Team Associated B6 & B6D thread

|

|||

#4968

springs, shock fluid, caster block bushings

#4969

Dude tbh they are the same car with a group of parts swapped. One can be built into the other and so on. If you race on med grip start with the D. If you race on super high like carpet then start with the 6, start there and then shape it into what you would like

#4973

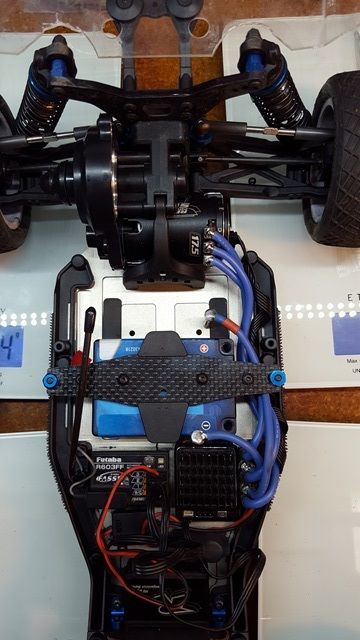

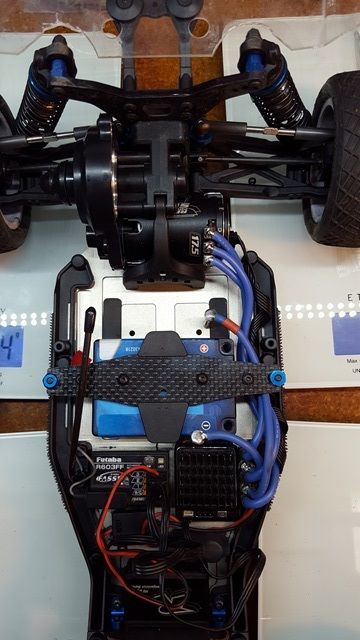

A few days ago I asked if anyone has figured out a way to use the LRP Super Shorty battery in this car. Well I have figured out the battery brace (Part# HBS116257) from a Hot Bodies D216 works very well. I have full range of all the positions just like the normal battery brace would. It also comes with the link and hole in the brace to remove the waterfall. Now the link wont work for the transmission part, you just have to use your own lower shock connector like normal.

#4975

Tech Addict

iTrader: (21)

I have a question for everyone, I recently got a B6 laydown car and when I was building it there was a lot of hand fitting parts and things that dont line up right. For example, the rear hinge pin mounts, they are super tight and take a good amount of work to get them to install, you have to loosen both screws and go back and forth to tighten it down to the chassis. Another was the screws that hold down the transmission, you have to torque the transmission case to line up some of the last holes. I have heard from a few others that these cars are better quality(materials and included parts) but they also say that this is one of the worst cars from AE in terms of overall quality control. I had to do a lot of hand fitting like the above or having to file down parts to make them fit and not bind. What has everyone else's opinions been?

#4976

here is a link to check out some build tips including polishing.

I have @ 30 packs on mine - broke the front bulkhead (thats a first) - nothing else.

#4977

Tech Addict

iTrader: (21)

I thought the build was sweet. I did dremel polish all of my hinge pins and ball studs though. also used my hitachi to drive 95% of the screws.

here is a link to check out some build tips including polishing.

I have @ 30 packs on mine - broke the front bulkhead (thats a first) - nothing else.

here is a link to check out some build tips including polishing.

I have @ 30 packs on mine - broke the front bulkhead (thats a first) - nothing else.

#4978

I am confused by what the stock setup should be for the rear arm mount inserts. Is it the one with the hole directly in the middle (just a dot on the back as listed in the back page?) or is it using the 1 with them facing the outside as in step 1 of bag 9-10? Thanks in advance.

#4979

Center dot on both.

649Likes

649Likes