the Hot Bodies D413 spec class lol.

Anyway, I ran my B6D with this setup except:

- No brass front bulkhead

- longer rear shocks

- orange front springs

- PT Racing oils (I need to confirm CSTs but I used PT Racings oil conversion basically to Losi but +2.5W I think for the conversion)

http://site.petitrc.com/setup/associ...gring20160429/

we are limited to non-hardpin tires on a carpet track which I would describe as very high traction as you can traction roll using harder tires like proline street fighters.

Its common to use slick clay compound tires all around, sauced with SXT 3.0 compound or the schumacher staggers up front and slicks in the rear.

My setup was just that, aka slicks rear, schumachers up front.

I ran with the battery all the back. (what does 5F mean battery position wise?) but also tried it forward, but liked all the way back better

Anyway, the main issue I had is that there is a portion of the track where the carpet changes from ozite to something tan where traction seems to come up slightly, and the carpet is more bumpy. When you hit this part coming down the long straight, you can get kicked around a bit and possibly traction roll. My vehicle also felt a bit inconsistent on sections where it was more bumpy. Finally its steering felt too aggressive I think about mid turn. I ended up running a good portion of negative expo to get a better feel at lower steering inputs.

For the main I ended up moving the shock position on the front arms out and the seemed to help calm things down a lot. I am wondering if I buy the purple springs that they will give me more of what i am looking for.

However, for the inconsistent bump handling, what do you guys recommend? I was thinking maybe going down 50CST to see if that helps as maybe the shock action was not occuring fast enough.

Other than that,the car is really good.

Oh, and I did bend a rear shock shaft (gold ones) and the guy insert that goes into the lower shock cap got hogged out. So will order some spares for that issue. Of the two types, which are more durable?

I do have a race report. we ran the first race of the winter series. Had about 60+ total entries which is really good for the area. Lots of 2wd and 4wd buggies, with the latter at points looking like the Hot Bodies D413 spec class lol.

Anyway, I ran my B6D with this setup except:

- No brass front bulkhead

- longer rear shocks

- orange front springs

- PT Racing oils (I need to confirm CSTs but I used PT Racings oil conversion basically to Losi but +2.5W I think for the conversion)

http://site.petitrc.com/setup/associ...gring20160429/

we are limited to non-hardpin tires on a carpet track which I would describe as very high traction as you can traction roll using harder tires like proline street fighters.

Its common to use slick clay compound tires all around, sauced with SXT 3.0 compound or the schumacher staggers up front and slicks in the rear.

My setup was just that, aka slicks rear, schumachers up front.

I ran with the battery all the back. (what does 5F mean battery position wise?) but also tried it forward, but liked all the way back better

Anyway, the main issue I had is that there is a portion of the track where the carpet changes from ozite to something tan where traction seems to come up slightly, and the carpet is more bumpy. When you hit this part coming down the long straight, you can get kicked around a bit and possibly traction roll. My vehicle also felt a bit inconsistent on sections where it was more bumpy. Finally its steering felt too aggressive I think about mid turn. I ended up running a good portion of negative expo to get a better feel at lower steering inputs.

For the main I ended up moving the shock position on the front arms out and the seemed to help calm things down a lot. I am wondering if I buy the purple springs that they will give me more of what i am looking for.

However, for the inconsistent bump handling, what do you guys recommend? I was thinking maybe going down 50CST to see if that helps as maybe the shock action was not occuring fast enough.

Other than that,the car is really good.

Oh, and I did bend a rear shock shaft (gold ones) and the guy insert that goes into the lower shock cap got hogged out. So will order some spares for that issue. Of the two types, which are more durable?

Last edited by Cain; 12-03-2016 at 07:41 PM.

#4584

whats the deal with sanding and sealing the carbon fiber shock towers? I built a 1/10th sedan a few years ago and I sanded and sealed all of the carbon fiber in the kit...are people still doing this for the shock towers? I think I read something that said there is no need anymore, although I could be wrong...

