Tekno RC SCT410.3 Thread

|

|||

#4624

#4625

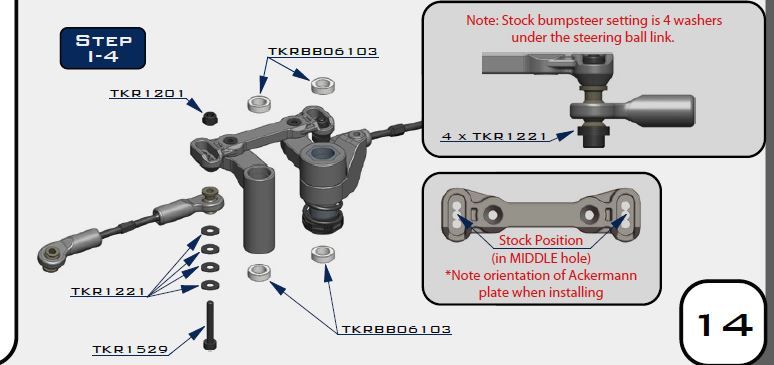

Yes and no. You can remove the washers entirely if they're not between the ball stud and the item in question (steering rack or spindle), and it won't change setup. However, without them, you may find the end of the screw rubbing on things, so you'd want to use a shorter screw then too. Leaving them stacked up makes this not needed, though I personally do it anyway and switch to a button head for the spindle side so that wheel flex doesn't let the wheel hit the top of the screw.

#4626

Yes and no. You can remove the washers entirely if they're not between the ball stud and the item in question (steering rack or spindle), and it won't change setup. However, without them, you may find the end of the screw rubbing on things, so you'd want to use a shorter screw then too. Leaving them stacked up makes this not needed, though I personally do it anyway and switch to a button head for the spindle side so that wheel flex doesn't let the wheel hit the top of the screw.

#4629

tell it again....haha

#4631

- Xray Gray Progressive springs (lower ride height and they worked well on my heavier Durango DESC10 so figured give them a try, especially as i don't have yellow springs lol) Range on these are

#358174 FRONT C = 0.7 to 0.8 lbs/in = 3.997 to 4.568

#358274 BACK C = 0.5 to 0.6 lbs/in = 2.855 to 3.426

- PT racing oil 700 Front, 600 rear

- Camber -2 all around

- Emulsion shocks

- Proline Ion tires and Proline Primes, both MC compound (tried as sets front and rear)

- chassis braces front, middle, rear

My impressions are that this is a very good base setup for the carpet we run here. We are limited to non hard pin tires which the carpet tires would fit, so that is why we run clay compounds as described. Basically ran ions as they were cheap and wanted to burn down the pins. I tried a set of primes from a buddy at the track to see if it would take away a bit of the bite I was experiencing causing traction rolling.

I have thought more about it after the race that I am not sure what the settings are on my steering range stops, however, when I initially had the vehicle going, I had my radio settings changed to fit my daughters driving style better and forgot to change it back initially, so it had the dual rate turned really down. I am assuming the steering stops are in essence doing the same thing.

If that is the case, I am wondering if the traction rolling I experienced could be partially due to that. As pins would most likely bite more than what I am seeing with a slick style tire, I am thinking the setup would handle the roll issues.

Anyway, my next course of action outside of another set of tires I am thinking would be:

- going to yellow springs (or equivalent rates) after comparing the rates to what the xrays offer. I hate to cut some springs though, maybe hot bodies springs like the old days would be an option at least for the fronts as they are already short and close in rates I think to some of the teknos.

- Adjusting roll center at the rear hingepin level

Based on this:

Raising Roll Center

Lower inside camber link position at brace/tower

Raise outside camber link position at hub/caster block

Lower hub/caster block mounting hole at arm

Raise the inside arm mounting location

Shorten camber link

Lower inside camber link position at brace/tower

Raise outside camber link position at hub/caster block

Lower hub/caster block mounting hole at arm

Raise the inside arm mounting location

Shorten camber link

* going with HRC rear hubs

* shorter link (this is what my previous carpet setup had going on)

* Raising the insert arm location by:

1. Raising position on C-Block and D-Block (Will probably start with C-Block)

How does all that sound?

outside of that vehicle is very close

Last edited by Cain; 01-08-2017 at 04:03 PM.

#4632

I ran the updated EB48.4 Ackerman parts using most of the indoor/outdoor setup on the Tekno page http://www.teknorc.com/wp-content/up...oor%20Dirt.pdf (I ran with different pistons and fluid than mentioned) and was pretty happy with how consistent it was.

I have struggled with my 410.3 in the past as it would work great and then the next time out with no changes it would drive totally different. It stayed very consistent and the handling was improved this past weekend, hopefully I'll be able to dial it in even more and it will remain consistent with the new .4 ackerman parts.

I have struggled with my 410.3 in the past as it would work great and then the next time out with no changes it would drive totally different. It stayed very consistent and the handling was improved this past weekend, hopefully I'll be able to dial it in even more and it will remain consistent with the new .4 ackerman parts.

#4634

Tech Master

iTrader: (93)

Ran my SCT410.3 using the Jesse Munn setup with a few changes:

- PT racing oil 700 Front, 600 rear

- Camber -2 all around

- Emulsion shocks

- Proline Ion tires and Proline Primes, both MC compound (tried as sets front and rear)

- chassis braces front, middle, rear

My impressions are that this is a very good base setup for the carpet we run here. We are limited to non hard pin tires which the carpet tires would fit, so that is why we run clay compounds as described. Basically ran ions as they were cheap and wanted to burn down the pins. I tried a set of primes from a buddy at the track to see if it would take away a bit of the bite I was experiencing causing traction rolling.

If that is the case, I am wondering if the traction rolling I experienced could be partially due to that. As pins would most likely bite more than what I am seeing with a slick style tire, I am thinking the setup would handle the roll issues.

- PT racing oil 700 Front, 600 rear

- Camber -2 all around

- Emulsion shocks

- Proline Ion tires and Proline Primes, both MC compound (tried as sets front and rear)

- chassis braces front, middle, rear

My impressions are that this is a very good base setup for the carpet we run here. We are limited to non hard pin tires which the carpet tires would fit, so that is why we run clay compounds as described. Basically ran ions as they were cheap and wanted to burn down the pins. I tried a set of primes from a buddy at the track to see if it would take away a bit of the bite I was experiencing causing traction rolling.

If that is the case, I am wondering if the traction rolling I experienced could be partially due to that. As pins would most likely bite more than what I am seeing with a slick style tire, I am thinking the setup would handle the roll issues.

Usually when my sct is traction rolling I take away some droop in the FR and RR. Do you remember your droop setting or did you try adjusting it?

What was your ride height the shock oil you were using?

#4635

Tech Master

This is great info cause a indoor off road turf track just opened up. I have been debating about getting PL carpet pin tires; one of my racing buddies prefers PL ions (MC).

Usually when my sct is traction rolling I take away some droop in the FR and RR. Do you remember your droop setting or did you try adjusting it?

What was your ride height the shock oil you were using?

Usually when my sct is traction rolling I take away some droop in the FR and RR. Do you remember your droop setting or did you try adjusting it?

What was your ride height the shock oil you were using?

219Likes

219Likes