Xray XB2 2WD Buggy Thread

|

|||

#3211

Truer words have never been spoken. looking at some replacement parts right now. outdrives and such. the rebuild gets expensive. may try the losi diff/outdrives since i have a de and ce.

#3212

If you've been watching the B6/B6D information, they're saying the b5m diff fits, but the outdrives are not as long. Which tells me the B6 diff MIGHT be the best fit. However, WillS and I came to the conclusion the Losi and Yok diff fits nicer.

Of course, this is all because we don't want to spend $60 on outdrives every other month because the Xray's are overpriced and wear too quickly, even when changing pins every week. Of course, Bent will come in here and tell me I'm wrong but I still don't care.

#3213

anybody having problems with there shocks binding. I have noticed after a few runs the washer on the very bottom gets pushed off to one side in the aluminum cap. then the shaft binds real bad. then if I loosen that bottom aluminum cap and recenter the washer its fine for a few more runs. then back to binding. ive got that bottom cap pretty much as tight as it can get. if I dont find a solution im going to have to switch to associated shocks.

#3214

anybody having problems with there shocks binding. I have noticed after a few runs the washer on the very bottom gets pushed off to one side in the aluminum cap. then the shaft binds real bad. then if I loosen that bottom aluminum cap and recenter the washer its fine for a few more runs. then back to binding. ive got that bottom cap pretty much as tight as it can get. if I dont find a solution im going to have to switch to associated shocks.

#3215

Had issue with a shock today. Finally had my DE strapped, then halfway thru the 1st heat started chassis slapping every small jump. Even when downsiding. Took the buggy off. Felt like shock had no oil in it and it leaked out. There was a small amount of oil at the bottom of the Rod end. Opened up the shock and it was full! Didn't have time to open everything up and just switched to my CE. Teack didn't have Xray parts so it's just sitting. Anyone had one of the shocks feel like it has no oil and its full? Time to rebuild the shocks but just wondering if this sounds familiar to anyone? Thx

QUOTE=Socket;14568722]Sounds like your seal stack is hammered. I'd tell you to rebuild them, new seals and plastic bushings.[/QUOTE]

QUOTE=Socket;14568722]Sounds like your seal stack is hammered. I'd tell you to rebuild them, new seals and plastic bushings.[/QUOTE]

#3216

Had issue with a shock today. Finally had my DE strapped, then halfway thru the 1st heat started chassis slapping every small jump. Even when downsiding. Took the buggy off. Felt like shock had no oil in it and it leaked out. There was a small amount of oil at the bottom of the Rod end. Opened up the shock and it was full! Didn't have time to open everything up and just switched to my CE. Teack didn't have Xray parts so it's just sitting. Anyone had one of the shocks feel like it has no oil and its full? Time to rebuild the shocks but just wondering if this sounds familiar to anyone? Thx

QUOTE=Socket;14568722]Sounds like your seal stack is hammered. I'd tell you to rebuild them, new seals and plastic bushings.

QUOTE=Socket;14568722]Sounds like your seal stack is hammered. I'd tell you to rebuild them, new seals and plastic bushings.

sounds like the c clip on top holding the piston has come loose

#3217

anybody having problems with there shocks binding. I have noticed after a few runs the washer on the very bottom gets pushed off to one side in the aluminum cap. then the shaft binds real bad. then if I loosen that bottom aluminum cap and recenter the washer its fine for a few more runs. then back to binding. ive got that bottom cap pretty much as tight as it can get. if I dont find a solution im going to have to switch to associated shocks.

#3218

nope took them all apart there definitely built right. I'm going to rebuild them and see how they hold up. only had 3 race days on them so far. seems a little extreme to have to rebuild your shocks that often. sounds like the other guy asking about shocks has exactly the same problem.

#3219

nope took them all apart there definitely built right. I'm going to rebuild them and see how they hold up. only had 3 race days on them so far. seems a little extreme to have to rebuild your shocks that often. sounds like the other guy asking about shocks has exactly the same problem.

His piston is probably not secured (no resistance is usually only something with the piston, or lack of oil) as previously referenced.

