how to "waterproof" a truck

#1

ok guys completely new to the new age of rc trucks. Interested in many aspects but would love a rockcrawling/trail driving rig. i live on the lake so there are some watery spots that i also think would be fun. Anyway to create something so the water doesnt damage the machine. thanks so much. This will be the first of many many questions. also what are some reccomendations for what im wanting. It will be very mild at first but if i really get into it i will be upgrading

#2

Tech Addict

iTrader: (11)

liquid tape or equivalent.. i work in the industry and got some electric motor insulation spray (CRC make it)

pull your esc, reciever and servo motor apart

liberally apply liquid tape (electronics only.. no moving parts)

put stuff back together

visit rccrawler.com has heaps of different opinions on this subject

pull your esc, reciever and servo motor apart

liberally apply liquid tape (electronics only.. no moving parts)

put stuff back together

visit rccrawler.com has heaps of different opinions on this subject

#4

Tech Rookie

Unfortunately that trick didn't work for my rig, cause it worked fine before and now I have no electronics!! Thanks for the tip, now I have to buy all new electronics!!

#5

Tech Master

iTrader: (6)

I disassembled my servo and applied marine electronics grease to the board and around the splined shaft. Re-assembled the servo and then applied a few coates of aerosol plasti-grip. Never had an issue.

As for the ESC and Rx, I just double balloon them.

Motor, I just make sure to keep the bearings/bushings well lubricated.

Finally the battery, I haven't done a thing except to blow them out w/ my air compressor to dry them out after use.

As for the ESC and Rx, I just double balloon them.

Motor, I just make sure to keep the bearings/bushings well lubricated.

Finally the battery, I haven't done a thing except to blow them out w/ my air compressor to dry them out after use.

#7

Tech Rookie

if you search youtube there are alot of vids on this subject, also how to's that are very help full

#8

Tech Master

iTrader: (45)

Liquid Tape over time WILL flake off. Especially if you have it for your servo. The heat/dirt will cause it to literally come off after a few wet runs.

Your best bet is to use Plastidip. Get the large can where you can dunk your servo in after you've taken it apart and applied with lithium grease, dielectric grease, or marine grease. I usually apply more grease around the spline then put those orange O rings over it for additional protection. Then once the Plastidip is drying I use my fingers to ensure a tight seal around the servo halves and the rubber grommet where the wires exit. After that I use a sharp hobby knife and cut out the heatsink area if you have them on the servo. If there are no heatsink fins on the servo you're all set.

All this can be found on YouTube. Squirrel does some good videos on waterproofing.

Also on your axles remove both halves and pack them with Lucas Red n Tacky or some cheap lithium grease to a point where they ooze out. Take some nitro cleaner after you reassemble them. This will keep mud/grit from getting inside the axles and binding up your ring/pinion.

ESC waterproofing use Plastidip as well after you remove the case. Same process with servo waterproofing above. Once it's almost dry it's pliable so use your fingers to ensure a watertight seal. Then cut out the excess with a hobby knife around the heatsink.

Plastidip is a lot better than ballooning the ESC due to heat issues. Or you can put your ESC in a Radio Shack project box and use silicone on the holes you drill out to run the wires.

Plastidip once dried is a thick rubber. Liquid Tape once dried is good for water resistance but must be recoated. I would only do Liquid Tape if I don't plan on submerging my truck.

Your best bet is to use Plastidip. Get the large can where you can dunk your servo in after you've taken it apart and applied with lithium grease, dielectric grease, or marine grease. I usually apply more grease around the spline then put those orange O rings over it for additional protection. Then once the Plastidip is drying I use my fingers to ensure a tight seal around the servo halves and the rubber grommet where the wires exit. After that I use a sharp hobby knife and cut out the heatsink area if you have them on the servo. If there are no heatsink fins on the servo you're all set.

All this can be found on YouTube. Squirrel does some good videos on waterproofing.

Also on your axles remove both halves and pack them with Lucas Red n Tacky or some cheap lithium grease to a point where they ooze out. Take some nitro cleaner after you reassemble them. This will keep mud/grit from getting inside the axles and binding up your ring/pinion.

ESC waterproofing use Plastidip as well after you remove the case. Same process with servo waterproofing above. Once it's almost dry it's pliable so use your fingers to ensure a watertight seal. Then cut out the excess with a hobby knife around the heatsink.

