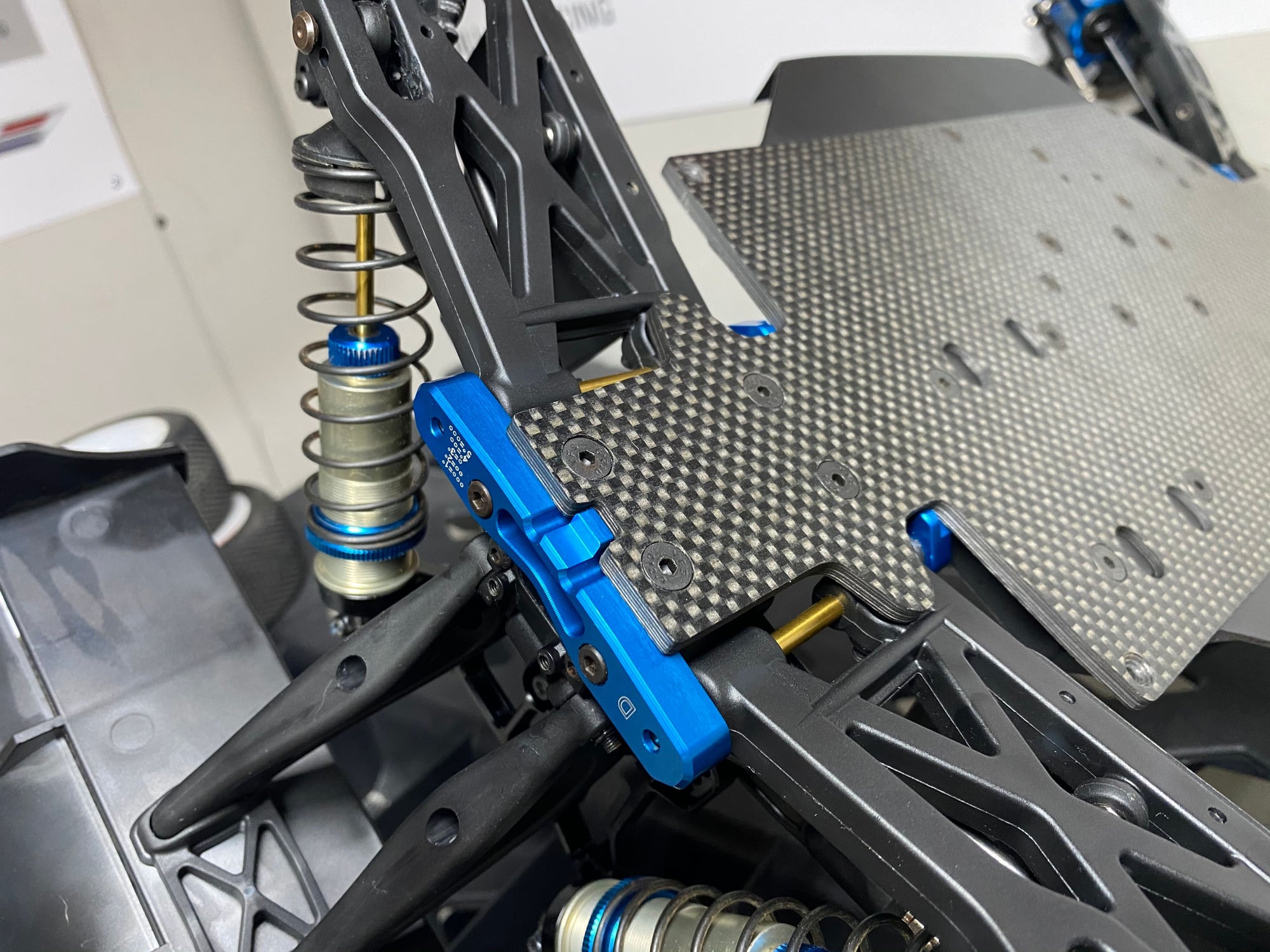

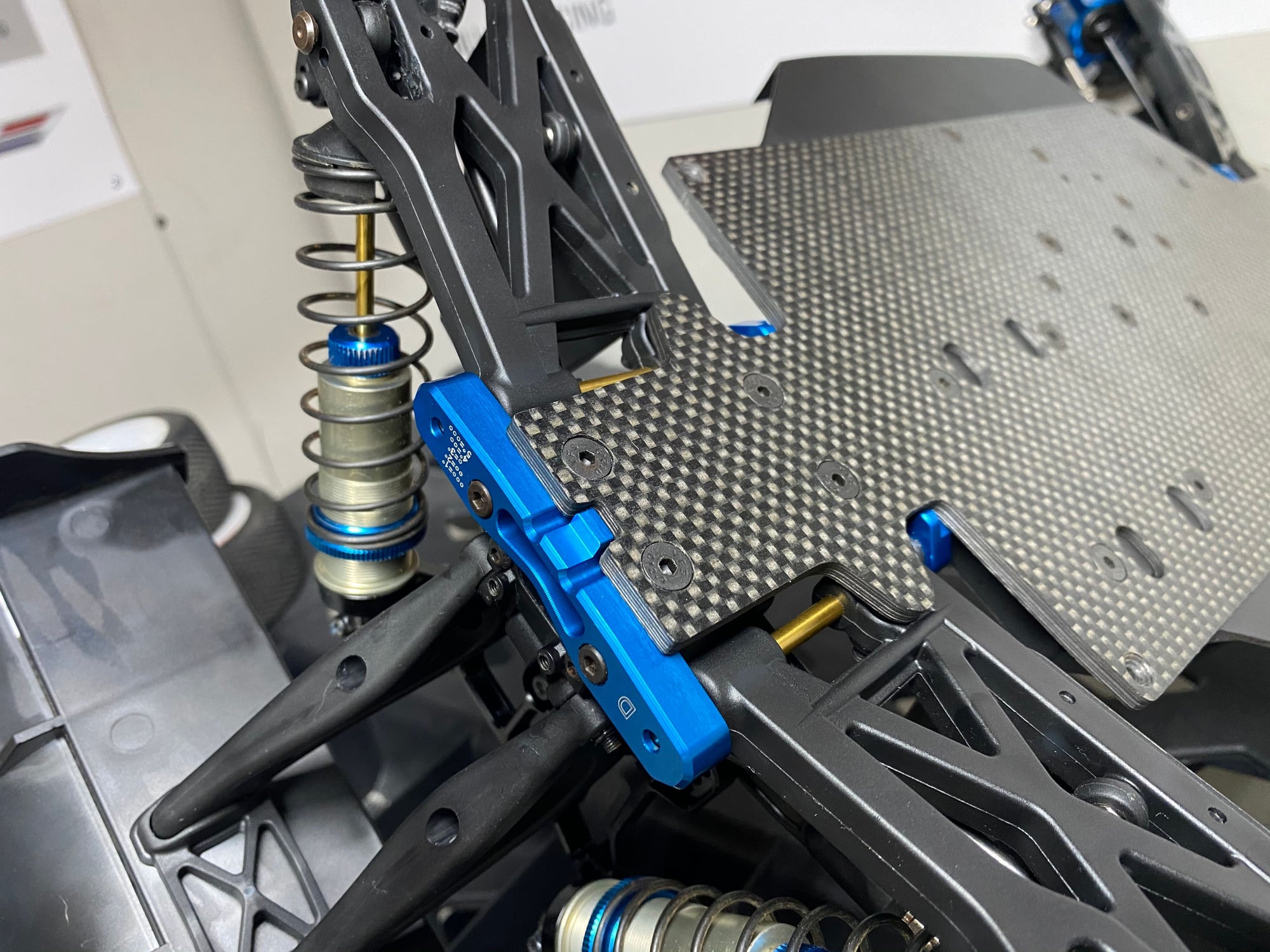

1/8 Carbon Fiber main chassis

#63

Tech Rookie

Mistake.

how can I delete this.

how can I delete this.

#64

Tech Adept

iTrader: (13)

Join Date: Mar 2011

Location: Shelby Township, MI 🇺🇸 & Shanghai 🇨🇳

Posts: 219

Trader Rating: 13 (100%+)

This one was made by SNR carbon some time ago

#65

Tech Regular

Iíve been playing with composites for a while now, and I couldnít see any reason why you couldnít make an excellent composite fabric as long as you have a basic understanding of the materials, and a good idea about what you want to accomplish.

Iíd start by either using the existing chassis to make a mould, or fashion a dummy chassis in the shape you want and then make a mould from it.

Depending on the stiffness required, Iíd probably lay some aramid on the bottom (and wrapped ďup the sidesĒ for abrasion resistance), 300gms/m2 2x2 twill would be ok, but possible a bit thick. In the centre, depending on how stiff you wanted it, 4 llayers of 90g/m2 or 2 layers of200g/m2 cloth, with the weave running either 0-180 degrees for longitudinal stiffness, or 315-45 if you wanted a more general rigidity. You could also run 1 layer going each direction, sacrificing a tiny bit of stiffness in each direction for overall multi direction rigidity. For the prototype Iíd definitely be keeping an eye on the thickness, but for a ďproductionĒ chassis you could use a few layers of lightweight as a sacrificial surface if your really concerned with abrasion.

I havenít calculated the thickness of a layup like that, Iíll try and remember to do it, but having had a little bit of a think about it itís definitely do-able, but is it desirable? Could it be too rigid?

