Xray XB2 2WD Buggy Thread

|

|||

#572

Any word on some smaller Spur Gears for the mates that race stock in the States?

#573

Tech Regular

iTrader: (1)

Yes while cornering (it lower's the roll center the more you roll).

Yes/no on bumps or smooth track it depends of course.

No while accelerating in a dead straight line (but the car will be more stable then which could FEEL in more traction but actually won't give more).

Yes/no on bumps or smooth track it depends of course.

No while accelerating in a dead straight line (but the car will be more stable then which could FEEL in more traction but actually won't give more).

#574

Ok, I don't disagree with anything you say. I understand there is a difference between the car pivoting and having actual weight transfer. I guess what's hard to calculate as a total is where stability and traction converge. I guess my error is in not differentiating between stability and mechanical traction, I used improper verbage.

#575

I don't want to get into a debate about anti squat but if 2 springs have the same rate:

Spring A compresses 10 cm

Spring B compresses 20 cm

Which spring has more force or weight applied on it?

Is this not the same reason why a softer spring in the rear will allow more rear grip?

Spring A compresses 10 cm

Spring B compresses 20 cm

Which spring has more force or weight applied on it?

Is this not the same reason why a softer spring in the rear will allow more rear grip?

Tricky to explain, hope this makes some sense, how it was always explained to me. From the side view adding anti squat causes the suspension travel to move not vertically but at an angle. With wheel down/rebound travel the wheels go forward a little. Under acceleration there is essentially a wedge effect, the wheels try to go forward and ride that angle down some. This forces the arm down - chassis up, that force adds to the shock spring force.

In practice the dynamics come into play, and like many chassis questions depends on traction, surface smoothness, and even driving style. The anti squat force happens quickly compared to the relatively slow action of the shock/spring and chassis movement, and it's less compliant. Ideal conditions, high traction smooth surface, anti squat can create a more immediate response and better acceleration. Less than ideal, lower traction and bumpy, the extra compliance of using the springs can help prevent breaking traction.

Short answer, it's possible for either to be true in a sense. Nobody said it was going to be easy, but that's part of the fun, the challenge.

#576

I'm a newbie t both carpet and Xray. And very stoked to say I just ordered my XB2 carpet. I've been following this entire thread and wanted to ask what do you use to drill your own Pistons? Bentka replied back that all the sponsored drivers are using the blanks and drilling them 1.6 & 1.7. What tools and or methods do people use to getting it right? Thanks

#577

Hey Kibish, there are several brands you can use. I have used this one with good luck, feel free to check it out:

http://www.amainhobbies.com/rc-cars-...-gmk0108/p7599

http://www.amainhobbies.com/rc-cars-...-gmk0108/p7599

#578

I'm a newbie t both carpet and Xray. And very stoked to say I just ordered my XB2 carpet. I've been following this entire thread and wanted to ask what do you use to drill your own Pistons? Bentka replied back that all the sponsored drivers are using the blanks and drilling them 1.6 & 1.7. What tools and or methods do people use to getting it right? Thanks

Hey Kibish, there are several brands you can use. I have used this one with good luck, feel free to check it out:

