Team Associated B6 & B6D thread

|

|||

#3601

Have a buggy on the way and may be stuck with the gear diff for a lil while.

#3603

Tech Regular

iTrader: (6)

I feel like it's binding when not bolted in still.

Didn't mean to open a can of worms with the bolt side. Just wanted to state what I did and if see if it mattered.

Anyway. I'm not sure what to do.. hmmmm maybe the diff is built wrong.. I'm a little lost right now. Mig by try to rebuild it and see what happens

Didn't mean to open a can of worms with the bolt side. Just wanted to state what I did and if see if it mattered.

Anyway. I'm not sure what to do.. hmmmm maybe the diff is built wrong.. I'm a little lost right now. Mig by try to rebuild it and see what happens

#3604

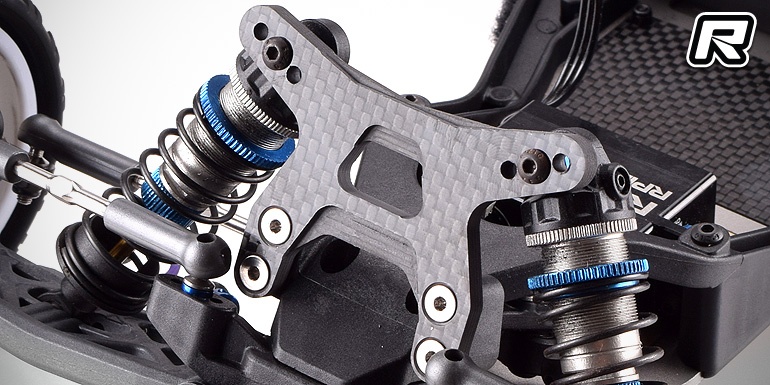

They give an idea on when they will have the front gullwing and the tall rear towers?

For you guys doing carpet or other high traction but have say "rumble" sections on the track, have you tried the tall rear towers and any comment on how well they work?

I have both tower types here buggy already setup with tall rears so could just give those a go on Nov 5th but would be curious if those who are in the know have ideas. One part of the track can be "rough" for carpet and when last running my DEX210F which is oriented more to carpet, I remember getting kicked around a bit more than I liked.

#3605

Since the down travel is the same only difference is the oil volume it should help more than hurt Imo. I do recommend running them in front of the tower though. If I go that way I think I will go with the schelle tower since it uses the short eyelets.

#3606

#3607

diff nut side topic....

It doesnt matter one bit what side the diffs go in the tranny. racer1812 alrdy told you guys like a million times this. Its a preference unless your building a 4wd wheeler or something like that.

if you THink it goes in a certain way. Fine, your right. Ill put it in the other way and guess what...its fine too.

It doesnt matter one bit what side the diffs go in the tranny. racer1812 alrdy told you guys like a million times this. Its a preference unless your building a 4wd wheeler or something like that.

if you THink it goes in a certain way. Fine, your right. Ill put it in the other way and guess what...its fine too.

Last edited by vr6cj; 10-06-2016 at 10:53 PM. Reason: grammer

#3608

Tech Regular

#3612

Tech Regular

#3613

Tech Regular

#3614

B5,B5M, & B4.2 manual says which side to put it on. I am pretty sure they were designed to be places on a specific side, too bad there's no AE design team support on here. I am sure every other AE manual I have seen also says which side it should be on. But neither here nor there... I haven't decided to go rogue and test out what would happen if I was a rebel and put it on the other side...

The right rear is the way the AE manuals state (or used to state). It really shouldn't matter since you go around turns both left and right.

#3615

I wonder if the diff nut should be replaced for those who feel it loosens on them and think it is because of on a certain side and the plastic material that is threaded is not acting like the lock part of the nut.

649Likes

649Likes