Team Associated SC5M Thread

|

|||

#2074

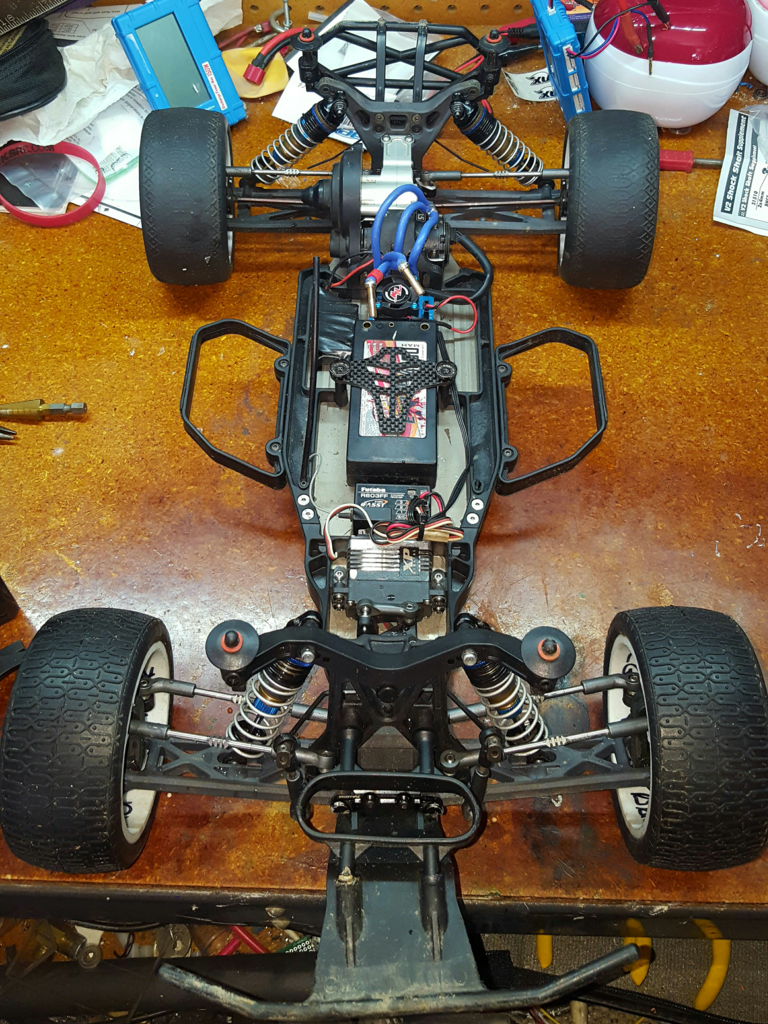

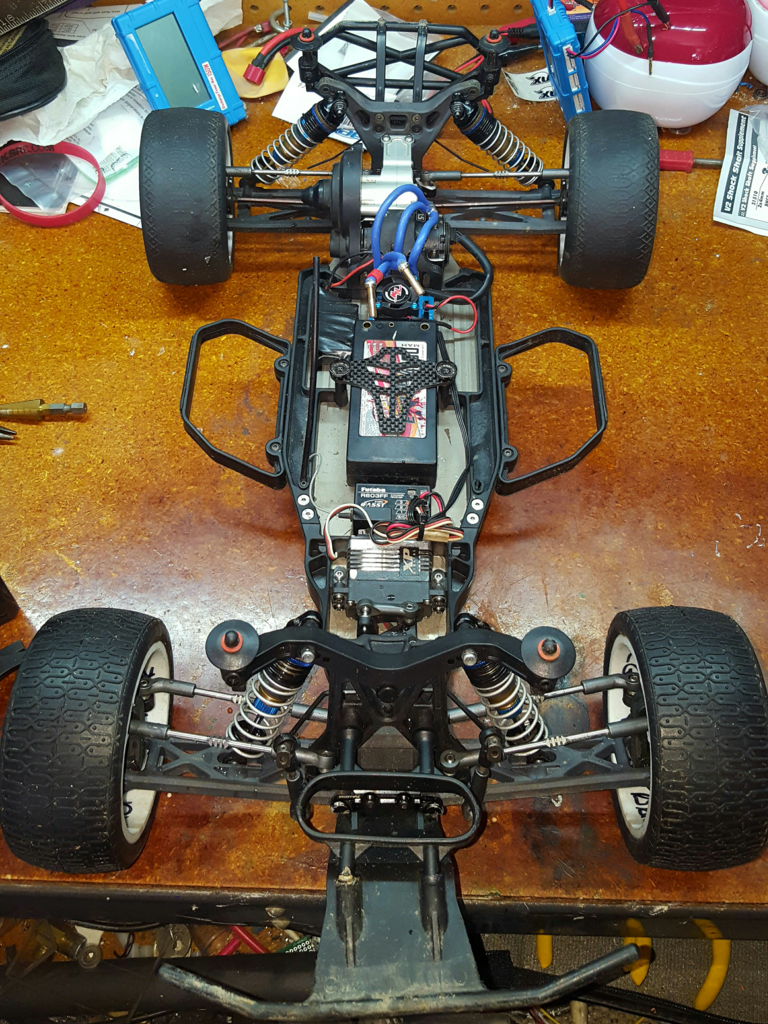

I run my SC5M with the MIP Eco All-In-1 tranny kit, in-line battery right up against the servo, buggy rear shock tower w/ truck springs, SC10 4x4 front sway bar and 13.5 Reedy, AKA Chain Links in front and Pro Line Electrons warn to slicks in the back. 26 front 24 in the back for ride height. The truck is very stuck to the ground. Flies well too. I race indoor med/high bite clay.

With such a heavy body for these vehicles, I doubt running a lay down tranny will provide you anything for lowering the CG.

With such a heavy body for these vehicles, I doubt running a lay down tranny will provide you anything for lowering the CG.

#2075

I run my SC5M with the MIP Eco All-In-1 tranny kit, in-line battery right up against the servo, buggy rear shock tower w/ truck springs, SC10 4x4 front sway bar and 13.5 Reedy, AKA Chain Links in front and Pro Line Electrons warn to slicks in the back. 26 front 24 in the back for ride height. The truck is very stuck to the ground. Flies well too. I race indoor med/high bite clay.

With such a heavy body for these vehicles, I doubt running a lay down tranny will provide you anything for lowering the CG.

With such a heavy body for these vehicles, I doubt running a lay down tranny will provide you anything for lowering the CG.

#2076

Originally I ran buggy towers front and rear along with buggy shocks. But I did not like the limit I had with the front shocks and springs not providing full travel. So I went to the truck front tower and shocks.