#4585

Tech Master

iTrader: (21)

Is there a certain glue you guys like for sealing towers? I was used to just using what i had on hand, but this time had some HPI glue that for this purchase was not good. Anyway, curious what others like.

I do have a race report. we ran the first race of the winter series. Had about 60+ total entries which is really good for the area. Lots of 2wd and 4wd buggies, with the latter at points looking like the Hot Bodies D413 spec class lol.

Anyway, I ran my B6D with this setup except:

- No brass front bulkhead

- longer rear shocks

- orange front springs

- PT Racing oils (I need to confirm CSTs but I used PT Racings oil conversion basically to Losi but +2.5W I think for the conversion)

http://site.petitrc.com/setup/associ...gring20160429/

we are limited to non-hardpin tires on a carpet track which I would describe as very high traction as you can traction roll using harder tires like proline street fighters.

Its common to use slick clay compound tires all around, sauced with SXT 3.0 compound or the schumacher staggers up front and slicks in the rear.

My setup was just that, aka slicks rear, schumachers up front.

I ran with the battery all the back. (what does 5F mean battery position wise?) but also tried it forward, but liked all the way back better

Anyway, the main issue I had is that there is a portion of the track where the carpet changes from ozite to something tan where traction seems to come up slightly, and the carpet is more bumpy. When you hit this part coming down the long straight, you can get kicked around a bit and possibly traction roll. My vehicle also felt a bit inconsistent on sections where it was more bumpy. Finally its steering felt too aggressive I think about mid turn. I ended up running a good portion of negative expo to get a better feel at lower steering inputs.

For the main I ended up moving the shock position on the front arms out and the seemed to help calm things down a lot. I am wondering if I buy the purple springs that they will give me more of what i am looking for.

However, for the inconsistent bump handling, what do you guys recommend? I was thinking maybe going down 50CST to see if that helps as maybe the shock action was not occuring fast enough.

Other than that,the car is really good.

Oh, and I did bend a rear shock shaft (gold ones) and the guy insert that goes into the lower shock cap got hogged out. So will order some spares for that issue.

I do have a race report. we ran the first race of the winter series. Had about 60+ total entries which is really good for the area. Lots of 2wd and 4wd buggies, with the latter at points looking like the Hot Bodies D413 spec class lol.

Anyway, I ran my B6D with this setup except:

- No brass front bulkhead

- longer rear shocks

- orange front springs

- PT Racing oils (I need to confirm CSTs but I used PT Racings oil conversion basically to Losi but +2.5W I think for the conversion)

http://site.petitrc.com/setup/associ...gring20160429/

we are limited to non-hardpin tires on a carpet track which I would describe as very high traction as you can traction roll using harder tires like proline street fighters.

Its common to use slick clay compound tires all around, sauced with SXT 3.0 compound or the schumacher staggers up front and slicks in the rear.

My setup was just that, aka slicks rear, schumachers up front.

I ran with the battery all the back. (what does 5F mean battery position wise?) but also tried it forward, but liked all the way back better

Anyway, the main issue I had is that there is a portion of the track where the carpet changes from ozite to something tan where traction seems to come up slightly, and the carpet is more bumpy. When you hit this part coming down the long straight, you can get kicked around a bit and possibly traction roll. My vehicle also felt a bit inconsistent on sections where it was more bumpy. Finally its steering felt too aggressive I think about mid turn. I ended up running a good portion of negative expo to get a better feel at lower steering inputs.

For the main I ended up moving the shock position on the front arms out and the seemed to help calm things down a lot. I am wondering if I buy the purple springs that they will give me more of what i am looking for.

However, for the inconsistent bump handling, what do you guys recommend? I was thinking maybe going down 50CST to see if that helps as maybe the shock action was not occuring fast enough.

Other than that,the car is really good.

Oh, and I did bend a rear shock shaft (gold ones) and the guy insert that goes into the lower shock cap got hogged out. So will order some spares for that issue.

