Xray XB4 thread

#9226

I just went ahead and spent the $25 to get new rods and ball cup ends. Luckily they had them at my local hobby store. Weird thing is the part number in the xray manual and the part from the store has the same part number, but the parts are slightly different in the hex offset. How ever, it should still work.

#9227

Sorry for getting out of topic. Does anyone know if the 2015 chassis is a direct fit on the older 2013 chassis? I like to get the 2016 but not in the budget right now. Thanks for any assistance.

#9228

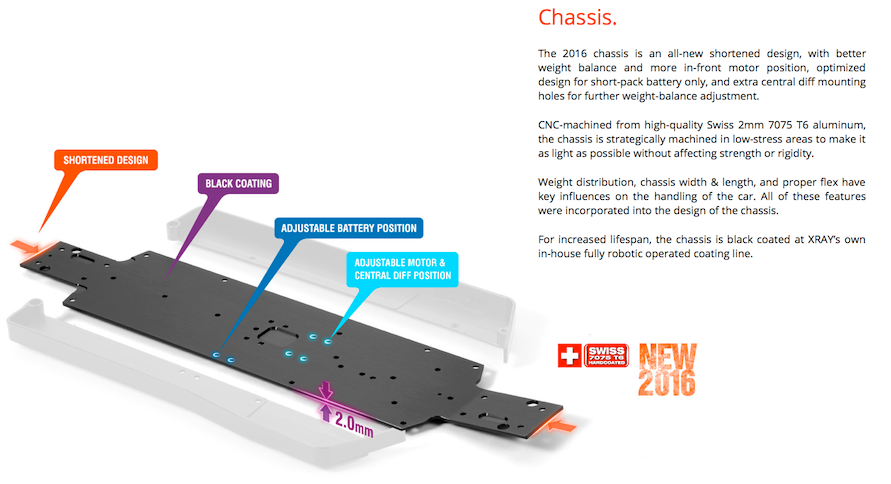

The '13/'14 chassis and layout are completely different to the '15 and now the '16 chassis and layout:

You would basically have to buy every chassis part, center drive shafts and slipper parts to make the conversion which would end up really expensive.

Better then to look for a used '15 and maybe sell your '13 to someone looking to get into the hobby.

Bent

#9229

Thank you for the quick reply.

#9230

Tech Master

iTrader: (123)

Looking at the 2016 car, and wondering how the composite gears in the diffs hold up because I run on super high bite clay track with slicks, and just wondering if I get this car do I need to go ahead and get the steel gears. Any advise would be appreciated because I never owned an Xray XB4 before.

#9231

Suby is right on point, as the composite diff gears are very durable. Even better the 16 XB4 Kit comes standard with the upgraded graphite 4 + 2 diff gears.

Super smooth, super quiet and very very durable.

I ran the upgraded graphite 4 + 2 diff gears f/r/c in my 15 and they worked flawlessly. Ninja silent, super smooth. Nice to know there standard for the 16 as they normally run $29 per diff.

Super smooth, super quiet and very very durable.

I ran the upgraded graphite 4 + 2 diff gears f/r/c in my 15 and they worked flawlessly. Ninja silent, super smooth. Nice to know there standard for the 16 as they normally run $29 per diff.

#9232

Looking at the 2016 car, and wondering how the composite gears in the diffs hold up because I run on super high bite clay track with slicks, and just wondering if I get this car do I need to go ahead and get the steel gears. Any advise would be appreciated because I never owned an Xray XB4 before.

Nice thing is the 16 XB4 comes with the upgraded graphite blend 2 + 4 diff gears. This info. was confirmed by Bentka as well.

Best,

#9234

#9235

Tech Master

iTrader: (21)

Raced my xb4 16 for the first time yesterday and all I can say is wow! It's completely different compared to the 15 but way way better. The car has a ton of steering yet is very stable and predictable. I am extremely pleased with the 16. On my carpet track I started with a setup very close to the yatabe setup. The 16 is worth the upgrade forsure. Now can I get the xb2 already!?

#9237

Tech Regular

iTrader: (6)

Hi everyone,

I've just purchased my first X-Ray, XB4 16 (long time associated user) and wanted to get some build advice in respect to the extending the life of the bevel gears.