Plastidip is a lot better than ballooning the ESC due to heat issues. Or you can put your ESC in a Radio Shack project box and use silicone on the holes you drill out to run the wires.

Plastidip once dried is a thick rubber. Liquid Tape once dried is good for water resistance but must be recoated. I would only do Liquid Tape if I don't plan on submerging my truck.

#9

Hey brother.

Many different methods exist, kinda like an ass, everyone has one but some are just better than others, haha. Mine happens to be good but remember all of them need to be monitored for damage and issues. I waterproof mostly everything and it sounds like we have the same running environment. Servos I open up and apply marine grease on the insides around any cracks to the outside of the casing so this will apply to all holes on the servo. I also apply it to the little gaskets around a servo case. I then spray the servo with liquid silicone, this applies a nice even shiny coat on the whole servo. After this I apply a little more marine grease around the spine horn area of the servo, this helps keep water out from the outside as well as lubricates your servo helping it turn a little easier.

Most anything can be waterproofed with both silicone spray and liquid silicone. Liquid tape and that plasti dip works however liquid tape doesn't last long at all and is pretty touchy depending on weather and heat! Silicone is pretty solid and doesn't require as much maintenance in my opinion. Plasti dip i find heats up servos and electronics quite fast especially if too thick a coat is applied which you'll find with plasti dip is hard to regulate even coats. Silicone spray, spray 2 even coats and your done. I usually open up my ESC,s and use silicone liquid and coat the whole inside electronics. This allows you to put the ESC back together where it looks perfectly normal but maintains your electronics while they are swimming. The 2 vids below the red and black trucks have mamba monsters 2200 motors all completely waterproof, NOT 1 issue.

http://www.youtube.com/watch?v=n3Mxbb1yXqc

http://www.youtube.com/watch?v=SBoTs2-xT7s

Hope this helps, and remember this is just my opinion and method, you are responsible for applying and for your own electronics.

LIK

Many different methods exist, kinda like an ass, everyone has one but some are just better than others, haha. Mine happens to be good but remember all of them need to be monitored for damage and issues. I waterproof mostly everything and it sounds like we have the same running environment. Servos I open up and apply marine grease on the insides around any cracks to the outside of the casing so this will apply to all holes on the servo. I also apply it to the little gaskets around a servo case. I then spray the servo with liquid silicone, this applies a nice even shiny coat on the whole servo. After this I apply a little more marine grease around the spine horn area of the servo, this helps keep water out from the outside as well as lubricates your servo helping it turn a little easier.

Most anything can be waterproofed with both silicone spray and liquid silicone. Liquid tape and that plasti dip works however liquid tape doesn't last long at all and is pretty touchy depending on weather and heat! Silicone is pretty solid and doesn't require as much maintenance in my opinion. Plasti dip i find heats up servos and electronics quite fast especially if too thick a coat is applied which you'll find with plasti dip is hard to regulate even coats. Silicone spray, spray 2 even coats and your done. I usually open up my ESC,s and use silicone liquid and coat the whole inside electronics. This allows you to put the ESC back together where it looks perfectly normal but maintains your electronics while they are swimming. The 2 vids below the red and black trucks have mamba monsters 2200 motors all completely waterproof, NOT 1 issue.

http://www.youtube.com/watch?v=n3Mxbb1yXqc

http://www.youtube.com/watch?v=SBoTs2-xT7s

Hope this helps, and remember this is just my opinion and method, you are responsible for applying and for your own electronics.

LIK

#10

Tech Initiate

I am a noob here, but, I want to chime in. Because, I have looked into this very extensively because, well, living in portland,OR... I see a lot of rain!

I recently used spray on electrical tape and lost that ESC... I dont use spray on anything anymore...

Before that and ever since I used Plastidip.

Mostly because of all the review saying how easy and great it worked!!

No problems Ever since...

As far as coating with plastidip, I completely disassemble my electronics coat them once, then depending on what the device is, I may re-assemble and fill the cavity with plastidip, OR, Coat it several times and cover it in shrink wrap... ESC's , if they are cased, and there is a way to inject the plastidip ill just do that ill fill it and re fill it after it dries until there is no way to fill it.. then no water can get in.. but never cover a heat sink... filling is fine because the heat sink rests on top of what needs to be cooled, and no dip will get between then to hold heat back...