On the rear, the tower and shocks locked me into using the inner holes on the arms and outer holes on the tower. I was not able to really get much adjustment with shock placement. But by using the buggy tower and truck shocks, I can run the shocks on the inner most hole on the tower and outer hole on the arms. By doing this I have a much more progressive spring rate and allows more rear body roll. I have 1mm limiter in the rear shocks and 2mm in the front. At this extreme shock angle, the rear wheels have a lot of drop, so they never leave the ground under hard braking into the corners. The heavy front sway bar is providing my truck from rolling too much and removes the traction roll issue.

Another thing to note about my setup, I am running Pro-Line PowerStroke springs front and rear. They are AE shocks though. The reason I run them is to move the shocks completely through their range. I find that with most springs that when I run full stroke, they don't extend the shocks to full droop. By running a very soft spring as the primary and a harder secondary spring, the primary spring runs collapsed until in the air or when an arm drops lower than the secondary spring expands. The primary spring will extend the arm down to full droop. This helps a huge amount in the air. If running only a single spring, the arms will fall/drop further than the spring will extend. So if one arm is freer/or less resistance than others, you land having one wheel touching before the others. And with a dual rate spring setup and progressive shock position, I have a very soft landing but still a stiff enough setup to reduce rough take off and landings from huge jumps. Which OCRC tends to lean towards.