At my local track (indoor carpet) historically the XRay users chew through bevel gears all too frequently, most recently someone went through 2 in one night with their new XB4 16. This has also been the achilles heel for the 15 models as well.

Given the cost associated with replacing these gears (and the DNFing)

1. Is there a mod to avoid or eliminate this issue?

2. Is this a common problem globally?

2. Why has X-Ray not addressed this issue in the 16 model?

Thanks for your assistance

I've just purchased my first X-Ray, XB4 16 (long time associated user) and wanted to get some build advice in respect to the extending the life of the bevel gears.

At my local track (indoor carpet) historically the XRay users chew through bevel gears all too frequently, most recently someone went through 2 in one night with their new XB4 16. This has also been the achilles heel for the 15 models as well.

Given the cost associated with replacing these gears (and the DNFing)

1. Is there a mod to avoid or eliminate this issue?

2. Is this a common problem globally?

2. Why has X-Ray not addressed this issue in the 16 model?

Thanks for your assistance

#9238

Tech Regular

iTrader: (6)

What a load off rubbish the typical crap we have come to expect from team drivers denying there is a problem and trying to make out that us the consumer are the problem, let me tell you something bentka i have been in rc since the 80s and no exactly what it takes to look after a race car, at the end off every race day i pull my xb4 down rebuild shocks, diffs, oil bearings and change any worn out or damaged parts yet i still keep having rear gear failure. If the gear is failing due to the handful of reasons you mentioned above then why is it only happening in the rear off the car and not the front i build my front and rear bulkheads are built exactly the same and why does X-ray not mention any of these building tips in there instructions, and before you say it i run my slipper with zero gap, so before you come on hear and fill our heads with rubbish and try and make out the gear failure is our problem think again, its time X-ray stopped denying the problem and just fixed it, don't forget we have seen this kinda of rubbish done before like when they tried to make out there was no problem with the rear suspension holder. I understand your need to defend X-ray as you are part off the factory team but please don't insult my intelligence and tell me the gear failure is my fault and also why does the problem only occur in my modified xb4 and not my stock one. And so you no i love X-ray and also hate when people rubbish XRAY, in my opinion it is the best kit on the market thats why i own 4 of them. FIX THE PROBLEM AND DONT TALK CRAP

IIt's worth pointing out that my 4wd associated gears have been taking a hammering for the past few months with no issues whatsoever, hence my confusion as to why this premium product experiences this common reoccurring problem.

#9239

We run the same bevel and pinion gear for a full season with no issues.

There's a reason why when we go to the track to practice and do setup testing we get 600+ laps done in an evening and the other guys get maybe 150-200 and spend the rest of the time wrenching.

In 98 out of the 100 times I help people at the track with stripped gears one of these things are the culprit.

For the remaining 2 out of 100 we change parts, problem goes away and we never actually pin pointed the exact issue.

What I'm trying to say is……..I'm always told by the owner that everything's perfect and every part has been inspected before I start disassembling…….but almost every single time I find one of the top 4 things on the list to be the culprit……why is that

Race kits with todays high powered motors (we run a boosted 4.5T) DO demand some actual maintenance from the owner to be able to withstand the abuse we throw at them.

Sometimes I wish everyone should have been forced to own a late 80's or early 90's race car running brushed motors and Nimh batteries before owning any R/C car at all so you would actually know the real struggle of keeping a car race ready

Here's Malin running at the worlds with her XB4 '16 with boosted 4.5T and slipper set to absolute minimum = 0mm gap.

So I can't for the life of me understand why people at the track need to run their slippers cranked down……..and then proceed to cry about why their gears wear out

The answer I usually get is; "I'm having problems clearing that jump……"

Rant over

PS! Not aimed at you personally ResultsRC

Bent

There's a reason why when we go to the track to practice and do setup testing we get 600+ laps done in an evening and the other guys get maybe 150-200 and spend the rest of the time wrenching.

- Over-tightened screws for bulkhead cover

- Over-tightened screws for diff housing

- Worn out bulkhead

- Already stripped one of the gears and only replaced one of them

- Shot bearings

- Slipper cranked down way too hard (we run 0mm on the spring)

In 98 out of the 100 times I help people at the track with stripped gears one of these things are the culprit.

