Team Associated B6 & B6D thread

|

|||

#3826

I forgot to ask if you are using expo in you transmitter. Using expo to soften the initial feel of the steering might help with having the feel of too much low speed steering. It will give more throw in the beginning of the range on the transmitter. Start with 30% expo and adjust from there. You with have to set it negative or positive depending on the manufacturer of your transmitter so look at your manual.

#3827

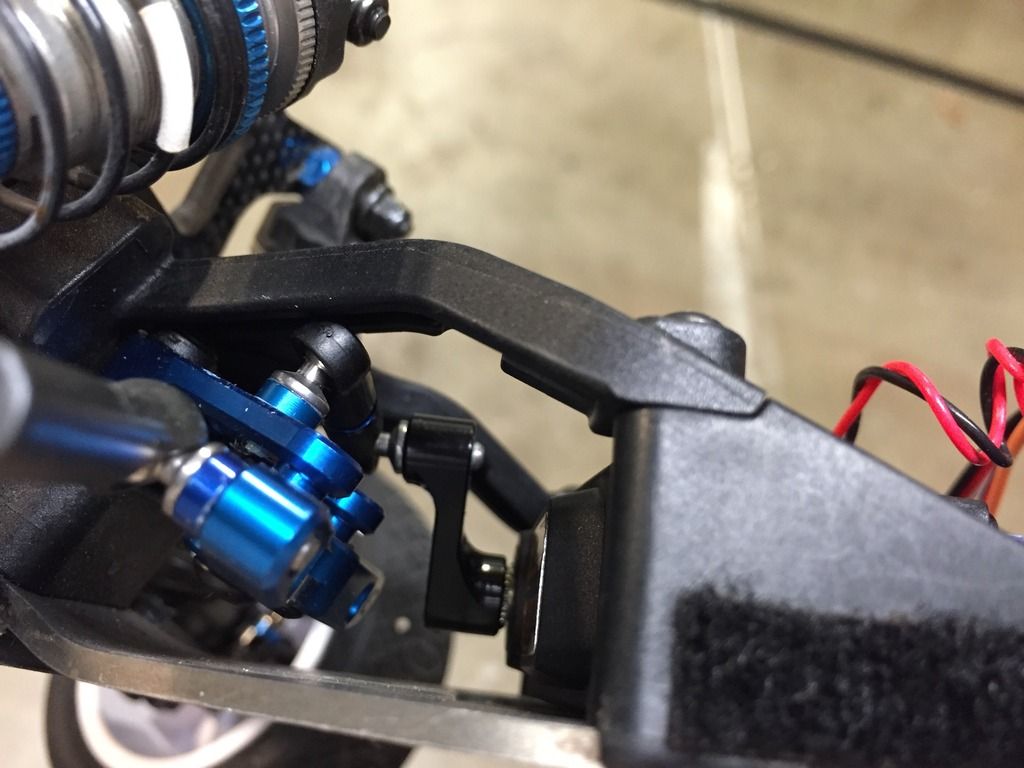

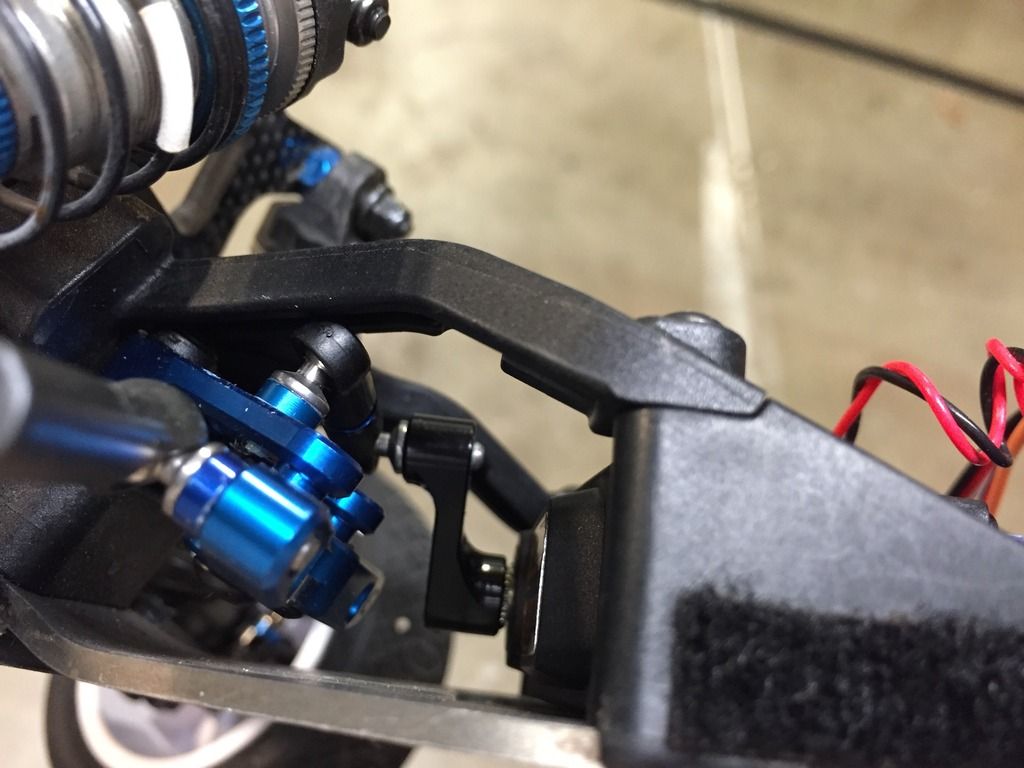

Any of you guys have the steering linkage hit the upper brace at full right (bellcranks full left)? With a Savox 1257TG mounted all the way back (no spacers) and an AE aluminum horn (I don't think this matters), I can only get 95% EPA.