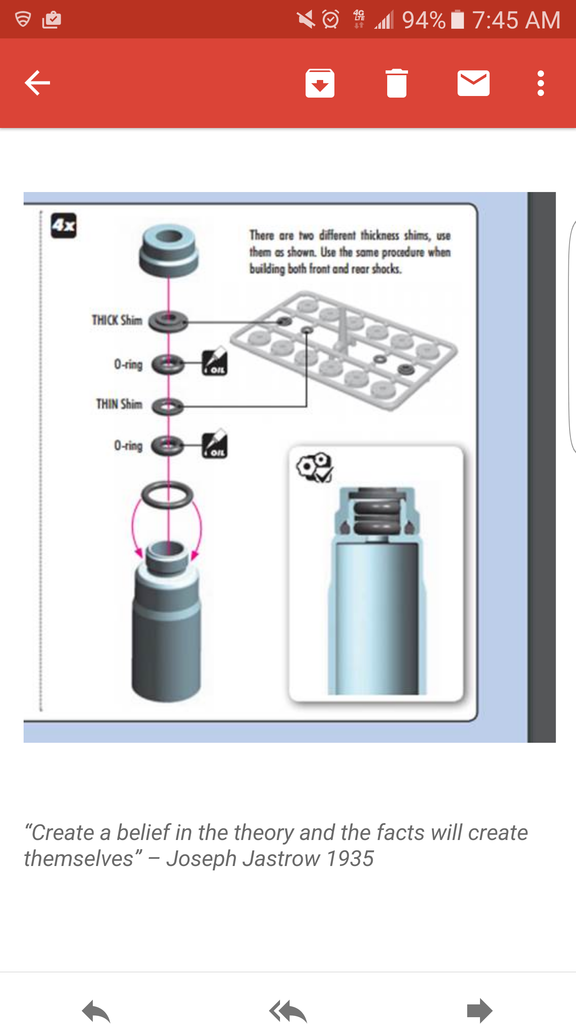

You're having issues with the 'thick shim', in Symmetricon's diagram?

#3220

nope took them all apart there definitely built right. I'm going to rebuild them and see how they hold up. only had 3 race days on them so far. seems a little extreme to have to rebuild your shocks that often. sounds like the other guy asking about shocks has exactly the same problem.

That said, there's a binding problem. Pull the pieces apart, sounds like swollen O rings or some flashing on the bushings, or a bent shock shaft.

The parts can't inherently do any of those functions themselves, they require a user to either put the parts together wrong, not presoak the orings, or crash and bend a shock shaft.

#3221

Tech Rookie

First I apologize if this has been asked but before I got my car I read the first 100 pages of this forum and now there are double that. I just don't have the time to check and see if this has been asked sorry.

So I am converting my XB2 CE to go to dirt. Our carpet track closed and our dirt track is now revamped. Anyways I don't have the money to buy the DE and don't really want to buy extra parts. So I am

Trying to tune my CE to the track the best way possible.

I assume that going full flex will help except that some of the screws they list as flex screws seem to be vital to the cars performance. So which screws do I remove to gain the most flex?

I have already move the both axels forward to give more weight in the rear and moved the shocks to the rear position. Next I will be playing with suspension ( springs/oils/piston) but first I want to get everything mechanically setup for looser track.

Thanks everyone!

So I am converting my XB2 CE to go to dirt. Our carpet track closed and our dirt track is now revamped. Anyways I don't have the money to buy the DE and don't really want to buy extra parts. So I am

Trying to tune my CE to the track the best way possible.

I assume that going full flex will help except that some of the screws they list as flex screws seem to be vital to the cars performance. So which screws do I remove to gain the most flex?

I have already move the both axels forward to give more weight in the rear and moved the shocks to the rear position. Next I will be playing with suspension ( springs/oils/piston) but first I want to get everything mechanically setup for looser track.

Thanks everyone!

#3222

Yokomo YZ2/Bmax 2 diff is a drop in fit. Needs a few shims on each side, and it's money. Also you'll need Bmax2 dogbones.

Last edited by Socket; 06-17-2016 at 10:02 AM.

#3224

333Likes

333Likes