When it comes to bearings and joints you have a choice of lubricants..

I use marine grease, or lithium...depending on the surface...

my diffs..

my bearings (stock bearings get a good massage in grease and i push the oil out.

joints like Cvd's that are exposed to water, elements... i just give them a light coating so they dont collect debris but still shed water... silicone spray would be perfect for this!!! a couple spray coats let it dry and your good no water will stick... and it will not rust ..!

oh the electric connections i pack grease inside so no water can get in... then connect them and wipe the excess off... and your golden...

I also use shrink wrap and hot glue to fill any spaces where water can get to any electrical connections.... I dont glue things together i am talkin about the back of a deans.. take a large tube of SW and activate it and then inject hot glue into the wrap where it meets the deans ... effectively filling it with plastic... then coat that with grease... yea i over kill it when it comes to water proofing...

i also fill the on off switch with grease... pop it out of its case(some are tiny switches in side a plastic case that is removable/mine was) fill the case with grease and slide it back on... the grease fills the switch and gets pushed out all the holes... just wipe...

I can take pictures if you like but after the initial coating and drive you fling off any excess grease and you can wipe any excess off you dont like...

the finished product is nice...

I know all this grease talk sounds like i have a mess under the hood.. but i wipe the excess off... its just to coat and fill any crevices before water does....

in this vid i go thew mud and water .. http://www.youtube.com/watch?v=ocA9ilhp0tw

... after it all while still ON... i just take a hose to it... hit the throttle to spin the tires dry and do inside..... i can video tap that also.. if you want ... its so sweet!!!!

so to recap..

Plastidip...

marine grease

It works for me ...

Read, read, read... know what you are doing before you start....

I recently used spray on electrical tape and lost that ESC... I dont use spray on anything anymore...

Before that and ever since I used Plastidip.

Mostly because of all the review saying how easy and great it worked!!

No problems Ever since...

As far as coating with plastidip, I completely disassemble my electronics coat them once, then depending on what the device is, I may re-assemble and fill the cavity with plastidip, OR, Coat it several times and cover it in shrink wrap... ESC's , if they are cased, and there is a way to inject the plastidip ill just do that ill fill it and re fill it after it dries until there is no way to fill it.. then no water can get in.. but never cover a heat sink... filling is fine because the heat sink rests on top of what needs to be cooled, and no dip will get between then to hold heat back...

When it comes to bearings and joints you have a choice of lubricants..

I use marine grease, or lithium...depending on the surface...

my diffs..

my bearings (stock bearings get a good massage in grease and i push the oil out.

joints like Cvd's that are exposed to water, elements... i just give them a light coating so they dont collect debris but still shed water... silicone spray would be perfect for this!!! a couple spray coats let it dry and your good no water will stick... and it will not rust ..!

oh the electric connections i pack grease inside so no water can get in... then connect them and wipe the excess off... and your golden...

I also use shrink wrap and hot glue to fill any spaces where water can get to any electrical connections.... I dont glue things together i am talkin about the back of a deans.. take a large tube of SW and activate it and then inject hot glue into the wrap where it meets the deans ... effectively filling it with plastic... then coat that with grease... yea i over kill it when it comes to water proofing...

i also fill the on off switch with grease... pop it out of its case(some are tiny switches in side a plastic case that is removable/mine was) fill the case with grease and slide it back on... the grease fills the switch and gets pushed out all the holes... just wipe...

I can take pictures if you like but after the initial coating and drive you fling off any excess grease and you can wipe any excess off you dont like...

the finished product is nice...

I know all this grease talk sounds like i have a mess under the hood.. but i wipe the excess off... its just to coat and fill any crevices before water does....

in this vid i go thew mud and water .. http://www.youtube.com/watch?v=ocA9ilhp0tw

... after it all while still ON... i just take a hose to it... hit the throttle to spin the tires dry and do inside..... i can video tap that also.. if you want ... its so sweet!!!!

so to recap..

Plastidip...

marine grease

It works for me ...

Read, read, read... know what you are doing before you start....

Last edited by Lordprimate; 01-25-2012 at 10:32 PM.

