Team Associated RC10 B5m Mid-Motor Thread

|

|||

#5521

Tech Fanatic

iTrader: (2)

http://www.rpmrcproducts.com/product...s/fixtools.htm I use this with motor spray. then one drop of oil. Just the way i do it..

#5523

Finished the roller tonight. Man, by the way some of you were talking about the ball cups, I was prepared for a fight. Turns out, it's no big deal. All I did was ChapStick the threads, and screwed them together. No drilling, taping, or reaming. Just thread and go. I can adjust all I want on the car and the cups are not popping off.

My only "issue" is the ball diff is NOT smooth. It's a bit notchy. I took it apart and re-did it several times. Same result. I'm hoping it will break-in. If not, that gear diff has my name on it.

My only "issue" is the ball diff is NOT smooth. It's a bit notchy. I took it apart and re-did it several times. Same result. I'm hoping it will break-in. If not, that gear diff has my name on it.

#5525

Depends on the size track you have, for a smaller track an 8.5 should be more than enough. I know most of the team drivers run 8.0 pretty much everywhere it seems.

#5526

#5527

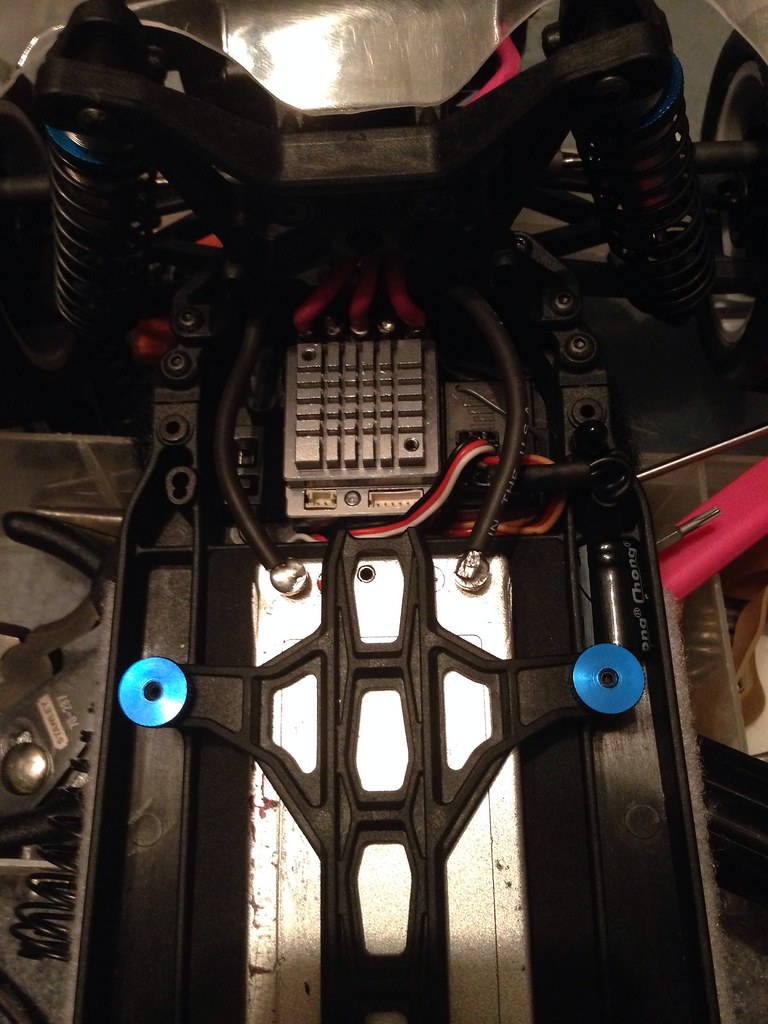

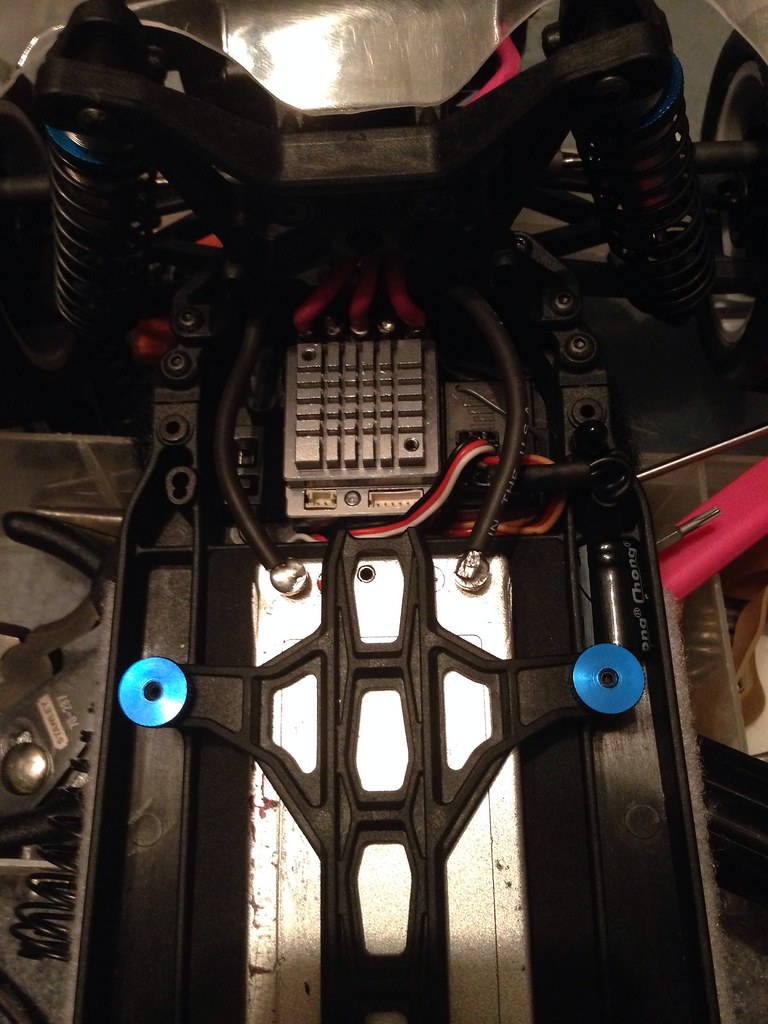

Really happy how the wiring came out, the Orion fit awesome.

#5528

Tech Rookie

How much of a difference does an aluminum top shaft really make in stock class? Is it a lot?

How long do they last?

So for the pinion, are stock guys also running aluminum pinions or regular steel ones. It seems like a lot of stock guys are running 33-34 tooth pinions which are pretty big.

Thanks

#5529

Tech Adept

#5530

Here's a bit of an odd question, I have a fair bit of fresh rubber mounted on b4.1 pin drive rear wheels, any chance that they will fit over the b5m drive pins with the hexes removed?

#5532

Pin wheels will fit over the drive pins but you would have to also use the axle spacer that goes behind the pin from the B4.

#5533