Edit: Just had a little bit more of a think about it, and could triple the layers Iíve suggested and come in under 3mm thick if you vac bagged I at about 1 bar, so it would probably be way too stiff unless that was the goal.

Iíd start by either using the existing chassis to make a mould, or fashion a dummy chassis in the shape you want and then make a mould from it.

Depending on the stiffness required, Iíd probably lay some aramid on the bottom (and wrapped ďup the sidesĒ for abrasion resistance), 300gms/m2 2x2 twill would be ok, but possible a bit thick. In the centre, depending on how stiff you wanted it, 4 llayers of 90g/m2 or 2 layers of200g/m2 cloth, with the weave running either 0-180 degrees for longitudinal stiffness, or 315-45 if you wanted a more general rigidity. You could also run 1 layer going each direction, sacrificing a tiny bit of stiffness in each direction for overall multi direction rigidity. For the prototype Iíd definitely be keeping an eye on the thickness, but for a ďproductionĒ chassis you could use a few layers of lightweight as a sacrificial surface if your really concerned with abrasion.

I havenít calculated the thickness of a layup like that, Iíll try and remember to do it, but having had a little bit of a think about it itís definitely do-able, but is it desirable? Could it be too rigid?

Edit: Just had a little bit more of a think about it, and could triple the layers Iíve suggested and come in under 3mm thick if you vac bagged I at about 1 bar, so it would probably be way too stiff unless that was the goal.

Last edited by Smokeyr67; 12-03-2020 at 02:47 AM.