For the remaining 2 out of 100 we change parts, problem goes away and we never actually pin pointed the exact issue.

What I'm trying to say is……..I'm always told by the owner that everything's perfect and every part has been inspected before I start disassembling…….but almost every single time I find one of the top 4 things on the list to be the culprit……why is that

Race kits with todays high powered motors (we run a boosted 4.5T) DO demand some actual maintenance from the owner to be able to withstand the abuse we throw at them.

Sometimes I wish everyone should have been forced to own a late 80's or early 90's race car running brushed motors and Nimh batteries before owning any R/C car at all so you would actually know the real struggle of keeping a car race ready

Here's Malin running at the worlds with her XB4 '16 with boosted 4.5T and slipper set to absolute minimum = 0mm gap.

So I can't for the life of me understand why people at the track need to run their slippers cranked down……..and then proceed to cry about why their gears wear out

The answer I usually get is; "I'm having problems clearing that jump……"

Rant over

| + YouTube Video | |

PS! Not aimed at you personally ResultsRC

Bent

We run mostly on high to very high grip astro and carpet with either center diff with 1.000.000 cst diff grease or slipper usually set to 0-0.5mm gap.

On low to medium grip clay or dirt we run either center diff with 500.000 cst diff grease or slipper usually set to 0mm gap.

You can feel relatively easy if the screws for either the bulkhead cover or diff housing have been over-tightened.

They should come to a noticeable stop when tightened all the way down.

One mistake a lot of people do is use an electric screw driver on too high of a speed and torque setting.

Too high of a speed will heat up both the screw and plastic resulting in expanded threads. This combined with over-tightening will quickly ruin the threads.

When using an electric screw driver I always use the low speed setting and only tighten down to 90% and then do the remaining 10% by hand to ensure not to over-tighten.

For the diff housing and the smaller screws I find these to have been over-tightened in 9 out of 10 cases.

This combined with overfilling the diff will allow the diff to expand as pressure and heat builds up. This expansion will have the same result as shimming the bevel gear 0.2-0.3 mm away from the pinion gear resulting in excessive wear on the gears and in the end stripping of the gears.

Xray have added material where the bearings rest to withstand the forces trying to expand the diff and thereby "pressing" and holding the diff together.

But with the forces applied to these relatively small gears something unfortunately have to give in the end.

People are in most cases also running their slippers way too tight which only adds to the forces applied as well as making the XB4 that much harder to drive.

The slipper is a fantastic tuning aid and should really be given just as much consideration as shock oils and tires but people tend to just "set and forget"……….

Bent

On low to medium grip clay or dirt we run either center diff with 500.000 cst diff grease or slipper usually set to 0mm gap.

You can feel relatively easy if the screws for either the bulkhead cover or diff housing have been over-tightened.

They should come to a noticeable stop when tightened all the way down.

One mistake a lot of people do is use an electric screw driver on too high of a speed and torque setting.

Too high of a speed will heat up both the screw and plastic resulting in expanded threads. This combined with over-tightening will quickly ruin the threads.

When using an electric screw driver I always use the low speed setting and only tighten down to 90% and then do the remaining 10% by hand to ensure not to over-tighten.

For the diff housing and the smaller screws I find these to have been over-tightened in 9 out of 10 cases.

This combined with overfilling the diff will allow the diff to expand as pressure and heat builds up. This expansion will have the same result as shimming the bevel gear 0.2-0.3 mm away from the pinion gear resulting in excessive wear on the gears and in the end stripping of the gears.

Xray have added material where the bearings rest to withstand the forces trying to expand the diff and thereby "pressing" and holding the diff together.

But with the forces applied to these relatively small gears something unfortunately have to give in the end.

People are in most cases also running their slippers way too tight which only adds to the forces applied as well as making the XB4 that much harder to drive.

The slipper is a fantastic tuning aid and should really be given just as much consideration as shock oils and tires but people tend to just "set and forget"……….

Bent

Just saw this which pretty much answers my previous posts questions

IIt's worth pointing out that my 4wd associated gears have been taking a hammering for the past few months with no issues whatsoever, hence my confusion as to why this premium product experiences this common reoccurring problem.