This week I'll be putting in the VRP 'XV2' Pistons front and rear and see how those work.

On the rear, the tower and shocks locked me into using the inner holes on the arms and outer holes on the tower. I was not able to really get much adjustment with shock placement. But by using the buggy tower and truck shocks, I can run the shocks on the inner most hole on the tower and outer hole on the arms. By doing this I have a much more progressive spring rate and allows more rear body roll. I have 1mm limiter in the rear shocks and 2mm in the front. At this extreme shock angle, the rear wheels have a lot of drop, so they never leave the ground under hard braking into the corners. The heavy front sway bar is providing my truck from rolling too much and removes the traction roll issue.

Another thing to note about my setup, I am running Pro-Line PowerStroke springs front and rear. They are AE shocks though. The reason I run them is to move the shocks completely through their range. I find that with most springs that when I run full stroke, they don't extend the shocks to full droop. By running a very soft spring as the primary and a harder secondary spring, the primary spring runs collapsed until in the air or when an arm drops lower than the secondary spring expands. The primary spring will extend the arm down to full droop. This helps a huge amount in the air. If running only a single spring, the arms will fall/drop further than the spring will extend. So if one arm is freer/or less resistance than others, you land having one wheel touching before the others. And with a dual rate spring setup and progressive shock position, I have a very soft landing but still a stiff enough setup to reduce rough take off and landings from huge jumps. Which OCRC tends to lean towards.

This week I'll be putting in the VRP 'XV2' Pistons front and rear and see how those work.

Last edited by Azzkikin; 12-13-2016 at 09:47 AM.

#2077

Oone of the biggest performance gains i have in my setup is ride height - 26/24 ; which i believe you are running. Just got to use the shortest shock cups and stack up a few limiters. Kit setup is 30/28 - traction roll city. 4mm is night and day.

#2078

Interesting setup - would be cool to see your setup sheet.

Oone of the biggest performance gains i have in my setup is ride height - 26/24 ; which i believe you are running. Just got to use the shortest shock cups and stack up a few limiters. Kit setup is 30/28 - traction roll city. 4mm is night and day.

Oone of the biggest performance gains i have in my setup is ride height - 26/24 ; which i believe you are running. Just got to use the shortest shock cups and stack up a few limiters. Kit setup is 30/28 - traction roll city. 4mm is night and day.

#2079

Originally I ran buggy towers front and rear along with buggy shocks. But I did not like the limit I had with the front shocks and springs not providing full travel. So I went to the truck front tower and shocks.

On the rear, the tower and shocks locked me into using the inner holes on the arms and outer holes on the tower. I was not able to really get much adjustment with shock placement. But by using the buggy tower and truck shocks, I can run the shocks on the inner most hole on the tower and outer hole on the arms. By doing this I have a much more progressive spring rate and allows more rear body roll. I have 1mm limiter in the rear shocks and 2mm in the front. At this extreme shock angle, the rear wheels have a lot of drop, so they never leave the ground under hard braking into the corners. The heavy front sway bar is providing my truck from rolling too much and removes the traction roll issue.

Another thing to note about my setup, I am running Pro-Line PowerStroke springs front and rear. They are AE shocks though. The reason I run them is to move the shocks completely through their range. I find that with most springs that when I run full stroke, they don't extend the shocks to full droop. By running a very soft spring as the primary and a harder secondary spring, the primary spring runs collapsed until in the air or when an arm drops lower than the secondary spring expands. The primary spring will extend the arm down to full droop. This helps a huge amount in the air. If running only a single spring, the arms will fall/drop further than the spring will extend. So if one arm is freer/or less resistance than others, you land having one wheel touching before the others. And with a dual rate spring setup and progressive shock position, I have a very soft landing but still a stiff enough setup to reduce rough take off and landings from huge jumps. Which OCRC tends to lean towards.

This week I'll be putting in the VRP 'XV2' Pistons front and rear and see how those work.