#4587

can you elaborate on what difference I would see exactly? Trying to understand why they are good versus the AE offering, assuming the AE offering match their rating.

Also, how do there ratings compare to AEs? (ex-a Yatabe X spring is Y in AE rating)

And am I correct as the part # goes up in size the stiffer the spring?

Yokomo Turf/Carpet Rear Shock Spring Rates:

Hard

YOKYAS-975: Purple

YOKYAS-1000: Black

YOKYAS-1025: Orange

YOKYAS-1050: Green

Yokomo Turf/Carpet Front Shock Spring Rates:

Hard

YOKYAS-650: Purple

YOKYAS-675: Black

YOKYAS-700: Orange

YOKYAS-800: Red

YOKYAS-825: Yellow

Also, how do there ratings compare to AEs? (ex-a Yatabe X spring is Y in AE rating)

And am I correct as the part # goes up in size the stiffer the spring?

Yokomo Turf/Carpet Rear Shock Spring Rates:

Hard

YOKYAS-975: Purple

YOKYAS-1000: Black

YOKYAS-1025: Orange

YOKYAS-1050: Green

Yokomo Turf/Carpet Front Shock Spring Rates:

Hard

YOKYAS-650: Purple

YOKYAS-675: Black

YOKYAS-700: Orange

YOKYAS-800: Red

YOKYAS-825: Yellow

#4589

Tech Master

iTrader: (21)

can you elaborate on what difference I would see exactly? Trying to understand why they are good versus the AE offering, assuming the AE offering match their rating.

Also, how do there ratings compare to AEs? (ex-a Yatabe X spring is Y in AE rating)

And am I correct as the part # goes up in size the stiffer the spring?

Yokomo Turf/Carpet Rear Shock Spring Rates:

Hard

YOKYAS-975: Purple

YOKYAS-1000: Black

YOKYAS-1025: Orange

YOKYAS-1050: Green

Yokomo Turf/Carpet Front Shock Spring Rates:

Hard

YOKYAS-650: Purple

YOKYAS-675: Black

YOKYAS-700: Orange

YOKYAS-800: Red

YOKYAS-825: Yellow

Also, how do there ratings compare to AEs? (ex-a Yatabe X spring is Y in AE rating)

And am I correct as the part # goes up in size the stiffer the spring?

Yokomo Turf/Carpet Rear Shock Spring Rates:

Hard

YOKYAS-975: Purple

YOKYAS-1000: Black

YOKYAS-1025: Orange

YOKYAS-1050: Green

Yokomo Turf/Carpet Front Shock Spring Rates:

Hard

YOKYAS-650: Purple

YOKYAS-675: Black

YOKYAS-700: Orange

YOKYAS-800: Red

YOKYAS-825: Yellow

#4590

Tech Apprentice

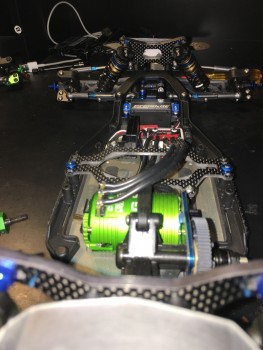

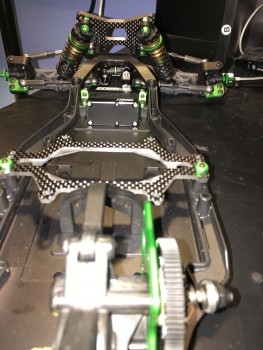

Pulled an all nighter and finished the whole build. So far its a B6D with a 1258tg servo, Orion R10 pro, Exotek aluminum steering servo and a set of Exotek alloy twist nuts for battery screws...other than that, its box stock bitch!!

I need battery suggestions, I have no clue about lipo batteries, this is my first foray into offroad after a long break in the hobby....

I need battery suggestions, I have no clue about lipo batteries, this is my first foray into offroad after a long break in the hobby....

649Likes

649Likes