IIt's worth pointing out that my 4wd associated gears have been taking a hammering for the past few months with no issues whatsoever, hence my confusion as to why this premium product experiences this common reoccurring problem.

Please also read the answers to these posts.

You have hundreds of people trashing on their XB4's month after month with no issues at all.

Here in Europe we run on high grip astro and carpet all the time……..with no issues at all during an entire season of racing at the highest level with boosted 4.5T motor.

People need to:

- Stop over-tightening screws for the diff housing (allows the diff housing/bevel gear to expand and affect gear mesh).

- Stop overfilling their diffs (allows the diff housing/bevel gear to expand and affect gear mesh).

- Stop over-tightening screws for the bulkhead cover using electric screw drivers (allows the diff bulkhead cover to expand and affect gear mesh).

- Replace worn out bulkhead.

- Replace both pinion and bevel gear if already stripped one of the gears.

- Replace shot bearings.

- Stop cranking their slipper down way too hard and instead set their slipper according to grip level (we run 0mm on the spring/loosest setting).

- Stop using the 1/8th buggy method of cranking the throttle to get the car back on its wheels.

Just one of these things will affect gear life…….then add up several of them and you WILL have problems !

Material have been added by Xray to where the bearings sit in the bulkhead and to the bevel gear to prevent the gear mesh to be affected by the above points, BUT there is a limit to what you can do before the responsibility has to be on the end user to actually make sure everything is done correctly.

These cars are race vehicles and DO require some knowledge from the end user to perform at their best.

Follow these tips and you will have zero problems with gears wearing out prematurely

Enjoy your upgrade from the B44.3

Bent

#9240

Tech Fanatic

iTrader: (1)

Please also read the answers to these posts.

You have hundreds of people trashing on their XB4's month after month with no issues at all.

Here in Europe we run on high grip astro and carpet all the time……..with no issues at all during an entire season of racing at the highest level with boosted 4.5T motor.

People need to:

Just one of these things will affect gear life…….then add up several of them and you WILL have problems !

Material have been added by Xray to where the bearings sit in the bulkhead and to the bevel gear to prevent the gear mesh to be affected by the above points, BUT there is a limit to what you can do before the responsibility has to be on the end user to actually make sure everything is done correctly.

These cars are race vehicles and DO require some knowledge from the end user to perform at their best.

Follow these tips and you will have zero problems with gears wearing out prematurely

Enjoy your upgrade from the B44.3

Bent

You have hundreds of people trashing on their XB4's month after month with no issues at all.

Here in Europe we run on high grip astro and carpet all the time……..with no issues at all during an entire season of racing at the highest level with boosted 4.5T motor.

People need to:

- Stop over-tightening screws for the diff housing (allows the diff housing/bevel gear to expand and affect gear mesh).

- Stop overfilling their diffs (allows the diff housing/bevel gear to expand and affect gear mesh).

- Stop over-tightening screws for the bulkhead cover using electric screw drivers (allows the diff bulkhead cover to expand and affect gear mesh).

- Replace worn out bulkhead.

- Replace both pinion and bevel gear if already stripped one of the gears.

- Replace shot bearings.

- Stop cranking their slipper down way too hard and instead set their slipper according to grip level (we run 0mm on the spring/loosest setting).

- Stop using the 1/8th buggy method of cranking the throttle to get the car back on its wheels.

Just one of these things will affect gear life…….then add up several of them and you WILL have problems !

Material have been added by Xray to where the bearings sit in the bulkhead and to the bevel gear to prevent the gear mesh to be affected by the above points, BUT there is a limit to what you can do before the responsibility has to be on the end user to actually make sure everything is done correctly.

These cars are race vehicles and DO require some knowledge from the end user to perform at their best.

Follow these tips and you will have zero problems with gears wearing out prematurely

Enjoy your upgrade from the B44.3

Bent

I'm running an XB4'14 and upgraded to the steel pinion and crown gears. No issues at all. Most critically of the above points, when running the composite crown and pinion, was ensuring that the slipper was set correctly. Before I learnt the importance of that and was continually setting by the 'punch and watch front end lift'/3 turns method, I crunched through AE pinions and crowns also.

Am waiting up for the XB2 and I'll pick up an XB4'16 at the same time to refresh

246Likes

246Likes