On the rear, the tower and shocks locked me into using the inner holes on the arms and outer holes on the tower. I was not able to really get much adjustment with shock placement. But by using the buggy tower and truck shocks, I can run the shocks on the inner most hole on the tower and outer hole on the arms. By doing this I have a much more progressive spring rate and allows more rear body roll. I have 1mm limiter in the rear shocks and 2mm in the front. At this extreme shock angle, the rear wheels have a lot of drop, so they never leave the ground under hard braking into the corners. The heavy front sway bar is providing my truck from rolling too much and removes the traction roll issue.

Another thing to note about my setup, I am running Pro-Line PowerStroke springs front and rear. They are AE shocks though. The reason I run them is to move the shocks completely through their range. I find that with most springs that when I run full stroke, they don't extend the shocks to full droop. By running a very soft spring as the primary and a harder secondary spring, the primary spring runs collapsed until in the air or when an arm drops lower than the secondary spring expands. The primary spring will extend the arm down to full droop. This helps a huge amount in the air. If running only a single spring, the arms will fall/drop further than the spring will extend. So if one arm is freer/or less resistance than others, you land having one wheel touching before the others. And with a dual rate spring setup and progressive shock position, I have a very soft landing but still a stiff enough setup to reduce rough take off and landings from huge jumps. Which OCRC tends to lean towards.

This week I'll be putting in the VRP 'XV2' Pistons front and rear and see how those work.