I notched it out a bit with a dremel and can now get full throw (limited only by caster blocks). Not sure if this is an issue with the Savox, an issue with the aluminum rack, or just normal...

I notched it out a bit with a dremel and can now get full throw (limited only by caster blocks). Not sure if this is an issue with the Savox, an issue with the aluminum rack, or just normal...

#3828

Tech Fanatic

iTrader: (19)

If you click on the wiki at the top of the page, there's a link to build tips. In it guys are taking that 2mm spacer out to get full throw. That would fix your problem without the dremeling. You already did it so it's no big deal now, but that's how several of us are getting full throw.

#3829

If you click on the wiki at the top of the page, there's a link to build tips. In it guys are taking that 2mm spacer out to get full throw. That would fix your problem without the dremeling. You already did it so it's no big deal now, but that's how several of us are getting full throw.

Not a big deal, but maybe this helps other racers out there.

#3831

imo this is a complete non issue with a high quality 8th scale servo most people run, they are generally capable of taking much more abuse than a 1500 gram 2wd can deliver

#3832

R/C Tech Elite Member

iTrader: (10)

Seen several 1258tg broken, a couple AE 1015, and several spectrum servos. All are 1/8

capable servos. 1/10 buggys with all aluminum steering deal out way more punishment to

the gearset in servos than anything i have seen in 8 years of nitro. We race on astro so the

speeds higher but the amount of servo failures latey is shocking.

capable servos. 1/10 buggys with all aluminum steering deal out way more punishment to

the gearset in servos than anything i have seen in 8 years of nitro. We race on astro so the

speeds higher but the amount of servo failures latey is shocking.

#3833

My bump steer has 2mm on the spindle steering plate thing in the front hub. What effect does removing them have? and is it dramatic on steering? Thx all couldn't find this. My car pushes big time and only difference from Kit setup is are Yok green rear springs, Schelle steering plates, and 2mm shim on front hub steering plate

#3834

My bump steer has 2mm on the spindle steering plate thing in the front hub. What effect does removing them have? and is it dramatic on steering? Thx all couldn't find this. My car pushes big time and only difference from Kit setup is are Yok green rear springs, Schelle steering plates, and 2mm shim on front hub steering plate

In general, you want the wheels to stay straight (no toe-in/toe-out) as the arms move up and down through the suspension travel. So that "bumps" do not "steer" the car as you run over them.

#3835

Tech Addict

Has anyone tips setting a B6D up for carpet?

I dont wanna buy 2 cars so I focused on our "summer" car. But that season's over so I need to work on the car.

So far I ordered the laydown conversion. What about shock settings or may a setup sheet I can use?

Thanks!

(What about anti roll bars? Just rear? front and rear?)

I dont wanna buy 2 cars so I focused on our "summer" car. But that season's over so I need to work on the car.

So far I ordered the laydown conversion. What about shock settings or may a setup sheet I can use?

Thanks!

(What about anti roll bars? Just rear? front and rear?)

#3836

Seen several 1258tg broken, a couple AE 1015, and several spectrum servos. All are 1/8

capable servos. 1/10 buggys with all aluminum steering deal out way more punishment to

the gearset in servos than anything i have seen in 8 years of nitro. We race on astro so the

speeds higher but the amount of servo failures latey is shocking.

capable servos. 1/10 buggys with all aluminum steering deal out way more punishment to

the gearset in servos than anything i have seen in 8 years of nitro. We race on astro so the

speeds higher but the amount of servo failures latey is shocking.

i race on super high grip carpet and have never had a servo fail or even seen one of my buddies have a servo gearset fail, i have on the other hand seen plenty of plastic servo horns and racks fail in the cars of newer / inexperienced drivers, needless to say they all upgrade to aluminium..

#3837

Tech Regular

why do people run a heavier C mount when theres enough room by it to just stick some weights in there for free?

#3838

So, more shims on the steering block would add more bump out on the tire under load? Ex: tight 180 turning right the left wheel (outer) would bump out decreasing turning radius? This is increased with more washers? Do I have this right and what are most running? Thx

It affects how much the steering links pull in/push out the wheels (toe-in/toe-out) as the arms move up and down.

In general, you want the wheels to stay straight (no toe-in/toe-out) as the arms move up and down through the suspension travel. So that "bumps" do not "steer" the car as you run over them.

In general, you want the wheels to stay straight (no toe-in/toe-out) as the arms move up and down through the suspension travel. So that "bumps" do not "steer" the car as you run over them.

#3839

I think you're going down the wrong path trying to solve your steering problem. These are not the steering fixes you are looking for.

#3840

Tech Rookie

well impressed with the B6, had my first race meeting with it, Im fairly new to buggies, meeting was first round of indoor, carpet track with wall ride and couple of jumps, all new to me LOL

theres a group of us that are always very very close on times on outdoors etc, in particular a mate that we usually within .1 second of each other per lap and average etc, end of 5 min qualifier, usually few seconds max between us depending on who had less ooops moments, they all running B6

round 1, first run, Im a lap up on them guys, and at least 1 second faster

by the end of the day I had a low 17 second best lap, with them in the mid 18s

what an amazing car, poor old B5m is going on Ebay and now unloved LOL

theres a group of us that are always very very close on times on outdoors etc, in particular a mate that we usually within .1 second of each other per lap and average etc, end of 5 min qualifier, usually few seconds max between us depending on who had less ooops moments, they all running B6

round 1, first run, Im a lap up on them guys, and at least 1 second faster

by the end of the day I had a low 17 second best lap, with them in the mid 18s

what an amazing car, poor old B5m is going on Ebay and now unloved LOL

649Likes

649Likes