http://www.amainhobbies.com/rc-cars-...-gmk0108/p7599

http://www.amainhobbies.com/rc-cars-...-gmk0108/p7599

Bent

#579

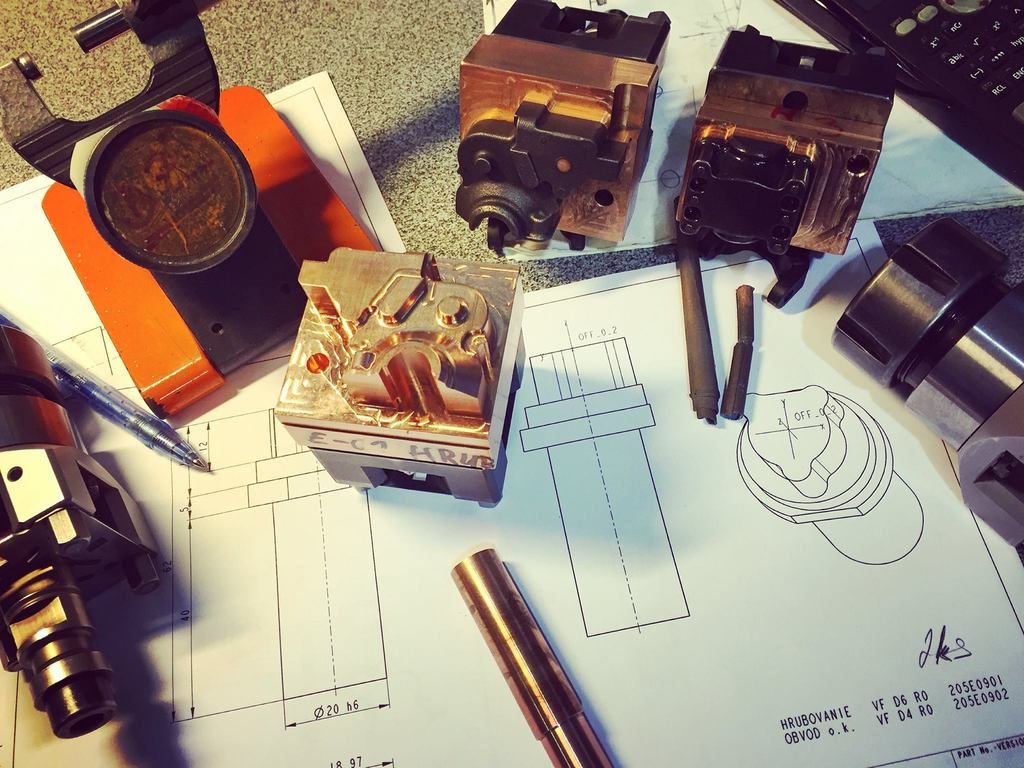

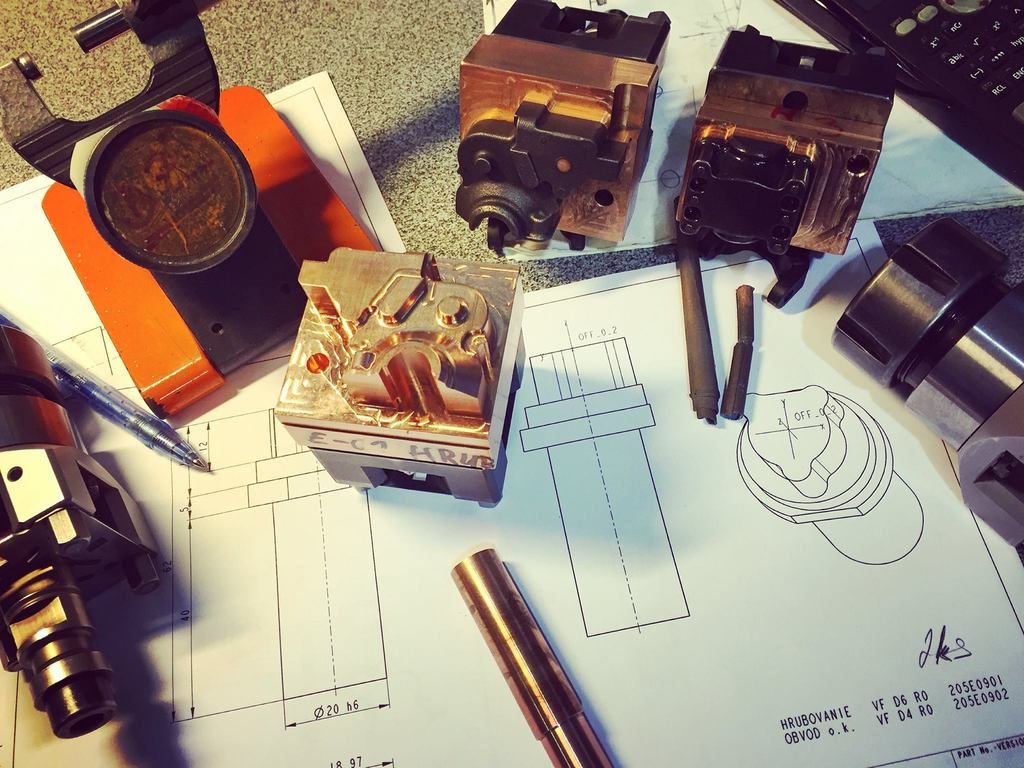

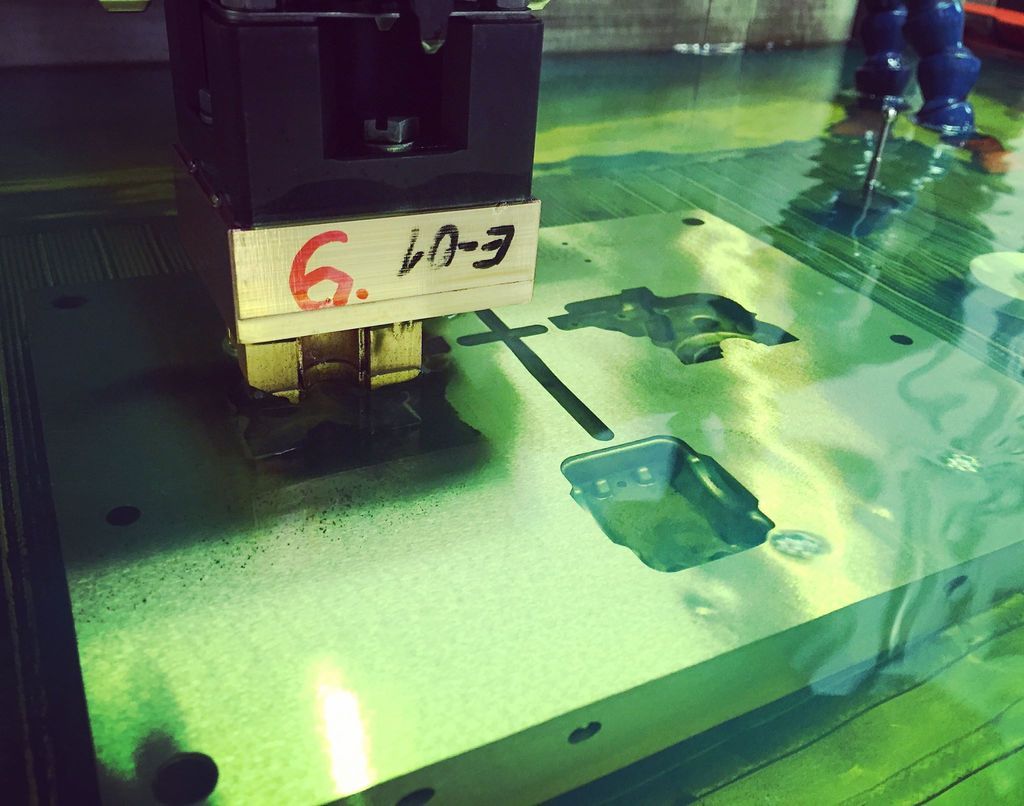

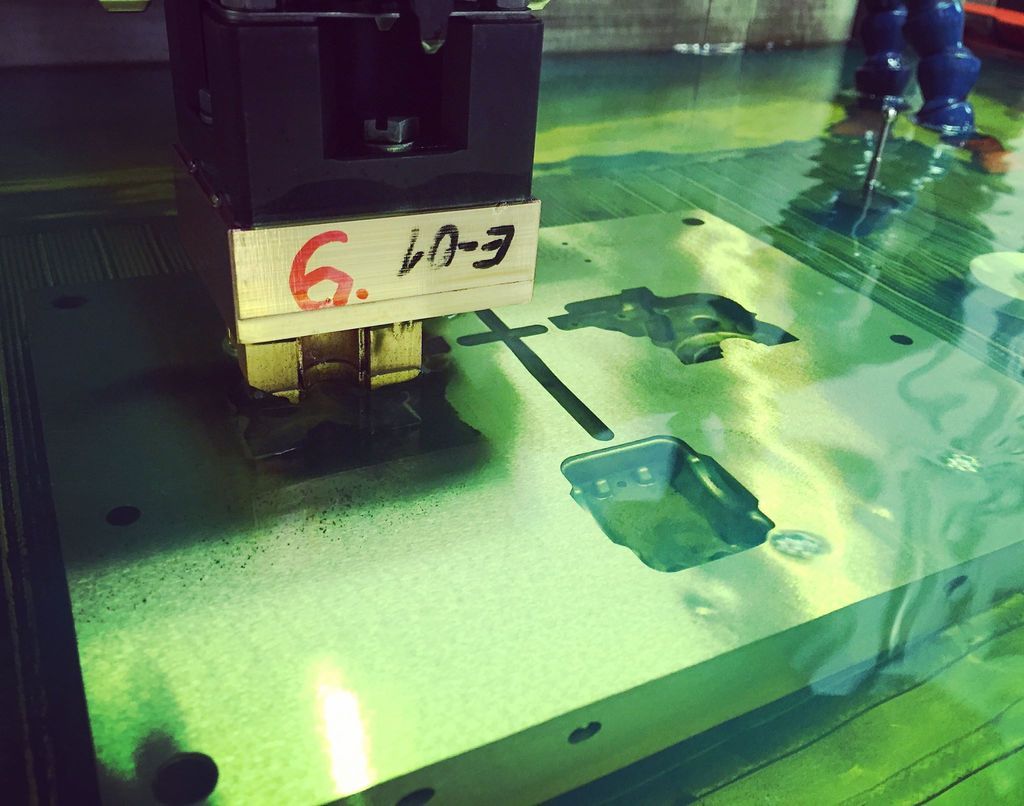

A couple of updates on the progress of the XB2 Dirt Edition from Juraj Hudy:

Bent

Final pre-production rapid prototype of the gear box cover installed on the motor holder. All fits nicely.

The gear box mould for XB2 Dirt in production.

Brass electrodes for the XB2 Dirt gear box. The black ones are already used.

#581

Does anyone know if the Schumacher Cougar 71T Slipper Spur Gear fits the XB2? Need a smaller spur for 17.5 Stock racing...

#582

Very impressive that Hudy has an EDM machine in-house and that they use it for all of their tooling. Also impressive that they have injection molding in-house! It is no longer the American business model to have engineering and manufacturing under one roof like that. Very cool!

#583

Alright, took the day off to dial in my XB2 and have reached and awesome indoor clay high bite setup! The car is easily as good as my rb6 was that I had for 6 months with to setup. I picked up another 3/10 of a second, more corner speed and more rear grip all with stock components...

#585

Alright, took the day off to dial in my XB2 and have reached and awesome indoor clay high bite setup! The car is easily as good as my rb6 was that I had for 6 months with to setup. I picked up another 3/10 of a second, more corner speed and more rear grip all with stock components...

I understand the "dirt" car isn't yet complete?

Wow, looking to be a very capable buggy platform.

333Likes

333Likes