Finished the roller tonight. Man, by the way some of you were talking about the ball cups, I was prepared for a fight. Turns out, it's no big deal. All I did was ChapStick the threads, and screwed them together. No drilling, taping, or reaming. Just thread and go. I can adjust all I want on the car and the cups are not popping off.

My only "issue" is the ball diff is NOT smooth. It's a bit notchy. I took it apart and re-did it several times. Same result. I'm hoping it will break-in. If not, that gear diff has my name on it.

My only "issue" is the ball diff is NOT smooth. It's a bit notchy. I took it apart and re-did it several times. Same result. I'm hoping it will break-in. If not, that gear diff has my name on it.

Only issues so far is manual call outs not matching a part or two with no suppliment sheet, and rear tower screws did not match lengths - one was 2mm shorter than the other. could be a user error though!

Tranny halves screwing in made snapping noises due to tightness.. we'll seeif the screws are in one piece today.

Kit build is probably the best ever for AE. Not much flashing to hassle with.

The biggest issue are the metric threads...my hand is tired from turning that wrench. Time for some power tools!

#5534

#5535

Tech Initiate

How much of a difference does an aluminum top shaft really make in stock class? Is it a lot?

How long do they last?

So for the pinion, are stock guys also running aluminum pinions or regular steel ones. It seems like a lot of stock guys are running 33-34 tooth pinions which are pretty big.

Thanks

How long do they last?

So for the pinion, are stock guys also running aluminum pinions or regular steel ones. It seems like a lot of stock guys are running 33-34 tooth pinions which are pretty big.

Thanks

Pinion size depends on spur gear, track conditions, motor brand, and driving style. I run Novak, which are known to run cooler and lean to the torque side. Currently I run 69/33 and have run as high as 35. Still coming off the track after full battery practice around 120 degrees. Have to temp the motor to find correct pinion. The manual has a good starting place of 31.

136Likes

136Likes