#11

easiest way to water proof, since you got to spring for new electrics.

traxxas XL5 esc, new version has a lipo cut off

traxxas waterproof servos,better yet, hitec now offers WP servos

traxxas WP receiver box, most of the current trucks come with em and they all over ebay cheap

traxxas XL5 esc, new version has a lipo cut off

traxxas waterproof servos,better yet, hitec now offers WP servos

traxxas WP receiver box, most of the current trucks come with em and they all over ebay cheap

#12

Bumping this thread to ask for more pics and vids of your waterproofed trucks and how-to vids. I know some are out there, but why even come here if everyone is going to point you elsewhere?

#13

Hate to tell you guys this(but mainly to the guy whining about his burnt up gear) , but you can never fully "Waterproof" your gear! All you are doing and only if you do it properly is water resiting your gear.

There are several trust worthy ways to water "resist" and a couple real good tip s videos from some proven techniques from some of the best(in my opinion) guys in the hobby when it comes to these types of things.

Here are the links.

http://www.youtube.com/watch?v=SzmK_tvbejE&feature=plcp

http://www.youtube.com/watch?v=zkUnpQViido&feature=plcp

ITS YOUR GEAR, YOU TOOK THE CHANCE!!

SO DON'T BLAME SOMEONE ELSE FOR YOUR SCREW UPS!!!

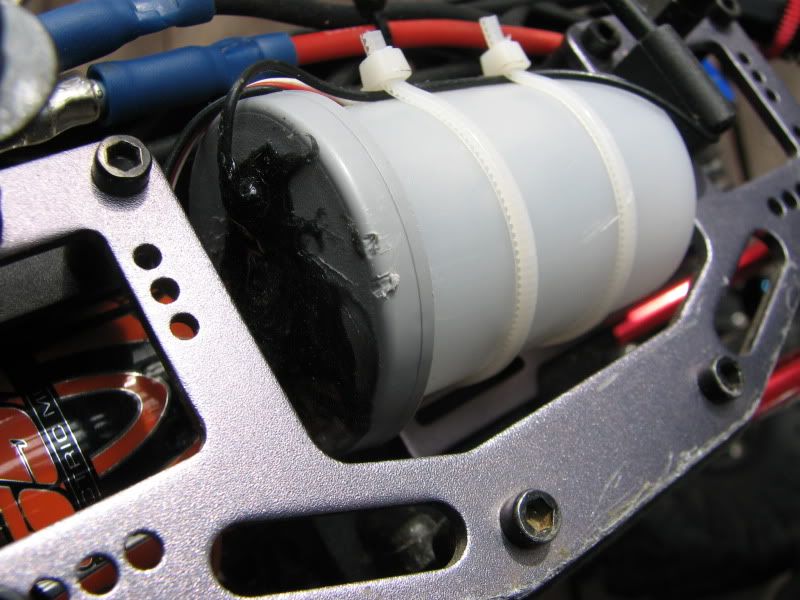

I hope these are helpfull vids and here is a couple pics of my TF2 water resistant,

There are several trust worthy ways to water "resist" and a couple real good tip s videos from some proven techniques from some of the best(in my opinion) guys in the hobby when it comes to these types of things.

Here are the links.

http://www.youtube.com/watch?v=SzmK_tvbejE&feature=plcp

http://www.youtube.com/watch?v=zkUnpQViido&feature=plcp

ITS YOUR GEAR, YOU TOOK THE CHANCE!!

SO DON'T BLAME SOMEONE ELSE FOR YOUR SCREW UPS!!!

I hope these are helpfull vids and here is a couple pics of my TF2 water resistant,

Last edited by k1ller rc; 09-08-2012 at 12:04 PM.

#14

Suspended

Some relies on your vehicle but several factors implement to all vehicle. First, increase the axle rest pipes up to an advanced stage. How high you go with these pipes relies on how much the water you think you will see. While you are at it, many signals and exchange situations also have rest pipes on top. You should increase these as well.

#15

Suspended

The one place where the water can do the most harm on any motor is at the air intake. Water is not unstable and when it gets into the tubes, it will secure the motor and sometimes crack supports, crankshafts, hooks, etc.

I would consider a snorkel brought up up to ceiling stage or probably an prolonged air consumption into the cab. Create sure either choice is enclosed well in the motor bay.

Above Ground Pools

I would consider a snorkel brought up up to ceiling stage or probably an prolonged air consumption into the cab. Create sure either choice is enclosed well in the motor bay.

Above Ground Pools

Last edited by Aidan8100; 05-13-2013 at 11:12 AM.