#2080

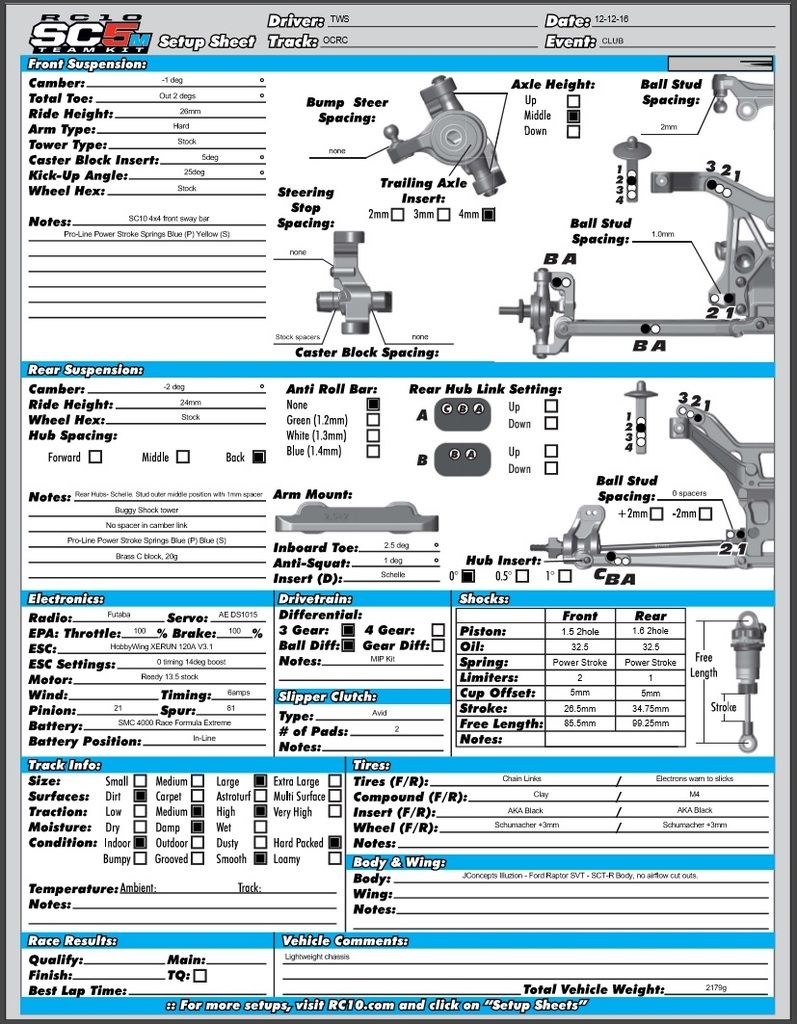

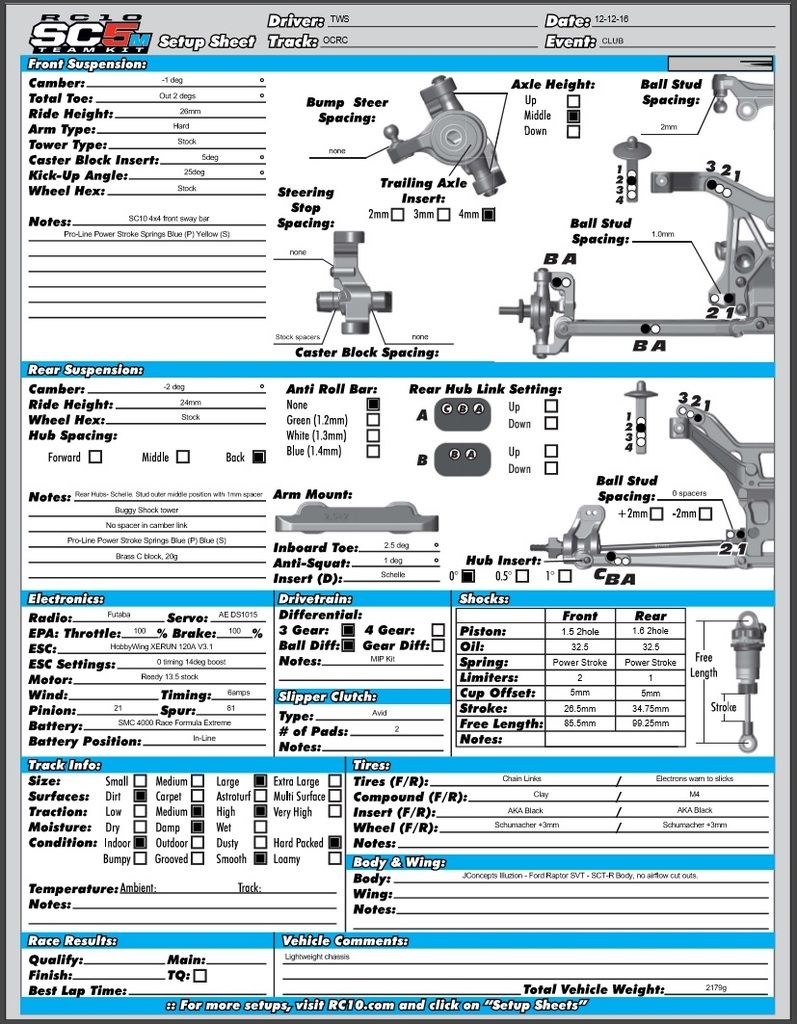

Ok, here is my setup and a shot of how it looks. And only 81g over minimum weight. Yes, currently the straight is at 120ft long

Last edited by Azzkikin; 12-14-2016 at 04:47 AM.

#2081

Tech Fanatic

iTrader: (5)

#2082

You must have to drive the truck super smooth/not punchy - rewards you with corner speed i am sure.

#2083

Give the setup as try and let me know what you think.

#2084

Tech Regular

iTrader: (17)

i am having some trouble with my ball diff. The car is a little over a month old. I feel like I am constantly having to adjust the diff. From a stop under hard acceleration you can hear the diff squeal / make some noise. I have the diff tightened all the way and then loosen about an 1/8th of a turn. Slipper nut is about a half turn in from flush at the end of the threads.

Has anyone changed to a gear dif? what all would be needed to do so? Any disadvantages of doing so? Below is my current setup if that helps.

8t Fantom Motor

160 amp Hobbywing XR10 Pro

86/23 pin/spur

High track clay / carpet

Has anyone changed to a gear dif? what all would be needed to do so? Any disadvantages of doing so? Below is my current setup if that helps.

8t Fantom Motor

160 amp Hobbywing XR10 Pro

86/23 pin/spur

High track clay / carpet

84Likes

84Likes